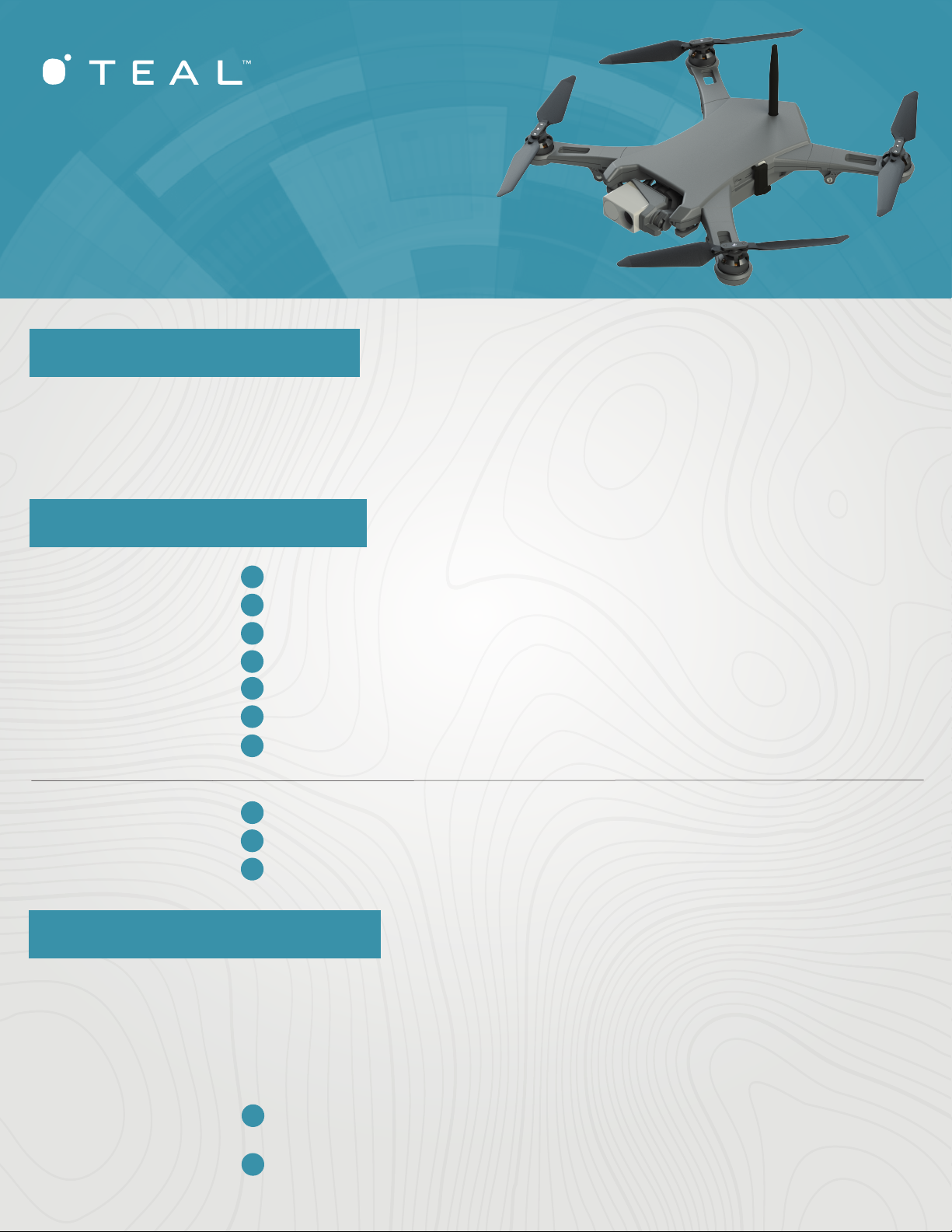

Teal GOLDEN EAGLE User manual

01

1

2

3

4

5

6

7

1

2

3

1

2

GOLDEN EAGLE SYSTEM

FIELD MAINTENANCE

& SCHEDULE

Field-replaceable items are parts that can easily be replaced in the field without requiring special expertise or

tools other than those provided in the Field Spares Kit. Repairs, upgrades, or software updates that cannot be

performed in the field are beyond the scope of this manual, and doing so may void conditions and terms of the

warranty.

