TCS Basys Controls SE1000 User manual

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

1

SE1000

Utility Meter Pulse Transducer

Product Manual

Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features ....................................1

Mounting....................................1

Wiring ......................................2

Programming ................................3

Operation ...................................5

Checkout & Troubleshooting ....................6

LED Description ..............................7

Communicating Controls

Description

The SE1000 is a microprocessor-based pulse monitor-

ing interface designed to monitor up to four pulse inputs.

Features

• Stand-alone or network operation

• Independently programmable inputst

• 32 character LCD display

• Four pulse inputs

Mounting

The SE1000 is designed for mounting using two #10

sheet metal screws.

R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

2

P u ls e in p u t fro m lo c al u tility .

3

2 4 V A C tra n sfo rm e r. S e e p o w e rin g in str uc tio n s.

2

1

F or c om m u n ic atio n w irin g, u s e tw is te d, s hie ld e d 1 8

A W G . M ust b e run se pa rate ly.

C

R

P O W E R

A

B

R E F

SE1000

UTILITY METER

PULSE TRANSDUCER

M ete r 1 D em a nd

+

2

3 33 3

AB

1

REF

D A T A

R S 4 85

M E TE R 1 M E TE R 2 M E TE R 3 M E TE R 4

PULSE INPUTS

K/Y Z K/Y Z K/Y Z K/Y Z

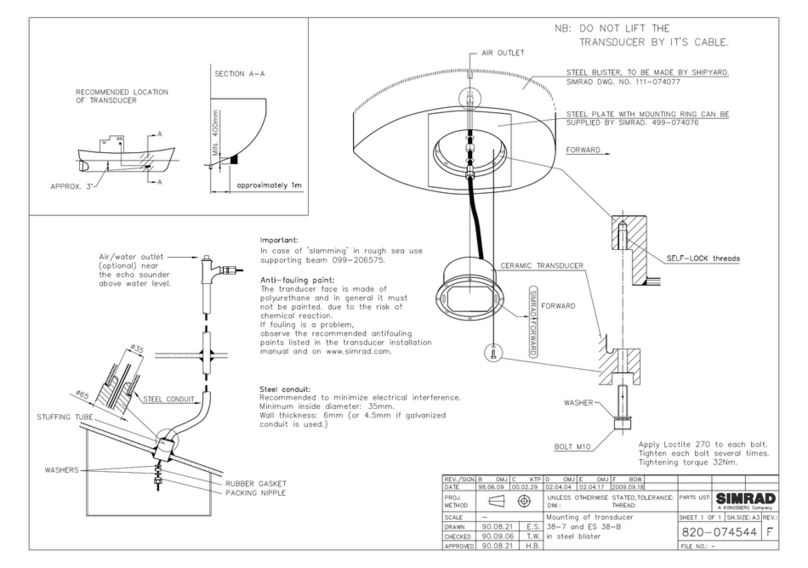

Wiring

The SE1000 uses terminal designations for wiring. See

diagram below.

POWERING THE SE1000

The SE1000 is powered from 24 VAC +/- 20 %.

If wiring for communications, dedicated power must be

used to power the SE1000. Several “S” series control-

lers may be powered from the same transformer, provid-

ed that the transformer has sufficient power. (Supertrols

require 5 VA @ 24 VAC.)

Caution: Do not connect to 120 VAC. When multiple

TCS Basys Controls devices are using a single

transformer, the polarity of the power wiring

must be maintained because all TCS devices

are half-wave rectified and have common return

paths.

R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

3

Programming

The SZ1000 may be programmed through the display

and keypad, or with a PC.

If programming with a PC, the following must be set

through the keypad prior to programming:

• Address (step #2)

• Baud rate (step #3)

For more information on programming through the PC,

consult your TCS software manual.

PROGRAMMING THROUGH THE KEYPAD

To access the programming screens, press both the

“Scroll” and “Next” keys simultaneously.

Scroll Key - The "Scroll" key is also used to

save any changes to the "current" screen and

advance to the next screen while program-

ming. The "Scroll" key is used to enter the

Programming Mode when pressed with the

"Next" key.

Next Key - Used to enter Programming Mode

when pressed with the “Scroll” key. Also used to

exit programming without saving changes to the

current screen.

Increment/Decrement Keys - Used to select the

desired value.

