TEC Electronics CANTEC-F2-U User manual

Version 04.09.2015

CAN-bus

CAN-bus interface

CANTEC-F2-U

CAN-bus interface for

analogue car-alarms, PDC & more

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page2

CAN-bus

Contents

1. Prior to installation

1.1. Delivery contents

1.2. Checking the compatibility of vehicle and function limitations

1.3. Planing programmable inputs and outputs

2. Pin definition and factory defaults of programmable outputs/inputs

3. Installation

3.1. Power and CAN connections

3.2. Vehicle recognition

3.2.1. Automatic vehicle recognition

3.2.2. Forced vehicle recognition

3.3. Connections of programmable outputs/inputs

4. Programming

4.1. Settings programming (MENU 1)

4.2. Programmable outputs/inputs configuration (MENU 2)

4.2.1. Programmable outputs (MENU 2 –options no. 1-12)

4.2.2. Programmable inputs (MENU 2 –options no. 13-16)

5. Reset to factory defaults

6. Specifications

7. Technical support

8. Customer-specific programmable output/input configuration (complete)

Product features

CANTEC-F2 is a universal CAN-bus interface, hereafter referred to as unit, designed for

connecting after-market car-alarm security, park-distance control, multimedia and service

systems to vehicles with CAN-bus. The Unit has a build in micro USB port for easy

programming with TECprog Software.

The unit has ten programmable outputs, two of which have changeable polarity. 24 different

output functions are available (see chapter 4.2.1., available programmable outputs functions

–table 4). Four programmable inputs are designed for controlling vehicle devices. 9 different

input functions are available (see chapter 4.2.2., available programmable inputs functions –

table 6).

Vehicle recognition (model selection) is carried out automatically - for the majority of

vehicles after connecton, turning ignition on and off + vehicle locking/unlocking by original

remote control key.

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page3

CAN-bus

Requirements

Vehicle See CANTEC-F2 compatibility list at

Limitations

Vehicle-specific functions See CANTEC-F2 vehicle-specific installation files

and compatibility list

TECprog software look at: http://tecel.ru/en/tecprog/

Look for product info at www.navlinkz.de or www.canbus-alarm.com

1. Prior to installation

Read the manual prior to installation.

Technical knowledge is necessary for installation. The place of installation must be free of

moisture and away from heat sources.

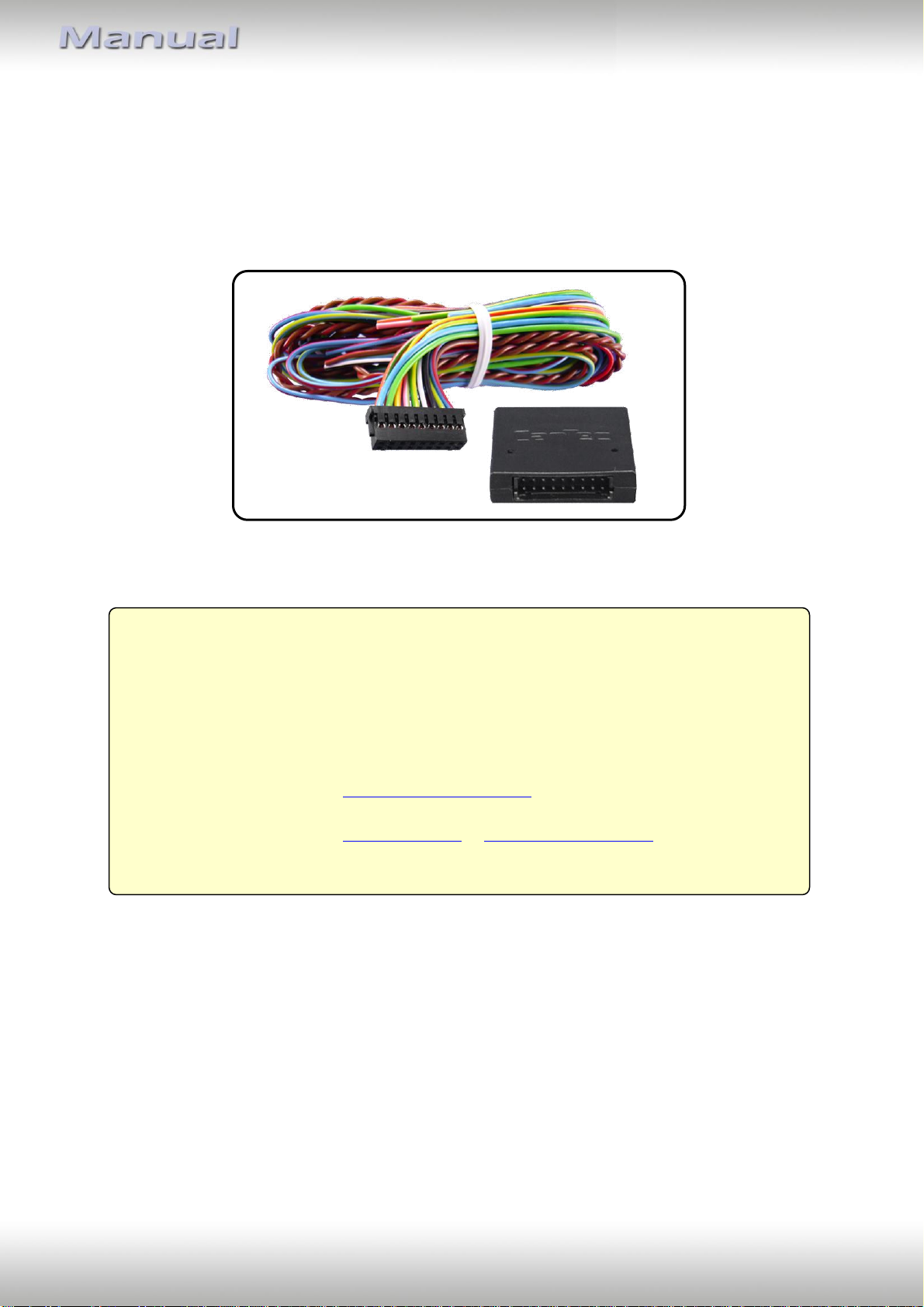

1.1. Delivery contents

1.2. Checking the compatibility of vehicle and function limitations

1.3. Planing programmable inputs and outputs

It is strongly recommended to read the complete manual and to plan in advance, which of

the available programmable input and output functions are needed for the specific

installation (see chapter 4.2.). Maximum currents of the unit’s programmable inputs and

outputs must match connected devices’ power consumption.

It is possible to do most of programming works with the TECprog software. Please connect

the Cantec Module with the build in Micro USB plug after you have installed the Software

from TEC website. The USB plug you find inside of the Cantec F2 housing, please open it

carfully if it is closed.

