TCS Basys Controls SZ2165 User manual

R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

1

SZ2165

Boiler Controller

Product Manual

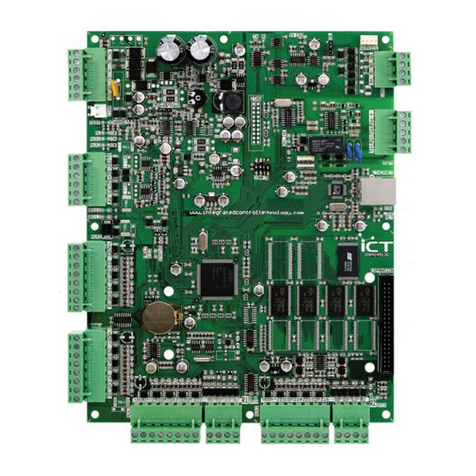

Description

The SZ2165 is a microprocessor based boiler controller. It is

designed for use on multi-stage boiler applications and includes

chiller support and control.

Features

• Stand-alone or network operation

• 365-day time clock with two holiday schedules, automatic leap

year and daylight saving correction

• No backup battery required for control parameters, schedule or

clock

• Hot water supply and return water temperature inputs

• Mixed water temperature input

• Chilled water supply and return temperature input

• Two digital outputs for chillers

• One digital output for alarm

• Outdoor air temperature input

• Outdoor air reset control

• Two digital inputs for pump status

• External time clock input

• Six digital outputs for boilers and boiler pumps

• Adjustable offsets and differentials on digital outputs

• Lead/Lag sequencing (rotation) of up to four boilers

• Two modulating analog outputs for valves and VFD

• LEDs for monitoring status

• Automatic rotation of pumps

• Alarm output

• Selectable normally open or normally closed relay outputs

Contents

Description ........................................... 1

Features ............................................. 1

Mounting............................................. 1

Wiring ............................................... 2

Setup ............................................... 3

Programming ......................................... 3

Sequence of Operations................................. 8

Checkout & Troubleshooting ............................. 8

LED Description ....................................... 9

Mounting

The SZ2165 is designed for mounting using four #10 sheet metal

screws. Prior to mounting, the jumpers should be placed. (See setup

instructions.) If the unit will be stand-alone, all programming should

be completed before installation. If the unit will be wired for communi-

cations, a unique address should be programmed into the unit. (See

programming instructions.)

R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

2

Wiring

The SZ2165 terminal designations are shown below.

REMOTE SENSOR WIRING

The SZ2165 accepts six 1000 Ω two-wire platinum sensors. Consult

the TS Series Temperature Sensor submittal datasheet for a com-

plete listing of packaging and application styles. When using TCS

Basys Controls three-wire sensors, use the black and red leads, and

either clip or twist off the white lead. The wiring length should not

exceed 250 feet.

1

Black

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

Red

MIXING VALVE

+ -

A

B

AO1

GND

DI1

DI2

POWER

GND

GND

GND

AO2

24

VAC

GND

DI4

DI3

DI5

SZ2165

BOILER CONTROLLER

ANALOG

OUTPUTS

DIGITAL

INPUTS

PUMP

BOILER PUMP1

BOILER PUMP2

OVERRIDE

BOILER/

CHILLER

CHILLER PUMP

NO1

COM

COM

COM

COM

COM

COM

B

NO2

NO3

A

NO9

NO8

NO7

NO6

NO5

COM

NO4

TEMPERATURE INPUTS

HOT WATER

SUPPLY RETURN

CHILLED WATER

SUPPLY RETURN OUTDOOR

MIXED

WATER

S U P E R T R O L

TM

KBPS

4.8

9.6

19.2

BOILER4

BOILER3

BOILER2

BOILER1

ALARM

CHILLER2

CHILLER1/

ENABLE

BOILER PUMP1

BOILER PUMP2

DIGITAL

OUTPUTS

ALARM

CHILLER2

CHILLER1/ENA

BOILER PUMP1

BOILER PUMP2

BOILER1

BOILER3

BOILER2

BOILER4

POWER

OVERRIDE

OCC SERVICE DATA

+P

AI1

PRESSURE

ANALOG

INPUTS

T

1

T

1

T

2

T

2

T

3

T

3

T

4

T

4

T

5

T

5

T

6

T

6

+

-

+ +

+

XMTR

4

4

REF

2-wire, 4 to 20 mA transmitter.Sensor input

wiring 18 AWG, twisted, shielded pair.

