TABLE

OF

CONTENTS

21

3

1.

Test

Equipment

Required

4

2.

Specifications

&

Service

Data

6

3.

Parts

ocation

24

6-3-5.

32

33

Block

Diagram

16

7.

5-8.

evel

Diagram

34

8.

Trouble-Shooting

35

9.

2

5-9.

5-10.

5-11.

5-12.

5-13.

5-14.

19

20

16

16

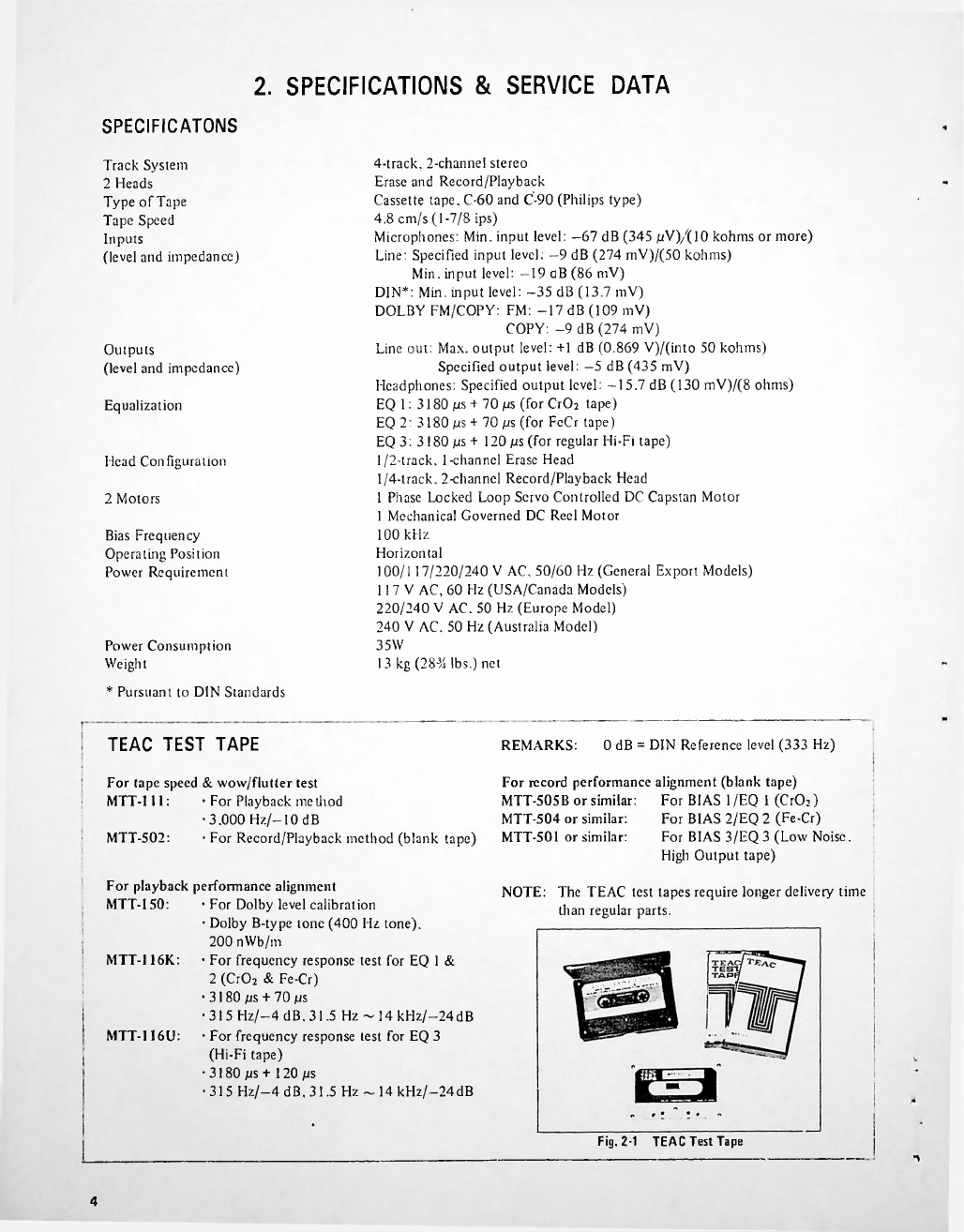

TEAC

Test

Tape

ubrication

............................................

Torque

Measurement

using

the

Cassette

Torque

Meter

Visual

Index

(for

5-6,

7,

8,

11

Sections)

Voltage

and

Frequency

Setting

Playback

Performance

Record/Playback

Head

Azimuth

Adjustments

................................

Specified

Output

evel

Setting

.

.

Frequency

Response

-Playback-

.

.

Signal

to

Noise

Ratio

-Playback-

.

5

11

13

15

17

7

7

7

7

8

8

8

9

9

10

10

11

11

4-1.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

4-8.

4-9.

4-10.

4-11.

4-12.

6-2.

6-2-1.

25

25

25

26

27

27

28

28

29

29

30

31

6-2-2.

6-2-3.

6-2-4.

6-2-5.

6-2-6.

6-3.

6-3-1.

6-3-2.

6-3-3.

6-3-4.

5-1.

5-2.

5-3.

54.

5-5.

5-5-1.

5-5-2.

5-6.

5-7.

12

12

12

13

13

14

14

14

15

6-4.

6-4-1.

6-4-2.

6-4-3.

6-4-4.

6-4-5.

6-4-6.

6-4-7.

6-4-8.

6-4-9.

.

.

21

.

.

22

22

.

.

23

VU

Meter

Calibration

-Playback-

....

23

Headphone

Output

evel

Checks

....

23

Monitor

Performance

24

Minimum

Input

evel

Checks

24

Specified

INE

Control

Setting

24

VU

Meter

Calibration

-Record-

24

ED

Peak

evel

Indicator

Calibration

DO BY

NR

COPY-OUT-FM

Switch

Function

Check

Recording

Performance

Bias

Trap

Adjustments

Record

Bias

Setting

Record

evel

Setting

Distortion

Checks

Frequency

Response

-Overall-

.

Signal

to

Noise

Ratio

■

Overall-

Dolby

NR

Effect

Measurement

Peak

imiter

Efficiency

Checks

Erase

Efficiency

6-4-10.

Channel

Separation

6-4-11.

Adjacent

Track

Crosstalk

Measurement

4.

Partial

Disassembly

of

Main

Parts

Case/Front.Panel

Tape

Transport

Chassis

Removal

.

.

.

Partial

Rotation

of

Front

Chassis

.

.

.

Head

Pinch

Roller

Cassette

Holder

Capstan

Motor

Capstan

Drive

Ass

’

y/Drive

Belt

.

.

.

.

Reel

Motor

.......................................

Brake

Plate

Ass'y

Reel

Tables

........................................

Idler

Ass

’

y

5.

Mechanical

Checks

and

Adjustments

Take-up

Torque

.................

Fast

Forward

&

Rewind

Torque

.

.

.

Pinch

Roller

Pressure

Brake

Tension

Tape

Speed/Wow

and

Flutter

Tape

Speed

Wow

and

Flutter

Flywheel

Bearing

Adjustment

CASSETTE

IN

Switch

Position

Adjustment

RECORD

SAFETY

Switch

Position

Adjustment

Cassette

Holder

Motion

Checks

....

Oil

Retaining

Washer

Clearance

Check

16

Eject

ock

ever

Adjustment

17

Pushbutton

Control

Checks

18

Auto-End

Stop

Facility

Check

19

Memory

Device

Function

Checks

....

19

6.

Electrical

Checks

and

Adjustments

6-1.

Adjustment

ocation