408- 7114

3of 4Rev B

A. Visual Inspection

1. Remove all lubrication and accumulated film by

immersing the tool (handles partially closed) into a

suitable degreaser that will not affect paint or

plastic material.

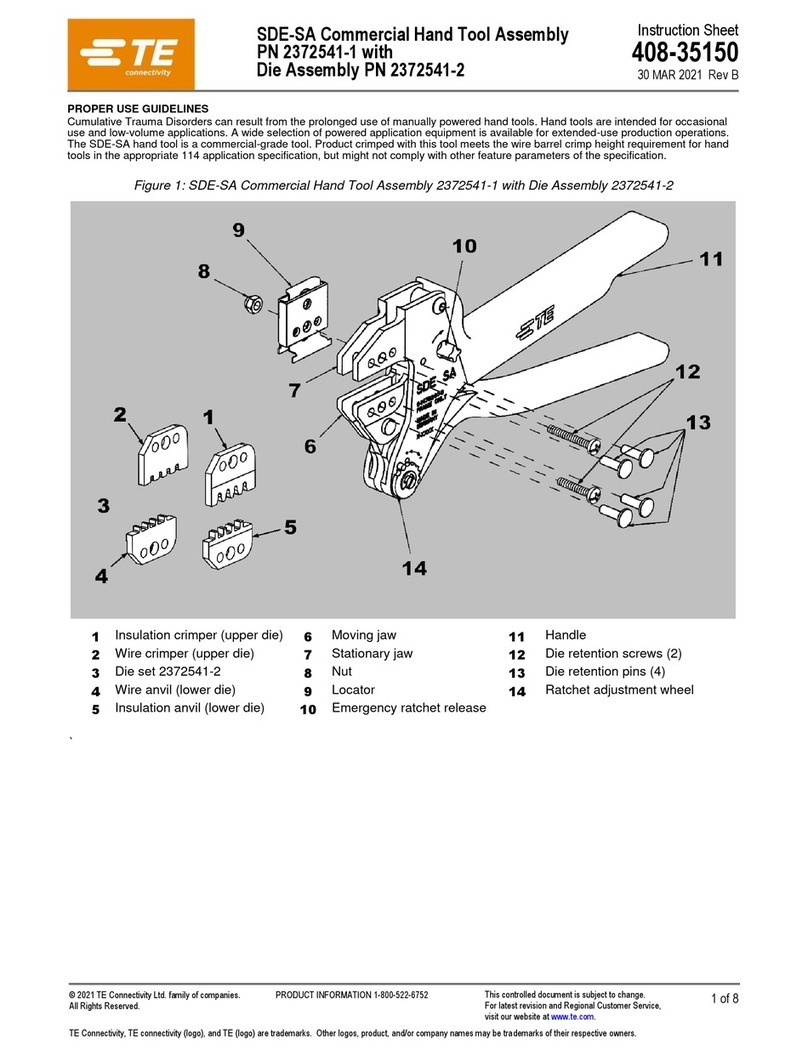

2. Make certain all retaining pins are in place and

are secured with the proper retaining rings. If

replacements are necessary, refer to Figure 5.

3. Close the tool handles until the ratchet releases,

and then allow the handles to open freely. If they

do not open quickly and fully, then the spring is

defective and must be replaced (see Section 5,

REPLACEMENT AND REPAIR).

4. Inspect the tool, with special emphasis on

checking for worn, cracked, or broken crimping

jaws. If damage to any part of the head is evident,

return the tool for evaluation and repair (see

Section 5, REPLACEMENT AND REPAIR).

