TECALEMIT HDA eco User manual

Operating manual

HDA eco

Fluid Inventory Control System

Item No.: 816700001, 81670000 , 816700004

Translation oft he original

operating manual

2 44 1670 001-GB-I HDA eco

Important!

The operating manual is always to be read before commissioning the equipment.

No warranty claim will be granted for faults and damage to the equipment arising

from insufficient knowledge of the operating manual.

Copyright

© HORN GmbH & Co. KG. All rights reserved.

Text, graphics and layout copyright protected. Reproduction and copying, including in

part, only permitted with written permission. Technical changes reserved.

Service Hotline +49 1805 900 301

(0,14 €/ in: on the German landline network, obile telephone max. 0,42 €/ in.)

service@tecalemit.de

Document No.: 44 1670 001-GB-I

Translation of document-no.: 44 1670 001-DE-I

As of: 1 .06.2021

44 1670 001-GB-I HDA eco 3

Content

1 Safety instructions ............................................................................................................ 6

2 Technical description ........................................................................................................ 8

2.1 Intended use ........................................................................................................................ 8

2.2 Description ........................................................................................................................... 8

2.3 Versions ................................................................................................................................ 8

2.4 Technical Data ..................................................................................................................... 9

2.5 Interfaces of the HDA eco ................................................................................................ 9

2.5.1 Interface flow meter ........................................................................................ 9

2.5.2 Interface level control ................................................................................... 11

2.5.3 Interface nozzle switch ................................................................................. 12

2.5.4 Interface pump motor ................................................................................... 13

2.6 Accessories ........................................................................................................................ 14

2.6.1 Software connection ...................................................................................... 15

2.6.1.1 mytecalemit Cloud............................................................................... 15

3 Assembly Instructions .................................................................................................... 16

3.1 Electric connection........................................................................................................... 16

3.1.1 Notes concerning electrical connection .................................................... 20

3.1.1.1 Relay Contact ........................................................................................ 20

3.1.1.2 Emergency mode switch .................................................................... 20

3.1.1.3 Battery Exchange ................................................................................ 21

3.1.1.4 Socket odem ...................................................................................... 21

3.1.1.5 Float Switch .......................................................................................... 21

3.1.1.6 Cable Shielding ..................................................................................... 21

3.1.2 Installation of the float switch .................................................................... 21

3.1.3 Installation of the level probe (Optional) ................................................. 21

3.1.4 Retrofitting the level probe interface ....................................................... 23

3.1.5 Connection of the RS232 / RS422 interface ............................................ 23

3.1.5.1 RS232-connection ............................................................................... 23

3.1.5.2 Printer connection ............................................................................... 24

3.1.5.3 RS422-Connection ............................................................................... 25

3.1.5.4 LAN Connection .................................................................................... 25

3.1.5.5 WLAN connection ................................................................................ 26

3.1.5.6 C R-connection ................................................................................... 27

3.1.5.7 Retrofitting the Data Interface ......................................................... 27

3.2 Calibration of the measuring system .......................................................................... 28

4 First steps – HDA eco...................................................................................................... 29

5 Operating of the Fluid Inventory Control System HDA eco .................................... 30

5.1 Switching on ...................................................................................................................... 30

5.1.1 Entry of values ................................................................................................ 30

5.2 Refuelling mode ................................................................................................................ 30

5.2.1 Driver identification (optional) ................................................................... 31

5.2.1.1 Vehicle identification (optional) ...................................................... 31

5.2.1.2 Tank content display (optional) ....................................................... 32

5.2.1.3 Software version display................................................................... 32

5.2.2 Dispensing without entering a code (optional) ....................................... 32

5.2.3 Entering the Odometer reading (optional) ............................................... 33

5.2.4 Entering the order number (optional) ....................................................... 33

5.2.5 Refuelling.......................................................................................................... 33

5.2.5.1 Entry of a preselected quantity ....................................................... 33

5.2.6 Refuelling procedure ..................................................................................... 34

4 44 1670 001-GB-I HDA eco

5.2.7 Data retrieval .................................................................................................. 34

