TE CERTI-CRIMP User manual

Instruction Sheet

1 of 10

© 2016 TE Connectivity family of companies

All Rights Reserved

*Trademark

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product, and/or company names may be trademarks of their respective owners.

PRODUCT INFORMATION

1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com.

408-1559

11 JAN 16 Rev U

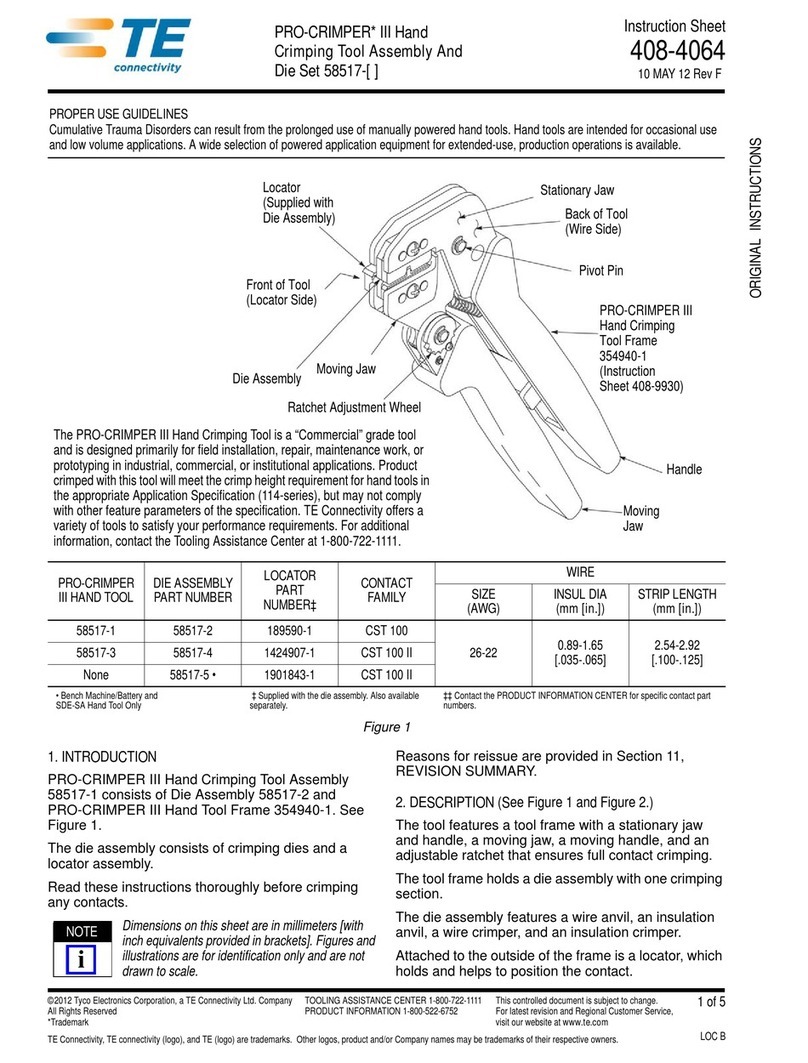

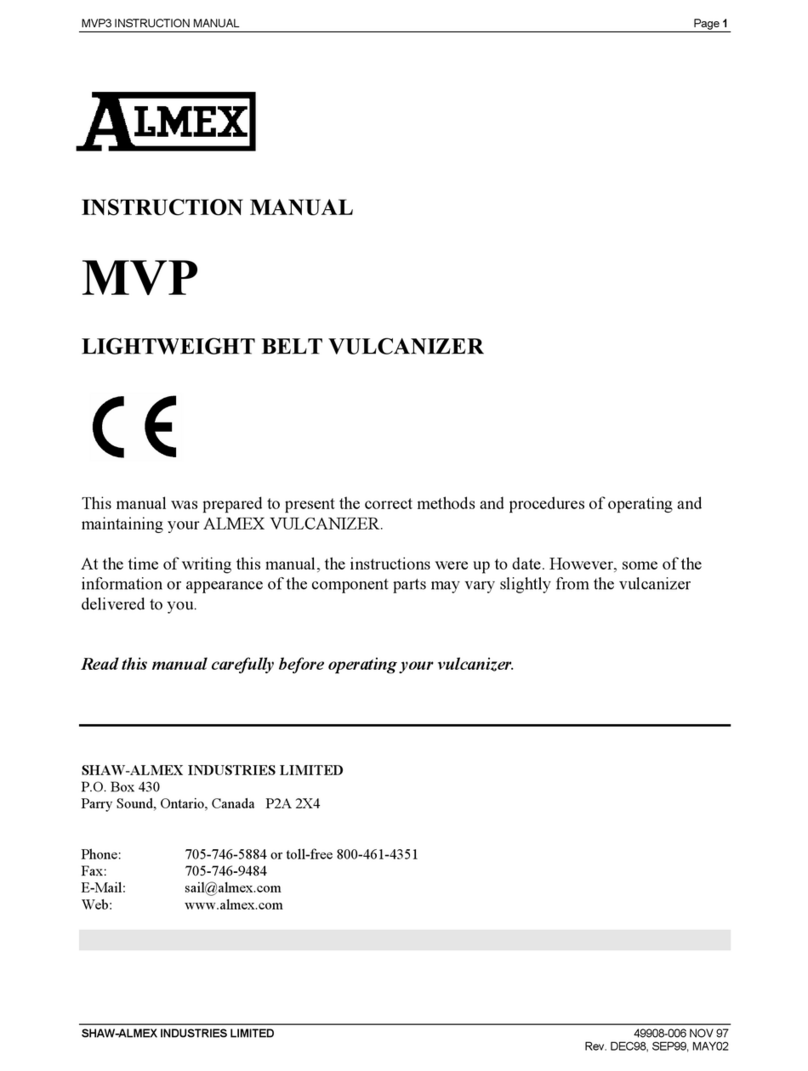

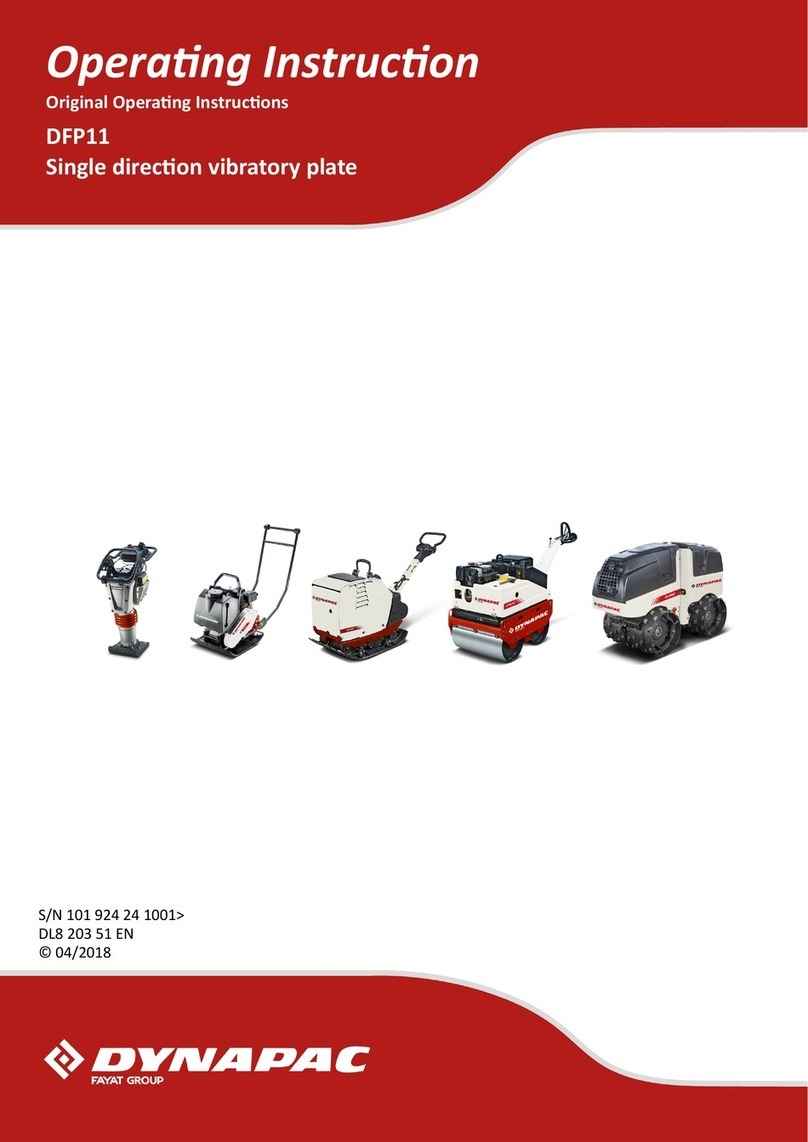

Figure 1

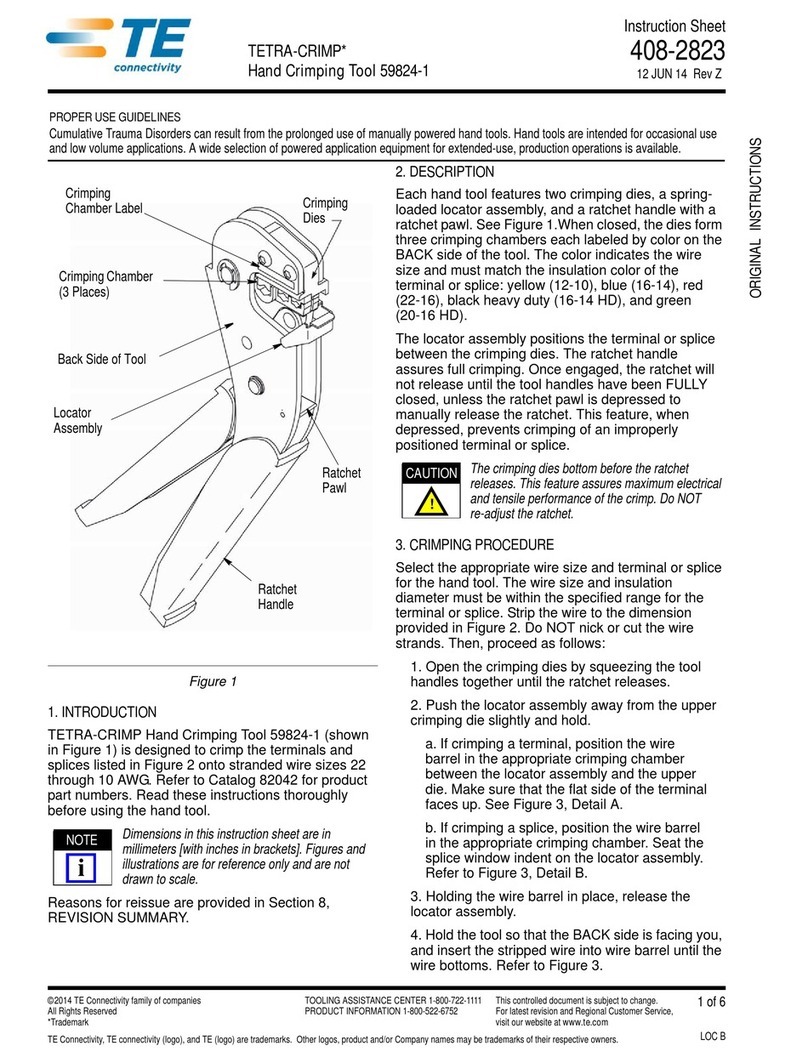

1. INTRODUCTION

CERTI-CRIMP hand crimping tools listed in Figure 1 are used to crimp the products onto the wire listed in

Figure 2.

NOTE

Dimensions in this instruction sheet are in millimeters [with inches in brackets]. Figures and illustrations are for reference only

and are not drawn to scale.