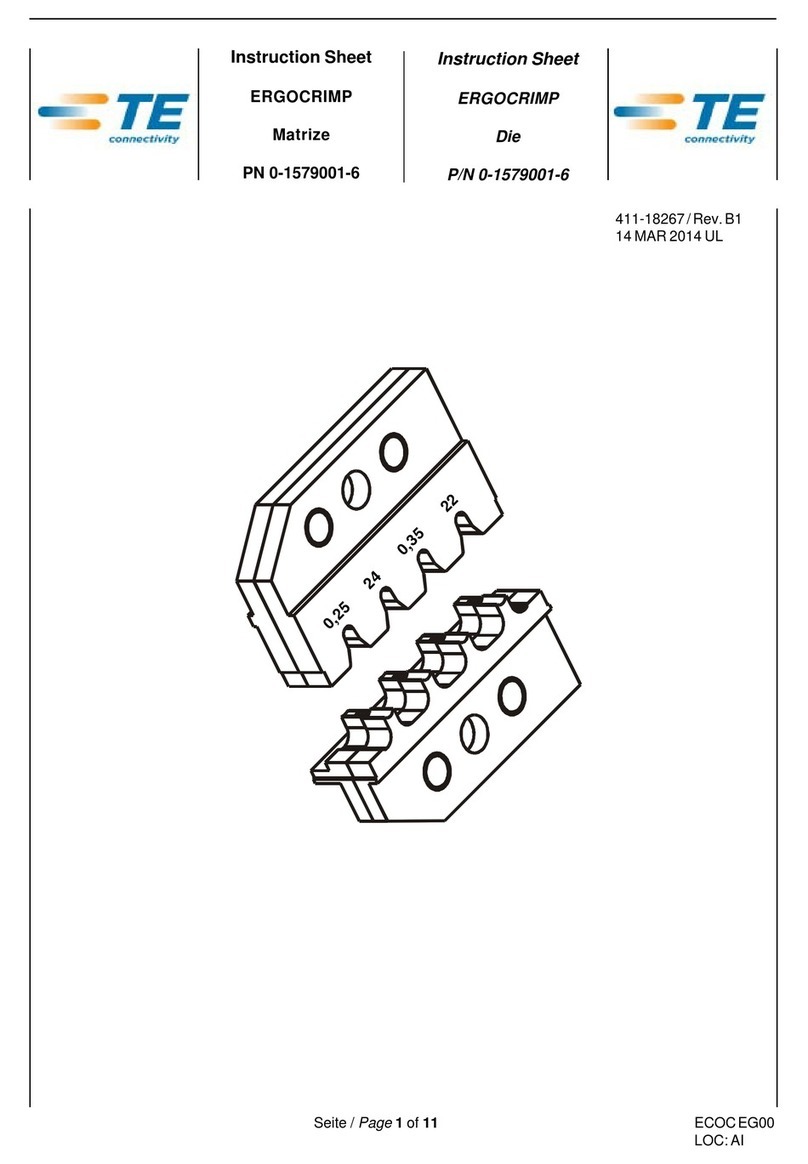

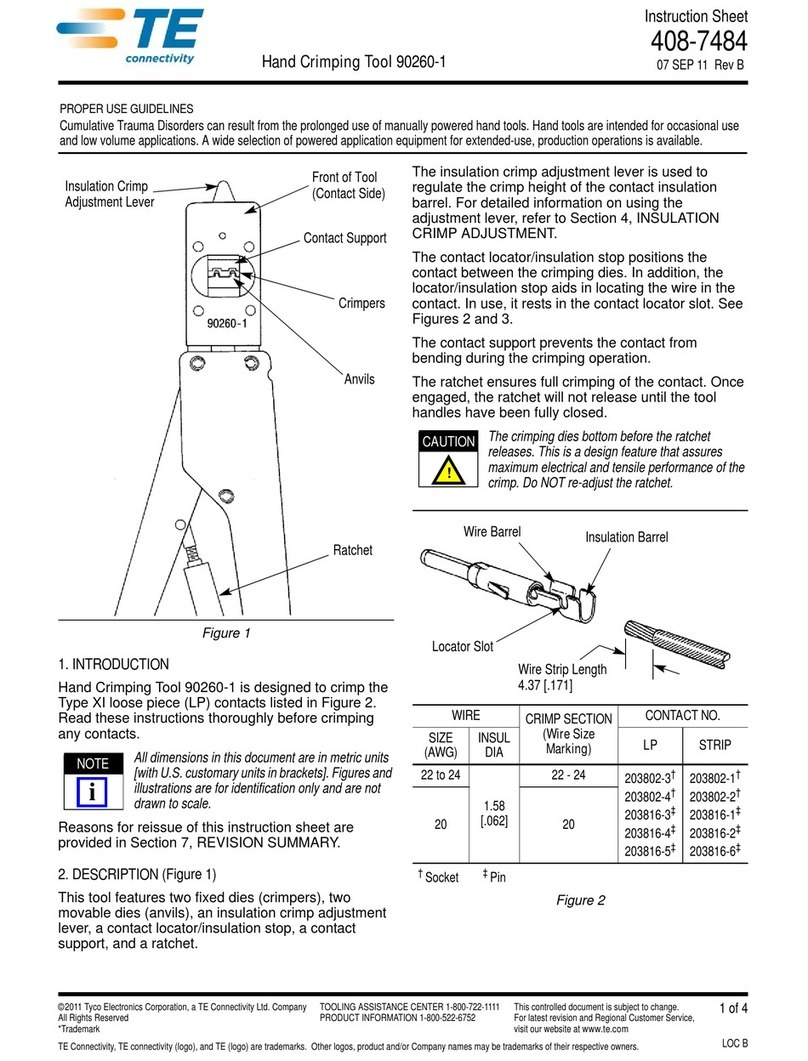

B. Crimp Height Inspection

This inspection requires the use of a micrometer, with

a modified anvil, as shown in Figure 4. The Crimp

Height Comparator RS--1019--5LP is recommended

and is available from:

Shearer Industrial Supply Co.

20 North Penn Street

York, PA 17401--1014

VALCO

1410 Stonewood Drive

Bethlehem, PA 18017--3527

or

Proceed as follows:

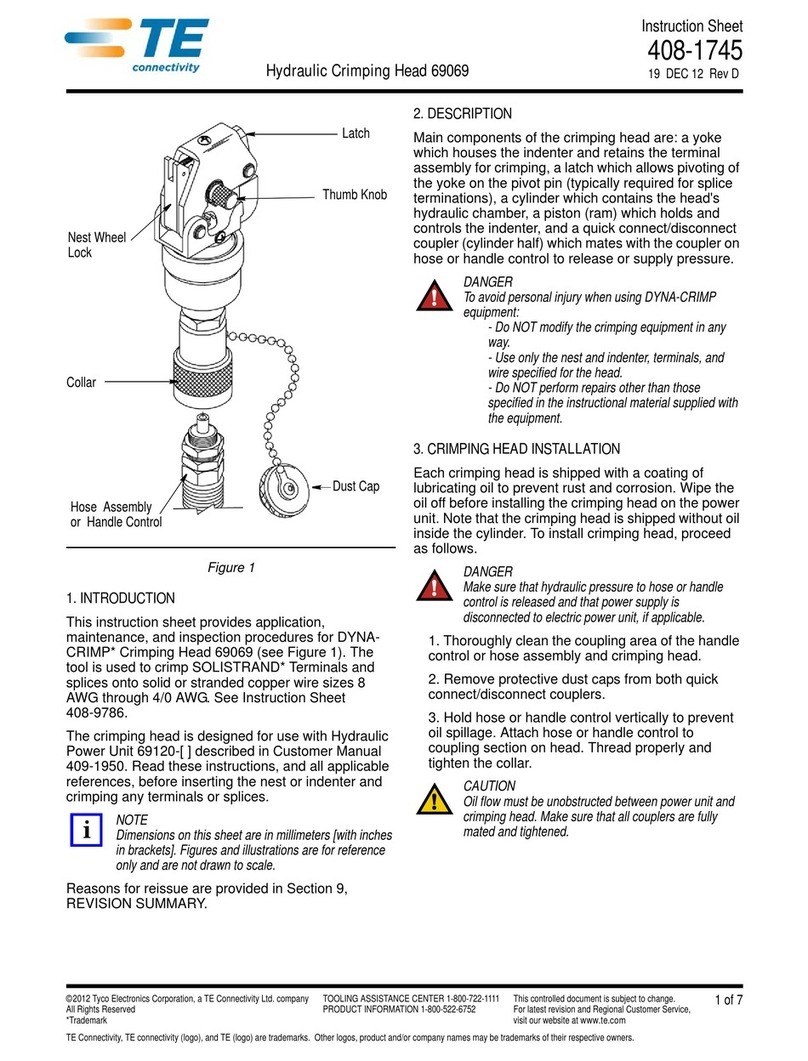

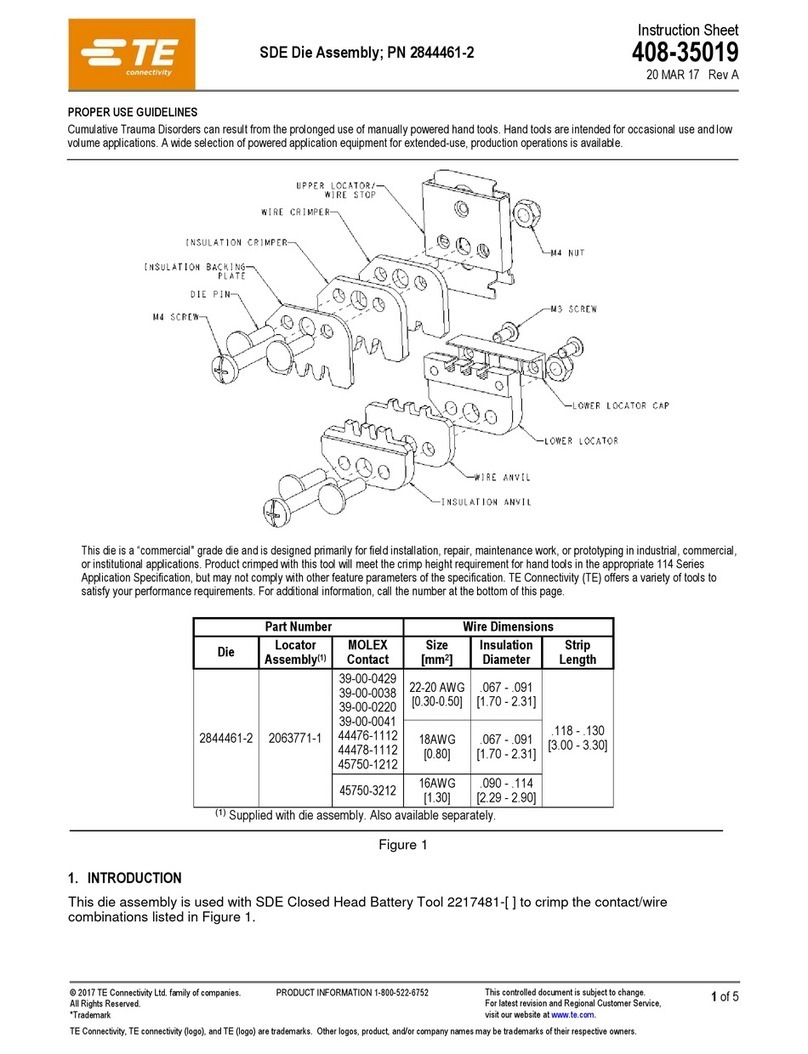

1. Refer to the chart in Figure 4 and select a

terminal and a wire (maximum size) for the hand

tool.

Position Point on

Center of Wire

Barrel Opposite

Seam

Modified

Anvil

“A”

+0.05 [+.002]

TERMINAL

NUMBER

WIRE SIZE

AWG (Max.)

CRIMP HEIGHT

DIM. “A”

60560 61403

60561 60751

60578

20 0.81 [.032]

Figure 4

2. Refer to Section 3, CRIMPING PROCEDURE,

and crimp the terminal accordingly.

3. Using a crimp height comparator, measure the

wire barrel crimp height as shown in Figure 4. If the

crimp height conforms to that shown in the chart,

the tool is considered dimensionally correct. If not,

return the tool for evaluation and repair (refer to

Section 5, REPLACEMENT AND REPAIR).

For additional information concerning the use of the

crimp height comparator, refer to Instruction Sheet

408--7424.

C. Ratchet Inspection

Obtain a 0.025 [.001] shim that is suitable for

checking the clearance between the bottoming

surfaces of the crimping jaws. Proceed as follows:

1. Select a terminal and maximum size wire for the

hand tool.

2. Position the terminal and wire between the

crimping jaws, as described in Section 3,

CRIMPING PROCEDURE.

3. Holding the wire in place, squeeze the tool

handles together until the ratchet releases. Hold

the handles in this position, maintaining just

enough tension to keep the jaws closed.

4. Check the clearance between the bottoming

surfaces of the crimping jaws. If the clearance is

0.025 [.001] or less, the ratchet is satisfactory. If

the clearance exceeds 0.025 [.001], the ratchet is

out of adjustment and must be repaired.

If the tool conforms to these inspection procedures,

lubricate it with a thin coat of any good SAE 20 motor

oil and return it to service.