7

Dry contact. Must not be powered.

4

Sensor input wiring 18 AWG, twisted, shielded pair.

3

For communication wiring, use twisted, shielded 22

AWG. Must be run separately.

1

24 VAC transformer. See powering instructions.

2

External relay. 24 VAC Coil

5

4 to 20 mA output. 600 ohm max. Do not power

actuator with power from the controller. The

controllers are half-wave rectified, whereby the

power ground is common with the signal ground.

6

REF

Add 500 ohm

resistor (included in bag) to

convert 0/4 to 20mA to, 0/2 to 10 VDC.

8

3 3 3 3 3 3

R

R

R

R

R

R

R

R

5

R

2

5

5

5

5

5

5

5

5

6

6

PA

VA

7

4

4

4

2

8

8

POWERING THE SZ2165

The SZ2165 is powered from 24 VAC +/- 20 %. If wiring for com-

munications, dedicated power must be used to power the SZ2165.

Several S-series controllers may be powered from the same trans-

former, provided that the transformer has enough power.

Caution: Do not connect to 120VAC. When multiple TCS/Basys

Controls devices are using a single transformer, the polar-

ity of the power wiring must be maintained because all

TCS devices are half-wave rectified and have common

return paths.

R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

3

Setup

BAUD RATE SELECTION

The SZ2165 must be programmed

using a PC and TCS Basys Controls

software. A communication baud

rate must be set by placing one

jumper in the area shown. This

baud rate must be the same for all

devices.

For a 4.8K baud rate.

For a 9.6K baud rate.

For a 19.2K baud rate.

Programming

The SZ2165 must be programmed with a PC. A jack on the face

allows local access for programming. If you plan to program the con-

troller while it is on a network, prior to putting the controller on the

network, a unique address must be set in the controller by accessing

it through the port on the front.

For more information on programming using a PC and the

TCS Insight software, consult your TCS software manuals.

CONTROLLER ADDRESS

The factory default

address for an SZ2165 is

165 . On the "Network>

Poll" tab, right click on

the desired controller and

select "Change Address

from the menu that appears. Next, select the desired address from

the use the drop-down menu and hit ENTER. Finally, click "Yes" in

the Change Controller Address window that appears.

INTERNAL TIME CLOCK

On the "Schedules>

Date and Time" tab, you

can see and modify the

controller’s time (military

time), day of the week,

date and year. Click on

"Read" if you would like to see the current time, day of week and

date in the controller. Click on "To PC Time" read these parameters

from your computer instead and automatically program them into the

SZ2165. Finally you can click on "Write" to send the updated time,

day of week, and date to the controller.

EVENT SCHEDULING

On the "Schedules>

Schedules" tab there

are two occupied time

periods per day, and thus

two time schedules (A

and B). Let us say that

the occupied time for

a particular day is from

8:00AM to 12:00PM and

from 1:00PM to 5:00PM.

In the “A” schedule you

could enter 8:00 to 12:00,

and in the “B” schedule

you could enter 13:00 to

17:00. You can reverse

the “A” and “B” sched-

ules also. You can also

enter 8:00 to 17:00 for the “A” schedule and 0:00 to 0:00 for the “B”

schedule. 0:00 (12:00AM)starts the day, and 24:00 (12:00AM) ends

the day. Note: occupied times that span midnight have to be coordi-

nated using two days’ time schedules.

NOTE: The start of an occupied period is delayed by the

power-on delay value.

HOLIDAY 1 / HOLIDAY 2

On the "Schedules>

Holiday" tabs the holiday

schedules set which days

in a year will use Holiday

1 & Holiday 2 schedules

as defined. Each holiday

consists of a month

and date, as well as the

number of days that the

holiday will be in effect.