Reasons for reissue of this instruction sheet are provided in Section 7, REVISION SUMMARY.

2. DESCRIPTION (Figure 1)

The handles and label (if applicable) of each tool are color-coded to match the color coding of the product to be

crimped. The tools may show more than one color code.

PRODUCT

COPPER WIRE

TYPE

SIZE RANGE (AWG)

PIDG Terminals and Splices

Solid or Stranded

30-14

PIDG Radiation Resistant Terminals and Splices

Stranded

27-14

PLASTI-GRIP Butt Splices

Solid or Stranded

26-22

PIDG Insulation Restricting Nylon Terminals

Stranded

26-14

PIDG FASTON* Receptacles 641321-1 (.187 Series) and 641324-1 (.110 Series)

Stranded

26-24

PLASTI-GRIP Terminals

Solid or Stranded

22-14

Spare Wire Cap

Stranded

22-14

Figure 2

These tools are members of the CERTI-CRIMP hand crimping tool family. The ratchet ensures full crimping of

the product. Once engaged, the ratchet will not release until the handles have been FULLY closed.

CAUTION

The crimping jaws bottom before the ratchet releases. This design feature ensures maximum tensile performance of the crimp.

DO NOT re-adjust the ratchet.

PROPER USE GUIDELINES

Cumulative Trauma Disorders can result from the prolonged use of manually powered hand tools. Hand tools are intended for occasional use and low

volume applications. A wide selection of powered application equipment for extended-use, production operations is available.

CERTI-CRIMP*

Hand Crimping Tools

Handles

Hand Crimping Tool

Part Numbers

46121

47304

47386

47386-5

47387

47907-1

48518-2

68343-1

69151-1

69454

169485

Ratchet

Label (Color Coded for PIDG*

and PLASTI-GRIP* Products)

Wire Size Range

Stamped Here

Locator

Label (Color Coded

for Sealed Splices)

Jaws

Insulation Crimp Adjustment Pins

(Shown in Position 3)

