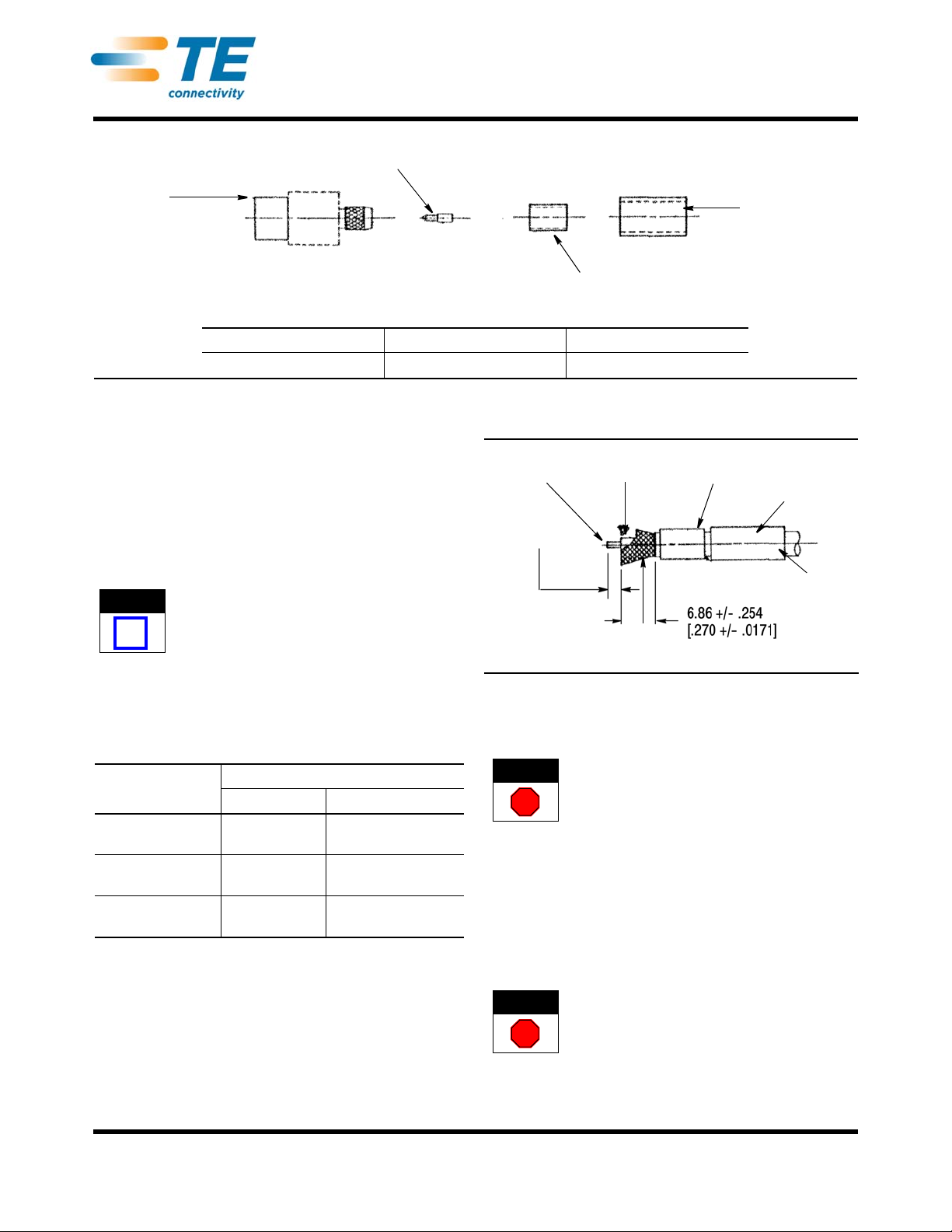

Housing

Subassembly

Center Contact

Outer Sleeve

Heat-Shrink

Tubing

TE PART NO. PREVIOUS PART NO. CABLE TYPE

1059540-1 4536-7341-02 RG55/U, 142, 223, 400

©2011 Tyco Electronics Corporation, a TE Connectivity Ltd. Company

All Rights Reserved

*Trademark

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product and/or Company names may be trademarks of their respective owners.

1of 2

Instruction Sheet

TOOLING ASSISTANCE CENTER

1-800-722-1111

PRODUCT INFORMATION

1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com LOC B

408-8267

OSP* Flange Mount Cable

Jack Connector 1059540-1 20 SEP 11 Rev B

Figure 1

1. INTRODUCTION

This instruction sheet contains the assembly

procedure for OSP Flange Mount Cable Jack

Connector 1059540-1. Refer to Figure 1. These

connectors are floating rear mount, crimp attachment

type connectors that attach to the cable listed in Figure

1. Figure 1 also contains the previous part number for

the flange mount cable jack connector.

Dimensions on this sheet are in millimeters [with

inches in brackets], unless otherwise specified.

Figures are not drawn to scale.

The table below references the tools required to apply

this connector. The table includes tool description, TE

part number, and the corresponding “previous” part

number.

TOOL

DESCRIPTION PART NO. CROSS-REFERENCE

TE NO. PREVIOUS NO.

Crimping Tool 1060713-1 5698-5014-54

(T-4718)

Crimping Die 1060714-1 5698-5015-54

(T-4702-1 Die No. B)

Contact Holder 1055454-1 2098-5221-10

(T-4578)

Reasons for revision can be found in Section 3,

REVISION SUMMARY.

2. ASSEMBLY PROCEDURES

2.1. Preparing the Coaxial Cable End (Figure 2)

1. Place the heat-shrink tubing and outer sleeve on

the cable.

Inner

Conductor Dielectric Heat-Shrink

Tubing

2.16 +/- .254

[.085 +/- .010]

Cable

Braid

Outer

Sleeve

Cable

Jacket

Figure 2

2. Using a knife, remove theend portion of the cable

jacket.

To avoid personal injury, be sure to use personal

protection, including gloves, when handling a knife,

3. Trim the cable braid to length.

4. Trim the cable dielectric to length.

5. Trim the inner conductor to length.

6. Flare the cable braid.

2.2. Soldering Center Contact to Cable Inner Conductor

(Figure 3)

The soldering equipment is hot. To avoid personal

injury, be sure to exercise caution when working

around soldering equipment.

1. Tin the inner conductor of the cable.