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page4

CAN-bus

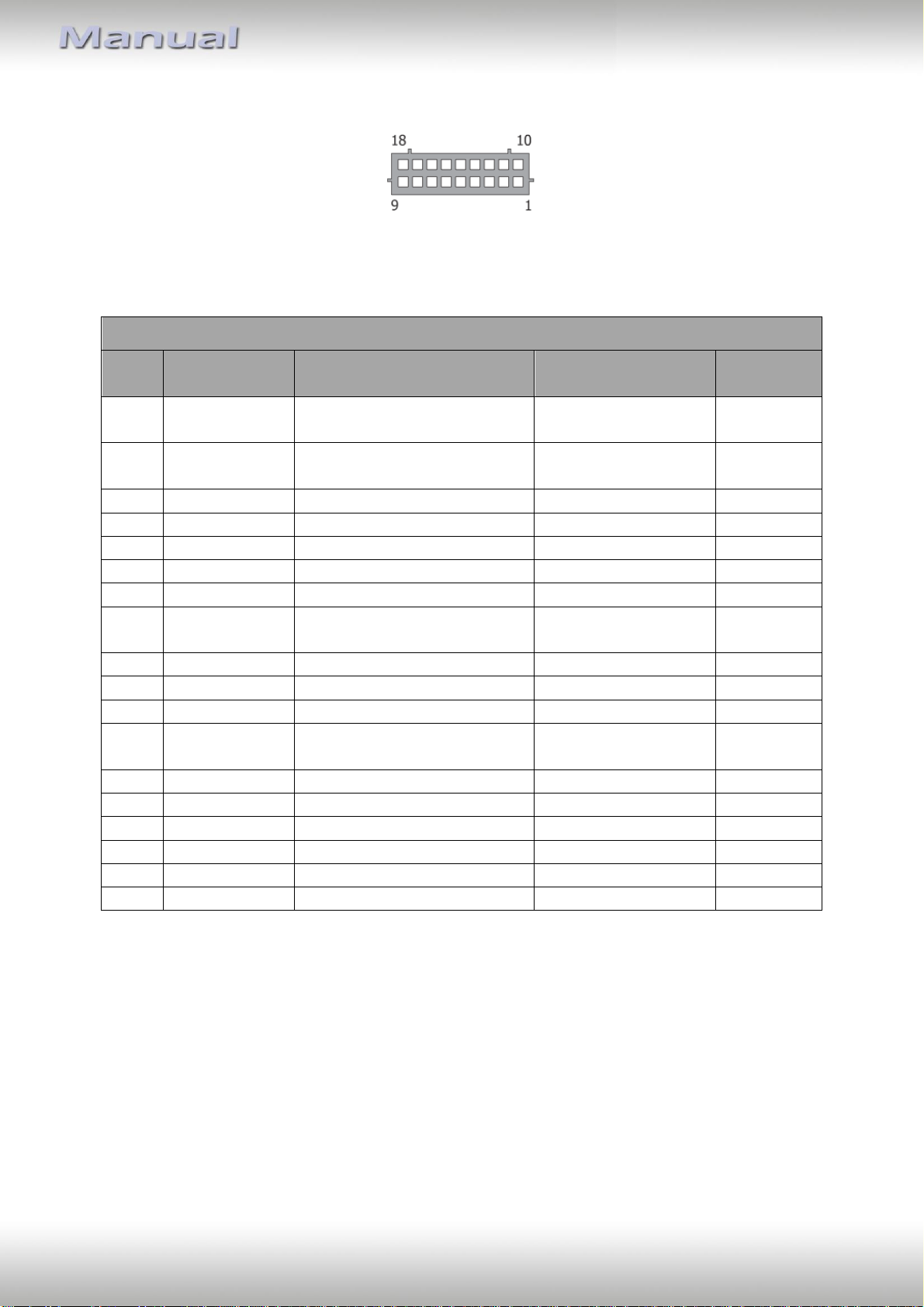

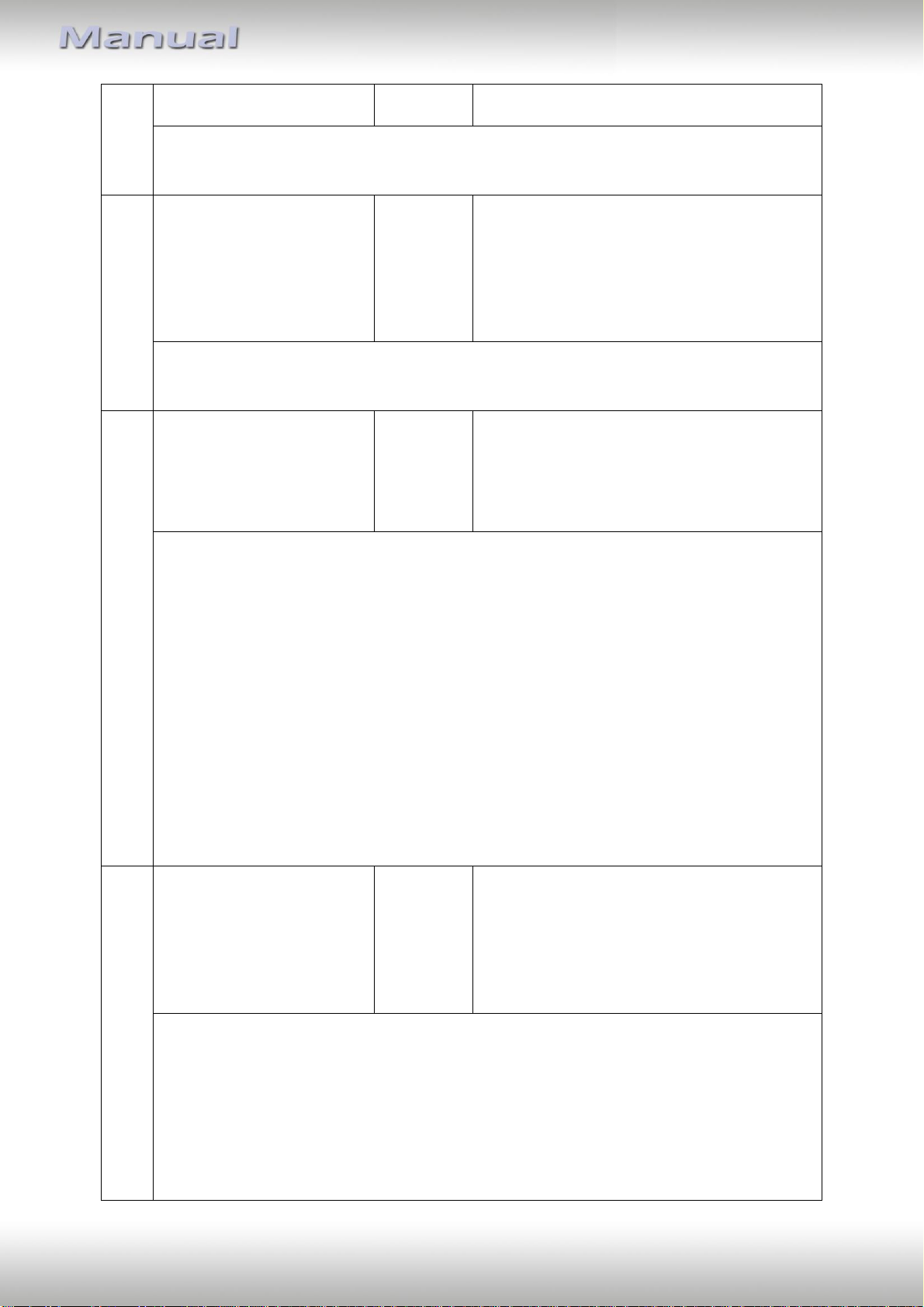

2. Pin definition and factory defaults of programmable outputs/inputs

Male pins of black-box 18pin port

Programmable outputs/inputs configuration can be done out via programming (see chapter

4.) or via TEC-PROG tool and software with Windows PC. Factory defaults are predefined

according to table 1. These settings can be restored by resetting the unit (see chapter 5.)

Pin definition and factory defaults of programmable outputs/inputs –table 1

Pin

no.