MONITORING

The "Monitoring" tab

displays the current tem-

peratures and the status

of all inputs and outputs.

These values are auto-

matically read when

accessing this tab initially

and are automatically

refreshed periodically

while viewing the tab. By

right clicking on a particu-

lar point, you can view

a live graph of that point

over time.

Black

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

Red

MIXING VALVE

-

A

B

R

AO

1

GND

DI

1

DI

2

POWER

GND

GND

GND

AO

2

24

VAC

GND

DI

4

DI

3

DI5

SZ2165

BOILER CONTROLLER

ANALOG

OUTPUTS

DIGITAL

INPUTS

PUMP

BOILER PUMP1

BOILER PUMP2

OVERRIDE

BOILER/

CHILLER

CHILLER PUMP

NO1

COM

COM

COM

COM

COM

COM

B

NO2

NO3

A

NO9

NO8

NO7

NO6

NO5

COM

NO4

TEMPERATURE INPUTS

HOT WATER

SUPPLY RETURN

CHILLED WATER

SUPPLY RETURN OUTDOOR

MIXED

WATER

U P E R T R O L

TM

KBPS

4.8

9.6

19.2

BOILER4

BOILER3

BOILER2

BOILER1

ALARM

CHILLER2

CHILLER1/

ENABLE

BOILER PUMP1

BOILER PUMP2

DIGITAL

OUTPUTS

ALARM

CHILLER2

CHILLER1/ENA

BOILER PUMP1

BOILER PUMP2

BOILER1

BOILER3

BOILER2

BOILER4

POWER

OVERRIDE

OCC SERVICE DATA

+P

AI

1

PRESSURE

ANALOG

INPUTS

T

1

T

1

T

2

T

2

T

3

T

3

T

4

T

4

T

5

T

5

T

6

T

6

-

+

PA

+

VA

+

XMTR

REF

-wire, 4 to 20 mA transmitter.Sensor input

wiring 18 AWG, twisted, shielded pair.

Dry contact. Must not be powered.

Sensor input wiring 18 AWG, twisted, shielded pair.

For communication wiring, use twisted, shielded 18

AWG. Must be run separately.

1

24 VAC transformer. See powering instructions.

External relay. 24 VAC Coil

4 to 20 mA output. 600 ohm max. Do not power

actuator with power from the controller. The controllers

are half-wave rectified, whereby the power ground is

common with the signal ground.

REF

Add 500O resistor (included in bag) to convert

0/4 to 20mA to, 0/2 to 10 VDC.

R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

4

DIGITAL INPUTS

On the "Programming> Digital Inputs" tab select whether you want

DI1, DI2, DI3, DI4 or DI5 to be “Local” or “Remote”. Local means that

the controller uses its own control program when looking at these

inputs. Remote means that the controller will only recognize input

changes originating from a PC or other communication device.

DI1 can be used for “Boiler Pump 1 Proving” or just “Monitoring”.

If Boiler Pump 1 Proving is selected, the controller will turn on the

Boiler Pump 1 and then wait 30 seconds to make sure the Pump is

on (DI1 is shorted). This can be accomplished with a flow switch, cur-

rent switch or some other device. Any time Boiler Pump 1 is on but

DI1 is not shorted, “Heating” will be shut down. To restart heating,

you must short DI1 to GND.

DI2 can be used for Boiler Pump 2 Proving or Monitoring. If Boiler

Pump 2 Proving is selected, the controller will turn on Boiler Pump

2 and then wait 30 seconds to make sure the Pump is on (DI2 is

closed). This can be accomplished with a flow switch, current switch

or some other device. Any time Boiler Pump 2 is on but DI2 is not

closed, Heating will be shut down. To restart heating, you must short

DI2 to GND.

DI3 can be used for Monitor, External Override or External Time

Clock. If External Override is selected, the controller will use its built-

in time clock and schedule to determine whether to be occupied or

unoccupied, and will also be occupied as long as DI3 is On (closed).