5.2.7.1 Data retrieval via USB flash drive .................................................. 35

5.2.7.2 Data retrieval via data cable ............................................................ 35

5.3 anagement operating mode / main menu .............................................................. 36

5.3.1 Refuelling data menu..................................................................................... 36

5.3.1.1 Show Refuellings ................................................................................. 37

5.3.1.2 Print Refuellings (Option ‚Printer‘) .................................................. 37

5.3.1.3 Reset Refuellings ................................................................................. 38

5.3.1.4 No. of Refuellings ................................................................................ 38

5.3.1.5 USB Report – Refuellings ................................................................... 39

5.3.2 Total Data enu .............................................................................................. 40

5.3.2.1 Display Totals ....................................................................................... 40

5.3.2.2 Reset Totals ........................................................................................... 40

5.3.2.3 USB Report – Totals............................................................................. 41

5.3.3 Ident Codes menu ........................................................................................... 41

5.3.3.1 Code ........................................................................................................ 42

5.3.3.1.1 PIN ....................................................................................... 42

5.3.3.1.2 Refuelling Limit ................................................................ 42

5.3.3.1.3 aximum Refuelling Time ............................................. 42

5.3.3.1.4 Odometer or Operating hours Request ...................... 42

5.3.3.1.5 Odometer or Operating hours Range .......................... 43

5.3.3.1.6 Odometer or Operating Hours Status ......................... 43

5.3.3.1.7 Lock / Release ID .............................................................. 43

5.3.3.1.8 Quota dispense quantity ................................................ 43

5.3.3.1.9 Quota time frame ............................................................. 43

5.3.3.2 aster ID ............................................................................................... 44

5.3.3.3 USB Report – IDs .................................................................................. 45

5.3.3.4 Web Update (optional) ....................................................................... 46

5.3.4 enu System ................................................................................................... 46

5.3.4.1 enu Refuelling Options ................................................................... 46

5.3.4.1.1 Identification ..................................................................... 47

5.3.4.1.2 Odometer y/n.................................................................... 47

5.3.4.1.3 Previous Odometer y/n .................................................. 47

5.3.4.1.4 Order y/n ........................................................................... 48

5.3.4.1.5 Nozzle switch y/n ............................................................ 48

5.3.4.1.6 Refuelling limit ................................................................. 48

5.3.4.1.7 ax. Refuelling time ....................................................... 48

5.3.4.1.8 Time Out Refuelling ......................................................... 48

5.3.4.1.9 Receipt (Option ‚Printer‘)................................................ 49

5.3.4.2 enu Dispensing Point ...................................................................... 49

5.3.4.2.1 Product number................................................................ 49

5.3.4.2.2 Pulses / Litres ................................................................... 49

5.3.4.2.3 Post Decimals .................................................................... 50

5.3.4.2.4 Automat Lock .................................................................... 50

5.3.4.2.5 Device Address ................................................................. 50

5.3.4.2.6 ax Zero Refuellings ...................................................... 50

5.3.4.3 enu Extended .................................................................................... 51

5.3.4.3.1 enu Date / Time ............................................................ 51

5.3.4.3.2 Contrast LCD ...................................................................... 52

5.3.4.3.3 Language ............................................................................ 52

5.3.4.3.4 Language from USB flash drive .................................... 52

5.3.4.3.5 Initialisation / Restoring Factory Settings ................. 53

44 1670 001-GB-I HDA eco 5

5.3.4.3.6 Info Configuration ............................................................ 53

5.3.4.3.7 Activation........................................................................... 53

5.3.4.3.8 Communication PIN ......................................................... 53

5.3.4.3.9 USB PIN............................................................................... 54

5.3.4.3.10 enu Interface for LAN socket modem option ........ 54

5.3.4.3.11 enu Interface for WiFi socket modem option ....... 59

5.3.4.3.12 enu Interface for C R socket modem option ........ 64

5.3.4.4 Transponder ID..................................................................................... 69

5.3.5 enu Fuel Tank ............................................................................................... 69