Harness wire

color

Functionality

Factory default

settings

Maximum

current

1

Blue/red

Programmable output (+ / -)

with changeable polarity*

Alternate hazard

lights control

200 mA

2

Blue/yellow

Programmable output (+ / -)

with changeable polarity*

Alternate central

locking control

200 mA

3

Black

Ground of power supply

-

-**

4

White/black

Programmable output (+)

Engine on

50 mA

5

Green/yellow

Programmable output (-)

Parking brake

50 mA

6

Pink/green

Programmable output (+)

Brake

50 mA

7

Yellow/red

Programmable output (+)

Ignition

50 mA

8

Green

Programmable input (-)

Central locking

closing + comfort

1.5 mA

9

Blue

Programmable input (-)

Central unlocking

1.5 mA

10

Brown/red

CAN-high of vehicle data bus

-

-

11

Brown

CAN-low of vehicle data bus

-

-

12

Red

+12V of power supply

-

750 (4) mA

***

13

Gray/black

Programmable output (-)

Security

50 mA

14

Gray/blue

Programmable output (-)

All doors

50 mA

15

Gray/green

Programmable output (-)

Trunk

50 mA

16

Gray/yellow

Programmable output (-)

Hood

50 mA

17

Orange/white

Programmable input (+)

Turn lights activation

1.5 mA

18

Orange/green

Programmable input (-)

Trunk opening

1.5 mA

* Outputs with changeable polarity. Outputs’ operation with load higher than the indicated

is not guaranteed and may damage the unit.

** Consumed current of output pin 3 depends on the load connected to all negative outputs.

*** Typical current rate is indicated for operation and standby modes. It may change

depending on positive outputs’ load.

Avoid making contact between ground and outputs pins 4, 6, 7 or +12V and outputs pins 5,

13-16. Otherwise the unit is damaged.

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page5

CAN-bus

3. Installation

3.1. Power and CAN connections

Disconnect the vehicle’s battery during installation or changes on the wiring!

Connect +12V, Ground, CAN-high and CAN-low wires of the unit’s harness to the

corresponding wires of the vehicle (see vehicle-specific installation file).

Connect the unit’s black-box to its harness and make sure that all other open end wires of

the harness do not short-circuit.

3.2. Vehicle recognition

For proper operation, the unit must recognize the vehicle and its specific CAN-bus, thus

vehicle group and sub-group. There are two ways:

3.2.1. Automatic vehicle recognition

After installing the unit to power and CAN-bus, by carrying out a set of simple actions (see

vehicle-specific installation file for procedure) the vehicle-specific group and sub-group are

defined automatically. To check correctness of group and sub-group the LED issues a number

of light signals (group number –pause, sub-group –pause).

If the unit identifies both vehicle group and sub-group, it emits triple series of light signals,

where the number of long signals corresponds with the group number, while the number of

short signals corresponds with the sub-group number.

If the unit identifies only the vehicle group, it stops emitting short light signals and

periodically emits series of lights signals, where the number of signals corresponds with

vehicle group.

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page6

CAN-bus

3.2.2. Forced vehicle recognition

Forced vehicle recognition is only to be executed

in exceptional cases, when automatic vehicle

recognition has failed.

Programming is carried out via programming

button and LED indicator, which are located in

the unit’s body. Prior to forced vehicle

recognition, the vehicle group previously must

not have been identified (if the vehicle group has

previously already been identified, a factory reset

is necessary) and the CAN-bus must not be

connected. Programming stops if the

programming button is not pressed within 60

seconds.

Programming sequence of forced vehicle recognition:

1. Connect the unit to power only and wait for permanent short fast light signals.

2. Press and release the programming button 10 times (begin this action not later than

10 seconds upon connecting the power source to the unit). If all the actions are

carried out correctly, the unit confirms with three light signals.

3. Enter option No. 1 –forced vehicle recognition (see table 2, chapter 4.1.) –by

pressing the programming button 1 time. The unit confirms the selection with

repeated single light signals.

4. Enter vehicle group number by pressing the programming button for the

corresponding number of times (see vehicle-specific installation file for group

number). The unit periodically emits series of light signals, where the number of

signals corresponds with the entered group number.

5. Wait at least 2 seconds.

6. Enter the vehicle sub-group number by pressing the programming button for the

corresponding number of times (see vehicle-specific installation file for sub-group

number). Check if the vehicle model has been chosen correctly. The unit emits light

signals (group number –pause, sub-group number –pause):

If the vehicle model is chosen correctly, press the programming button once.

Light signals stop and the vehicle model is saved.

If the vehicle model has been chosen incorrectly, press the programming

button twice. Repeat the programming beginning from point 4.

7. Reconnect unit to CAN-bus.

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page7

CAN-bus

3.3. Connections of programmable outputs/inputs

After successful vehicle recognition disconnect the unit’s black-box from its harness.

Connect all the input and output wires to the corresponding places. Make sure that

unneeded output/input wires are isolated.

4. Programming

All programming is done by the unit’s programming button, LED and the vehicle’s brake

pedal. The unit’s settings and input/output functions can be changed or checked in two

menus after entering their programming modes. In MENU 1 it is possible to change settings

–activate/deactivate functions, or change values or algorithms of functions (see chapter

4.1.). In MENU 2, the functions which shall be used on the unit’s programmable outputs (see

chapter 4.2.1.) and on the programmable inputs (see chapter 4.2.2.) can be defined.

4.1. Settings programming (MENU 1)

Follow the below programming sequence to change or check settings of MENU 1:

1. Turn on ignition.

2. To enter MENU 1, press the programming button 10 times. The unit confirms with

three light signals.

3. After selecting the option desired from table 2, to change or check its status, press

the programming button for the number of times corresponding with the option

number (no.). The unit confirms with the same number of light signals.

4. To enter the programming mode, press and hold the brake pedal*. The unit informs

about the status of the chosen option by the corresponding number of LED light

signals. There is no countdown until programming mode is deactivated.

5. Change the option’s setting value (exception: option no. 9 –PDC control button - see

table 2 instead**) by pressing the programming button for the number of times

required to move from current setting to the required setting value while the last

setting value is followed by the first one. (e.g., in order to change option no. 5

(comfort timer channel) from setting value 3 to 1, press the programming button 4

times). The unit confirms new the setting value with the corresponding amount of

light signals.

6. Release the brake pedal. The unit’s light indication changes from option setting back

to option number. It is possible to proceed with programming the next option or to

leave the programming mode.

7. Move to next option’s programming by pressing the programming button for the

number of times required to navigate from current option’s number to the required

option’s number while the last option’s number is followed by the first one.

8. The unit leaves the programming mode and saves all settings in permanent memory,

60 seconds after last action if brake is not pressed or when ignition is switched off.

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page8

CAN-bus

*Note –If the vehicle’s brake pedal is not visible on CAN-bus (see vehicle-specific installation

file), the unit’s trunk opening input is used (GND impulse instead of brake pedal press).