FIELD REPLACEABLE ITEMS

MAINTENANCE SCHEDULE

AFTER 10 FLIGHT

HOURS (OR AS

NEEDED)

Clear and format SD Card media

Clean all sensors and the vehicle with a damp cloth and a can of air

Fully discharge all batteries and charge back to full capacity

Verify that the gimbal and camera connectors and securely seated

Update the Golden Eagle and the TAC software

Delete and re-download oine maps to ensure the latest versions

Clear flight logs from the Golden Eagle

AFTER 150 FLIGHTS

(OR AS NEEDED)

Replace propeller assemblies

Replace rotor arm assemblies

Retire battery pack after 150 charge/discharge cycles

ROTOR ARM REPLACEMENT

Damaged or worn rotor arms require the entire assembly to be replaced but can easily be done so in the field.

The arms are prewired with the motor installed, and only need to be locked into place and secured with a

single Torx T8 screw per arm. The Torx T8 screwdriver is included in the Field Repair Kit.

Arms are keyed to the appropriate sockets on the airframe so that CW and CCW arms cannot be inadvert-

ently interchanged.

REPLACEMENT

INSTRUCTIONS

Place the drone on its back on a table or workspace where the antenna

can hang o the edge to prevent being damaged.

Remove the single T8 Torx screw on the motor arm using a T8 Torx

screwdriver.

© 2022 Teal Drones, Inc. SUP-00005, REV A

!

Step 4

3

4

5

6

7

1

2

3

4

5

REPLACEMENT

INSTRUCTIONS

(CONTINUED)

Set the screw aside for re-use.

Carefully pull the arm straight out from its socket in the drone.

Insert the new arm into the airframe. Push firmly until you feel the connectors

“click”.

NOTE: If you feel any resistance and the arm will not easily click into place,

ensure that you are not attempting to insert a CW arm into a CCW position,

and vice-versa.

Tools Needed:

One (1) T8 Torx Screwdriver

Removal:

One (1) T8 Torx Screw Per

Rotor Arm

Use a Torx T8 screwdriver to tighten the screw to 0.6N*m (0.44 ft-lbs) and

secure the arm into place.

Make sure that the motor functions properly before the next flight.

CAMERA & GIMBAL PAYLOAD REPLACEMENT

Both the FLIR Hadron EOIR camera and gimbal can be replaced in the field. Use the specific tools to ensure

that no components are damaged in the process. Use the following instructions to replace both parts.

REPLACEMENT

INSTRUCTIONS

Place the drone on its back on a table or workspace where the antenna can

hang o the edge to prevent being damaged.

Remove the two (2) M3 x 8mm screws on the gimbal brackets using a T8

Torx screwdriver.

Tools Needed:

One (1) T8 Torx Screwdriver

Removal:

Two (2) M3 x 8mm Screws

Set the screws aside for re-use.