ORIGINAL INSTRUCTIONS

408-1559

Rev U

2 of 10

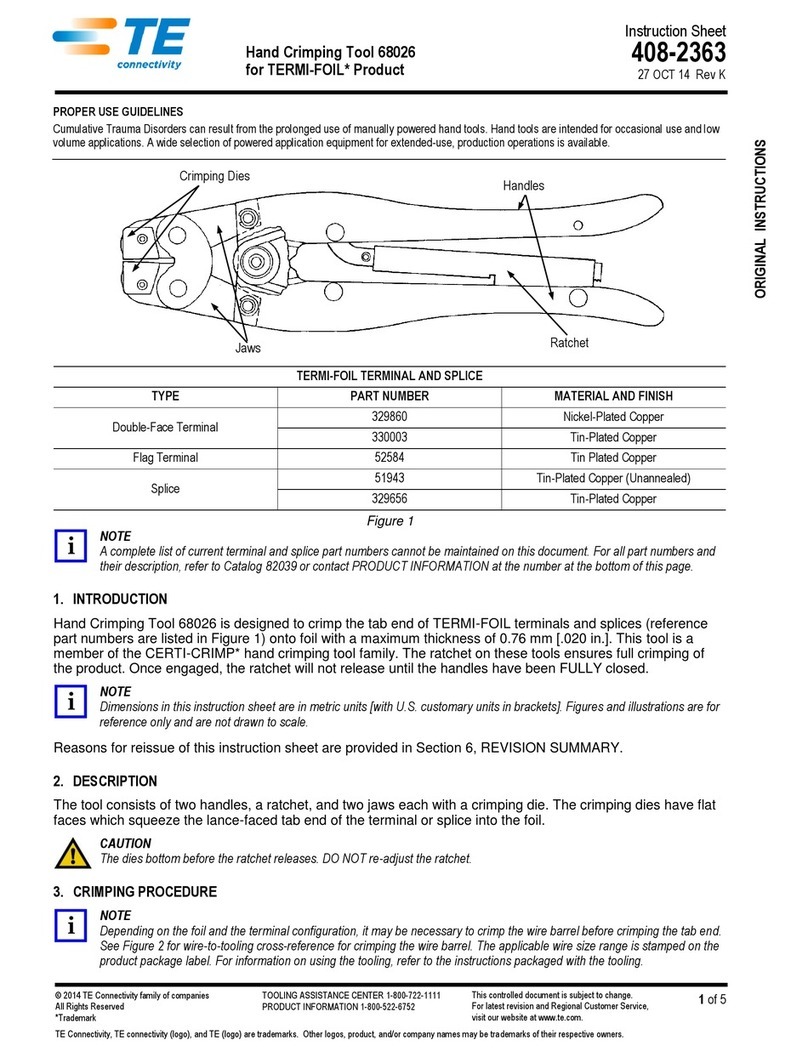

3. CRIMPING PROCEDURE

Refer to Figure 3 to ensure that the correct tool and product combination is being used. Figure 3 also lists the

number of dots (or dots and rib) that appear embossed on a crimped product when it is crimped using the

correct tooling.

3.1. PIDG and PLASTI-GRIP Terminal and Splice and PIDG FASTON Receptacle

1. Strip the wire to the dimension provided in Figure 3 being careful to avoid nicking or cutting the

conductor(s).

CAUTION

DO NOT use wire with nicked or missing conductor(s).

2. Open the tool jaws by closing the tool handles until the ratchet releases, then allow the handles to

open fully.

TOOL

PRODUCT

WIRE

PART

NO.

COLOR

CODE

DOT

CODE

DESCRIPTION

INSUL COLOR

SIZE RANGE

(AWG)

INSUL DIA

RANGE

STRIP LENGTH

TERMINAL

SPLICE

46121

169485

Red and

Yellow

1

PIDG Terminals and Splices

Yellow

26-22

---

4.0-4.8

[5/32-3/16]

4.4-5.2

[11/64-13/64]

PLASTI-GRIP Butt Splices

47304●

Yellow

---

PIDG Terminals

47907-1

Blue and

White

2

PIDG Terminals and Splices

Natural Translucent

24-20

---

4.8-6.6

[3/16-7/32]

5.6-6.4

[7/32-1/4]

PIDG Radiation Resistant

Terminals and Splices

Natural Translucent

with White Stripe

47386

47386-5

Red and

Yellow

1

PIDG Terminals

MS 25036-143 through -147

Yellow

26-24

---

5.2-6.0

[13/64-15/64]

---

PIDG Radiation Resistant

Terminals

MS 7928/4-143 through -147

Natural with Yellow

Stripe

47386

47386-5

Red and

Yellow

1

PIDG Terminals and Splices

Red

22-16

---

5.2-6.0

[13/64-15/64]

6.4-7.1

[1/4-9/32]

PLASTI-GRIP Terminals

PIDG Radiation Resistant

Terminals and Splices

Natural Translucent

with White Stripe

69151-1●

Red

---

PIDG Terminals and Splices

Red

22-16

---

5.2-6.0

[13/64-15/64]

6.4-7.1

[1/4-9/32]

PLASTI-GRIP Terminals

PIDG Radiation Resistant

Terminals and Splices

Natural Translucent

with White Stripe

69454

Red

1 Dot

1 Rib

PIDG Terminals and Splices

Red

22-18

---

5.2-6.0

[13/64-15/64]

6.4-7.1

[1/4-9/32]

PLASTI-GRIP Terminals

PIDG Radiation Resistant

Terminals and Splices

Natural Translucent

with White Stripe

47387

Blue and

Green

2

PIDG Terminals and Splices

PLASTI-GRIP Terminals

Blue

16-14

1.04-2.62

[.041-.103]

5.2-6.0

[13/64-15/64]

6.4-7.1

[1/4-9/32]

Green

20-16

HD

0.41-1.65

[.016-.065]

PIDG Radiation Resistant

Terminals and Splices

Natural Translucent

with Blue Stripe

16-14

---

20-16

HD

●Use Tight Insulation Support for Wires with Thin Wall Insulation

Figure 3 (cont’d)

408-1559

Rev U

3 of 10

TOOL

PRODUCT

WIRE

PART

NO.