METER 1 TYPE:

ELEC 1 PH

Meter 1 Type Screen.

Select either ELEC 1 PH, BTU, WATER,

GAS, ELEC 3 PH. This screen does not

show if NO was selected in step 4.

METER 1 CT VALUE:

0.60

Meter 1 CT Value Screen.

Enter the value for the CT wired to Meter

input 1 (this value should be provided on

the CT or Energy Meter from the Utility).

This screen does not show if NO was

selected in step 4 or if BTU, Water or Gas

was selected in step 5.

METER 1 P/REV:

4.00

Meter 1 Pulse Per Revoltion Screen.

Enter the value for the Pulses per revolt-

ion for meter input 1, (this value should

be provided on the CT or Energy Meter

from the Utility). This screen does not

show if NO was selected in step 4.

METER 1 CONSTANT:

1.00

Meter 1 Constant Screen.

Enter the value for the constant for meter

input 1 (this value is provided from utility

company). This screen does not show if

NO was selected in step 4.

METER 1 CU FT/P:

5.00

Meter 1 Cubic Feet Per Pulse Screen.

Enter the value for Cubic Feet per pulse.

This only applies to Water, GAS and

BTU (this value is provided from utility

company). This screen does not show if

NO was selected in step 4.

METER 1 MULT:

1.00

Meter 1 Multiplier Screen.

Enter the multiplier for meter input 1 (this

value is provided from utility company).

This screen does not show if NO was

selected in step 4.

SETUP METER 2:

NO

Meter 2 Setup Screen.

Select either Yes or No to program Meter

input two. If no is selected skip to step 18.

METER 2 TYPE:

ELEC 1 PH

Meter 2 Type Screen.

Select either ELEC 1 PH, BTU, WATER,

GAS, ELEC 3 PH. This screen does not

show if NO was selected in step 11.

METER 2 CT VALUE:

0.60

Meter 2 CT Value Screen.

Enter the value for the CT wired to Meter

input 2 (this value should be provided on

the CT or Energy Meter from the Utility).

This screen does not show if NO was

selected in step 11 or if BTU, Water or

Gas was selected in step 12.

5.

6.

7.

8.

9.

10.

11.

12.

13.

ENTER ACCESS

CODE: 000

Access Code Entry Screen.

Enter the access code. If the wrong

access code is entered, the program

reverts to the main screen. 248 is the

default access code.

SET ADDRESS:

100

Controller Address Screen.

If using a PC to access the SE1000, set

a unique address from 0 to 255, exclud-

ing 248.

SET BAUD RATE:

9.6K

Communication Baud Rate Screen.

Is using a PC to access SE1000, all con-

trollers on a network must be set to the

same baud rate. Choose between 2.4K,

4.8K, 9.6K and 19.2K.

SETUP METER 1:

NO

Setup Meter 1 Screen.

Select either Yes or No to program Meter

input one. If no is selected skip to step 11.

1.

2.

3.

4.

Meter 1 Demand

0.00 kW

+

Main Monitoring Screen

R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

4

METER 2 P/REV:

4.00

Meter 2 Pulse Per Revoltion Screen.

Enter the value for the Pulses per revolt-

ion for meter input 2 (this value should be

provided on the CT or Energy Meter from

the Utility). This screen does not show if

NO was selected in step 11.

METER 2 CONSTANT:

1.00

Meter 2 Constant Value Screen.

Enter the value for the constant for meter

input 2 (this value is provided from utility

company). This screen does not show if

NO was selected in step 11.

METER 2 CU FT/P:

5.00

Meter 2 Cubic Feet Per Pulse Screen.

Enter the value for Cubic Feet per pulse.

This only applies to Water, GAS and

BTU (this value is provided from utility

company). This screen does not show if

NO was selected in step 11.

METER 2 MULT:

1.00

Meter 2 Multiplier Screen.

Enter the multiplier for meter input 2 (this

value is provided from utility company).

This screen does not show if NO was

selected in step 11.

SETUP METER 3:

NO

Meter 3 Setup Screen.

Select either Yes or No to program Meter

input two. If no is selected skip to step 25.

METER 3 TYPE:

ELEC 1 PH

Meter 3 Type Screen.

Select either ELEC 1 PH, BTU, WATER,

GAS, ELEC 3 PH. This screen does not

show if NO was selected in step 18.