5.3.5.1 Stock Control......................................................................................... 70

5.3.5.2 Tank Parameter enu (Option Level Probe) ................................ 70

5.3.5.2.1 Form / Tank Shape........................................................... 70

5.3.5.2.2 ax. Volume / aximum Tank Volume...................... 70

5.3.5.2.3 Height / aximum Filling Height ................................. 71

5.3.5.2.4 Density edium ............................................................... 71

5.3.5.2.5 Sensor Type ....................................................................... 71

5.3.5.2.6 Offset Sensor..................................................................... 71

5.3.5.2.7 in. Volume / Cut Off Volume ...................................... 71

5.3.5.2.8 Zero Point Compensation Sensor ................................. 72

5.3.5.3 Tank Level (Level Probe Option) ..................................................... 72

6 Spare parts ....................................................................................................................... 73

6.1 Exchange of the buffer battery .................................................................................... 74

6.2 Type Plate and Warning Signs ...................................................................................... 74

7 Trouble shooting What to do, if…? ............................................................................... 75

8 Disposal ............................................................................................................................. 79

8.1 Return of batteries........................................................................................................... 79

Annex A. enu Structure anagement Operation ........................................... 80

Annex B. Functional Principle hdmanager.net .................................................. 83

Annex C. Functional Principle mytecalemit Cloud ............................................ 84

Annex D. Data export or Import via USB-flash-drive ...................................... 85

6 44 1670 001-GB-I HDA eco

1 Safety instructions

This device was manufactured taking into account the relevant laws and directives for ensuring

security as well as the protection of the environment and health. Despite this, its use may result

in hazards for persons and material assets. Hence, it is essential that the instructions in this

manual are complied with.

Warning notices and symbols

In this operating manual, the following symbols are used to point out especially important in-

formation:

Specific details on the economic use of the device.

Specific details and or instructions for damage prevention.

Details and or instructions for preventing injury to persons or extensive material dam-

ages

Intended use

Use the device only when it is in perfect working condition and only for its intended purpose

while observing all safety precautions and risks. In particular, all malfunctions that could pose

a safety hazard are to be corrected immediately.

The device and its components are intended for use exclusively with the liquids listed and only

for the purpose described. Any other use or additional manner of usage is not intended.

Organizational measures

This operating manual is to be kept within easy reach at the place of operation. The nameplate

and the warning labels on the device must be observed and kept completely legible at all times.

Qualified personnel

The personnel for installation, commissioning, operation, and maintenance of the device must

possess the relevant and adequate qualifications for these tasks. The operator must ensure that

the contents of this manual are fully understood and implemented by the personnel.

Maintenance and repairs

Do not make any changes, extensions and/or modifications to the device without the manufac-

turer's permission. Replacement parts must conform to the technical specifications defined by

the manufacturer. For original parts, this conformity is always guaranteed.

Hazardous substances

In exceptional cases, the components of this device may contain hazardous substances. In ac-

cordance with the requirements of the European REACH regulation, we provide current infor-

mation on this on our homepage, in the download section.

Observe all safety regulations for the respective product when handling oils, greases, fuels and

other chemical substances!

Water protection

The device has been constructed for use with water contaminants. It is to be operated such that

bodies of water cannot be polluted by it. All applicable regulations at the place of operation are

to be complied with!

Hydraulics

Only personnel with special knowledge of and experience in hydraulics are allowed to perform

work of any type on hydraulic equipment. Depressurize the device before performing any work

on it. All pressure-bearing components are to be inspected regularly for leaks and damage.

44 1670 001-GB-I HDA eco 7

Electrical energy

Work on electrical equipment is only to be performed by qualified electricians. De-energize the

machine and system components before performing any work on the device.

The insulation on all live parts is to be inspected regularly for damage.

8 44 1670 001-GB-I HDA eco

2 Technical description

2.1 Intended use

The HDA eco is designed as a Fluid Inventory Control System for use in industry,

workshops, filling stations and similar facilities.