COLOR

CODE

DOT

CODE

DESCRIPTION

INSUL COLOR

SIZE RANGE

(AWG)

INSUL DIA

RANGE

STRIP LENGTH

TERMINAL

SPLICE

46121

169485

47304●

Red and

Yellow

1

PIDG Insulation Restricting

Nylon Terminals

Yellow with 3

Black Stripes

26

0.66-1.40

[.026-.055]

4.8-5.6

[3/16-7/32]

---

Yellow with 3

Blue Stripes

24

0.79-1.40

[.031-.055]

47386

47386-5

Red and

Yellow

1

PIDG Insulation

Restricting Nylon

Terminals

MS 7928/1-1 through -10

Yellow with 3

Black Stripes

26

0.66-1.40

[.026-.055]

6.4-7.1

[1/4-9/32]

---

Yellow with 3

Blue Stripes

24

0.79-1.40

[.031-.055]

47386

47386-5

69151-1●

Red and

Yellow

Tool

69151-1

Mod F

Red Only

1

PIDG Insulation Restricting

Nylon Terminals

Red with 3

Green Stripes

22

0.97-1.40

[.038-.055]

6.4-7.1

[1/4-9/32]

---

Red with 3

Red Stripes

20

1.17-2.79

[.046-.110]

Red with 3

White Stripes

18

1.42-2.79

[.056-.110]

47387

Blue and

Green

2

PIDG Insulation Restricting

Nylon Terminals

Blue with 3

Blue Stripes

16

1.60-3.30

[.063-.130]

6.4-7.1

[1/4-9/32]

---

47386

47386-5

Red and

Yellow

1

Spare Wire Cap 328307

Red

22-18

---

8.0-8.7

[5/16-11/32]

47387

Blue and

Green

2

Spare Wire Cap 328308

Blue

16-14

---

48518-2

---

---

PIDG FASTON Receptacles

641321-1 (.187 Series) and

641324-1 (.110 Series)

Yellow■

26-24

---

4.8-5.6

[3/16-7/32]

68343-1

6.35

[.250]

Exp.

Blue

2

PLASTI-GRIP Terminals

Blue

16-14

3.81-6.35

[.150-.250]

5.2-6.0

[13/64-15/64]

---

●Use Tight Insulation Support for Wires with Thin Wall Insulation

■For Reference Only – (Check Product-to-Tool Match Using Part Numbers)

Figure 3 (end)

3. Place the product in the jaws as shown in Figure 4 or Figure 5.

4. Close the tool handles until the product is held firmly in place. DO NOT deform the wire barrel.

5. Insert properly stripped wire(s) into the wire barrel as shown in Figure 4 or Figure 5.

CAUTION

DO NOT allow wire insulation to enter the wire barrel.

Figure 4

408-1559

Rev U

4 of 10

6. Complete the crimp by closing the tool handles until the ratchet releases.

7. Release the tool handles, allow the handles to open fully, and remove the crimped product.

8. To crimp the other wire barrel of a splice, re-position the uncrimped wire barrel in the tool as shown in

Figure 5, and repeat Steps 2 through 7.

9. Inspect the crimped product according to Figure 7. Product not meeting these conditions should NOT

be used. If the wire insulation grip is not satisfactory, refer to Section 4 to adjust the grip using the

insulation crimp adjustment pins.

3.2. Spare Wire Cap

1. Strip the wire to the dimension provided in Figure 3, being careful to avoid nicking or cutting the

conductor(s).

CAUTION

DO NOT use wire with nicked or missing conductor(s).

Figure 5

2. Place the tool insulation crimp adjustment pins in Position 3.

3. Close the tool handles until the jaws partially close, but leave enough space for the spare wire cap to

be inserted between the jaws.

4. Raise the locator so that the end of the cap rests against the recessed surface of the locator as shown

in Figure 6.

Figure 6

408-1559

Rev U

5 of 10

5. Close the tool handles until the spare wire cap is held firmly in place. DO NOT deform the wire barrel.

6. Insert a properly stripped wire into the wire barrel until the wire bottoms.

7. Hold the wire in position, and complete the crimp by closing the tool handles until the ratchet releases.

8. Release the tool handles, allow the handles to open fully, and remove the crimped spare wire cap.

9. Inspect crimped product according to Figure 7. Product not meeting these conditions should NOT be

used.

Figure 7

408-1559

Rev U

6 of 10

4. INSULATION CRIMP ADJUSTMENT

The insulation crimp section of the hand tool has three positions: 1 (tight), 2 (medium), and 3 (loose) to adjust

the wire insulation crimp grip. To adjust the insulation grip, proceed as follows:

4.1. PIDG Terminals and Splices and PIDG FASTON Receptacles

NOTE

PIDG terminals and splices feature a wire insulation “grip”.

1. Insert the insulation crimp adjustment pins into Position 3. Refer to Figure 1.

CAUTION

Make sure that both insulation crimp adjustment pins are in the same position.