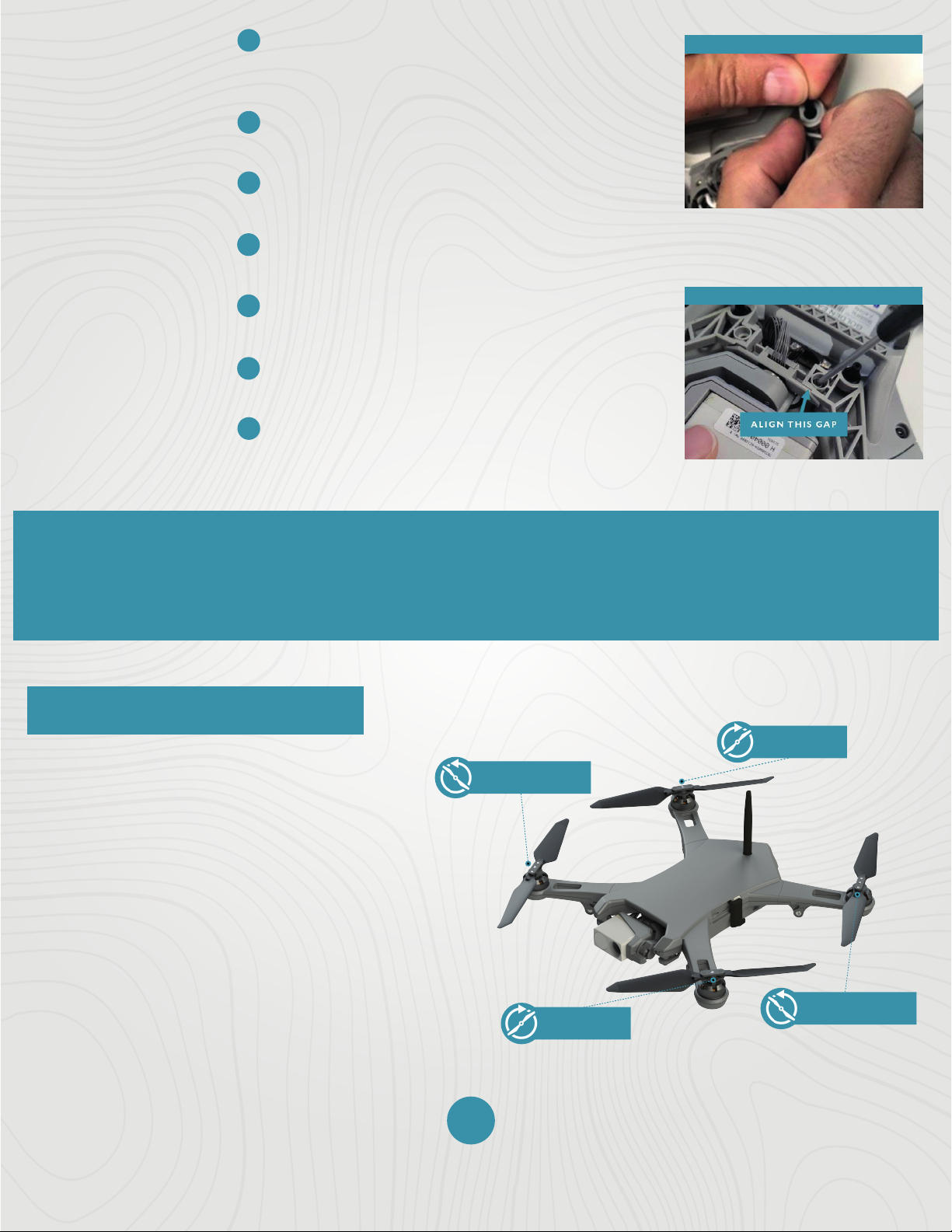

Squeeze the side latches of the camera data

cable connector to release the connector (as

shown in the image to the right).

Carefully pull the connector straight up to

disconnect it from its socket in the drone.

02

© 2022 Teal Drones, Inc. SUP-00005, REV A

Step 15

Step 10

Step 6

Step 18

Step 14

6

7

8

9

10

11

12

13

14

15

16

17

18

19

CAUTION: The exposed PCB is ESD

sensitive and static discharge can damage

the electronics. Minimize handling of the

exposed PCB.

Use your fingernail or a flathead screwdriver to

press on the tab on the motor control cable

connector (as shown in the image to the right).

Carefully pull the connector up to disconnect it

from its socket in the drone.

REPLACEMENT

INSTRUCTIONS

(CONTINUED)

Use a T5 Torx screwdriver to remove the

four (4) M1.6 x 4mm screws from the back of the Hadron camera.