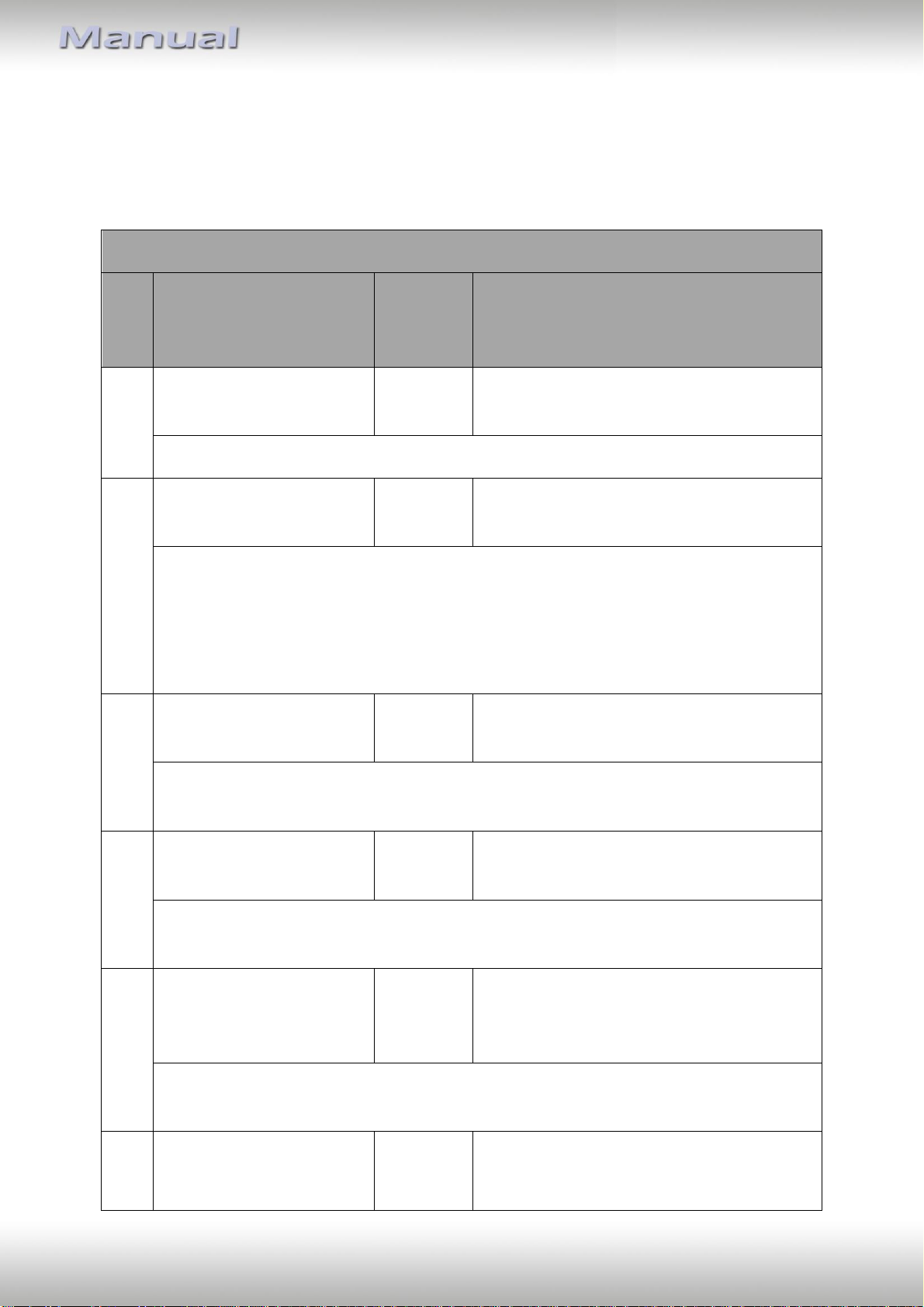

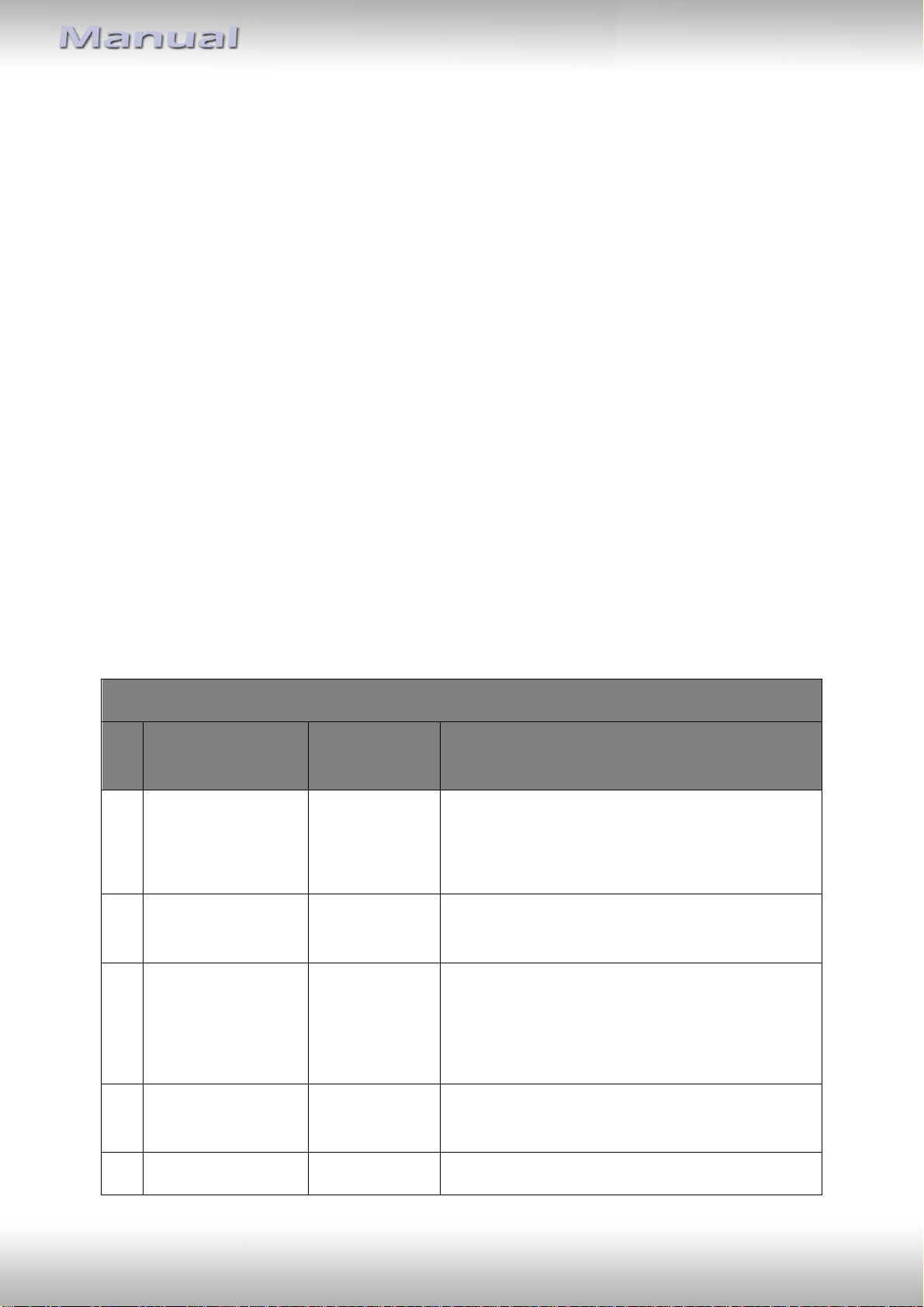

Settings (MENU 1) –table2

no.

Option description

Setting

range/

default

LED signals, notes

1

Forced vehicle recognition

- / -

See chapter 3.2.2. Forced vehicle

recognition

Forced vehicle group and sub-group assignment, when automatic has not worked.