2. Place a terminal or splice into the tool jaws as shown in Figure 4 or Figure 5.

3. Insert UNSTRIPPED wire into ONLY the insulation barrel of the terminal or splice.

4. Close the tool handles to complete the crimp.

5. Remove the crimped terminal or splice and check the insulation crimp by bending the wire back and

forth once. The terminal or splice should retain its grip on the wire insulation. If the wire pulls out, set

BOTH insulation crimp adjustment pins to the next higher position (2).

6. Perform another crimp, and repeat the adjustment as necessary until the correct insulation grip is

attained. DO NOT use a tighter setting than required.

4.2. PLASTI-GRIP Terminals and Splices

NOTE

PLASTI-GRIP terminals and splices feature a wire insulation “support”. The terminal or splice insulation should ideally be in

contact with the wire insulation.

Set the insulation crimp adjustment pins into position according to the following:

—3 for wire having a large insulation diameter

—2 for wire having a medium insulation diameter

—1 for wire having a small insulation diameter

CAUTION

Make sure that both insulation crimp adjustment pins are in the same position.

5. MAINTENANCE AND INSPECTION

Hand crimping tools are inspected before shipment. The tool received should be inspected immediately upon

arrival to ensure that the tool has not been damaged during shipment, and that it performs according to the

criteria described in this sheet. If a tool is damaged upon arrival, retain the shipping container, file a claim with

the carrier, and notify TE immediately.

5.1. Daily Maintenance

1. Remove dust, moisture, and other contaminants from the tool with a clean brush or a soft, lint-free

cloth. DO NOT use objects that could damage the tool.

2. Make sure that the proper retaining pins are in place and are secured with the proper retaining rings.

3. Make certain that all pins, pivot points, and bearing surfaces are protected with a THIN coat of any

good SAE 20 motor oil. DO NOT oil excessively.

4. When the tool is not in use, keep the handles closed to prevent objects from becoming lodged in the

crimping areas and store the tool in a clean, dry area.

5.2. Periodic Inspection

Regular inspections should be performed by quality control personnel. A record of scheduled inspections

should remain with the tool or be supplied to supervisory personnel responsible for the tool. Though

408-1559

Rev U

7 of 10

recommendations call for at least one inspection per month, the inspection frequency should be based on the

amount of use, working conditions, operator training and skill, and established company standards. These

inspections should be performed in the following sequence:

Visual Inspection

1. Remove all lubrication and accumulated film by immersing the tool (handles partially closed) in a

suitable commercial degreaser that will not affect paint or plastic material.

2. Make certain that all retaining pins are in place and are secured with retaining rings. If replacements

are necessary, refer to the parts list in Figure 10.

3. Inspect crimping areas for pitted or chipped surfaces.

4. Close the tool handles until the ratchet releases, then allow handles to open freely. If they do not open

quickly and fully, the spring is defective and must be replaced. Refer to Section 6, REPLACEMENT

AND REPAIR.

Gaging Crimping Chamber

This inspection requires the use of plug gages conforming to the dimensions listed in Figure 8. To gage

the crimping chamber, proceed as follows:

1. Close the jaws by squeezing the tool handles together until the jaws have bottomed, and then HOLD

the handles in this position. DO NOT force the jaws beyond initial contact.

2. Align the GO element of the gage with the wire barrel crimp section of the crimping chamber. Refer to

Figure 9. Push the element straight into the crimping chamber without using force. The GO element

must pass completely through the crimping chamber.

3. Align the NO-GO element of the gage with the same crimp section, and try to insert the element. The

NO-GO element may start entry, but it must not pass completely through the crimping chamber. Refer

to Figure 9.

4. Repeat the gage inspection for the insulation crimp section of the crimping chamber, making sure to

use the correct plug gage.

If the crimping chamber conforms to the gage inspection, the tool is considered dimensionally correct. If

the crimping chamber does not conform to the inspection, the tool must be repaired. Refer to Section 6,

REPLACEMENT AND REPAIR.

For additional information concerning the use of the plug gage, refer to Instruction Sheet 408-7424.

Ratchet Inspection

Obtain a .025-mm [.001-in.] shim that is suitable for checking the clearance between the bottoming

surfaces of the jaws. To inspect the ratchet control, proceed as follows:

1. Refer to Figure 3, and select a product and maximum size wire.

2. Position the product in the crimping chamber according to Paragraph 3.1, Steps 1 through 5 or

Paragraph 3.2, Steps 1 through 6.

3. While holding the wire in place, squeeze the tool handles together until the ratchet releases. Holding

the tool in this position, maintain just enough pressure to keep the jaws closed.

4. Check the clearance between the bottoming surfaces of the jaws. If the clearance is .025 mm

[.001 in.] or less, the ratchet is satisfactory. If clearance exceeds .025 mm [.001 in.], the ratchet is out

of adjustment and must be repaired. Refer to Section 6, REPLACEMENT AND REPAIR. If the tool

conforms to this inspection procedure, lubricate it with a THIN coat of any good SAE 20 motor oil, and

return it to service.

6. REPLACEMENT AND REPAIR

Customer-replaceable parts are listed in Figure 10. Parts other than those listed should be replaced by TE to

ensure quality and reliability. For customer repair service or to order replacement parts, call 1-800-522-6752, or

fax your purchase order to 717-986-7605, or write to: Customer Service (038-035), Tyco Electronics

Corporation, PO Box 3608, Harrisburg, PA 17105-3608.