It is intended for the control of dispensing during the refuelling of vehicles with liquid

and pumpable operating media.

The installation and operation of the Wonder Box in explosion hazardous areas is

not permitted. This would constitute a risk of explosion!

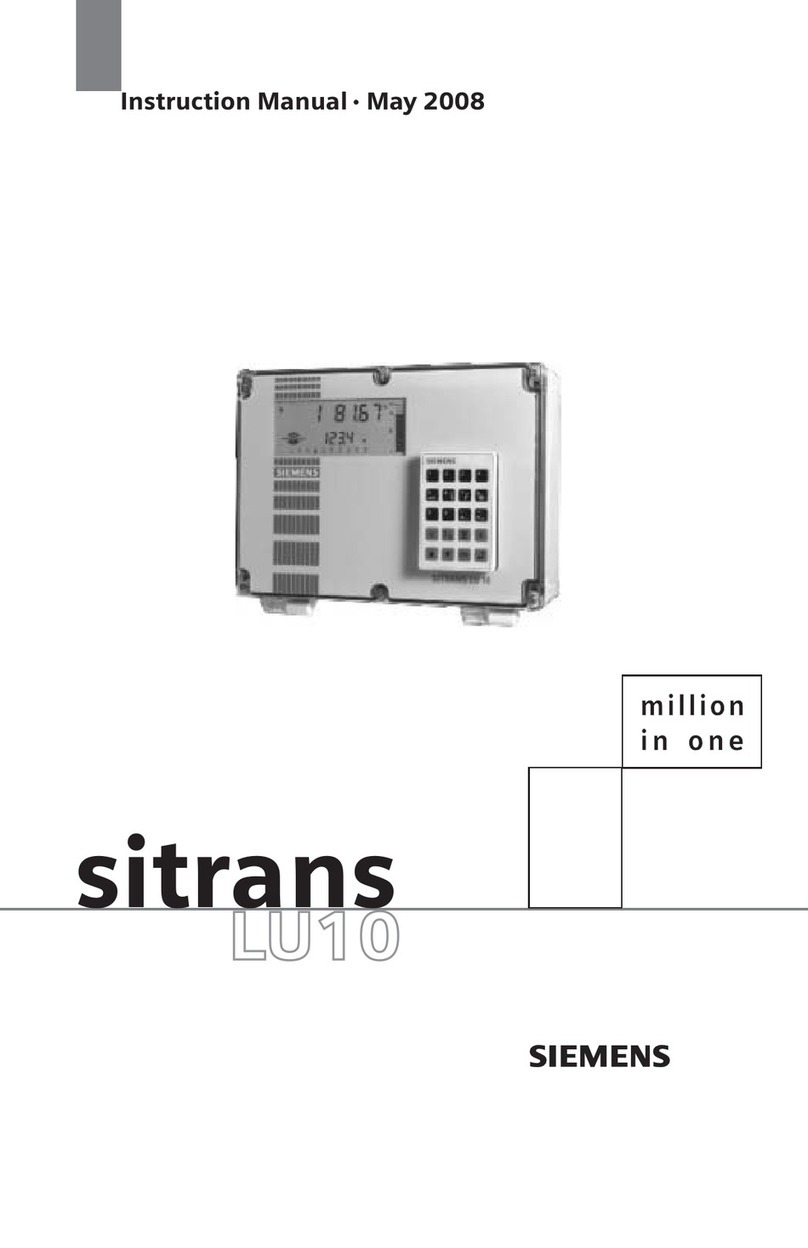

2.2 Description

The HDA eco fluid inventory control system is designed for controlling and recording

the filling of small and medium sized fleets of vehicles at petrol stations or in the

yards of vehicle pools. It is however also used in connection with other meters in the

field of workshops and industrial enterprises. Up to 2,000 drivers and up to 2,000 ve-

hicles can be administered.

A delivery transaction is initiated once the operator's authorization to fill has been

checked. The identification of the operator can take place by entering a code or via a

transponder. In addition, other optional requests can be set up: Driver, vehicle, mile-

age, order number and pre-selection quantity.