2

Original car alarm control

-/enabled

LED is on –factory car alarm control is on

LED is off –factory car alarm control is off

If ON, the unit locks and unlocks the vehicle with the same commands that activate

(deactivate) the original alarm system (via original remote control, door lock etc.). If

OFF, the unit locks (unlocks) the vehicle with commands that don’t activate

(deactivate) the original alarm system. (E.g. central lock locking/unlocking via vehicle

interior button).

3

Sequential door opening

-/disabled

LED is on –the function is on

LED is off –the function is off

Activating or deactivating the sequential door opening. If activated upon one

unlocking command only driver’s door is unlocked, after two commands all doors.

4

Automatic windows

closing (comfort feature)

-/enabled

LED is on –the function is on

LED is off –the function is off

Activating or deactivating automatic windows closing comfort feature when using the

central lock. If ON, 2 seconds after central locking the unit will close the windows.

5

Comfort timer channel

function operation length

–output function no. 24

1-6 / 3

One LED signal per 10 seconds

Time during which timer channel (comfort) function stays active. Set in 10-second

intervals.

6

Central locking alternative

control algorithm of

1-3/-

1 –impulse negative control

2 –impulse positive control

3 –impulse negative control (when central

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page9

CAN-bus

output pin 2

locking status is not available)

In most cases the algorithm and polarity are set automatically when recognizing the

vehicle.

7

Hazard lights alternative

control algorithm of

output pin 1

1-5 / -

1 –impulse negative control

2 –status negative control

3 –impulse positive control

4 –status positive control

5 –lamps control (negative)

In the majority of cases the algorithm is set automatically when recognizing the

vehicle.

8

Parking distance control

(PDC) system algorithm –

output functions no. 17-19

1-3/1

1 –“Activation on rear gear”

2 –“Activation on speed”

3 –“Activation on rear gear with priority of

switching off”

“Activation on rear gear” - Front and rear parking sensors are activated when reverse

gear is engaged or by PDC control button (see option no. 9). Deactivation upon speed

reaches 15km/h or by PDC control button.

“Activation on speed” - Front parking sensors are active as long as the vehicle’s speed

is less than 15km/h. Rear parking sensors are active if the vehicle moves back and its

speed is less than 15km/h. Activation (when speed < 15km/h) and deactivation

possible by PDC control button. Automatic (re-)activation on ignition on.

“Activation on rear gear with priority of switching off”. Same algorithm as

“Activation on rear gear”, but if parking sensors have been deactivated by PDC control

button no automatic activation on engaged reverse gear until next ignition on or

activation by PDC control button.

9

PDC control button –

output functions no. 17-19

-/-

Any OEM (factory) vehicle’s button which is

“visible” in CAN-bus can be used. Also any

(negative/positive) button connected to the

corresponding output of the unit. Also the

length of control press can be determined.

PDC control button assigning algorithm. Press and hold the button that you have

chosen as PDC button for the particular time:

Control with short press –keep button pressed less than 2 seconds

Control with long press (2.5 sec) –keep button pressed 3-5 seconds

Control by status (on/off) –keep the button pressed longer than 5 seconds

The LED light is off while the button press is detected. Release the button. The unit

emits one light signal and turns off. 6. of programming sequence (chapter 4.1.)

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page10

CAN-bus

4.2. Programmable outputs/inputs configuration (MENU 2)

In MENU 2, the programmable outputs and inputs can be set to other functions than the

predefined factory defaults (see chapter 2.).

Follow the below programming sequence to change or check programmable output/input

functions of MENU 2:

1. Turn on ignition.

2. To enter MENU 2, press the programming button 12 times. The unit confirms with

four light signals.

3. After selecting the programmable output’s/input’s option no. desired to

change/check (see chapters 4.2.1. or 4.2.2., tables 3 or 5), press the programming

button for the number of times corresponding with the option number (no.). The unit

confirms with the same amount of light signals.

4. To enter the programming mode, press and hold the brake pedal*. The unit informs

about the status of the chosen option by the corresponding number of LED light

signals. There is no countdown until programming mode is deactivated.

5. Change the option’s function no. by pressing the programming button for the

number of times required to move from current setting to the required setting value

while the last setting value is followed by the first one. (e.g., in order to change

option no. 5 (positive output –pin 4) from factory default function no. 13 - engine on

to function no. 21 - brake, press the programming button 8 times). The unit confirms

new the setting value with the corresponding number of light signals.

6. Exceptions: programmable output functions no. 8, 10 and 15 require additional

programming sub-sequence, see corresponding function no. in table 4.

7. Release the brake pedal. The unit’s light indication changes from option setting value

back to option number. It is possible to proceed with programming the next option

or to leave the programming mode.

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page11

CAN-bus

8. Move to next option’s programming by pressing the programming button for the

number of times required to navigate from current option’s number to the required

option’s number while the last option’s number is followed by the first one.

9. The unit leaves the programming mode, and saves all settings in permanent memory,

60 seconds after last action if brake is not pressed or when ignition is switched off.

*Note –If the vehicle’s brake pedal is not visible on CAN-bus (see vehicle-specific installation

file), the unit’s trunk opening input is used (GND impulse instead of brake pedal press).

4.2.1. Programmable outputs (MENU 2 –options no. 1-12)

Pin 1 and 2 are, if necessary for this vehicle, preset to alternate hazard lights control and

alternate central locking control, including the required polarity (see vehicle-specific

installation file). If alternate hazard lights control and alternate central locking control are

not necessary, both pins are programmable (max. 200mA) with changeable polarity. When

assigning any of the available output functions to these two programmable outputs, it is

necessary to set the required polarity.

All other outputs are generally programmable and can be changed from their factory

defaults (see chapter 2. - table 1) to any other available output function (see chapter 4.2.1.,

table 4) with max. 50mA. It is possible to use the same function for more than one output.

It is possible to enter the from table 4 chosen output function for each programmable

output into below table 3.