5. REPLACEMENT AND REPAIR

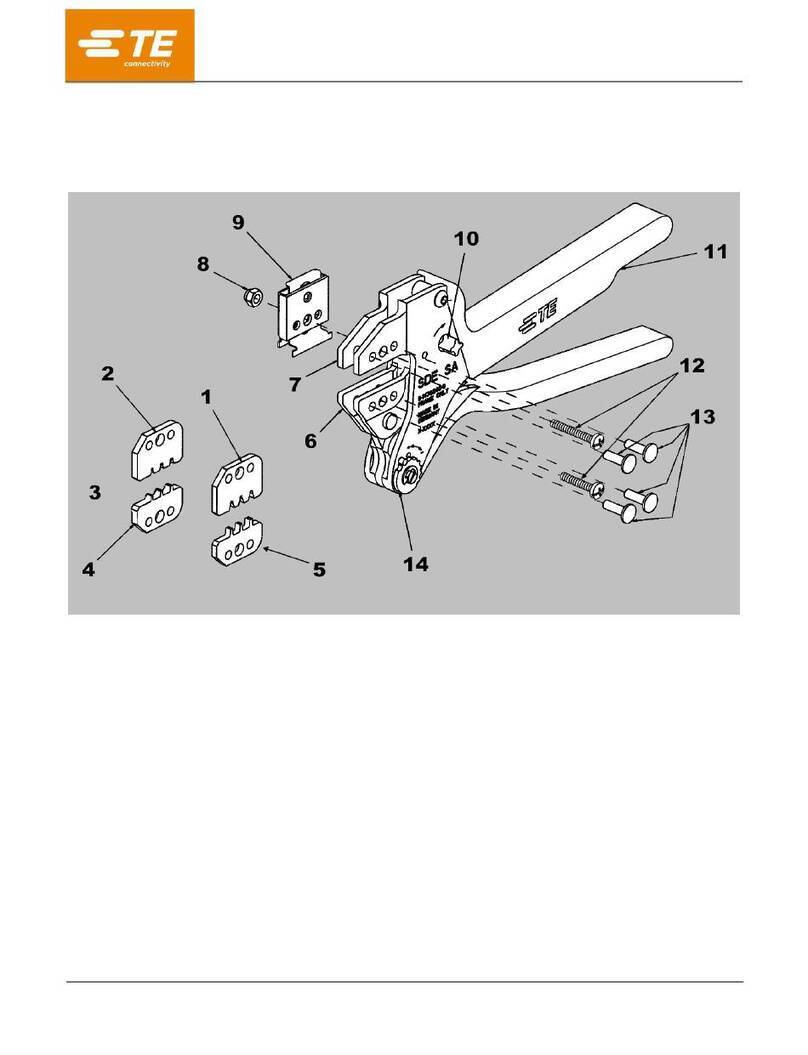

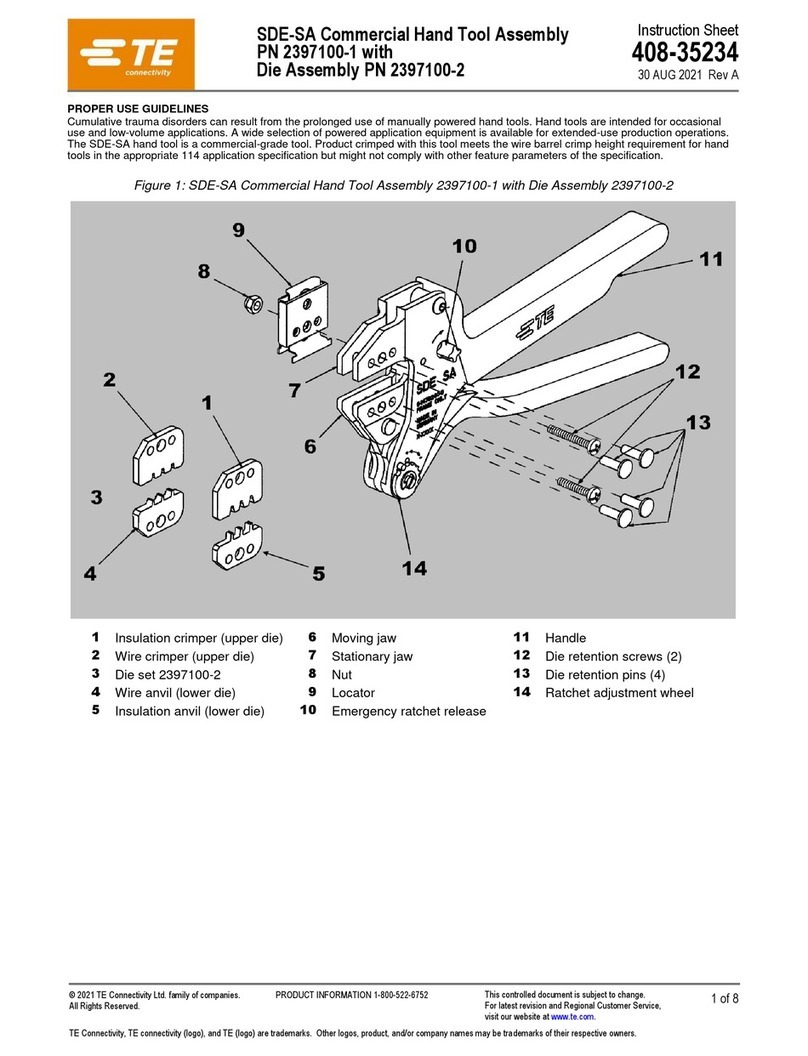

The parts listed in Figure 5 are customer--

replaceable. A complete inventory can be stocked

and controlled to prevent lost time when replacement

of parts is necessary. Order replacement parts

through your TE Connectivity representative, or call

1--800--526--5142, or send a facsimile of your

purchase order to 1--717--986--7605, or write to:

CUSTOMER SERVICE (38--35)

TYCO ELECTRONICS CORPORATION

P.O. BOX 3608

HARRISBURG, PA 17105--3608

Tools may be returned for evaluation and repair. For

tool repair service, contact a representative at

1--800--526--5136.

6. REVISION SUMMARY

Since the previous version of this document, the

following changes were made:

:Updated document to corporate requirements.