408-1559

Rev U

8 of 10

7. REVISION SUMMARY

Updated document to corporate requirements

Added dimensional callout in Figure 8

Added new NOTE to Figure 9

TOOL

JAW CLOSURE♦ DIAMETER A

GAGE ELEMENT♦♦ DIAMETER B

DIMENSION

GO

NO-GO

GO

NO-GO

C (WIDTH)

R (RADIUS)

46121

169485

1.600 [.0630]

1.753 [.0690]

1.600-1.608

[.0630-.0633]

1.750-1.753

[.0689-.0690]

---

---

47304

1.600 [.0630]

1.753 [.0690]

1.600-1.608

[.0630-.0633]

1.750-1.753

[.0689-.0690]

47386

47386-5

2.768 [.1090]

2.921 [.1150]

2.768-2.776

[.1090-.1093]

2.918-2.921

[.1149-.1150]

47387

68343-1

3.022 [.1190]

3.175 [.1250]

3.022-3.030

[.1190-.1193]

3.172-3.175

[.1249-.1250]

47907-1

2.260 [.0890]

2.413 [.0950]

2.260-2.268

[.0890-.0893]

2.410-2.413

[.0949-.0950]

48518-2

1.600 [.0630]

1.753 [.0690]

1.600-1.608

[.0630-.0633]

1.750-1.753

[.0689-.0690]

69151-1

2.768 [.1090]

2.921 [.1150]

2.768-2.776

[.1090-.1093]

2.918-2.921

[.1149-.1150]

69454

2.616 [.1030]

2.718 [.1070]

2.616-2.624

[.1030-.1033]

2.715-2.718

[.1069-.1070]

3.962 [.156]

3.454 [.136]

♦Jaw closure dimensions apply when wire barrel jaws are bottomed, but not under pressure. ♦♦Material: Tool Steel

Figure 8 (cont’d)

408-1559

Rev U

9 of 10

TOOL

JAW CLOSURE♦ DIMENSION F

GAGE ELEMENT♦♦ DIMENSION G

DIMENSION W

(WIDTH)

GO

NO-GO

GO

NO-GO

46121

169485

0.762 [.0300]

1.27 [.0500]

0.762-0.77

[.0300-.0303]

1.267-1.27

[.0499-.0500]

3.05 [.120]

47304

0.762 [.0300]

1.27 [.0500]

0.762-0.77

[.0300-.0303]

1.267-1.27

[.0499-.0500]

3.05 [.120]

47386

47386-5

0.762 [.0300]

1.27 [.0500]

0.762-0.77

[.0300-.0303]

1.267-1.27

[.0499-.0500]

3.05 [.120]

47387

1.016 [.0400]

1.524 [.0600]

1.016-1.024

[.0400-.0403]

1.521-1.524

[.0599-.0600]

4.75 [.187]

47907-1

0.762 [.0300]

1.27 [.0500]

0.762-0.77

[.0300-.0303]

1.267-1.27

[.0499-.0500]

2.36 [.093]

48518-2

0.762 [.0300]

1.27 [.0500]

0.762-0.77

[.0300-.0303]

1.267-1.27

[.0499-.0500]

3.05 [.120]

69151-1

0.762 [.0300]

1.27 [.0500]

0.762-0.77

[.0300-.0303]

1.267-1.27

[.0499-.0500]

3.05 [.120]

69454

0.762 [.0300]

1.27 [.0500]

0.762-0.77

[.0300-.0303]

1.267-1.27

[.0499-.0500]

3.05 [.120]

68343-1

1.828 [.0720]

2.337 [.0920]

1.828-1.836

[.0720-.0723]

2.334-2.337

[.0919-.0920]

4.75 [.187]

♦Jaw closure dimensions apply when wire barrel jaws are bottomed, but not under pressure. ♦♦Material: Tool Steel

Figure 8 (end)

Figure 9

W ±0.13 [±.005]

NOTE: Most insulation barrel gages are designed

to check one side of the crimp nest at a time.