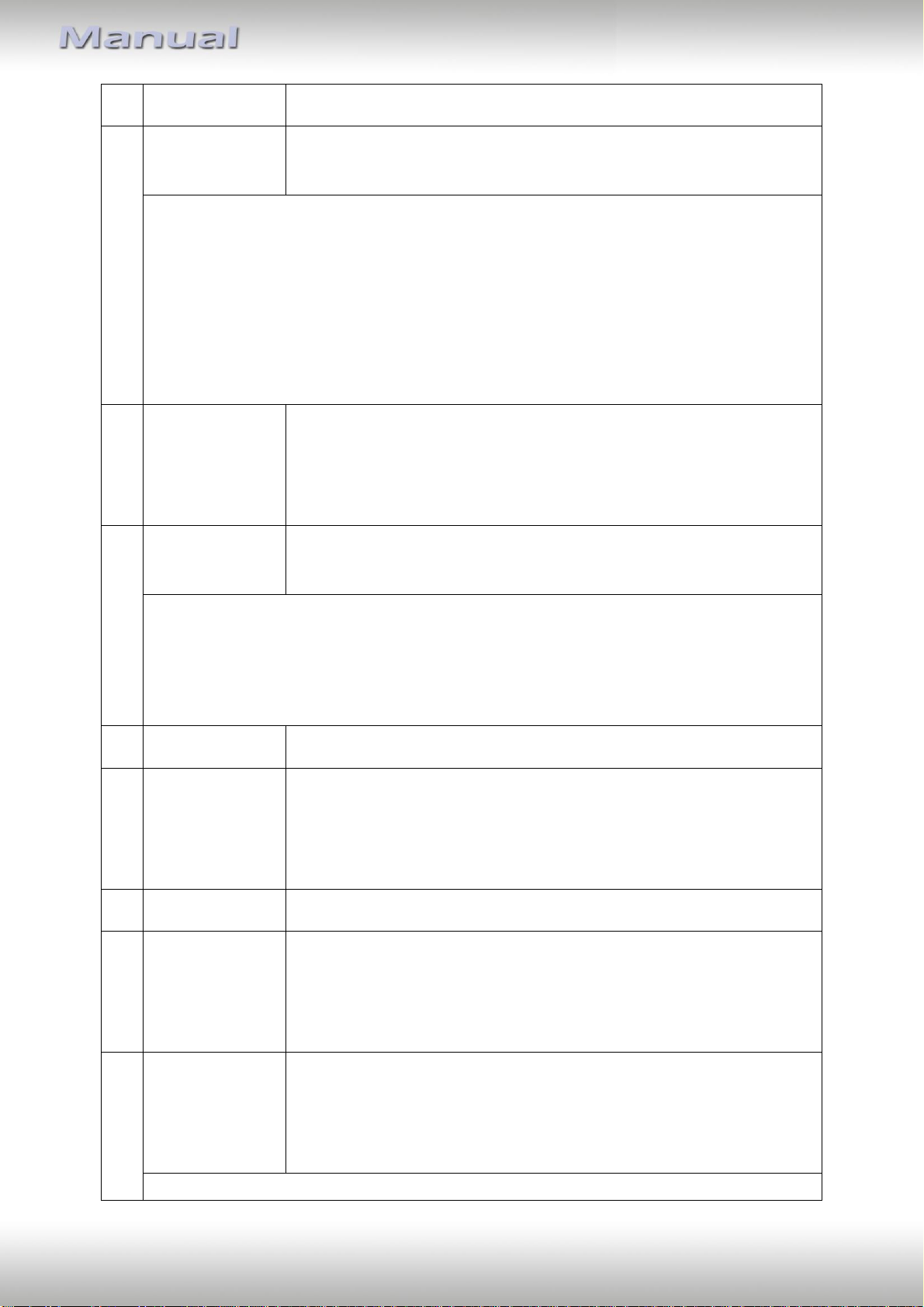

Programmable outputs configuration (MENU 2) –table 3

no.

Option description

Setting range /

default

Notes (enter programmed/planned output

functions from table 4)

1

Output (+/-) pin 1

(1-24) / Hazard

lights alternate

control

Hazard lights alternate control is used in

vehicles where hazard lights control via CAN-

bus is not possible.

2

Output pin 1

polarity

- / Negative

polarity

LED is on –positive

LED is off –negative

3

Output (+/-) pin 2

(1-24) /

Central locking

alternate

control

Central locking alternate control is used in

vehicles where central locking control via CAN-

bus is not possible.

4

Output pin 2

polarity

-/ Negative

polarity

LED is on –positive

LED is off –negative

5

Output (+) pin 4

1-24/13

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page12

CAN-bus

6

Output (-) pin 5

1-24/22

7

Output (+) pin 6

1-24/21

8

Output (+) pin 7

1-24/11

9

Output (-) pin 13

1-24/1

10

Output (-) pin 14

1-24/8

11

Output (-) pin 15

1-24/8

12

Output (-) pin 16

1-24/8

The setting range 1-24 in table 3, equals the available programmable output functions from

table 4.

Output functions no. 8, 10 and 15 have sub-settings for which the sub-sequences to chapter

4.2. are also described in table 4.

Available programmable output functions –table 4

no.

Function

Function description

1

Security

Constant level signal while the unit is in Secure mode.

2

Arming impulse

0.8 sec long impulse when the unit is armed.

3

Disarming

impulse

0.8 sec long impulse when the unit is disarmed.

4

Trunk opening

via original

remote control

impulse

0.8 sec long impulse on trunk opening command of original remote

control.

5

Original alarm

system panic

Constant level signal while original alarm system (if one is installed)

is in alert mode.

6

Siren panic

30 sec long constant level signal when one of the zones is triggered

in security mode: trunk, doors, hood opening. This function can be

used in vehicles that are not equipped with an original alarm

system. The signal stops when the vehicle leaves security mode.

7

Panic on horn

from external

Impulse signal while there is an input signal on a programmable

input which is defined as horn control.

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page13

CAN-bus

input

8

Doors, hood and

trunk

Constant level signal when any of the preprogrammed doors, hood

or trunk is open.

Programming sub-sequence: Any combination of doors, hood and trunk opening can be

chosen to trigger this programmable output. For purpose of description, the doors,

hood and trunk is below referred to as doors. Release brake. Open only doors that are

supposed to be indicated by this output, keep the rest closed (doors can be open in

advance). Press the brake again. The unit confirms with series of 8 light signals and the

open doors are be assigned as trigger(s) to this output. If the brake is not pressed, the

previous assignment stays saved. After releasing the brake, the unit starts indicating

the option’s no.8. of programming sequence (chapter 4.2.).

9

Sensors ignoring

Constant level signal while in security mode with the trunk open if it

is opened with original remote control. Also the signal is formed for

the time while comfort feature is active. This function is designed

for organizing sensors’ deactivation in order to evade false alarms.

10

Original buttons

Constant level signal when a preprogrammed vehicle button is

pressed.

Programming sub-sequence: Without releasing the brake, press desired button (see

vehicle specific installation file for visible buttons). Upon button identification, the unit

stops emitting short light signals and emits series of 10 light signals. If brake is released

prior to identification, the previous assignment stays saved. After releasing brake, the

unit starts indicating the option’s no. 8. of programming sequence (chapter 4.2.).

11

Ignition

Constant level signal while ignition is on (including engine start).

12

ACC

Constant level signal while vehicle ACC is on (first key position, may

be congruent with ignition in some vehicles). Deactivation when the

key is removed from the ignition lock. Can be used as accessory

power supply for multimedia systems.

13

Engine on

Constant level signal while engine is on.

14

Engine rpm

Impulse signal with impulse sequence frequency proportionate to

vehicle crank rotation frequency. 1 impulse/sec corresponds with

crank rotation frequency of 20rpm. Signal is designed for

determining estimated, but not the exact rpm.

15

Transmission

condition

Constant level signal when the transmission is set to

preprogrammed gear (P, R, N, D). For robotized transmissions the

following gears can be programmed: R, N, D). For manual

transmissions only R gear is available.

Programming sub-sequence: Without releasing the brake, set the transmission to

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page14

CAN-bus

required gear: P, N, D or R. Release and press the brake again. The unit stops emitting

short light signals and indicates option setting number with series of 15 light signals. If

the brake is not pressed, the previous assignment stays saved. After releasing the

brake, the unit starts indicating the option’s no. 8. of programming sequence

(chapter 4.2.).

16

Vehicle moving

Constant level signal while the vehicle speed has exceeded a certain

threshold rate (varies from vehicle to vehicle but within 5-10km/h).

17

Front parking

sensors

activation

Constant level signal for front-parking sensors activation according

to algorithm chosen in MENU1 (table 2), no. 8

18

Rear parking

sensors

activation

Constant level signal for rear-parking sensors activation according to

algorithm chosen in MENU1 (table 2), no. 8

19

Parking distance

control LED

indicator

Indicator the PDC system condition.