If External Time Clock is chosen, the controller will not use its built

in time clock and schedule to determine whether to be occupied or

unoccupied. The controller will be occupied as long as DI3 is On

(closed) and unoccupied as long as DI3 is Off (Open). NOTE: the

start of an occupied period is delayed by the power-on

delay value.

DI4 is available for monitoring. Select “Boiler/Chiller Alarm” to moni-

tor alarm conditions such as High Temperature, Low Water Level,

etc. (Note: no action will be taken by the controller for this alarm. It

is only being monitored.) Select “Monitoring” to detect more general

conditions.

If monitoring is selected, there is an option to enable Domestic

Hot Water (DHW) Override. When Domestic Hot Water Override is

enabled and DI4 is applied, the boiler pumps will turn off and the

boiler stages will maintain the high limit setpoint regardless of the

reset schedule. This override will operate for a 1 hour maximum,

after which the boiler pump will turn back on and the unit will function

normally.

DI5 can be used for Chiller Pump Proving or Monitoring. If Chiller

Pump Proving is selected, the controller will turn on the Chiller Pump

and then wait 30 seconds to make sure the Pump is on (DI5 is

closed). This can be accomplished with a flow switch, current switch

or some other device. Any time the Chiller Pump 1 is on but DI5 is

not shorted, Cooling will be shut down. To restart cooling, you must

short DI5 to GND.

REMOTE OVERRIDE

Using DI3 you can override the controller (put it in Occupied Mode).

First, using hte drop-down menu select "External Override" as the

function for DI3. Next using the Source drop-down menu select

"Remote" (this means the values come via software). Finally, select

"ON" from the Override drop-down menu and then click "Write

Page". This will bring the controller to occupied mode permanently.

NOTE: You must change the Source back to Local in

order for the controller to go back into normal operation.

BOILER AND PUMP RELAYS

The Boiler Pump and Boiler Stage Relay Outputs can operate in

N.O. (Normally Open) or in N.C. (Normally Closed) mode. The

default is N.O., whereby when the pump or stage output is On, the

relay closes. NOTE: if using N.C. mode, you will need to

have pilot relays to turn on the pumps and stages, and

the LED indication on the SZ2165 will be reversed, i.e.

when the pump or stage is On, the LED is Off and when

the pump or stage is Off, the LED is On. N.C. mode will

have the pumps and stages fail On.

BOILER PUMPS

Choose whether or not to enable Boiler Pump Operation. If not

selected, the boiler pump outputs will not function.

The boiler pumps can be rotated automatically based on their

run times. Choose whether to enable the Automatic Boiler Pump

Rotation, and if so, enter the time in hours that one pump must run

before switching to the other pump.

LEAD BOILER PUMP

Choose whether Boiler Pump 1 or Boiler Pump 2 will be used as

the Lead boiler pump. The other one will be treated as the backup

pump. This selection can be used to manually alternate the boiler

pumps.

ENABLE PUMP LUBE

Choose whether you want to enable the enable pump lube function.

The Enable Pump Lube function turns on the pump every Sunday

morning at 4:00AM for the allotted purge time that is programmed in

for that particular pump.

SERVICE/ALARM STATUS

The Service Status field on the "Monitoring" tab shows various sta-

tus messages depending on which alarms have been setup - OK,

CWS_Hi/Lo (chilled water supply), HWS_Hi/Lo (hot water supply),

BLP1 (bolier pump 1 prove), BLP2 (boier pup 2 prove), DI4 (bolier/

chiller alarm), DI5 (chiler pump prove).

R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

5

SETPOINTS

Enter Occupied and Unoccupied tem-

perature setpoints for Hot Water Supply,

Chilled Water Supply, Mixed Water,

Hot Water Return and Analog Input

(Pressure). Also enter a High and Low

Limit for each setpoint, if desired.

RESET

The analog outputs and digital output

stages on the SZ2165 can be setup

to use a reset function. This is done

by placing a check in the appropriate

Enable Reset box. When using the reset

function, the Hot Water Supply, Chilled

Water Supply, Mixed Water, Hot Water

Return and/or Analog Input (Pressure)

are the Primary temperature inputs and

the Outdoor Air Temperature is the Reset

input.

