408-2281

5of 8

Rev CD

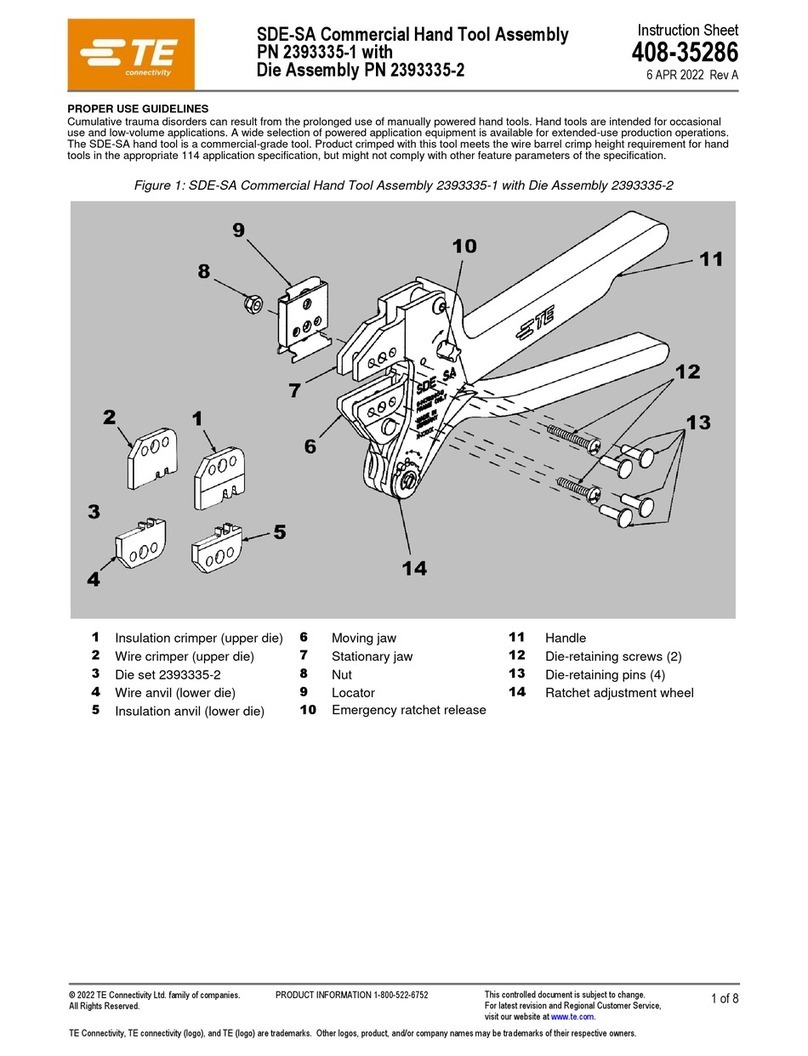

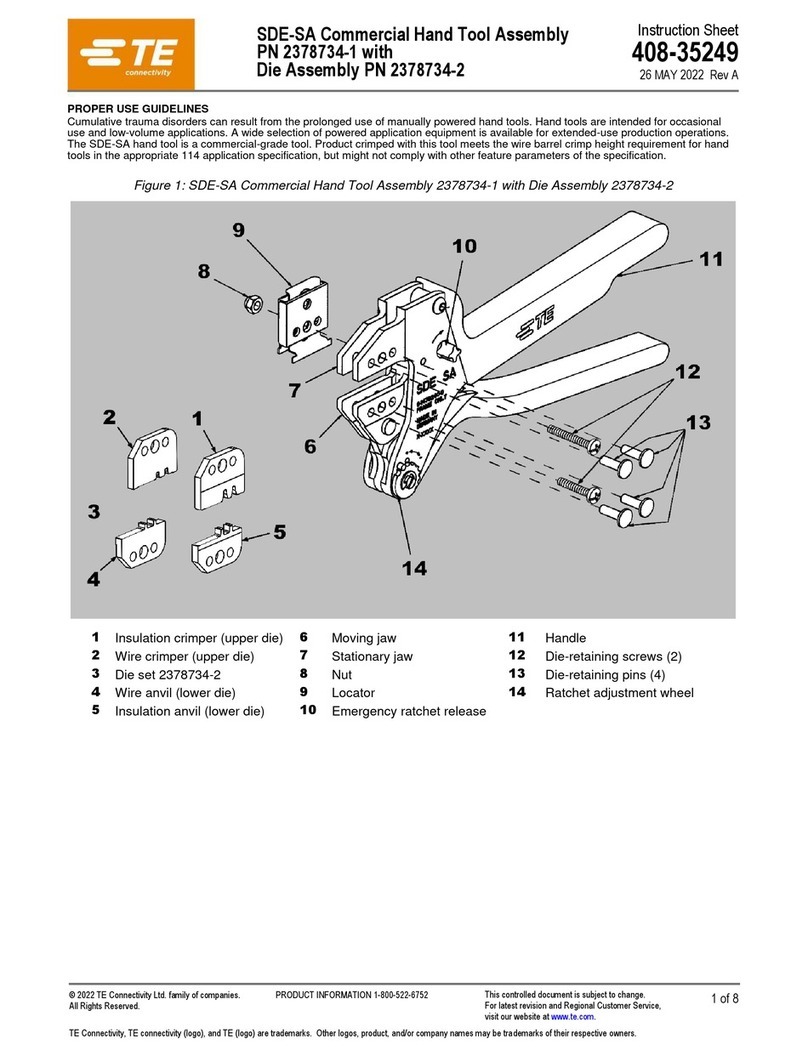

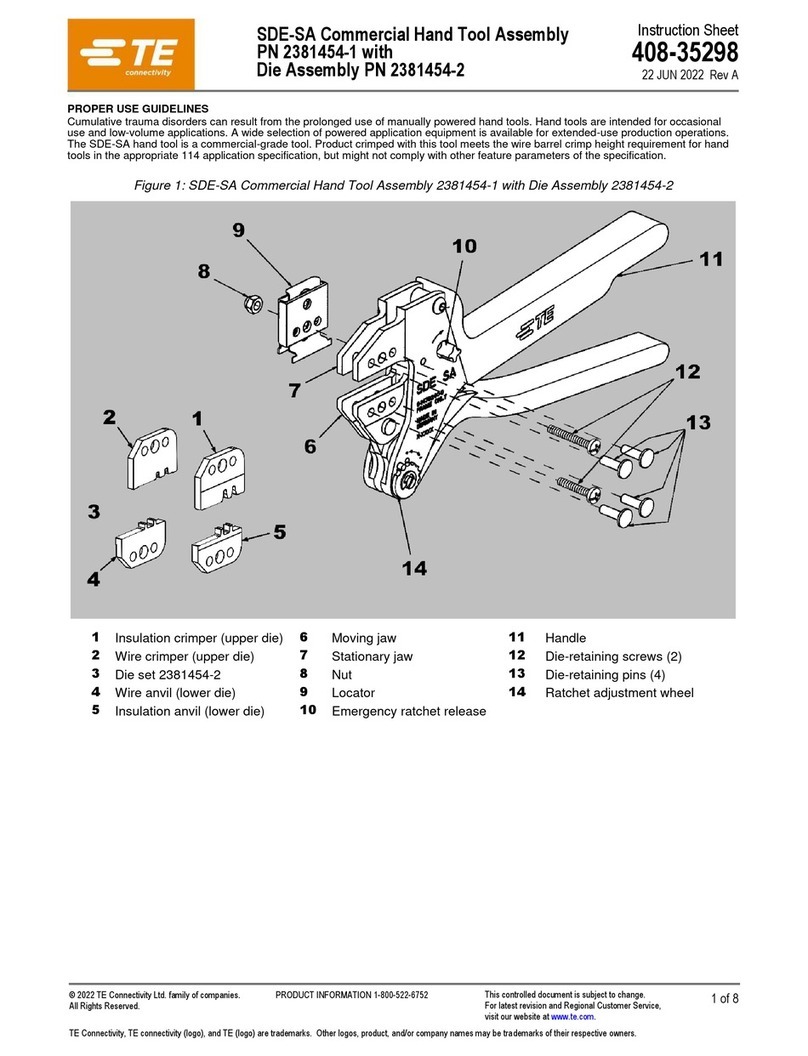

4.2. Splice

IMPORTANT: To ensure a quality crimp, gage the die

assembly at the beginning of a run, after changing a

die assembly — and then periodically during the run.

Refer to Paragraph 6.2 for gaging instructions.

The first (preferred) method is:

1. Before each crimp, apply a spray dry lubricant to

the crimping area of the dies to reduce sticking of

the splice in the dies.

2. Insert the properly stripped wire fully into the wire

barrel of the splice. When crimping a splice with a

color-coded band, insert the correct copper wires

into the color-coded banded end of the splice.

Ensure that there are no exposed strands.

DO NOT turn or twist the wire or splice during wire

insertion; otherwise, the internal screen of the

splice could turn and cut into the wires during

crimping.

