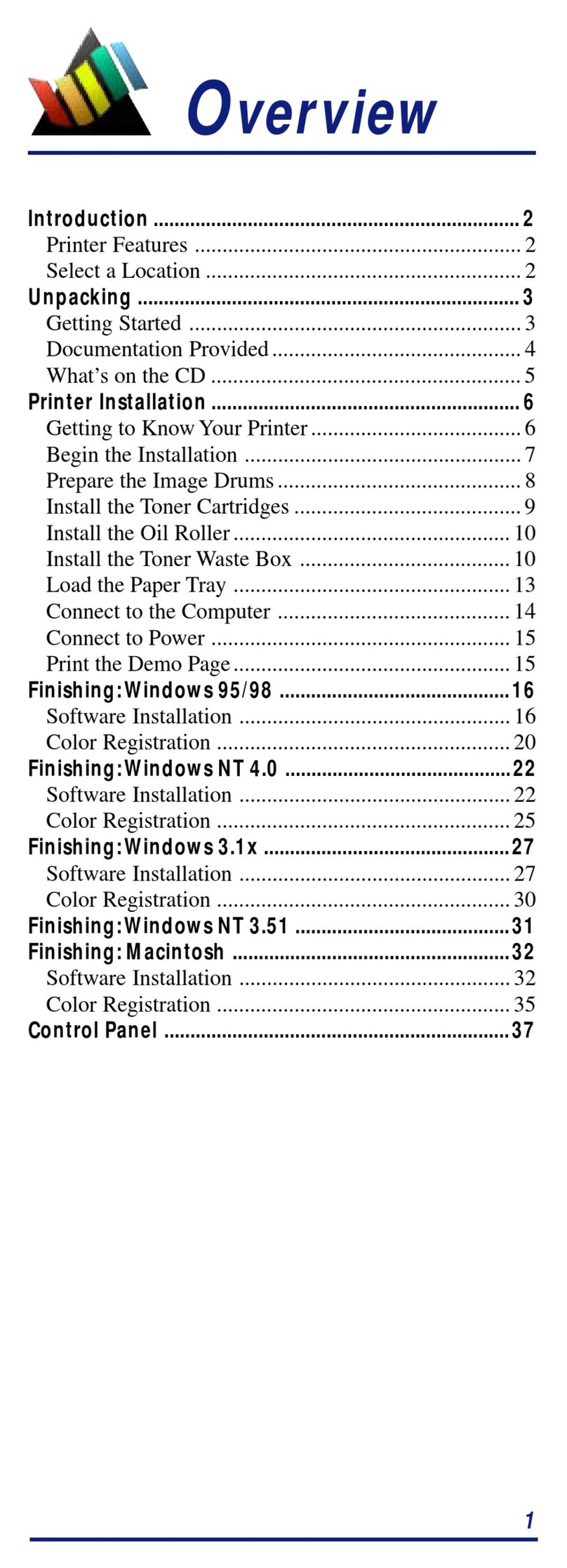

1

1. Overvie

nic

T410

w

1.1 Tech al Data

T400

Print Type yDirect Thermal/ Thermal Transfer, Direct Thermal onl

Resolution 0.125 mm (8 dot/mm, 203 dpi) 0.083 mm (12 dot/mm, 305 dpi)

Speed User s lectable

2 to 6 ips User selectable

2 to 4 ips

e

from 50 mm/sec to 150 mm/sec from 50 mm/sec to 100 mm/sec

Darkness 5 / 6 steps selectable (by Printer Driver)

Print Area Print width 104 mm (4.1 in.) x

5.6 in.) Print width 104 mm (4.1 in.) x

400 mm (15.6 in.)400 mm (1

Media Width 25 (0.98 in.) ~ 115 mm (4.5 in.)

.1 in.) ~ 118 mm (4.6 in.) incl. Backing paper)(28 (1

Media Length and Batch:

Calliper Dispense:

Cutter:

Tear-Off

15 (0.6 in.) ~ 397 mm (15.6 in.) (18 (0.71 in.) ~400 mm (15.6

in.) incl. Backing paper) 0.08 (0.003 in.) ~ 0.19 mm (0.075 in.)

20 (0.78 in.) ~ 120 mm (4.7 in.) (23 (0.91 in.) ~ 123 mm (4.8

in.) incl. Backing paper) 0.08 (0.003 in.) ~ 0.19 mm (0.075 in.)

20 (0.78 in.) ~397 mm (15.6 in.) (23 (0.91 in.) ~400 mm (15.6

in.) incl. Backing paper) 0.08 (0.003 in.) ~ 0.19 mm (0.075 in.)

