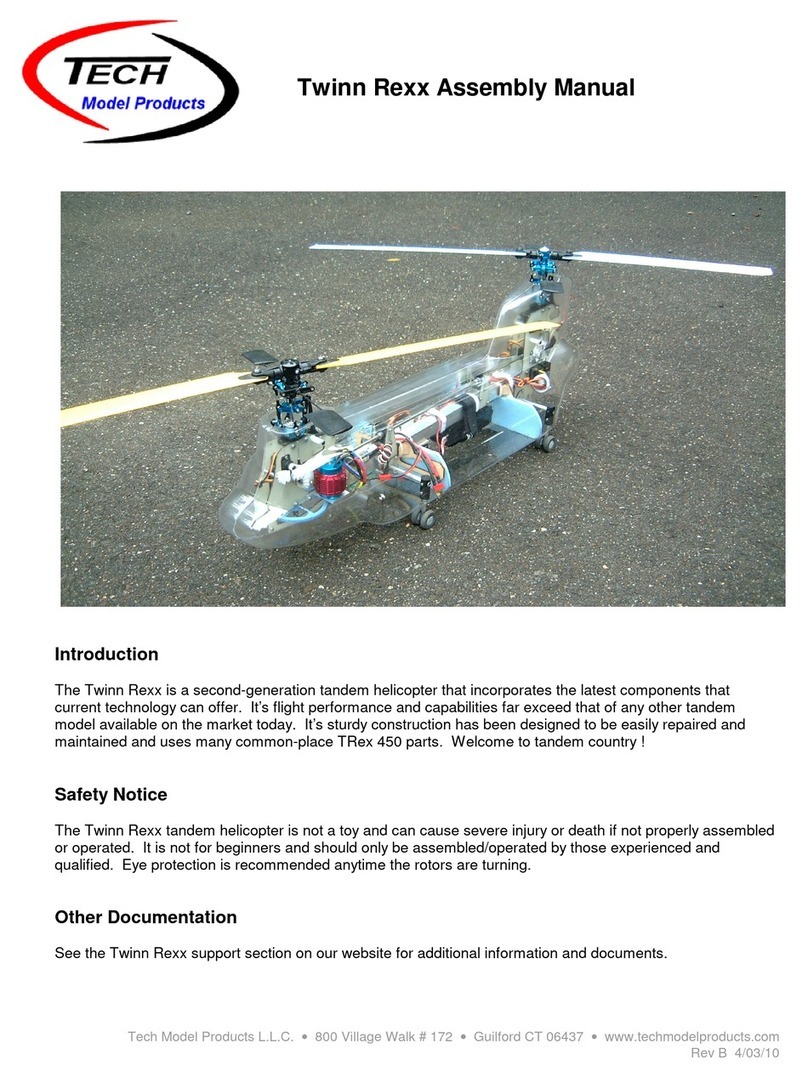

TECH Twinn Rexx CH47 User manual

Tech Model Products L.L.C. •www.techmodelproducts.com •Rev A 5/20/18

Twinn Rexx CH47 Body Assembly Instructions

See this manual online at www.techmodelproducts.com/support.htm

This is a sport scale replica of the famous CH47 Chinook tandem rotor helicopter. It is designed to attach to

the Twinn Rexx frame with only four screws. The body halves can be screwed/taped together or a

combination of both. A cutout or hatch underneath allows access to the battery etc. The body is about

68.5cm (27 inches) and weighs 230 grams (8.2 ounces) unpainted.

Kit Contents: Qty:

Left body panel 1

Right body panel 1

Body to frame mounting hardware 1

Body support kit 1

Tools Required: Materials Required:

Lexan scissors (curved) Acetone (used as glue)

Drill with #34 bit (0.11") & 2mm bit (0.078") 5 minute epoxy

Rotary tool - carbide cutter, sanding drums Wood glue/White glue (optional)

Hobby knife #11 blade Tape

Paper punch Thin CA

2mm tap and drill set (0.062" drill bit) M2x6 button head screws

Sanding block 220 grit

Tech Model Products L.L.C. •www.techmodelproducts.com •Rev A 5/20/18

1. Remove the body halves from the formed panels. Using a sharp scissor, cut around the

perimeter of each body panel leaving about 1 cm of excess plastic. With a curved scissor, cut the

remaining plastic away from the body panels. Take your time. Do not under cut - tend towards

removing less material than needed which can later be sanded away easily. See Figure 1.

2. Sand the body edges smooth. Using a sanding block with fine sandpaper (225), gently sand away

any excess plastic from the edges. Using a flat wood block on the inside of the body will help get a

perfect edge. Again, take your time. A rotary tool fitted with a sanding drum will work as well but it is

easy to undercut. Tip - Use a rotary tool with speed control and slow it down.

3. Cut the landing gear holes. Using a rotary tool with a carbide cutter, cut each landing gear hole

out. Use a sanding drum to finish it smooth. Tip - Make the holes a bit larger than marked. A trim

ring can be used later to cover it up. A larger hole will help reduce the possibility of damage in the

event of a crash. . See Figure 2.

4. Cut the tower holes. Using a rotary tool with a carbide cutter, cut each tower hole as marked (or as

desired). Use a sanding drum to finish smooth.

5. Make the plastic washers. Using scrap material, make about a dozen (12) plastic washers by first

drilling holes and then punching out the washer with a paper punch. Use a #34 (0.11") drill bit. See

Figure 3.

6. Drill the body to frame mounting holes. Attach the four (4) Nylon standoffs to the frame with the

4-40 x 3/8 screws. Hold one of the body panels to the frame and verify that the frame mounting

holes line up with the drill marks on the body. Adjust as required and re-mark if needed (or as

desired).

