Honeywell EXCEL 5000 OPEN ZAPP User manual

Other Honeywell Controllers manuals

Honeywell

Honeywell V4055F Operation manual

Honeywell

Honeywell UDC3300 User manual

Honeywell

Honeywell S8600B User manual

Honeywell

Honeywell R7426B Operation manual

Honeywell

Honeywell MT8-024 User guide

Honeywell

Honeywell Design and Application Product manual

Honeywell

Honeywell ML6194 Operation manual

Honeywell

Honeywell 301C User manual

Honeywell

Honeywell PRO 2000 Series User manual

Honeywell

Honeywell Experion C300 User manual

Honeywell

Honeywell AQS51-KAM Operation manual

Honeywell

Honeywell CIPer 50 User manual

Honeywell

Honeywell CENTRA LINE EAGLEHAWK Installation and operation manual

Honeywell

Honeywell L7224A User manual

Honeywell

Honeywell WEB-600E User manual

Honeywell

Honeywell Ex-Or MSM2000D Installation and operation manual

Honeywell

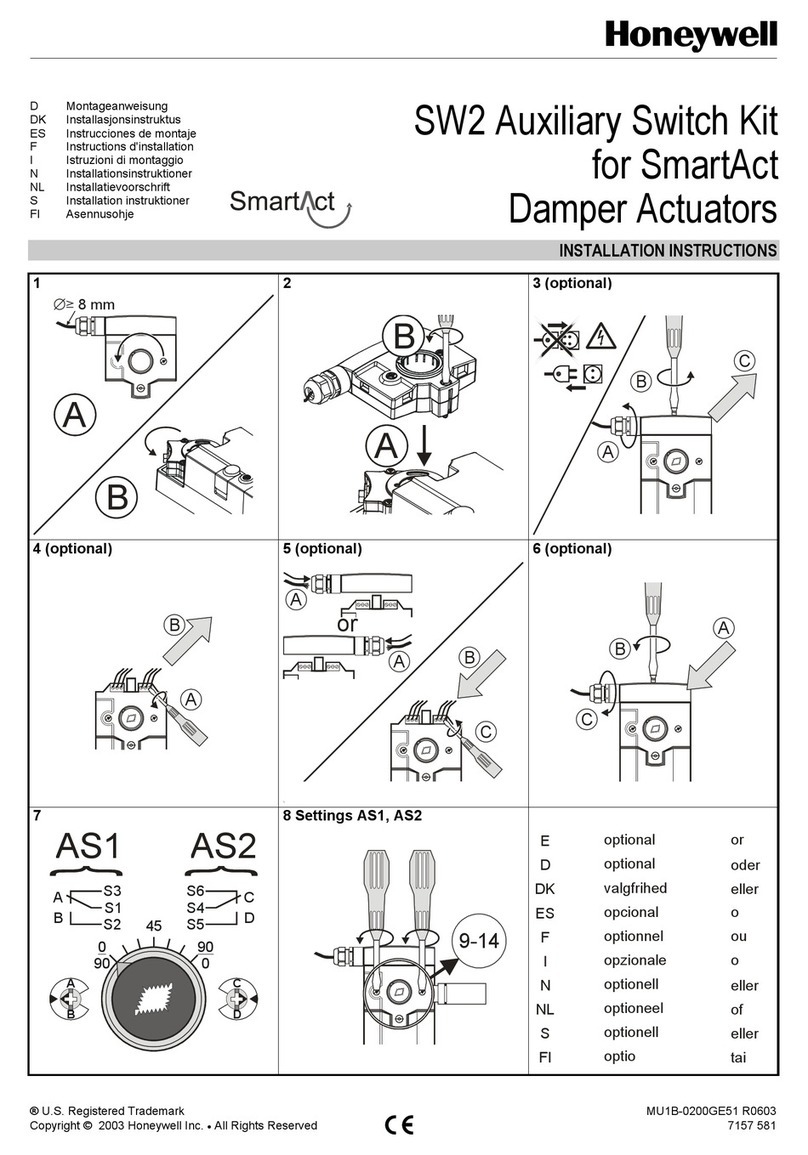

Honeywell SW2 User manual

Honeywell

Honeywell V4055A User manual

Honeywell

Honeywell 10260S Series User manual

Honeywell

Honeywell V4062A User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions