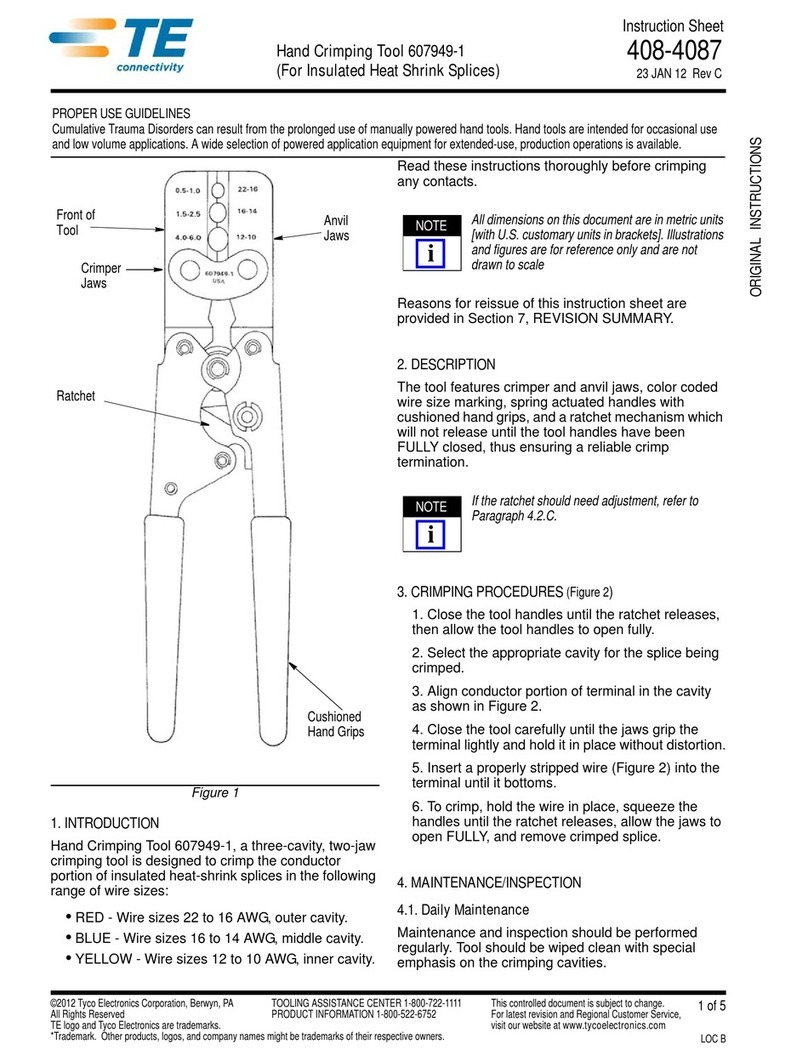

TE Connectivity 408-8569 User manual

Other TE Connectivity Crimping Tools manuals

TE Connectivity

TE Connectivity 2161651 Series Reference guide

TE Connectivity

TE Connectivity 2386892-1 User manual

TE Connectivity

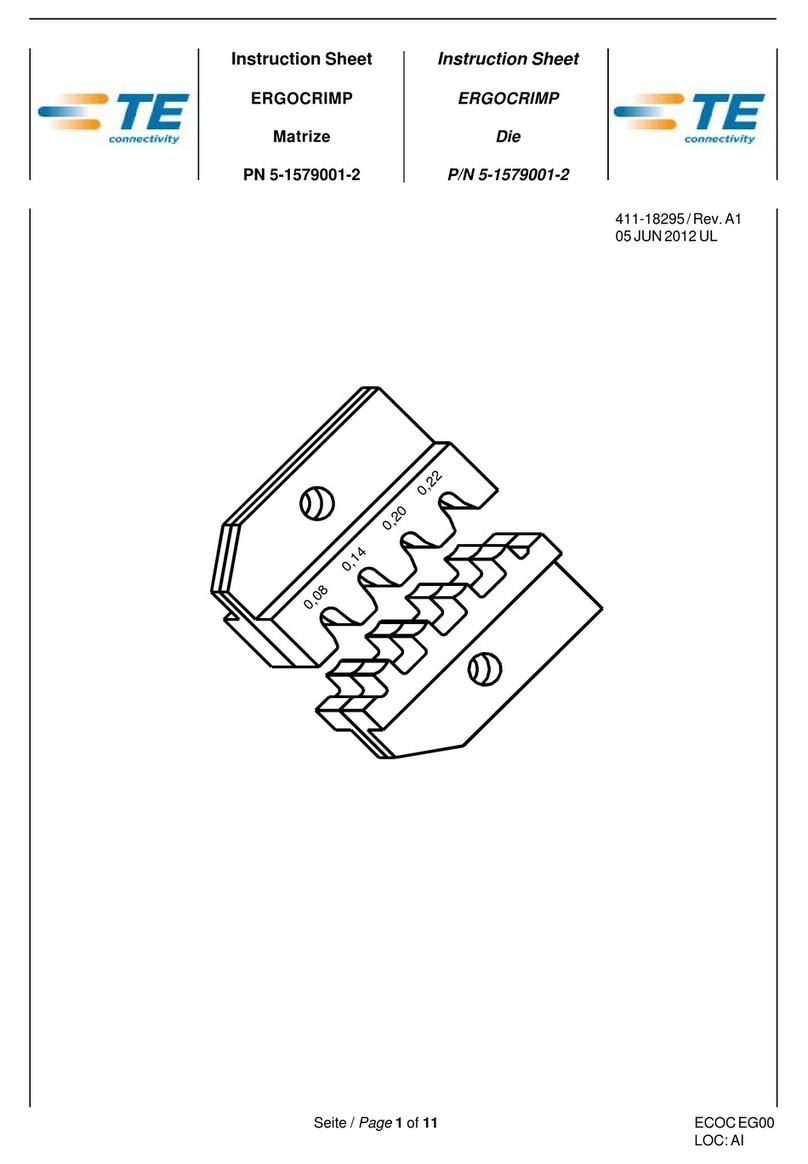

TE Connectivity ERGOCRIMP 5-1579001-2 User manual

TE Connectivity

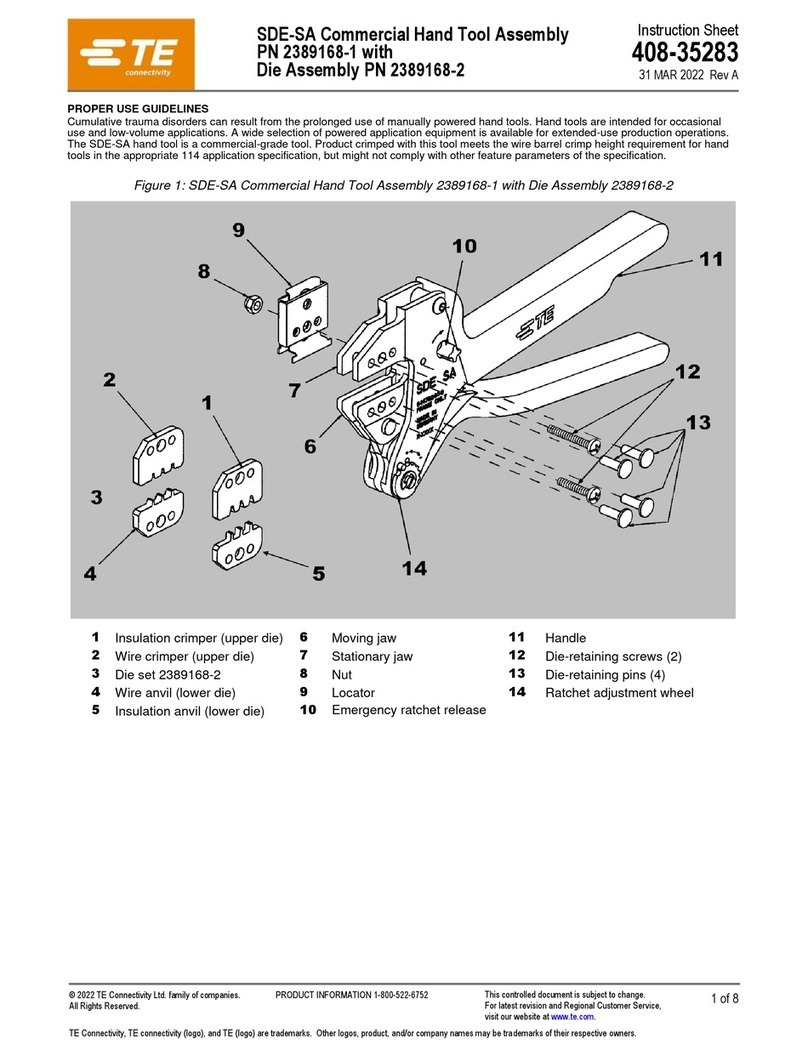

TE Connectivity SDE-SA User manual

TE Connectivity

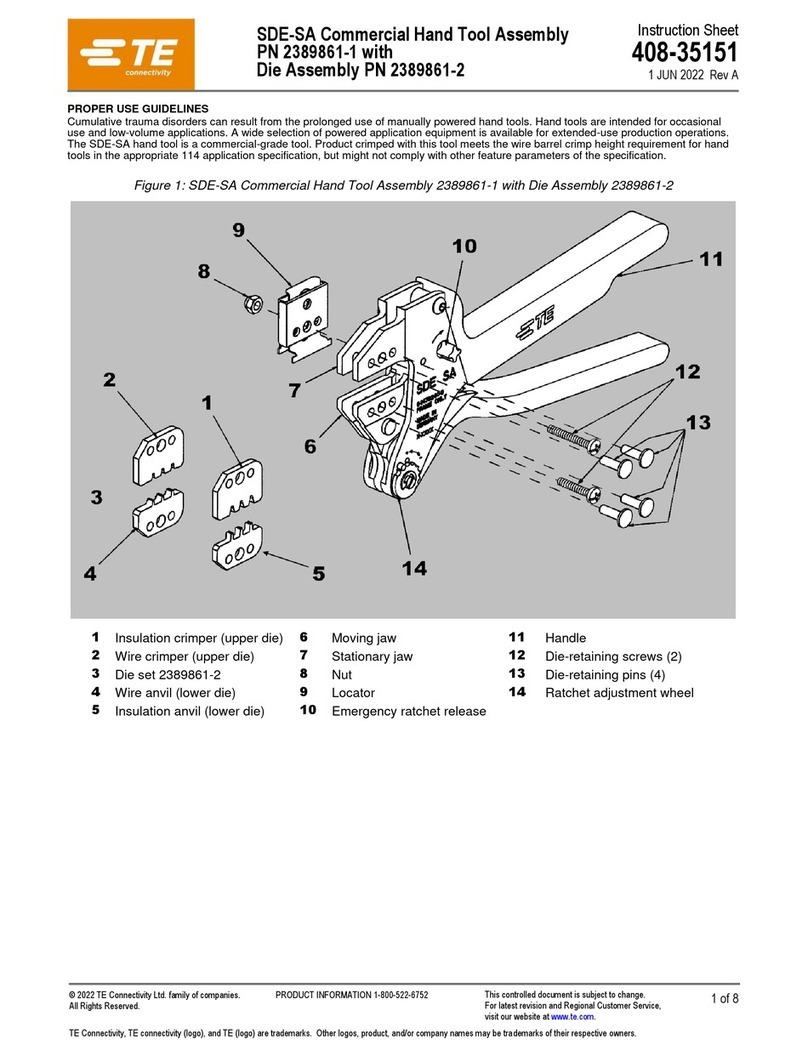

TE Connectivity SDE-SA 2389861-1 User manual

TE Connectivity

TE Connectivity FFC-MQS User manual

TE Connectivity

TE Connectivity PRO-CRIMPER III User manual

TE Connectivity

TE Connectivity 68321-1 User manual

TE Connectivity

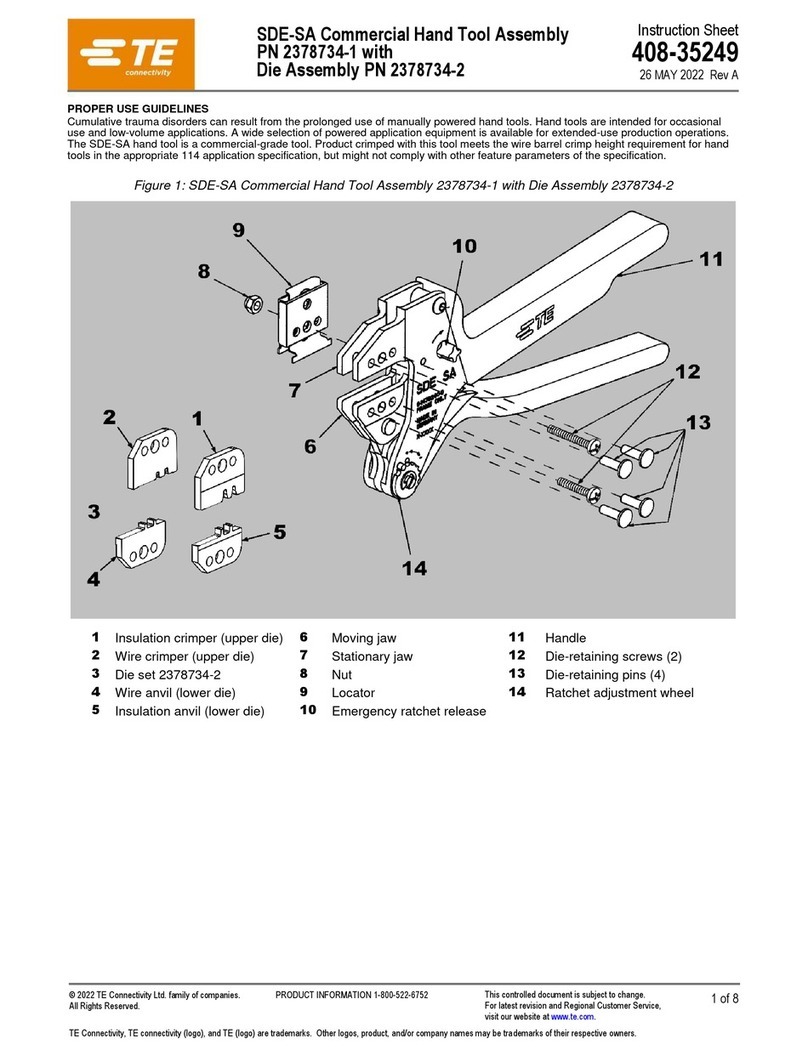

TE Connectivity SDE-SA User manual

TE Connectivity

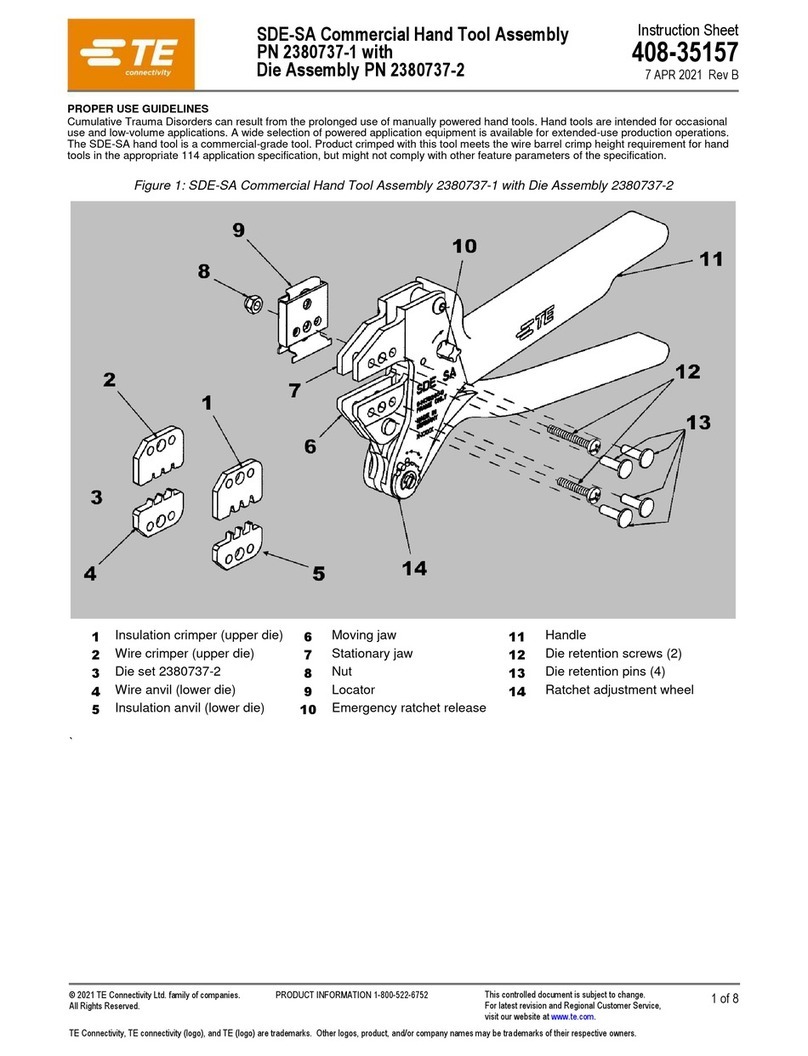

TE Connectivity SDE-SA User manual

TE Connectivity

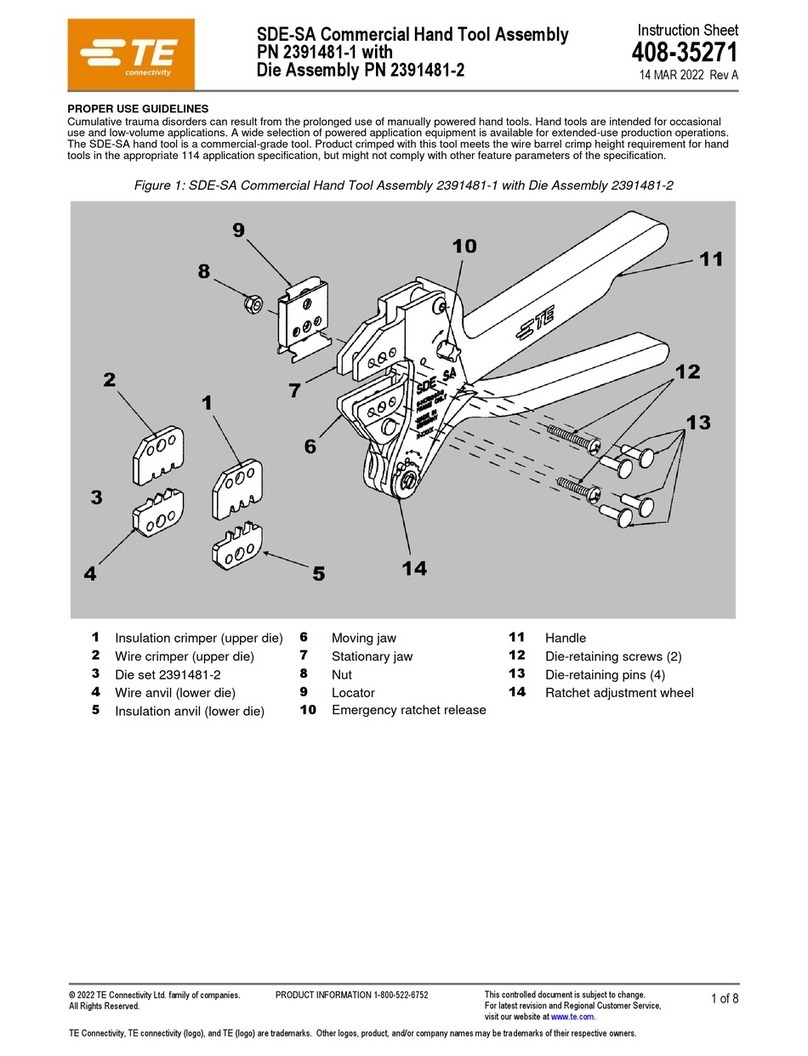

TE Connectivity SDE-SA User manual

TE Connectivity

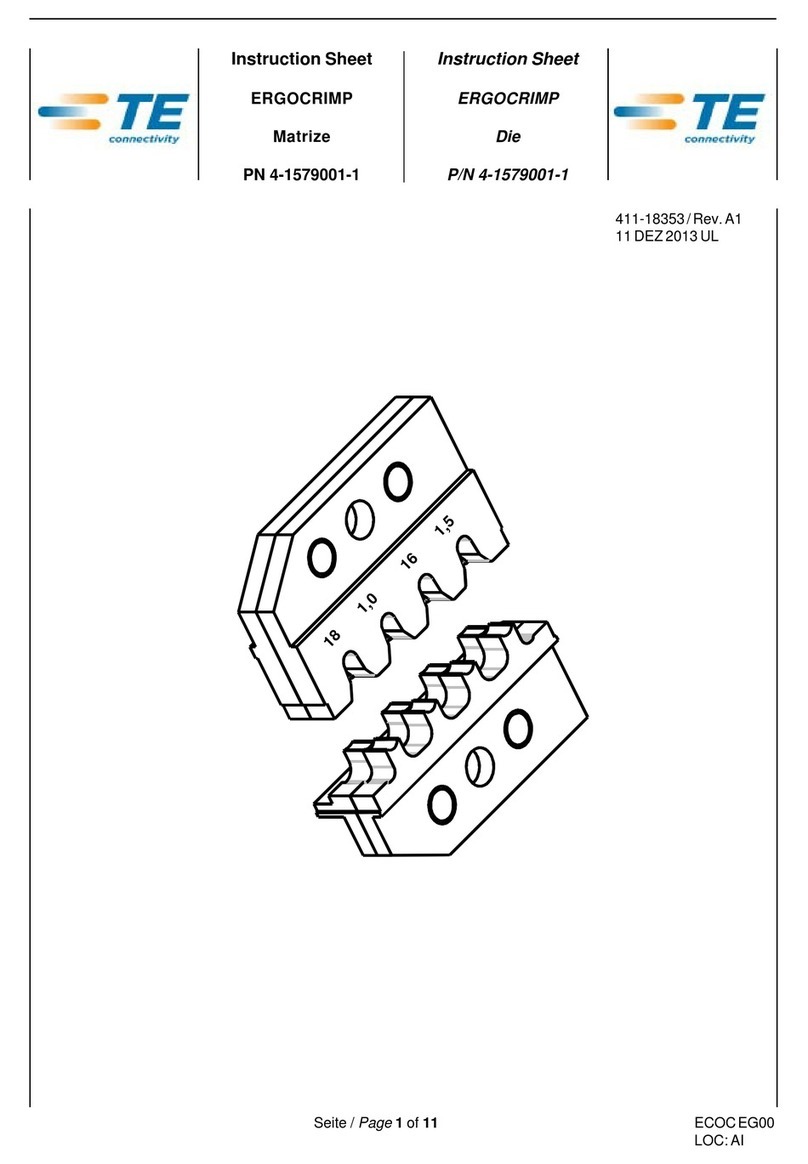

TE Connectivity ERGOCRIMP 539 685-2 User manual

TE Connectivity

TE Connectivity 2391481-2 User manual

TE Connectivity

TE Connectivity 528008-4 User manual

TE Connectivity

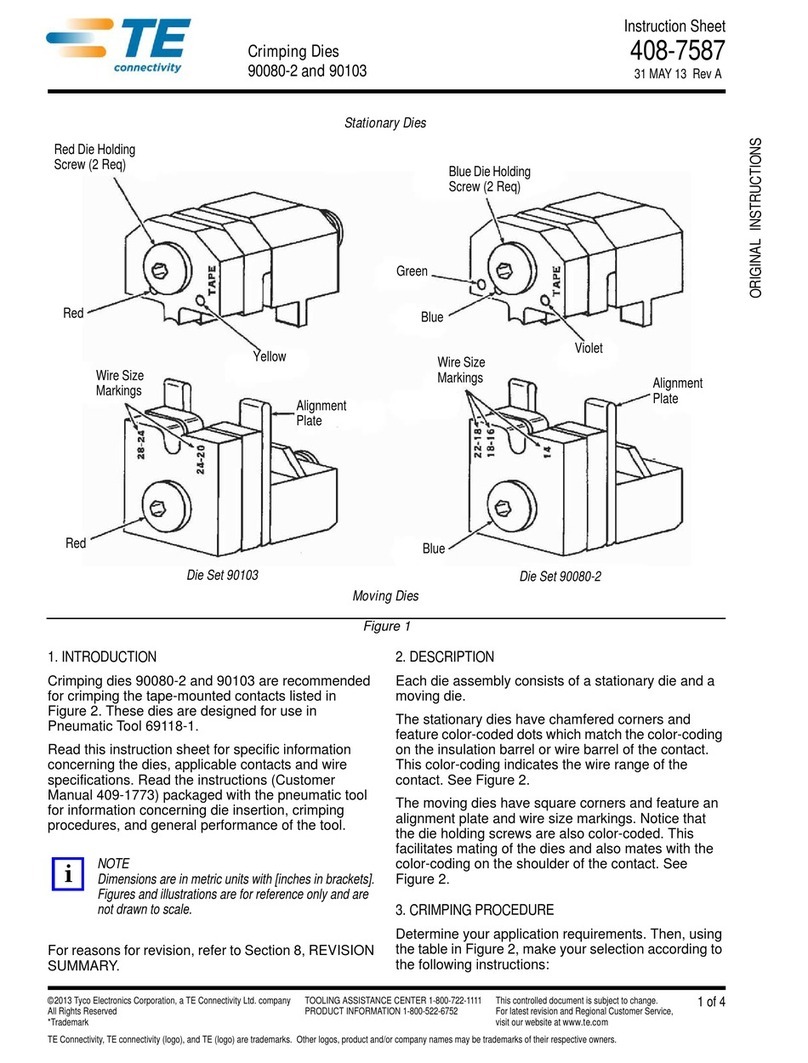

TE Connectivity 90080-2 User manual

TE Connectivity

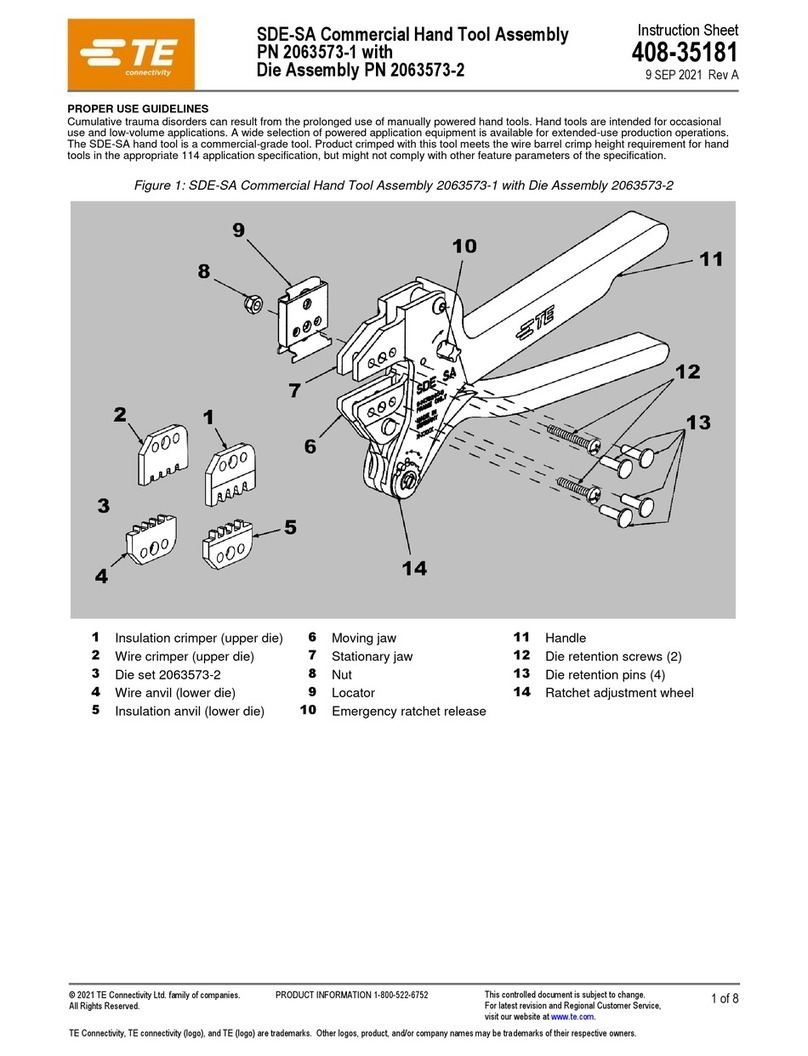

TE Connectivity 2063573-1 User manual

TE Connectivity