The HDA eco receives pulses from a sensor which are proportion to the volume, cal-

culates the dispensed volume via the stored pulse value and displays these two meas-

urements on a two line text display. The measured data are stored in a non-volatile

data storage unit with the time stamp of the battery-buffered real time clock. Via var-

ious interfaces (e.g. RS2 2, RS422, USB, LAN, WLAN), it is possible to transfer the

measured data for further processing on a PC.

With the help of a fill level switch or a fill level probe, the HDA eco can monitor a

tank in such a way so that if a specified fill level is not reached, the extraction point

is blocked (protection against idle running). When using a fill level probe, the current

fill level can be displayed.

2.3 Versions

Item No.: 816700001 HDA eco

Item No.: 81670000 HDA eco / Version USA

Item No.: 816700004 HDA eco / Cyrillic Display

44 1670 001-GB-I HDA eco 9

2.4 Technical Data

Dimensions (WxHxD) Ca. 190 x 230 x 8 mm

Nominal voltage 100 ... 240 V / 0 ... 60 Hz

Ambient temperature -20°C bis + °C

Protection class IP 4

Maximum switching current 10 A

Weight Ca. 1 kg

No. of dispensing points 1

Maximum pulse frequency flow meter 240 Hz

Maximum failure elevation of the used

measuring equipment

Flow meter Ca. 0,1%

Level sensor Ca. 1%

2.5 Interfaces of the HDA eco

2.5.1 Interface flow meter

Take care that the used combination of flow meter and pump fits to the HDA eco.

The HDA eco can only work with a maximum pulse frequency of 240 Hz.

To find out that the used equipment fits to the HDA eco please recheck the equipment

with the following formulas:

Calculation of the pump for a given flow meter:

Maximum flow rate of the pump = 14400

Pulse value of the flow meter l

min

The used value for the pulse rate needs the unit [pulse/l] for the calculation.

Calculation of the flow meter for a given pump:

Maximum pulse value of the flow meter = 14400

Maximum flow rate of the pump pulse

l

The value for the flow rate needs the unit [pulse/l] for the calculation.

Calculation example to check the pump for a given flow meter:

Pulse rate of the flow meter: 5 ,95 pulse/l (FMOG100)

Maximum flow rate = 14400

Pulse rate =14400

53.95 = 2 .9 l

min

10 44 1670 001-GB-I HDA eco

Calculation example to check the flow meter for a given pump:

Maximum flow rate of the pump: 64 l/min

Maximum pulse value = 14400

Flow rate =14400

4 = 225 pulse

l

Connection of a flow meter (Typical application):

Explanation

No. Description

1 External flow meter

2 Connection clamp inside HDA eco

3 HDA eco internal

Specification

Parameter min. ma .

Operating voltage 4,9V , V

Supply outputcurrent 0mA

Input voltage -0,20V , V

Treshold level „low“ 1,1V

Treshold level „high“ 3,6 V

Pulse duration, “high” or “low” 1, ms

Input pulse frequency 120Hz

If an external power supply is used for the flow meter, the input voltage of the HDA

eco must not exceed the values shown above. Otherwise, the device will perman-

ently be damaged.

44 1670 001-GB-I HDA eco 11

2.5.2 Interface level control

Connection of a level control:

Use either a level switch (1) or a level gage (2). Never use both parallel.

Explanation

No. Description

1 Level switch (nc)

2 Level gauge 4-20mA

3 Connection clamp inside HDA eco

4 HDA eco internal

Input configured for level gauge

Parameter min. max.

Supply voltage 16V 22V

Input current range 3mA 22mA

Input configured for level switch

Parameter min. max.

Switching voltage 22V

Switching current 4. mA . mA

The input configuration for connection of a level gauge 4 – 20 mA is an option and

must be ordered separately!

12 44 1670 001-GB-I HDA eco

2.5.3 Interface nozzle switch

Typical connection of a nozzle switch:

Explanation

No. Description

1 Nozzle switch

2 Connection clamp inside HDA eco

3 HDA eco internal

Input Nozzle switch

Parameter min. max.