If parking sensors work according to “Activation on rear

gear” or “Activation on rear gear with priority of switching

off “ algorithm, LED indicator is ON when the sensors are

active

If parking sensors works according to “Activation on speed”

or “Activation on rear gear with priority of switching off “

algorithm, LED indicator is OFF when the sensors are not

active

20

Speed

Impulse signal with impulse sequence frequency proportionate with

vehicle movement speed. 1 imp/sec corresponds with 1km/h speed.

This signal is designed for determining estimated but not the exact

speed.

21

Brake

Constant level signal when the brake pedal is pressed.

22

Parking brake

Constant level signal when parking brake is activated.

23

Parking lights

Constant level signal when the external lights are activated.

24

Comfort timer

channel

Constant level signal during a certain time period (from 10 to 60

seconds) after arming the vehicle. The time is set in units of 10sec.

4.2.2. Programmable inputs (MENU 2 –options no. 13-16)

All other inputs are generally programmable and can be changed from factory defaults (see

chapter 2., table 1) to available input functions (see chapter 4.2.2., table 5) with max. 50mA.

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page15

CAN-bus

It is possible to enter the from table 6 chosen input function for each programmable input

into below table 5.

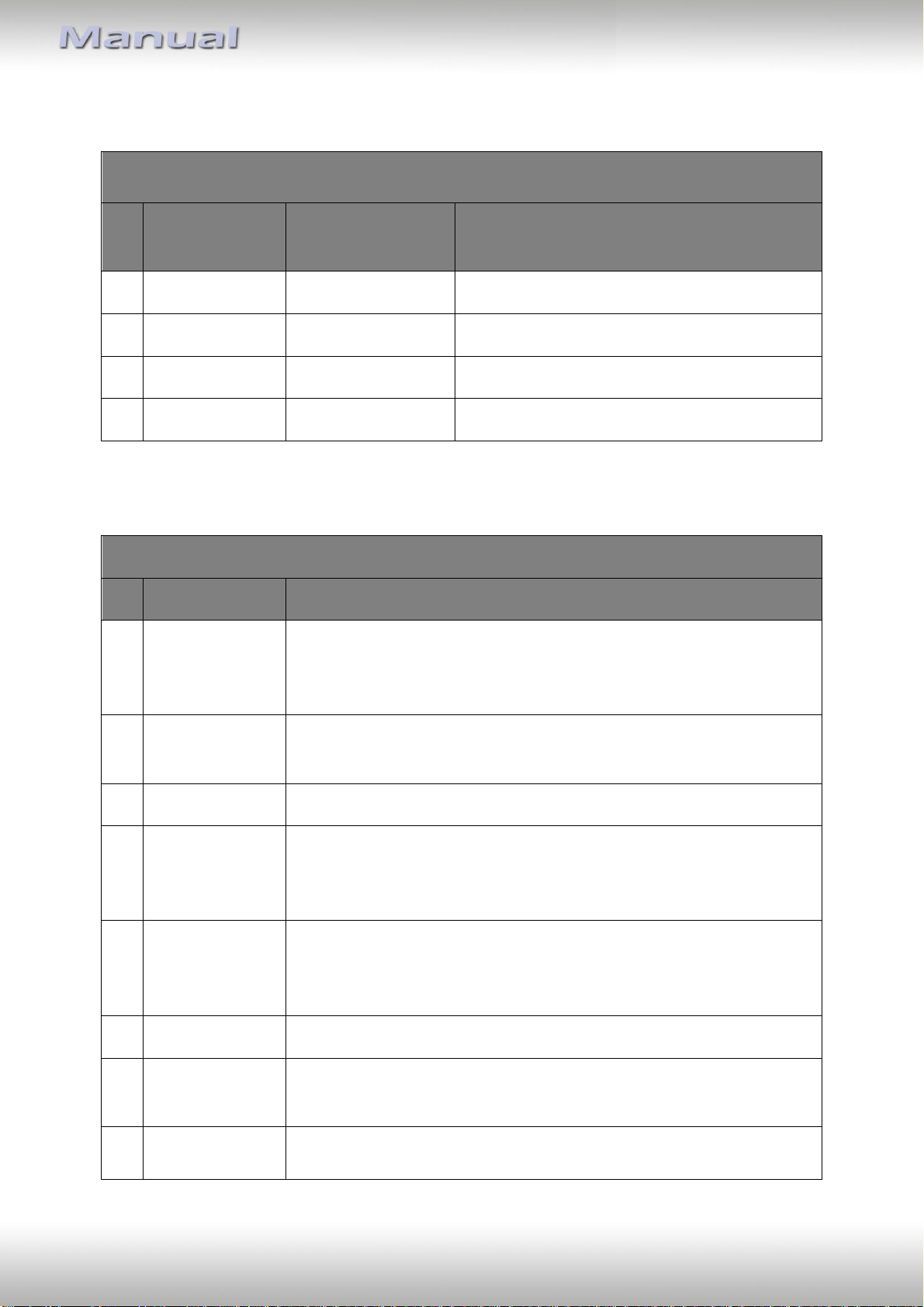

Programmable inputs configuration (MENU 2) –table 5

no.

Option

description

Setting range /

default

Notes (enter programmed/planned output

functions from table 6)

13

Input (-) pin 8

1-9/1

14

Input (-) pin 9

1-9/2

15

Input (+) pin 17

1-9/4

16

Input (-) pin 18

1-9/3

The setting range 1-9 in table 5, equals the available programmable input functions from

table 6.

Available programmable inputs functions –table 6

no.

Function

Function description

1

Central locking +

Comfort

Trigger input (impulse) for central locking. When input signal is >2

seconds, windows comfort closing is started. Windows’ closing stops

when the signal stops. CAN-bus or alternate.

2

Central

unlocking

Trigger input (impulse) for central unlocking. CAN-bus or alternate.

3

Trunk opening

Trigger input (impulse) for s opening the trunk lid via CAN-bus.

4

Hazard lights

activation

Trigger input (impulse) for hazard lights, one flash per impulse. On

some vehicles, uneven lamp blinking may be observed while the

impulses are fed evenly. CAN-bus or alternate.

5

Horn control

Trigger input (constant) activates the programmable output

function no. 7 –“panic on horn from external input”. Sound output

in intervals. Stopping the input feed stops this function.

6

Engine start

Engine starts via CAN-bus (only some Cadillac, Chevrolet, Hummer).

7

Central lock is

locked (status)

Trigger input (constant) to provide “locked” status in vehicles where

it is not available on CAN-bus (see vehicle-specific installation file).

8

Central lock is

unlocked

Trigger input (constant) to provide “unlocked” status in vehicles

where it is not available on CAN-bus (see vehicle-specific installation

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page16

CAN-bus

(status)

file).

9

PDC control

button

Used for providing control of PDC (parking distance control) with

optional external button (required when no “visible” CAN-bus

buttons available).

5. Reset to factory defaults

By hardware reset, all programmable settings and functions of the unit are restored to factory

default and the vehicle recognition (group and sub-group) is erased. To restore factory defaults:

Detach the unit from power source and CAN-bus.

Press and hold the programming button.

With the programming button pressed, supply power to the unit (CAN-bus must remain

disconnected). The unit emits permanently short fast light signals.

Detach the power source and release the programming button.