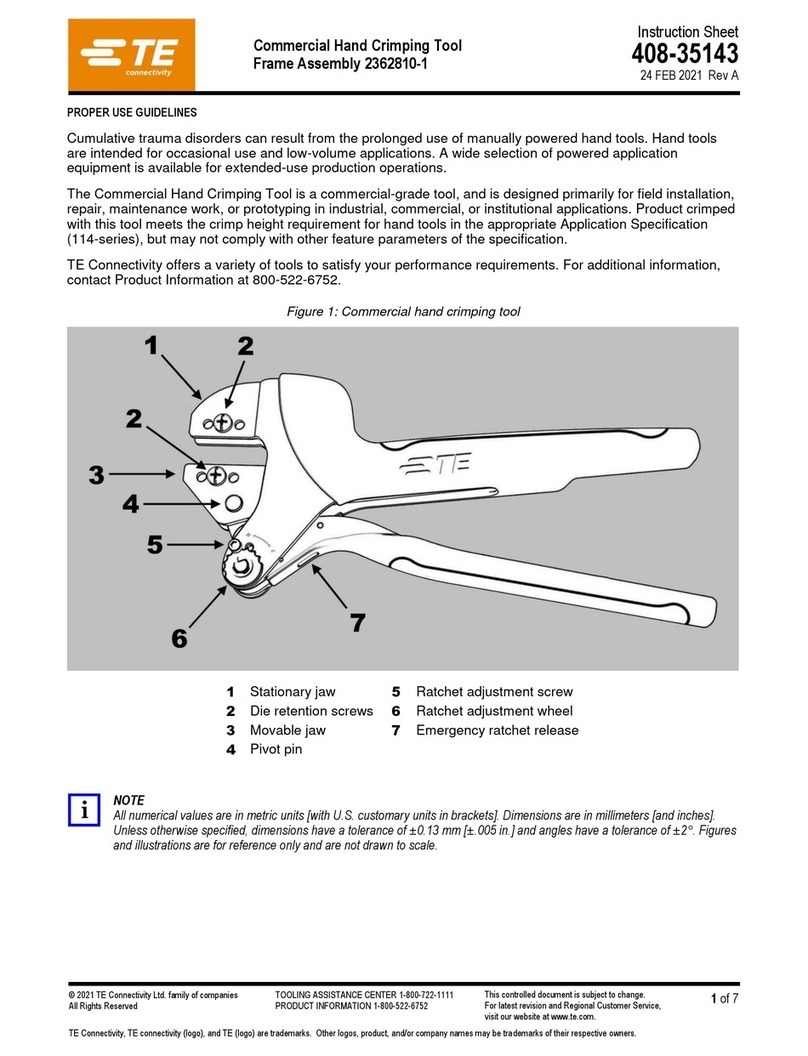

3. Position the splice in the stationary die (nest) so

that edge of the die is within the width of the

circumferential crimp alignment mark of the splice.

The asterisk alignment mark on the splice must be

inside the die, facing up, and in alignment with the

alignment dot of the die. See Figure 5.

Make sure that the splice is properly aligned in the

stationary die (nest) so that the moving die (anvil)

will crimp the wire barrel of the splice.

4. Holding the wire in place, activate the power unit

to complete the first wire barrel crimp.

5. When the first wire barrel crimp is completed,

remove the crimping head pin, open the yoke, and

remove the splice.

6. To crimp the other wire barrel of the splice, rotate

the splice or crimping head 180 degrees, and

position the splice in the die so that the asterisk

alignment mark on the spliceis inside the die, facing

up, and in alignment with alignment dot of the die.

See Figure 5. Follow the same steps used to crimp

the first wire barrel (Steps 1 through 5).

The second (alternate) method is:

This method is only slightly different than the first

(preferred)method.Thedifferenceiswhen thewire

is inserted into the wire barrel.

1. Before each crimp, apply a spray dry lubricant to

the crimping area of the dies to reduce sticking of

the splice in the dies.

2. Position the splice in the stationary die (nest) so

that edge of the die is within the width of the

circumferential crimp alignment mark of the splice.

The asterisk alignment mark on the splice must be

inside the die, facing up, and in alignment with the

alignment dot of the die. See Figure 5.

Figure 5

3. Jog the power unit to advance the ram to hold the

splice in place. Make sure not to deform the wire

barrel; otherwise, it may be difficult to insert the wire

into the wire barrel of the splice.

4. Insert the properly stripped wire fully into wire

barrel of the splice. When crimping a splice with a

color-coded band, insert the correct copper wires

into the color-coded banded end of the splice.

Ensure that there are no exposed strands.

DO NOT turn or twist the wire or splice during wire

insertion; otherwise, the internal screen of the

splice could turn and cut into the wires during

crimping.

5. Holding the wire in place, activate the power unit

to complete the other wire barrel crimp.

6. When the wire barrel crimp is completed, remove

the crimping head pin, open yoke, and remove the

splice.

7. To crimp the other wire barrel of the splice, rotate

the splice or crimping head 180 degrees, and

position the splice in the die so that the asterisk

alignment mark on the splice is inside the die, facing

up, and in alignment with alignment dot of the die.

See Figure 5. Follow the same steps used to crimp

the first wire barrel (Steps 1 through 5).

*

Wire

Pin

Die Alignment

Dot

Asterisk

Alignment

Mark of

Splice

Edge of Anvil (Moving Die)

Within Width of Circumferential

Crimp Alignment Knurl of Splice

*

Anvil

(Moving Die)

Die Alignment

Dot

CircumferentialCrimp

Alignment Knurl

of Splice