Set the screws aside for re-use.

Disconnect the Hadron camera from the gimbal

by carefully pulling it away from the gimbal (as

shown in the image to the right).

Tools Needed:

One (1) T5 Torx Screwdriver

Removal:

Four (4) M1.6 x 4mm Screws

Check that the gasket around the PCB on the

Hadron camera is properly aligned and adjust if

needed.

Push the Hadron camera onto the gimbal. Press

firmly until you feel the connector “click” into

place.

Use a T5 Torx screwdriver to secure the four (4)

M1.6 x 4mm screws in the back of the Hadron

camera.

Connect the camera data cable connector to

the mating socket in the drone so that the side

of the cable as shown in the image to the right

is facing towards the front of the drone.

Connect the gimbal motor cable connector to

the mating socket in the drone so that the tab

on the connector is facing toward the front of

the drone (as shown in the image to the right).

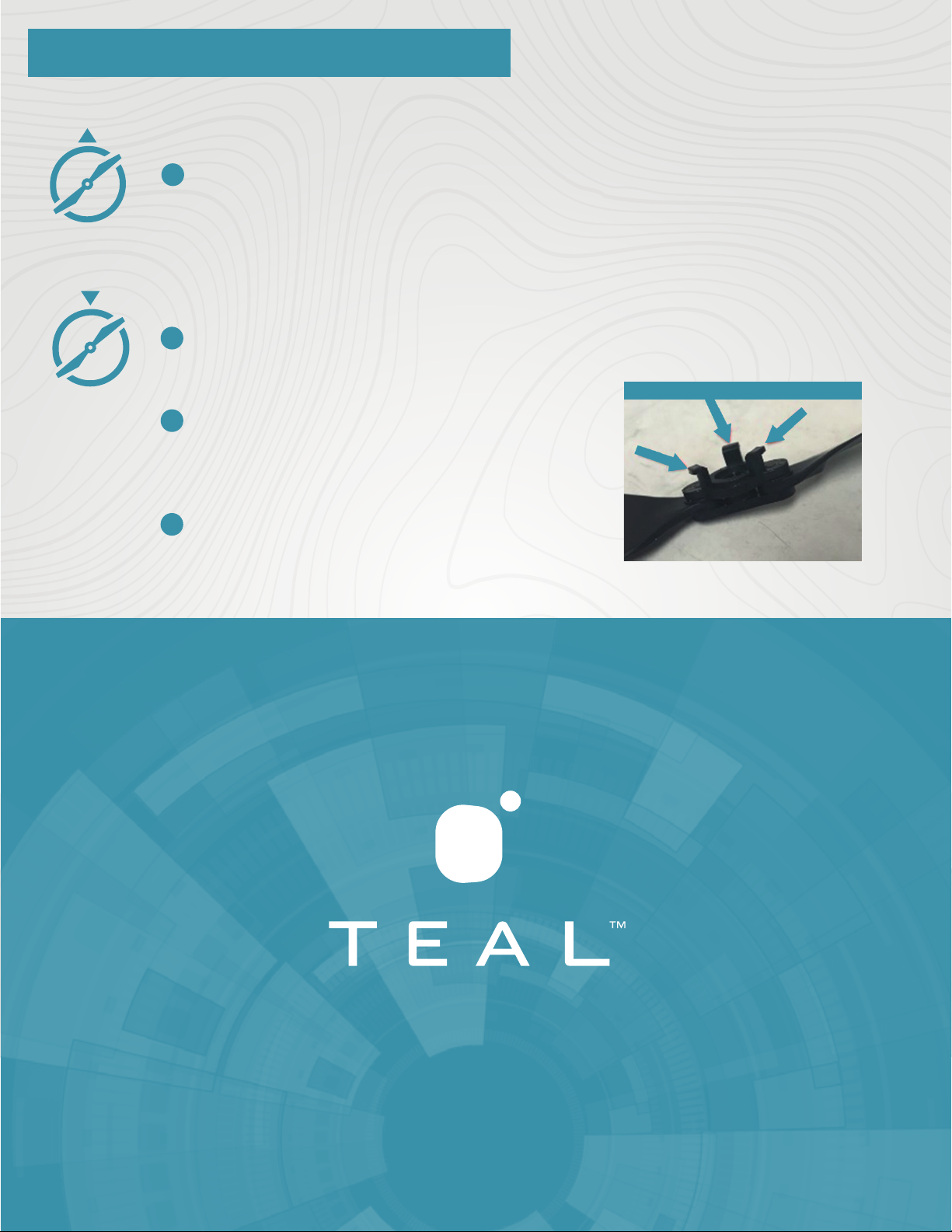

Align the threaded inserts on the gimbal under

the holes on the gimbal brackets.

Place the two (2) M3 x 8mm screws into the

holes on the gimbal brackets.

Align the gaps (as shown in the image to the

right).

Use a Torx T8 screwdriver to tighten the

screws to 0.6 N*m (0.44 ft-lbs).

03

© 2022 Teal Drones, Inc. SUP-00005, REV A

2

1

3

4

5

6

✓

✓

✓

7

8

9

Step 5

Step 7

Step 9

PAYLOAD MOUNTING BRACKET REPLACEMENT

The gimbal brackets can be easily replaced in the field; however, the black silicone gimbal dampers

cannot. If the dampers need to be replaced or serviced, please contact Teal Drone Customer Support or

an authorized service center.

REPLACEMENT

INSTRUCTIONS

Place the drone on its back on a table or workspace where the antenna can

hang o the edge to prevent being damaged.

Make sure that the camera data cable and gimbal motor cable are not

strained in any way.