METER 3 CT VALUE:

0.60

Meter 3 CT Value Screen.

Enter the value for the CT wired to Meter

input 3 (this value should be provided on

the CT or Energy Meter from the Utility).

This screen does not show if NO was

selected in step 18 or if BTU, Water or

Gas was selected in step 19.

METER 3 P/REV:

4.00

Meter 3 Pulse Per Revoltion Screen.

Enter the value for the Pulses per revolt-

ion for meter input 3 (this value should be

provided on the CT or Energy Meter from

the Utility). This screen does not show if

NO was selected in step 18.

METER 3 CONSTANT:

1.60

Meter 3 Constant Value Screen.

Enter the value for the constant for meter

input 3 (this value is provided from utility

company). This screen does not show if

NO was selected in step 18.

14.

15.

16.

17.

18.

19.

20.

21.

22.

METER 3 CU FT/P:

5.00

Meter 3 Cubic Feet Per Pulse Screen.

Enter the value for Cubic Feet per pulse.

This only applies to Water, GAS and BTU

(this value is provided from utility com-

pany). This screen does not show if NO

was selected in step 18.

METER 3 MULT:

1.00

Meter 3 Multiplier Screen.

Enter the multiplier for meter input 3 (this

value is provided from utility company).

This screen does not show if NO was

selected in step 18.

SETUP METER 4:

NO

Meter 4 Setup Screen.

Select either Yes or No to program Meter

input two. If no is selected skip to step 32.

METER 4 TYPE:

ELEC 1 PH

Meter 4 Type Screen.

Select either ELEC 1 PH, BTU, WATER,

GAS, ELEC 3 PH. This screen does not

show if NO was selected in step 25.

METER 4 CT VALUE:

0.60

Meter 4 CT Value Screen.

Enter the value for the CT wired to Meter

input 4 (this value should be provided on

the CT or Energy Meter from the Utility).

This screen does not show if NO was

selected in step 25 or if BTU, Water or

Gas was selected in step 26.

METER 4 P/REV:

4.00

Meter 4 Pulse Per Revoltion Screen.

Enter the value for the Pulses per revolt-

ion for meter input 4 (this value should be

provided on the CT or Energy Meter from

the Utility). This screen does not show if

NO was selected in step 25.

METER 4 CONSTANT:

1.60

Meter 4 Constant Value Screen.

Enter the value for the constant for meter

input 4 (this value is provided from utility

company). This screen does not show if

NO was selected in step 25.

METER 4 CU FT/P:

5.00

Meter 4 Cubic Feet Per Pulse Screen.

Enter the value for Cubic Feet per pulse.

This only applies to Water, GAS and

BTU (this value is provided from utility

company). This screen does not show if

NO was selected in step 25.

METER 4 MULT:

1.00

Meter 4 Multiplier Screen.

Enter the multiplier for meter input 4 (this

value is provided from utility company).

This screen does not show if NO was

selected in step 25.

23.

24.

25.

26.

27.

28.

29.

30.

31.

In the following picture, both Type A and C are shown.

Three pulses are shown, labeled 1, 2, and 3. Notice

how the Type A output closes and opens for each pulse,

where the Type C output simply changes state.

If you have a Type C device (3 terminals KYZ), you will

need to double the multiplier. The SE1000 only counts

the contact closures for the K and Z terminals. Doubling

the multiplier will correct this problem.

PROGRAMMING THE METER CONSTANTS:

CT Value: The value of the CT wired to the meter.

This value is usually provided on the CT or on the util-

ity output meter. This value is only used for and electric

meter.

P/REV: The Pulses per revolution for the meter.

This value is usually provided from the utility company.

CONSTANT: The value of the constant for the meter

is usually provided from the utility company and many

times is located on the electric or gas bill.

CU FT/P: The value for Cubic Feet per pulse. This

only applies to Water, GAS and BTU, and is usually

found on the utility meter itself.

MULT: The multiplier for the meter can be used

to scale the meter output or correct for KYZ meter. The

multiplier is used to convert the pulses to engineering

unit data. For example, if your meter provides one pulse

per 0.01KWH, then a constant of 0.01 is required.

MULTIPLIER:

Each model of power meter is different and has a differ-

ent multiplier. For example, if the meter is a Type A and

reports 1/10 kWh per pulse, set the input multiplier to

0.1. If the meter is a Type C and reports 1/10 kWh per

pulse, set the input multiplier to 0.2.