Switching voltage , V

Switching current 1.3 mA

A nozzle switch that is qualified for the low current has to be used, e.g. a reed

switch.

44 1670 001-GB-I HDA eco 13

2.5.4 Interface pump motor

Pump motor circuit diagram

HDA eco circuit board version E HDA eco circuit board version F

Key

No. Description

1 External pump motor

2 Terminal block in HDA eco

3 HDA eco, internal

Relay

Parameters Min. Max.

Switching voltage 2 0 VAC

Rated current 10 A

Note:

If, instead of the pump motor, a contactor is connected, note that in the "off" state of

the pump relay (see above, Rel1) a current of approx. .5mA flows through the RC el-

ement of the spark quenching. In the case of sensitive contactors, it may be the case

that they do not drop out.

This can be remedied by using an RC element (e.g. 100 Ohm + 0.47µF, item no.

450 00550), and/or an additional resistor parallel to the coil of the contactor. A 10

kOhm resistor with a 7W load capacity is sufficient in most cases.

14 44 1670 001-GB-I HDA eco

2.6 Accessories

The following accessories are available for the Wonder Box:

Artikel-Nr. Benennung

233400170

Interface RS422

(Plug-in PCB; please indicate the se-

rial number & year of manufacture

of the dispenser when ordering for

retrofitting)

233400190

Interface RS232

233400032

/ -33 LAN Interface

23340003

WLAN Interface

CMR – Module (cellular mobile radio)

233400038

GPRS – Module

233400042

UMTS – Module

23340004

LTE – Module

233400200

TAG (Key for driver/vehicle identifica-

tion)

233400081

USB TAG reader

23340016

Float switch

233400160

Interface level probe

(When ordering for retrofitting in-

clude the serial number and year of

manufacture)

233400470

Activation code fee (activation by telephone when retro-

fitting the level probe)

224010000

Level probe 200 mbar (tank height max. 3m; cable length

m)

224020000

Level probe 300 mbar (tank height max. 3m; cable length

m)

2240 0000

Level probe 00 mbar (tank height max. m; cable length

7m)

224061000

Terminal box with pressure

compensaton filter

(for extending the cables of the level

probes)

The right choice of the additional components like pumps or flow meters depends of

the medium and the place of usage. For this please contact the HORN TECALEMIT Ser-

vice.

Service Hotline +49 1805 900 301

or

service@tecalemit.de

44 1670 001-GB-I HDA eco 15

2.6.1 Software connection

Manage your tank data conveniently on the PC or tablet.

2.6.1.1 mytecalemit Cloud

Use our mytecalemit Cloud for managing your tank data.

Safe, reliable, easy, intuitive and flexible. Start immediately at

www.mytecalemit.com. Got questions? We’re happy to advise you.

For a graphical representation of the options offered by mytecalemit Cloud, please re-

fer to Annex C.

Artikel-Nr. Beschreibung

227000000

mytecalemit Cloud

Base module petrol station

227000100 Reporting and service module

227000200 Level module

227000300 Full-Service Package

227001100 mytecalemit Data module SIM card M2M petrol station

2277020 0 mytecalemit factory-made

software preconfigured

0 Drivers/Vehicles

227702100 100 Drivers/Vehicles

227702 00 00 Drivers/Vehicles

227702800 Software commissioning and instruction

227702900 Software commissioning and instruction on-site

16 44 1670 001-GB-I HDA eco

3 Assembly Instructions

The electronics of the HDA eco are installed in a plastic housing with a removable

housing cover.

Before the wiring work always remove the cover of the housing with the keyboard

film.

The flat ribbon cable is very sensitive and should not be pulled or twisted!

Remove the cover as follows:

Loosen the four lid screws and carefully lift the cover

Pull out the plug of the ribbon cable attached to the keyboard

Carefully disconnect the plug of the transponder antenna and pull it out

Put the cover to the side

Before HDA eco initial operation the optional socket modem has to be checked for

proper fit. A loose socket modem has to be pressed into its socket carefully. If in-

serting a socket modem the right position has to be double checked! Due to a

wrongly installed socket modem damages to the device may occur. In case of doubt

the HORN TECALEMIT Service has to be contacted.