408-1559

Rev U

10 of 10

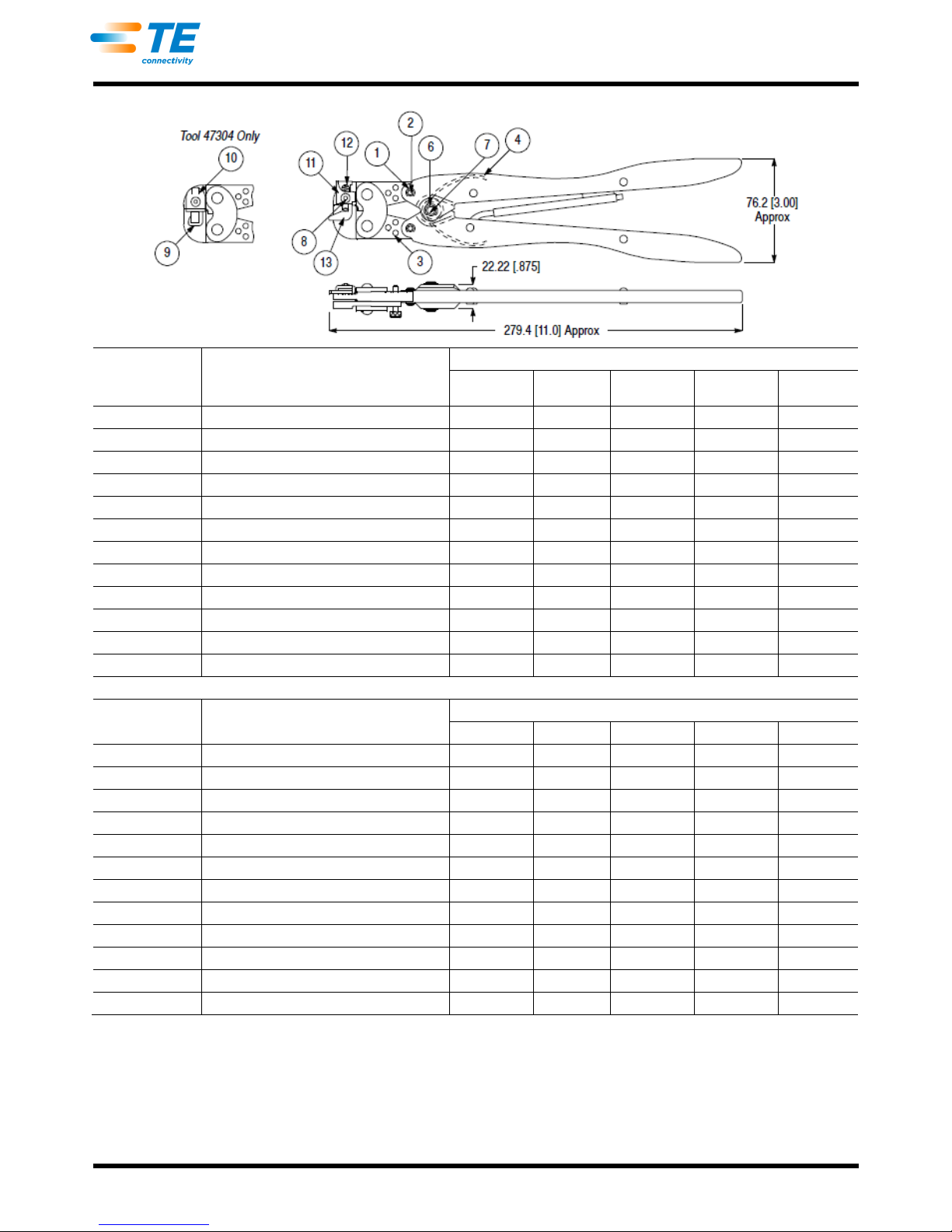

ITEM

DESCRIPTION

PART NUMBER FOR TOOL

46121

47304

47386

47386-5

47387 &

68343-1

1

RING, Retaining

21045-3

21045-3

21045-3

21045-3

21045-3

2

PIN, Retaining

1-23619-6

1-23619-6

1-23619-6

1-23619-6

1-23619-6

3

PIN, Adjustment

39207

39207

39207

39207

39207

4

SPRING

39364

39364

39364

39364

39364

6

RING, Retaining

21045-6

21045-6

21045-6

21045-6

21045-6

7

PIN, Retaining

2-23620-9

2-23620-9

2-23620-9

2-23620-9

2-23620-9

8

SCREW

3-306105-9

3-21016-4

9-305927-1

9-305927-1

9-305927-1

9

SUPPORT

---

39193

---

---

---

10

STOP

---

302765

---

---

---

11

LOCATOR, Housing

302994

---

302994

302994

302994

12

SPRING

301201

---

301201

301201

301201

13

LOCATOR

3-304052-6

---

302993

302993

45965-6

ITEM

DESCRIPTION

PART NUMBER FOR TOOL

47907-1

169485

48518-2

69151-1

69454

1

RING, Retaining

21045-3

21045-3

21045-3

21045-3

21045-3

2

PIN, Retaining

1-23619-6

1-23619-6

1-23619-6

1-23619-6

1-23619-6

3

PIN, Adjustment

39207

39207

39207

39207

39207

4

SPRING

39364

39364

39364

39364

39364

6

RING, Retaining

21045-6

21045-6

21045-6

21045-6

21045-6

7

PIN, Retaining

2-23620-9

2-23620-9

2-23620-9

2-23620-9

2-23620-9

8

SCREW

3-306105-9

3-21016-4

9-305927-1

9-305927-1

9-305927-1

9

SUPPORT

---

---

---

---

---

10

STOP

---

---

---

---

---

11

LOCATOR, Housing

302994

302994

302994

302994

302994-1

12

SPRING

301201

301201

301201

301201

2-304668-6

13

LOCATOR

303542

575960-4

125644-7

302993

4-304052-6

Figure 10

Table of contents

Other TE Power Tools manuals