You need to enter a primary occupied

and unoccupied setpoint in the Setpoints

section above. These setpoints will be

adjusted up and down based on the out-

door air temperature, the reset setpoint

and the reset factor. The analog output(s)

and digital output(s) will be controlled

using these calculated setpoint(s).

You need to enter a reset setpoint. A

comparison between the outdoor air

temperature and this setting will be used

in determining the calculated setpoint for

each respective input.

You need to enter a reset ratio factor. This

is the number of units that the respective

input setpoint is raised when the outdoor

air temperature falls below the reset set-

point by 1 unit, or the number of units that

the respective input setpoint is lowered

when the outdoor air temperature rises

above the reset setpoint by 1 unit.

example - A hot water valve is controlled using an outdoor air reset

schedule. If the outdoor air temperature is 0°F, the hot water tem-

perature is controlled at 200°F. If the outdoor air temperature is 60°F,

the hot water temperature is controlled at 80°F.

The hot water supply temperature setpoint is set to 140.

(200 + 80) / 2 = 140

The reset setpoint for the hot water supply temperature is set to 30.

(0 + 60) / 2 = 30

The reset factor for the hot water supply temperature is set to 2.

(200 - 80) / (60 - 0) = 120 / 60 = 2

OUTPUTS

For the Pump Outputs you need to enter an Occupied and

Unoccupied Outdoor Air Temperature Setpoint.

For a Cooling output (Chiller Stage(s)) the relay energizes when the

input equals the Chilled Water Setpoint + Offset + Differential and de-

energizes when the input falls to the Chilled Water Setpoint + Offset.

For a Heating output (Boiler Stages) the relay energizes when the

input equals the Hot Water Setpoint - Offset - Differential and de-

energizes when the input rises to the Hot Water Setpoint - Offset.

Enter the Offset and Differential values here.

DELAYS

Enter the Minimum ON and Minimum OFF times (in seconds) here

for all of the output stages, as well as a Purge Time and Minimum

ON and OFF times (in minutes) for the Loop pump. A Purge Time

is the amount of time (in minutes) that the pump will continue to run

after all of the stages are off.

BOILER CONTROL

The boiler can be controlled by either Hot Water Supply Temperature

or by Gauge Pressure. Choose the signal that the boiler will be con-

trolled from. Note - all outputs (Analog and Digital) will be controlled

based on this decision.

MIXED WATER

If using a valve to control mixed water temperature, place a check in

the “Enable Mixed Water Control" checkbox. When you do this, AO1

will be used to control the Mixed Water Temperature independent of

Hot Water or Chilled Water control.

R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

6

PROPORTIONAL + INTEGRAL

The Proportional + Integral function implements a way to anticipate

the need for heating using the boiler stages. This function works in

conjunction with the programmed offsets and differentials. Select

whether to enable the Proportional + Integral function. By default,

this function is disabled when the “Integral Setting” is zero. When

enabled, the integral setting can be from 1 to 255. Larger numbers

speed up the response, while smaller numbers slow down the

response.

TEMPERATURE INPUT CALIBRATION

The six tempera-

ture inputs are fac-

tory calibrated. However,

depending on the appli-

cation (long wire runs,

etc.), there may need

to be a field adjustment

done to these readings.

The “Adjusted Reading”

is the reading that the

SZ2165 actually uses for

control. The Offset Value

is the number of degrees

that the actual input temperature has been adjusted. For example:

You measure the hot water supply temperature and it reads 71°.

The SZ2165 reading is 72° and the Hot Water Supply Temperature

already has an offset of -2.0°. All you need to do is change the offset

value to -3.0° and you’re done. The SZ2165 will now read 71°.

The Hot Water Supply and Return inputs are scaled 40 to 240°F (4.4

to 115.6°C). The Chilled Water Supply and Return inputs are scaled

0 to 100°F (-17.8 to 37.8°C). The Mixed Water input is scaled 20 to

220°F (-6.7 to 104.4°C). The Outdoor input is scaled -40 to 160°F

(-40 to 71.1°C). These ranges are fixed and cannot be changed.