You must obtain the correct pulse multiplier from the

meter manufacturer prior to configuring the SE1000.

Some power meters have an option to configure the

multiplier. Options often include 1, 0.1, 0.01, kWh per

pulse. The best method to configure the pulse is to

select the smallest multiplier available, considering the

maximum load and pulse rate. To calculate the pulse

rate, use the following formula:

Pulses = KW*3600*multiplier

Second

In general, the SE1000 calculates electric meter con-

sumption and demand as follows:

R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

5

SET ACCESS CODE:

248

Access Code Screen.

Enter an access code (0 to 255) that will

be used to enter the programming mode.

The default is 248.

Meter 1 Demand

0.00 kW

Main Monitoring Screen.

Operation

METER INPUTS

There are four meter inputs available. Each one is setup

for a dry contact and cannot be changed. Each input

(Meter 1, Meter 2, Meter 3 & Meter 4) can be configured

to accept signals representing electrical, BTU, water or

gas usage. The required parameters will be provided

by either the utility company involved or on the current

transducer (CT) used to generate the pulse signal.

METER TYPES

The SE1000 supports various meter types. Selecting a

meter type changes the default values as they are used

to calculate meter consumption and demand for that par-

ticular meter. For each of the four SE1000 meter inputs,

there are five selectable options:

ELEC 1 PH: Electric single phase meter.

ELEC 3 PH: Electric three phase meter.

GAS: Gas meter.

WATER: Water meter

BTU: BTU meter

Utility pulse meters can be one of two different types,

depending on whether they count the leading and trail-

ing edges of the pulse or only the leading edge of the

pulse as a single count. A pulse output can be either a

mechanical relay or solid state device. The pulse output

corresponds to a unit/time of a monitored quantity. The

amount of time between states of a pulse output corre-

sponds to the meter demand and the number of pulses

is proportional to the meter’s consumption.

Below is a diagram depicting two types of utility meter

pulse outputs. Meter Type A counts only the leading

edge as a single pulse and the trailing edge is ignored.

Meter Type C is known as a true KYZ meter and counts

both the leading and trailing edges as a pulse, effectively

doubling the number of pulses as seen by Meter Type

A. The SE1000 measures Type A output only; however,

KYZ functionality can be mimicked by using a “Meter

Multiplier” value of 2.

32.

33.

R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

6

Demand = ((CTValue*MtrConst*MtrMult))

(PPRValue*PulseTimeDiff)

Consumption = ((PulseCount*CTValue*MtrConst*MtrMult))

PPRValue

The above diagram depicts how a single pulse and the

pulse time difference are represented on a pulse waveform

input into the SE1000.

Checkout & Troubleshooting

CHECKOUT

You may verify the status of each meter input by press-

ing the "Scroll" key and then using the "Increment" and

"Decrement" keys to cycle through the various screens.

1. Verify all wiring prior to powering the controller.

2. Turn power on. The controller will display a momentary

screen with the model and version number, and then the

main monitoring screen.

Meter 1 Demand

*SE1000*

TCS V3.0(C)

3. Take note of the current readings for all meters. Since

the SE1000 is used only for monitoring, and if the read-

ings appear to be correct, you are done.

4. If a value does not appear to be correct, scroll through

the meters to view the desired input and verify that a

value (other than 0) is being shown.

5. Go back into programming mode and adjust various

parameters as required to make the value appear cor-

rectly.

6 If a value shown as 0, the SE1000 is not retrieving a

pulse signal. Verify the pulse signal is being generated

at the meter or CT and check the input wiring.

TROUBLESHOOTING

No Display

Check for 24 VAC on terminals “R” and “C”.

Incorrect Monitoring Value Displayed

If any of the meter inputs are showing incorrect values,

verify the programming parameters for that meter. If any of

the meter inputs are showing 0, verify the pulse signal is

working. See checkout for details.

MONITORING SCREENS

Continually pressing the scroll button or next button and

the increment/decrement button allow more extensive

monitoring. The screens are shown below.

METER 1 DEMAND

0.00 kW

Main Monitoring Screen

METER 1 DEMAND

0.00kW

Meter 1 Demand Screen.

Displays Current Demand, units will vary

based on type of meter selected.