27 (1.06 in.) ~ 397 mm (15.6 in.) (30 (1.18 in.) ~ 400 mm (15.6

in.)incl. Backing paper) 0.08 (0.003 in.) ~ 0.19 mm (0.075 in.)

Label Roll Maximum Roll Diameter: 110 mm (4.3 in.) (Face out)

Label Inner Core Diameter: 40 mm (1.6 in.)

Media Types Die-Cut Label; Continuous material; Tag material, Roll type- Face-

out, Fan fold type, 2 color thermal paper

Carbon Ribbon 100 meter (325 ft.) long, Face out, I.D. 12.7 mm (0.5in.),

O.D. 39 mm(1.5 in.), Thickness: 4.5 Micron, black and colored up to

111 mm (4.4 in.) wide, center adjustment

Bar-Codes UPC-E / UPC-A, NW-7, Code 39, Code 93, Code 128, UCC / EAN

128, ITF 2 of 5, Industrial 2 of 5, Matrix 2 of 5, MSI, Bookland, Post-

net, RSS Composite Code

Bar-C :3, 2:5ode Ratios 1:2, 1

Bar-Cod Sizes Height: 4 dots to 600 dots; width – user definablee

Rotational capability 360° Rotation (0°, 90°, 180° and 270°)

2-D C Code, PDF 417, Micro PDFodes QR Code, Veri Code, Maxi

Fonts Outline FontU, S, M, XU, XS, XM, XB, XL, OCR-A, OCR-B,

Label nSe sing Reflective Sensor (eye-mark) bottom reading

(Gap) movableSee-through sensor

CPU 32 bit RISC / 80MHz

Memo te; Expanded: Flash-ROM 2 x 2Mbytery Standard: Flash-ROM 2MBy

Capacit Input Buffer 2.9MByte, SDRAM 8MBytey

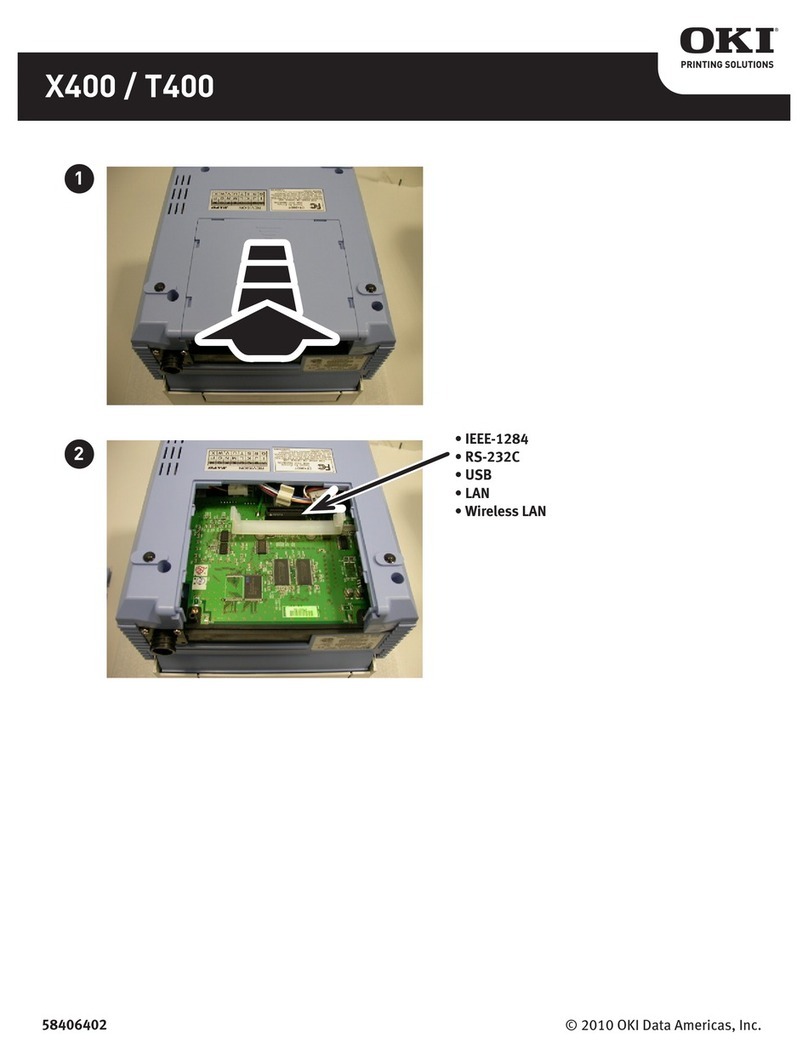

Interface ECP Parallel (IEEE1284),RS232C, USB, LAN, Wireless LAN