Remove the two (2) M3 x 8mm screws on the gimbal brackets using a T8

Torx screwdriver.

Tools Needed:

One (1) T8 Torx Screwdriver

Removal:

Two (2) M3 x 8mm Screws

Set the screws aside for re-use.

Use your fingers or plastic pliers that will not

damage the silicone damper to hold the body of

one of the front dampers in place (as shown in

the image to the right).

Firmly, but slowly, pull the bracket away from the

damper body until the end of the damper pulls

through the hole.

Follow the same directions to remove the rear

damper (as shown in the image to the right).

Remove the remaining dampers.

Set the new bracket so that the recesses for the

screw head and dampers are visible and away

from the body of the drone (as shown in the

image to the right).

Manually move the gimbal pitch and roll axis and check for binding or obstructions.

Ensure that no wires are pinched.

Power on the system and confirm the gimbal properly functions and is properly oriented.

SYSTEM

CHECKOUT

04

© 2022 Teal Drones, Inc. SUP-00005, REV A

10

11

12

13

14

15

16

Step 10

Step 15

✓

✓

✓

!

REPLACEMENT

INSTRUCTIONS

(CONTINUED)

Hold the bracket in place and pull the end of

the silicone damper through the hole in the

bracket (as shown in the image to the right).

Make sure that the damper is properly seated

in the bracket.

Repeat this procedure for the remaining

dampers.

Align the threaded inserts on the gimbal

under the holes on the gimbal brackets.

Place the two (2) M3 x 8mm screws into the

holes on the gimbal brackets.

Align the gaps (as shown in the image to the

right).

Use a Torx T8 screwdriver to tighten the

screws to 0.6 N*m (0.44 ft-lbs).

Manually move the gimbal pitch and roll axis and check for binding or obstructions.

Ensure that no wires are pinched.

Power on the system and confirm the gimbal properly functions and is properly oriented.