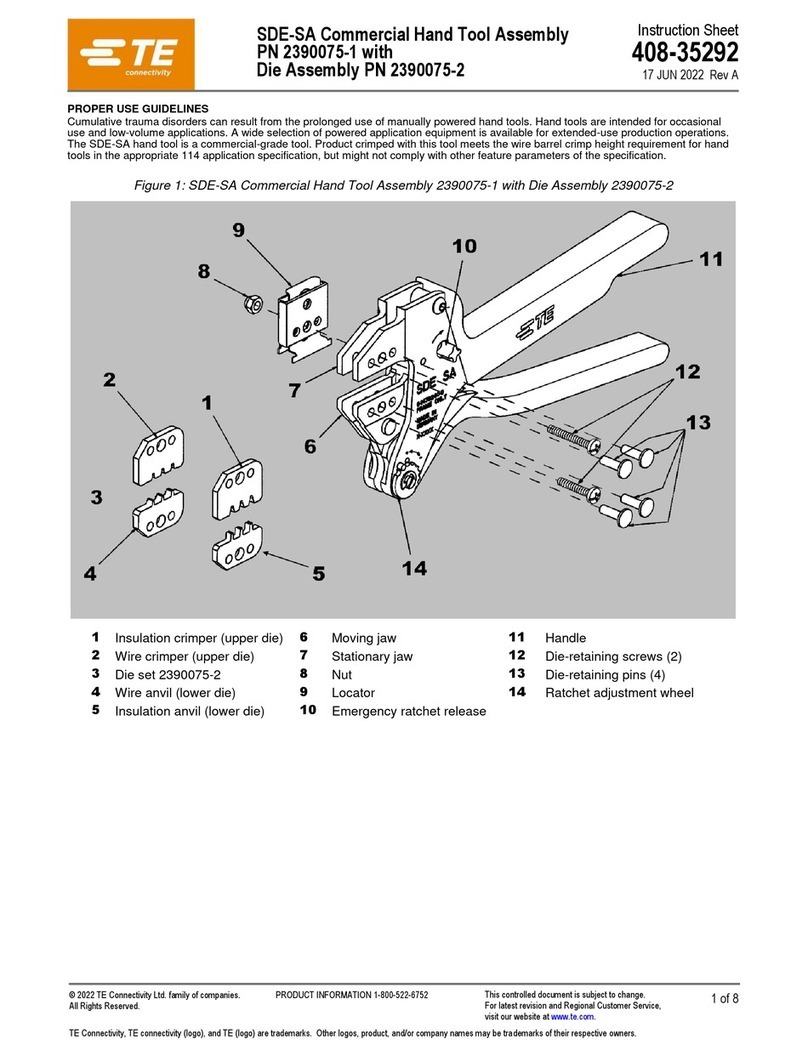

TE Connectivity 2390075-1 User manual

TE Connectivity

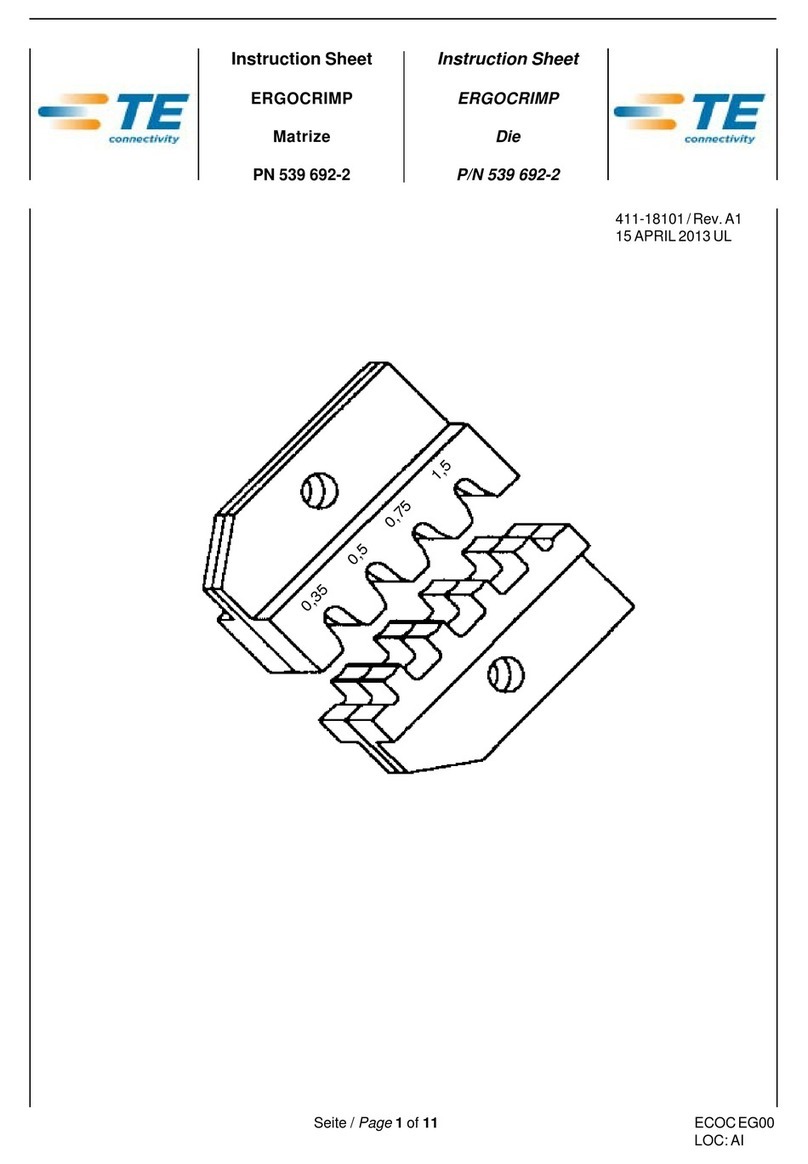

TE Connectivity ERGOCRIMP 539 692-2 User manual

TE Connectivity

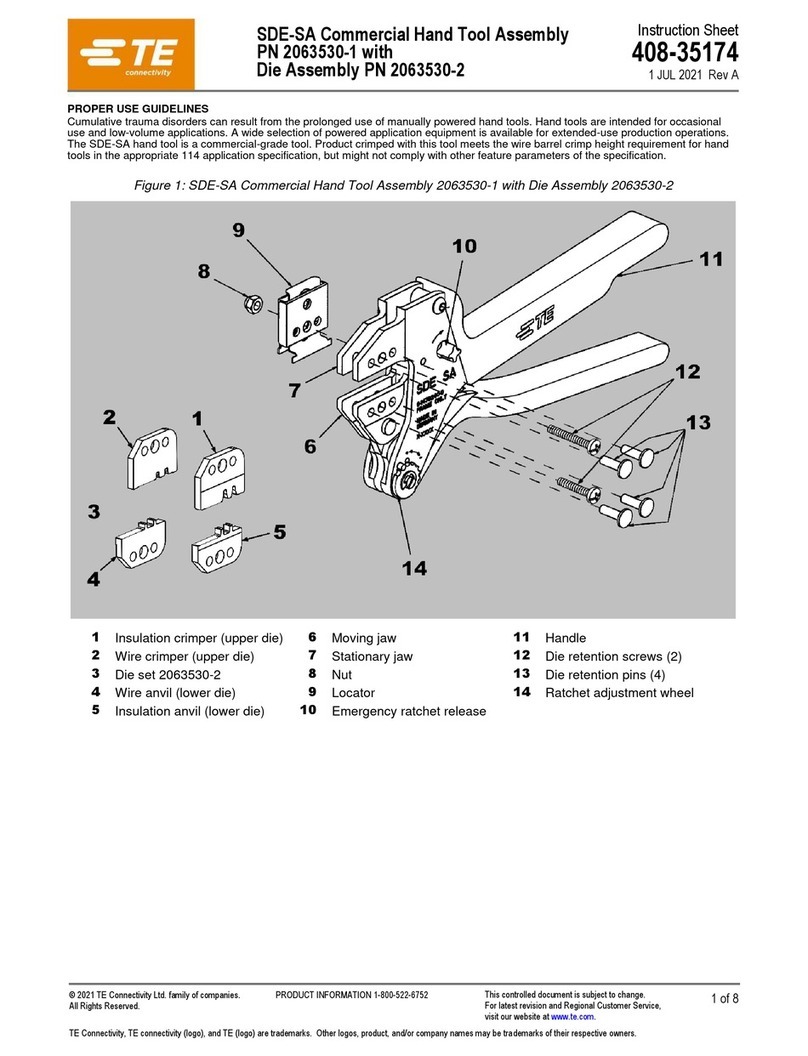

TE Connectivity 2063530-1 User manual

TE Connectivity

TE Connectivity 69376 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

molex

molex 207129 Series Specification sheet

molex

molex 207129 Series Specification sheet