HOT/CHILLED WATER TEMPERATURE ALARMS

Choose whether to enable High and Low Water Temperature Alarms.

If enabled, you will need to enter a High and Low Limit for each

desired Water Temp Alarm.

AI PRESSURE RANGE

The boiler can be controlled by either Hot Water Supply Temperature

or by Gauge Pressure. If controlled by gauge pressure, choose the

range of the pressure transducer as being either 0 to 100 psi, 0 to

500 psi, or custom. If custom select 0 to 100 psi and fill in the AI

pressure range high limit.

BOILER STAGE ROTATION

Choose whether to enable Boiler Stage Rotation. Boiler rotation is

cyclical, i.e. before rotation, Boiler 1 is the first stage, Boiler 2 is the

second stage, Boiler 3 is the third stage and Boiler 4 is the fourth

stage. After one rotation, Boiler 2 is the first stage, Boiler 3 is the

second stage, Boiler 4 is the third stage and Boiler 1 is the forth

stage. If using Boiler Stage Rotation, select the number of weeks

between rotations and select the time of day that you would like the

rotation to occur, or enable rotation based on runtime, then enter the

time between change (5 hours to 1000 hours).

BOILER STAGES

Select the number of Boiler Stages that will be used in the Boiler

Stage Rotation. If using 4 stages, you can select to “Swap” stages

1 & 2 with stages 3 & 4. This is useful if using two boilers with two

stages each.

BOILER STAGE ORDERING

Select the boiler stage ordering. The term Boiler refers to the physi-

cal connections to the SZ2165. The term Stage refers to the order

in which the boiler stages cycle on and off. The factory default is to

have Boiler 1 be Stage 1, Boiler 2 be Stage 2, Boiler 3 be Stage 3

and Boiler 4 be Stage 4. Note: the boiler stages can be placed in any

order whether using boiler rotation or not. If boiler rotation is used,

this is the starting order, after which the boiler stages will be rotated

in order.

CHILLER 1 / PUMP ENABLE

Chiller Stage 1 can either be the first of two stages of chiller control,

or it can be treated like a pump (or enable) function. If selected as

a pump (or enable) function, outdoor air temperature will determine

when this output energizes. If selected as chiller stage 1, chilled

water temperature will determine when this output energizes.

CHILLER STAGE ROTATION

If Chiller Stage 1 was not selected to be a pump in the above step,

choose whether to enable Chiller Stage Rotation. If using Chiller

Stage Rotation, select the number of weeks between rotations and

select the time of day which you would like the rotation to occur.

Note: the chiller stages can be placed in any order whether using

chiller rotation or not. Chiller Stage 1 must not be enabled as a

Pump. If chiller rotation is used, this is the starting order, after which

the chiller stages will be alternated.

CHILLER STAGE ORDERING

Select the chiller stage ordering. The term Chiller refers to the physi-

cal connections to the SZ2165. The term Stage refers to the order

in which the chiller stages cycle on and off. The factory default is to

have Chiller 1 be Stage 1 and Chiller 2 be Stage 2.

ANALOG OUTPUT 1

Analog output one on the SZ2165 can be used to control Hot Water

Supply Temperature, Mixed Water Temperature or control based on

Pressure.

During the occupied time, an analog output modulates to maintain a

heating or cooling temperature setpoint. During the unoccupied time

you will need to choose whether the analog output will modulate,

remain at 20mA, or remain at (0 or 4)mA.

A proportional band (throttling range), whether you want the ana-

log output to modulate from 4 to 20mA or 0 to 20mA, and direct or

reverse action must also be programmed.

For control without "Integral" and "Derivative", enter 0 for both. The

proportional band is 0 to 100%, while the integral and derivative val-

ues are numbers from 0 to 255. The default PID values for AOI are

R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

7

P=4, I=25, D=200, PID Step=5, PID delay=2 and PID Error DB=0.