SYSTEM

CHECKOUT

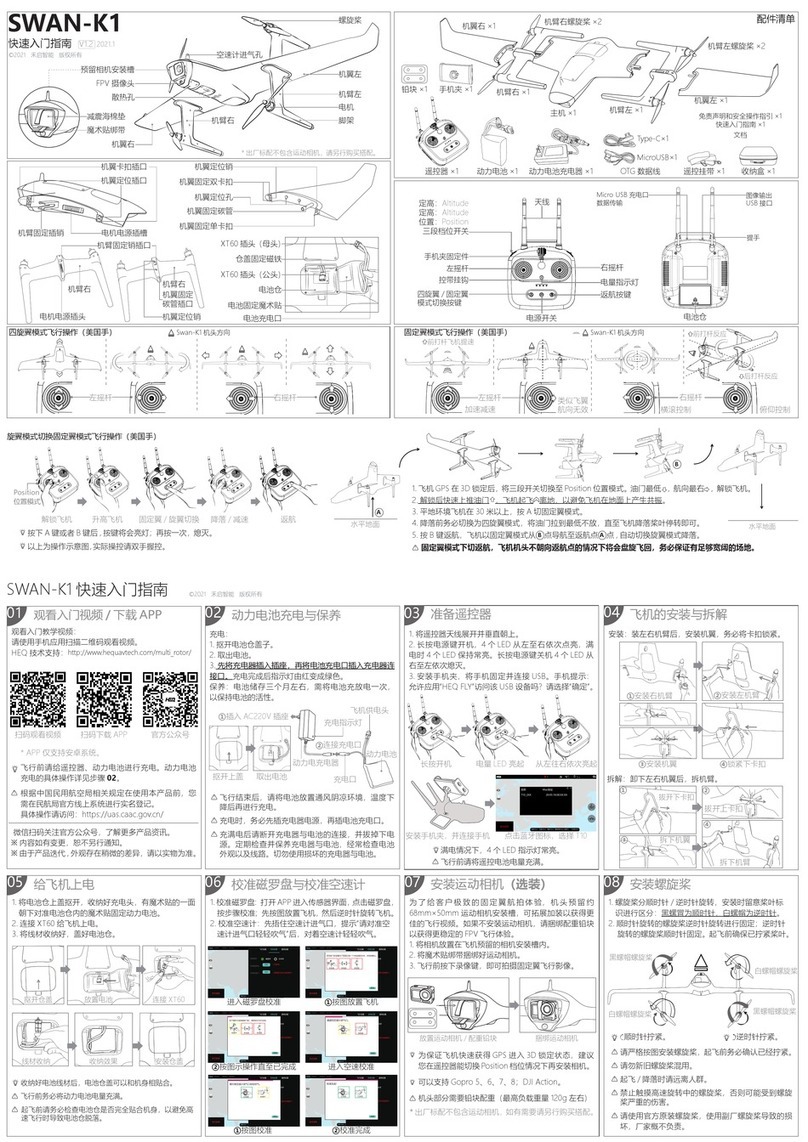

PROPELLER REPLACEMENT

Individual damaged or worn propellers require

the entire 2-prop assembly to be replaced, but

are easily installed, removed, or replaced with

a simple push-and-twist method that requires

no tools or hardware.

The propeller assemblies are keyed so that

CCW and CW props cannot be inadvertently

mounted to the wrong hub.

The two CW prop assemblies have black rivets

that secure their blades, and the two CW

propeller motors have a black ring below the

spring.

The two CCW prop assemblies have silver

rivets that secure their blades, and the two

CCW propeller motors have a silver ring below

the spring.

NOTE: CW prop assemblies lock into place by turning

it in a CCW direction, and CCW prop assemblies lock

into place by turning it in a CW direction.

CLOCKWISE

PROPELLER (CW)

COUNTERCLOCKWISE

PROPELLER (CCW)

COUNTERCLOCKWISE

PROPELLER (CCW)

CLOCKWISE

PROPELLER (CW)

05

© 2022 Teal Drones, Inc. SUP-00005, REV A

Step 1

1

1

2

3

PROPELLER INSTALLATION

PROPELLER REMOVAL

To remove a prop assembly, push down and rotate it a quarter turn until it hits

its mechanical limit. Allow the spring to push the hub up, then pull the assembly

o the shaft.