METER 1 COUNT

0

Meter 1 Count Screen.

Displays Current Consumption, units will

vary based on type of meter selected

CONSUMPTION 1

0.00 kWh

Meter 1 Consumption Screen.

Displays Current pulse count, units will

vary based on type of meter selected.

METER 2 DEMAND

0.00kW

Meter 2 Demand Screen.

Displays Current Demand, units will vary

based on type of meter selected.

METER 2 COUNT

0

Meter 2 Count Screen.

Displays Current Consumption, units will

vary based on type of meter selected

CONSUMPTION 2

0.00 kWh

Meter 2 Consumption Screen.

Displays Current pulse count, units will

vary based on type of meter selected.

1.

2.

3.

4.

5.

6.

METER 3 DEMAND

0.00kW

Meter 3 Demand Screen.

Displays Current Demand, units will vary

based on type of meter selected.

METER 3 COUNT

0

Meter 3 Count Screen.

Displays Current Consumption, units will

vary based on type of meter selected

CONSUMPTION 3

0.00 kWh

Meter 3 Consumption Screen.

Displays Current pulse count, units will

vary based on type of meter selected.

METER 4 DEMAND

0.00kW

Meter 4 Demand Screen.

Displays Current Demand, units will vary

based on type of meter selected.

METER 4 COUNT

0

Meter 4 Count Screen.

Displays Current Consumption, units will

vary based on type of meter selected

CONSUMPTION

0.00 kWh

Meter 4 Consumption Screen.

Displays Current pulse count, units will

vary based on type of meter selected.

METER 1 DEMAND

0.00 kw

Main Monitoring Screen

LED Description

PROGRAM/DATA

This LED will be lit when the controller is within the

programming setup menus. It will blink when the unit is

being accessed by a PC.

7.

8.

9.

10.

11.

12.

R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

7

Rev:0310

C3679

Table of contents

Popular Transducer manuals by other brands

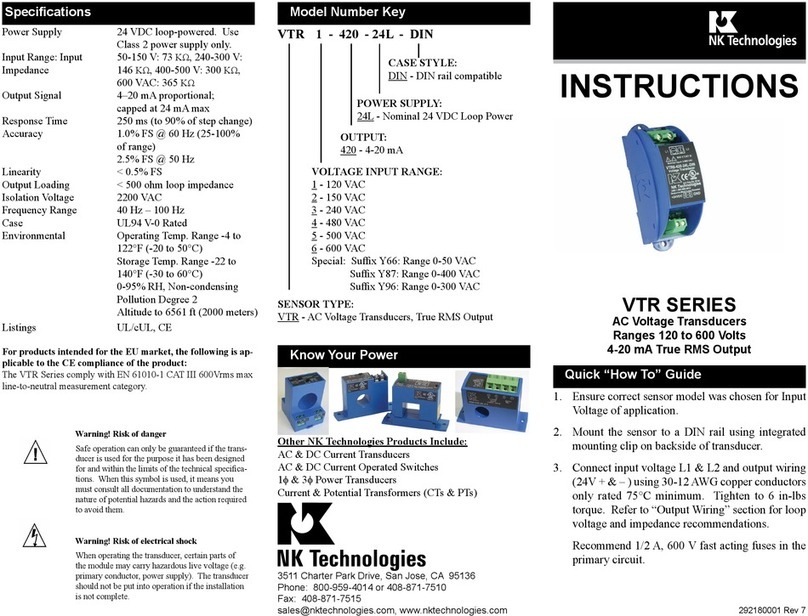

NK TECHNOLOGIES

NK TECHNOLOGIES VTR Series instructions

Sensor Technology

Sensor Technology TorqSense SGR530 Series user manual

Cleco

Cleco P2182BA/EN instruction manual

Philips

Philips Avalon CTS M2720A Service guide

Camille Bauer

Camille Bauer SINEAX DME 406 operating instructions

Electro-Voice

Electro-Voice DH3 Technical specifications

RS PRO

RS PRO ICA 31 instruction manual

Brooks Instrument

Brooks Instrument SolidSense II Series Installation & operation manual

Yamaha

Yamaha SYSTEM56C Service manual

Consilium

Consilium SAL R1E Installation

Ulthera

Ulthera DeepSEE DS 4 - 4.5 Instructions for use

M-system

M-system LT-UNIT Series quick start guide