6. Specifications

BATT/ACC range 9V ~ 15V

Stand-by power drain <4mA

Power consumption 9W

Temperature range -40°C to +85°C

Weight (box with harness) 45g

Dimensions (box only) B x H x T 30 x 30 x 7 mm

Version 12.11.2013 TEC-6050-2 CANTEC-F2 V5

Page17

CAN-bus

7. Technical Support

NavLinkz GmbH TEC electronics ltd

EU-distribution and tech dealer-support manufacturer

Eurotec-Ring 45 16th Parkovaya 30, Bld.1

D-47445 Moers 105484 Moscow, Russia

Tel +49 2841 94997 0

http://www.navlinkz.de http://www.canbus-alarm.com

8. Customer-specific programmable output/input configuration (complete)

For reason of better comprehension, in chapter 4.2., programmable outputs and inputs are

separated. Full configuration can be noted in the below table. For support reasons, we also

suggest to apply the extra serial number sticker in CANTEC-F2 box here:

________________

Pin definition and customer-specific outputs/inputs configuration

Pin

no.

Harness wire

color

Functionality

Factory default

settings

Maximum

current

1

Blue/red

Programmable output (+ / -)

with changeable polarity*

200 mA

2

Blue/yellow

Programmable output (+ / -)

with changeable polarity*

200 mA

3

Black

Ground of power supply

reserved

4

White/black

Programmable output (+)

50 mA

5

Green/yellow

Programmable output (-)

50 mA

6

Pink/green

Programmable output (+)

50 mA

7

Yellow/red

Programmable output (+)

50 mA

8

Green

Programmable input (-)

1.5 mA

9

Blue

Programmable input (-)

1.5 mA

10

Brown/red

CAN-high of vehicle data bus

reserved

11

Brown

CAN-low of vehicle data bus

reserved

12

Red

+12V of power supply

reserved

13

Gray/black

Programmable output (-)

50 mA

14

Gray/blue

Programmable output (-)

50 mA

15

Gray/green

Programmable output (-)

50 mA

16

Gray/yellow

Programmable output (-)

50 mA

17

Orange/white

Programmable input (+)

1.5 mA

18

Orange/green

Programmable input (-)

1.5 mA

Table of contents

Other TEC Electronics Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Paravan

Paravan Gear Control operating instructions

Over Armour Offroad

Over Armour Offroad CA-MAVERICKX3-4-TC01 Instructions for Installation and Care

PNEUMATIC

PNEUMATIC KU-RE-LO00-02 Installation instruction

Phonocar

Phonocar 5/988 instruction manual

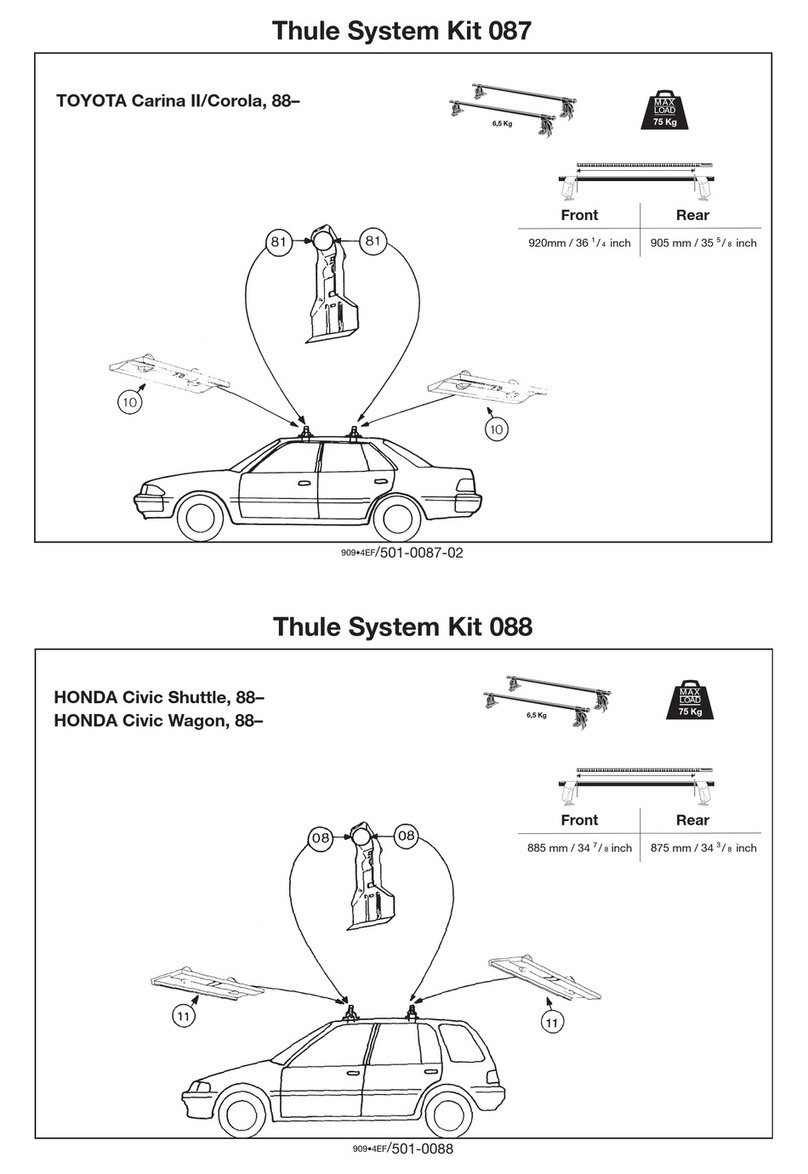

Thule

Thule 1376 instructions

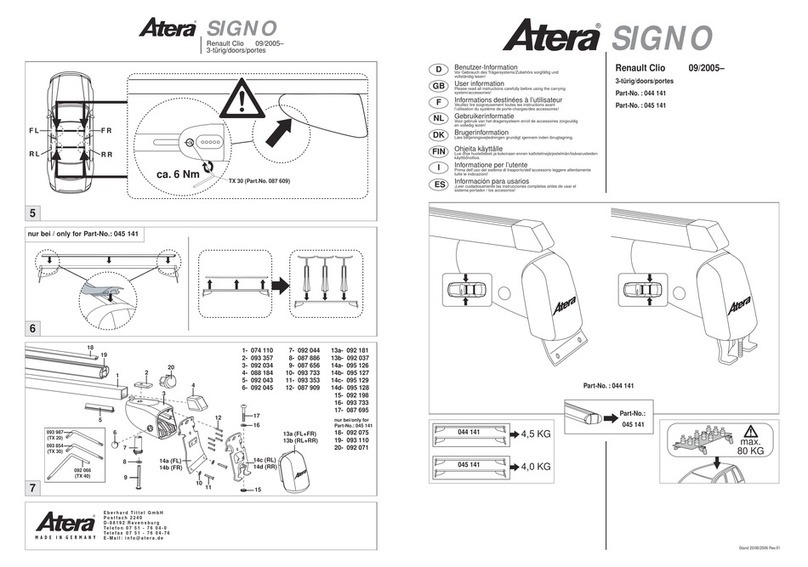

Atera

Atera SIGNO 044 141 User information

Paxton Automotive

Paxton Automotive Novi Supercharger 1200 Owner's installation guide

Thule

Thule 1172 RAPID SYSTEM Fitting instructions

EOinnovations

EOinnovations EOC3103 instruction manual

UNAVi

UNAVi F1 installation guide

Westfalia

Westfalia F-2010-2B instruction manual

Thule

Thule 87 Mounting & installation