Using a hobby knife with a #11 blade, make a pilot hole on each drill mark by rotating the knife point

on the center of the mark. Drill the holes using a #34 (0.11") drill bit. See Figure 3.

Attach a body panel to the frame using two 4-40 x 3/8 button head screws. Use two (2) plastic

washers inside the body to shim it outward. Note: The rear strut mounts (TW-402) may need to be

trimmed to clear the body (bottom rear section of the strut mounts).

The rear body mounting holes may need to be widened a bit (slotted) to allow adjustments to the

drive shaft.

Now repeat the above steps for the other body panel. Be sure the two body halves line up. The

mounting hole locations may require adjustment and/or more washers may be needed.

7. Attach a plastic washer to each body mounting hole. For strength, attach a plastic washer to

the inside of each body mounting hole using Acetone as a glue. Just center the washer around the

hole and apply a small drop of Acetone so it flows between the washer and body. Too much can eat

away at the body. Practice on scrap first. Allow to cure.

8. Make the body joining tabs. Using scrap material, make about fifteen (15) plastic body joining

tabs. Each tab consists of a rectangular piece 1 cm wide by 2 cm long with two stacked circular

discs glued to it. Glue with Acetone. The circular discs are made with a paper punch. See Figure 4.

Use a hobby knife with a #11 blade and make a pilot hole on the tab. The hole should be centered

on the tab's disc. Drill the holes using a (0.062") drill bit. Tap each tab hole with a 2mm tap.

9. Attach the body joining tabs. Glue the tabs to one side of the body using Acetone or thin CA (CA

is preferred here). Each tab is positioned such that the center of the discs are about 3mm from the

edge of the body. The tabs should be bent and shaped to conform to the body for best results. Use

Figure 4 as a guide for the tab locations. More or less tabs can be used as desired. Also, tape can

be used in some areas instead of tabs. See Figure 5.

Tech Model Products L.L.C. •www.techmodelproducts.com •Rev A 5/20/18

10. Drill the body joining holes. Mount the body halves to the frame with the four 4-40 screws. Verify

that they are in the correct position and butt together properly. Now use tape to join them along the

entire seam so they will stay in position while marking the holes for drilling.

Mark the locations of the holes at each tab. Take your time.

Use a hobby knife with a #11 blade and make a pilot hole on each mark. Drill the holes using a 2mm

drill bit. A slightly larger drill can be used to compensate for misalignment. See Figure 5.

11. Assemble the plastic and CF (or wood) body supports. The wood body parts are assembled as

shown using 5 minute epoxy or wood glue. See Figure 6.

The plastic and CF version is included with the latest kits and replaces the wood parts.

Each bracket gets a CF rod centered through the holes and glued with CA. When cured, coat the

joints with epoxy. The remaining four plates get glued with CA to the end of each rod. The foam

supports attach to the plates with servo tape or epoxy. See Figure 6A.

12. Attach the plastic and CF (or wood) body supports to the frame. Attach the front and rear body

supports to the frame with two (2) plastic cable ties on each. The rear support is taller. See Figures

6B, 7 for the approximate locations.

13. Attach the foam body supports. Cut two each of the front and rear foam supports using the

template provided. They are cut from 1/4" foam board. See Figure 8.

Mount one of the body halves to the frame with two 4-40 screws. Attach the front and rear foam

supports to the plates (or plywood) using epoxy or servo tape. Position the foam supports such that

they touch the inside and bottom surfaces of the body. Repeat the above procedure for the other

body panel.

14. Cut the battery access hole in the bottom of the body. The exact location and size of the access

hole depends on where the battery is mounted. Generally, a 5 cm wide hole by about 15 cm long

hole will be adequate. Determine the best location for the hole and cut it out. Rounded corners are

recommended. See Figure 9.

15. Final mounting to the frame. The body halves are mounted to the frame with four (4) 4-40 screws.

The body halves are attached to each other using M2x6 button head screws. Tip - A very small drop

of thin CA applied to the screw threads, and allowed to dry, will work as a thread locker.

16. Finishing. The body is made of PETG plastic which is compatible with most types of modeling

paints. The surface should be lightly sanded with a 400 grit sandpaper and then sprayed with one or

two light coats of paint. Avoid using primer if possible since it adds weight. Paints like Krylon brand

come in a variety of camouflage colors, are very easy to apply and dry in a few minutes.

17. Engines. See the full scale CH47 drawings on the Twinn Rexx support page. The engines can be

carved from light weight Styrofoam etc. and glued to the body. An engines kit is available on our

web store.

Tech Model Products L.L.C. •www.techmodelproducts.com •Rev A 5/20/18

Figure 1

Figure 2

Tech Model Products L.L.C. •www.techmodelproducts.com •Rev A 5/20/18

Figure 3

Figure 4

Figure 5

Figure 6

2 cm

1cm

3mm

Tech Model Products L.L.C. •www.techmodelproducts.com •Rev A 5/20/18

Figure 6A

Figure 6B

Tech Model Products L.L.C. •www.techmodelproducts.com •Rev A 5/20/18

Figure 7

Figure 8

Figure 9

Table of contents

Other TECH Toy manuals

Popular Toy manuals by other brands

Fisher-Price

Fisher-Price CFM96 instruction sheet

LEGO

LEGO DC Comics Super Heroes 76085 Assembly instructions

Kettler

Kettler 8881?900 Assembly instructions

MTHTrains

MTHTrains RailKing RealTrax manual

Faller

Faller OLD-TOWN TOWER WITH WALL 232171 Assembly instructions

Parkside

Parkside PP 1500 A1 Operation and safety notes