See the PID Control Factors section for more details.

ANALOG OUTPUT 2

Analog output two can be used to control a Heating Device (based

on Hot Water Supply Temperature), a Cooling Device (based on

Chilled Water Supply Temperature) or control based on Hot Water

eturn Temperature.

During the occupied time, an analog output modulates to maintain a

heating or cooling temperature setpoint. During the unoccupied time

you will need to choose whether the analog output will modulate,

remain at 20mA, or remain at (0 or 4)mA.

A proportional band (throttling range), whether you want the ana-

log output to modulate from 4 to 20mA or 0 to 20mA, and direct or

reverse action must also be programmed.

For control without "Integral" and "Derivative", enter 0 for both. The

proportional band is 0 to 100%, while the integral and derivative val-

ues are numbers from 0 to 255. The default PID values for AO2 are

P=4, I=25, D=200, PID Step=5, PID delay=2 and PID Error DB=0.

See the PID Control Factors section for more details.

PID CONTROL FACTORS

There are three main factors involved in PID control - the propor-

tional, the integral and the derivative factors. The proportional factor

dictates how much gain the input signal error should be given with

respect to the derivative and the integral error terms. A large integral

factor will cause the output to respond quickly to changes on the

input however the output could oscillate and overshoot the setpoint.

A large derivative factor will cause the output response to be slug-

gish and slow to change and the output will settle above the desired

set point. The derivative term is divided by the PID delay. The default

values programmed at the factory are a good point; however, those

values should be adjusted/tuned as needed for your particular instal-

lation to achieve the desired operation.

PID OPTIONS

The default values are Step Constant=1, PID delay=10 and PID Error

DB=0. The Step Constant determines how large of step the output

takes - the larger the number, the smaller the step size. The Step

Constant is typically 1, but should NEVER be 0 (doing so will cause

the system to stay at full output). The Delay parameter specifies how

quickly the output should evaluate error between the current output

and the desired output. The PID delay can be used to offset a slow

moving motor allowing the motor to catch up to its input signal before

the error term is reevaluated. The Error Deadband allows the system

to overlook error between the desired setpoint and the input signal to

help the system stabilize. The Error Deadband is typically 0. It is pre-

dominantly used in a situation where a small amount of error would

cause a large swing in the output or response (for example, CFM

output versus supply or input pressure).

DELAY ON POWER

After recovering from a

power loss, the controller

will wait this amount of

time before starting to

control. Different control-

lers in one building can

have different delays so

that all units don’t come on at the same time. Enter a delay time (in

seconds) that you want the Controller to use on power up.

DAYLIGHT SAVING TIME

Daylight Saving Time (DST) in the U.S. is currently from the 2nd

Sunday of March to the 1st Sunday of November. Products shipped

starting in 2007 with firmware version 1.5 or higher accommodate the

new DST schedule. Products shipped starting in 2008 with firmware

version 2.0 or higher accommodate the new DST schedule and have

the ability to be programmed to accommodate any future schedules

that may be used. Should the schedule change and you need to

customer program the DST start and end dates, simply enable the

"Daylight Saving Time" option within the software and enter the start-

ing month + week and the ending month + week.

COMMUNICATION FAILURE

If "Enable Comm. Loss Function" is selected, the SZ2165 will go

into occupied control mode if communications with it is lost and it will

stay in the mode until communications returns. The "Delay Before

Loss of Comm Function" value is the number of seconds the unit will

wait after communications are lost before engaging the Comm. Loss

Function. Be sure to set the Comm. Delay time to at least 60 sec-

onds as the QD2040 and QD2010 poll the local controller network

once per minute.

HOLIDAY VANISHING

Choose whether to enable the Holiday Vanishing Feature. If checked,

the SZ2165 will make the number of days for a holiday 0 after the

holiday is over. This will keep the holiday from occurring in subse-

quent years if it is not reprogrammed.