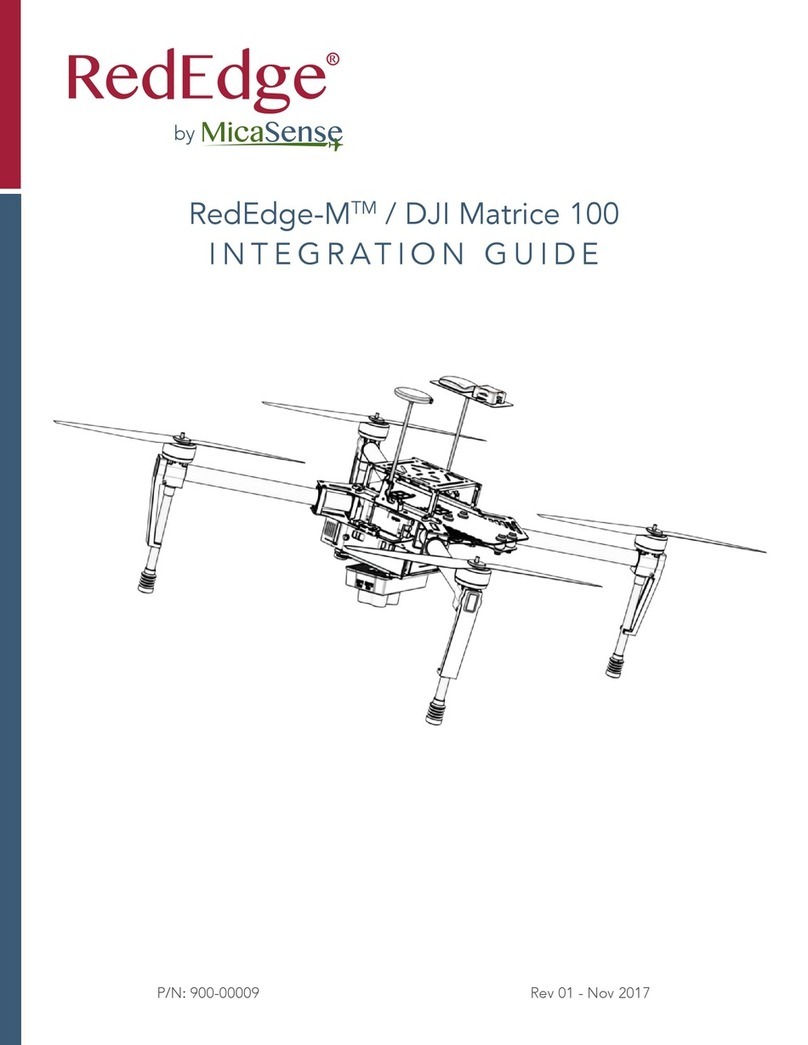

To attach a prop assembly to a motor, line up and insert the three (3) bent legs on

the underside of the prop assembly into the three (3) slots on the motor (as

shown in the image to the right).

Push down to compress the spring on the

shaft, then rotate a quarter turn until it hits

its mechanical limit. Allow the spring to

push the hub up into its locked position.

Verify that the newly installed propellers

spin feely.

PROPELLER REMOVAL & INSTALLATION

TEALDRONES.COM

06

© 2022 Teal Drones, Inc. SUP-00005, REV A

Table of contents

Other Teal Drone manuals

Popular Drone manuals by other brands

HEQ

HEQ SWAN-K1 quick start guide

MicaSense

MicaSense RedEdge-M / DJI Matrice 100 Integration guide

Wowitoys

Wowitoys Folding Elf H4805 user manual

Ultimate Drone Fishing

Ultimate Drone Fishing Poseidon Pro Pre-Flight Checklist

Reely

Reely TQ Performance Drone RtF operating instructions

Autel Robotics

Autel Robotics EVO Lite Series quick start guide