3.1 Electric connection

The HDA eco is operated on 100V … 240V / 50 … 60 Hz. The power consumption is

about 5 W. The maximum switching current is approx. 10 A.

Work on the electrical equipment of the device may only be carried out by a quali-

fied electrician or by trained persons under the guidance and supervision of a qual-

ified electrician according to electro-technical guidelines.

For trouble-free operation, an electrical connection from the distribution box with

residual current circuit breaker must be selected!

44 1670 001-GB-I HDA eco 17

Connection plan, circuit board version E

Lithium battery

Fuse

LEDs operating voltage

}

}

Mains voltage

Pump motor

Serial interface

Connection

RFID antenna

eyboard connection

Emergency mode

switch

LAN interface

18 44 1670 001-GB-I HDA eco

Connection plan, circuit board version F

Emergency

mode switch

LAN interface

Lithium battery

Fuse

LEDs operating voltage

}

Mains voltage

Pump motor /

contactor

Serial inter-

face

Connection

RFID antenna

eyboard connection

Jumper

44 1670 001-GB-I HDA eco 19

Terminals version E

Terminal strip Terminal Signal

X1

L Mains voltage - live

PE Mains voltage - protective earth

N Mains voltage - neutral

Pu Switched phase for motor

2. L and Pu Emergency mode switch

X2

Socket modem serial RS422 RS232

1 GND GND

2 TX- DSR

3 TX+ DTR

4 GND GND

RX- RX

6 RX+ TX

PE Earth terminal

X3

V+ Pulse generator operating voltage

+ .2V

PI Pulse input

GND Pulse generator ground

NS Enabling contact

(potential-free contact)

GND

LS + Sensor (4-20 mA) operating voltage +

or float switch

LS - Sensor (4-20 mA) operating voltage -

or float switch

X4 RFID antenna connection

X Display connection

X6 Keyboard connection

X7 USB port

X8 Not used

X9 Not used

X18 Socket modem LAN RJ 4 plug LAN

Terminals version F

Terminal strip Terminal Signal

X1

L Mains voltage - live

PE Mains voltage - protective earth

N Mains voltage - neutral

NO Switched phase for motor/contactor

when jumper (WJ-COM) is installed

WJ and COM Without a jumper, COM and NO are

potential-free

2. COM and NO Emergency operation switch

X2

Socket modem serial RS422 RS232

1 GND GND

2 TX- DSR

TX+ DTR

4 GND GND

20 44 1670 001-GB-I HDA eco

5 RX- RX

6 RX+ TX

PE Earth terminal

X

UB Pulse generator operating voltage

+ .2V

IG Pulse input

GND Pulse generator ground

ZV Release contact

(Potential-free contact)

GND

LS + Sensor (4–20mA)

Operating voltage +

LS - Sensor

(4–20mA) Operating voltage -

X4 RFID antenna connection

X5 Display connection

X6 Keyboard connection

X7 USB port

X8 Not used

X9 Not used

Switch

Switch No. Position Operation

S1 (DIL-Schalter)

1 On Initialisation

Off Normal operation

2 On Programming

Off Normal operation

LEDs

LED Function Comments

18V 18 V operating voltage present

,2V .2 V operating voltage present

DSR Serial interface signal DSR active Remote station

operational

DTR Serial interface signal DTR active HDA eco operational

RxD Serial interface signal RX active Send data

TxD Serial interface signal TX active Receive data

3.1.1 Notes concerning electrical connection

3.1.1.1 Relay Contact

The relay contact for the pump motor is protected by fuse F1 (10 A slow-blow, 5x20.

3.1.1.2 Emergency mode switch

The emergency mode switch bridges the relay contact for controlling the pump, e.g. in

the case of a defective customer activated terminal. In emergency operation mode, no

filling is registered!

This manual suits for next models

3

Table of contents