OVERRIDE STATUS

The "Time Allowed" field is the number of minutes from 0 to

255 (4 hr., 15 min.) which the controller will hold an unoccu-

pied system occupied, when its override button is pressed. You

can also enable "Occupied Override" which allows the over-

ride to work during occupied periods. In that case, the control-

ler would go from occupied to unoccupied when its override

button is pressed.

REMOTE OVERRIDE

In order to override

the controller (put it to

Occupied Mode), select

“ON” from the drop-down and then click on WRITE PAGE. This will

bring the controller to occupied mode for the amount of time set on

the previous screen in the “Time Allowed” box. If the override time

needs to be extended, make sure that "On" is selected and then

click WRITE PAGE. This will restart the override timer. To stop the

override, select “OFF” from the drop-down and then click on WRITE

PAGE.

R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

8

Sequence of Operation

HOT WATER

SUPPLY TEMP

BOILER STAGE 4

BOILER STAGE 3

BOILER STAGE 2

BOILER STAGE 1

OFFSET

DIFFERENTIAL TYPICAL OF HEATING

140°F

PROPORTIONAL

BAND (PID)

MIXING

VALVE

OUTDOOR AIR

TEMPERATURE

CHILLER ENABLE /

HYSTERESIS

60°F

CHILLER STAGE 1

CHILLED WATER

SUPPLY TEMP

CHILLER STAGE 1

CHILLER STAGE 2

OFFSET

DIFFERENTIAL TYPICAL OF COOLING

45°F

PROPORTIONAL

BAND (PID)

MIXING

VALVE

BOILER PUMP 1

60°F

OUTDOOR AIR

TEMPERATURE

20°F

BOILER PUMP 2

HYSTERESIS

HYSTERESIS

Checkout & Troubleshooting

CHECKOUT

1. Be sure to check and verify all wiring before powering the

SZ2165.

2. Turn power on. The SZ2165 "Power" LED should light up. Then

the Service LED will blink for 15 seconds while the electronics

stabilize.

3. If the SZ2165 has not been pre-programmed, It should be pro-

grammed at this time.

4. Increase and decrease the Heat and Cool setpoints. This must be

done from a PC. Observe the operation of the relay stages and or

analog ouput(s).

5. Note that the operation of the SZ2165 will depend on how it is

programmed.

The SZ2165 is now ready for operation.

TROUBLESHOOTING

Power LED will not come on

Check for 24 VAC on terminals “24 VAC” and “GND”. The rest of

the trouble shooting must be done with a PC and the Revelation

Professional software.

No communications

Make sure baud rate selection jumper for the QD1010 and the

SZ2165 are the same, and that Revelation is configured for that

same baud rate. Address 248 will always work provided that the

SZ2165 is NOT connected to a network.

Inputs do not read correctly

The SZ2165 is calibrated at the factory. For the loop supply tem-

perature and other temperature readings make slight adjustments

(+/- 12% of the input span). on “Screen D” of the SZ2165 program-

ming screens. (See Temperature Input Calibration on page 6.)

Output operation is not correct

Check programmed parameters, in particular “Reverse” and “Direct”

acting selections and “Heat” or “Cool” selections for the analog out-

puts, and “Offset”and “Differential” selections and “Delay Times” for

the relay outputs. Check wiring.

A pump won't turn on

If a pump will not turn on when it should, DI1, DI2 or DI5 may be set

for a pump proving function. If a pump fails, DI1, DI2 or DI5 must be

momentarily shorted in order to restart the respective pump.

LED Description

Sixteen LEDs on the unit allow the occupant to view the current

operating status of the SZ2165.

POWER: This LED will be lit whenever the unit has power.

DIGITAL OUTPUTS: These LEDs will be lit when the corre-

sponding relay outputs are on. Relaly outputs include pumps, boiler

stages, chiller stages, etc.

OCC: This LED will be on whenever the unit is operating in the

occupied mode.

SERVICE: This LED will be on whenever the unit has a service

condition. This LED also blinks on powerup until the electronics sta-

bilize.

DATA: This LED will blink when the unit is being accessed by a

PC.

Rev: 0911

C3545_REV2

Table of contents

Other TCS Basys Controls Controllers manuals