INTRODUCTION ...................................................2

NOTES AND ADVICE............................................6

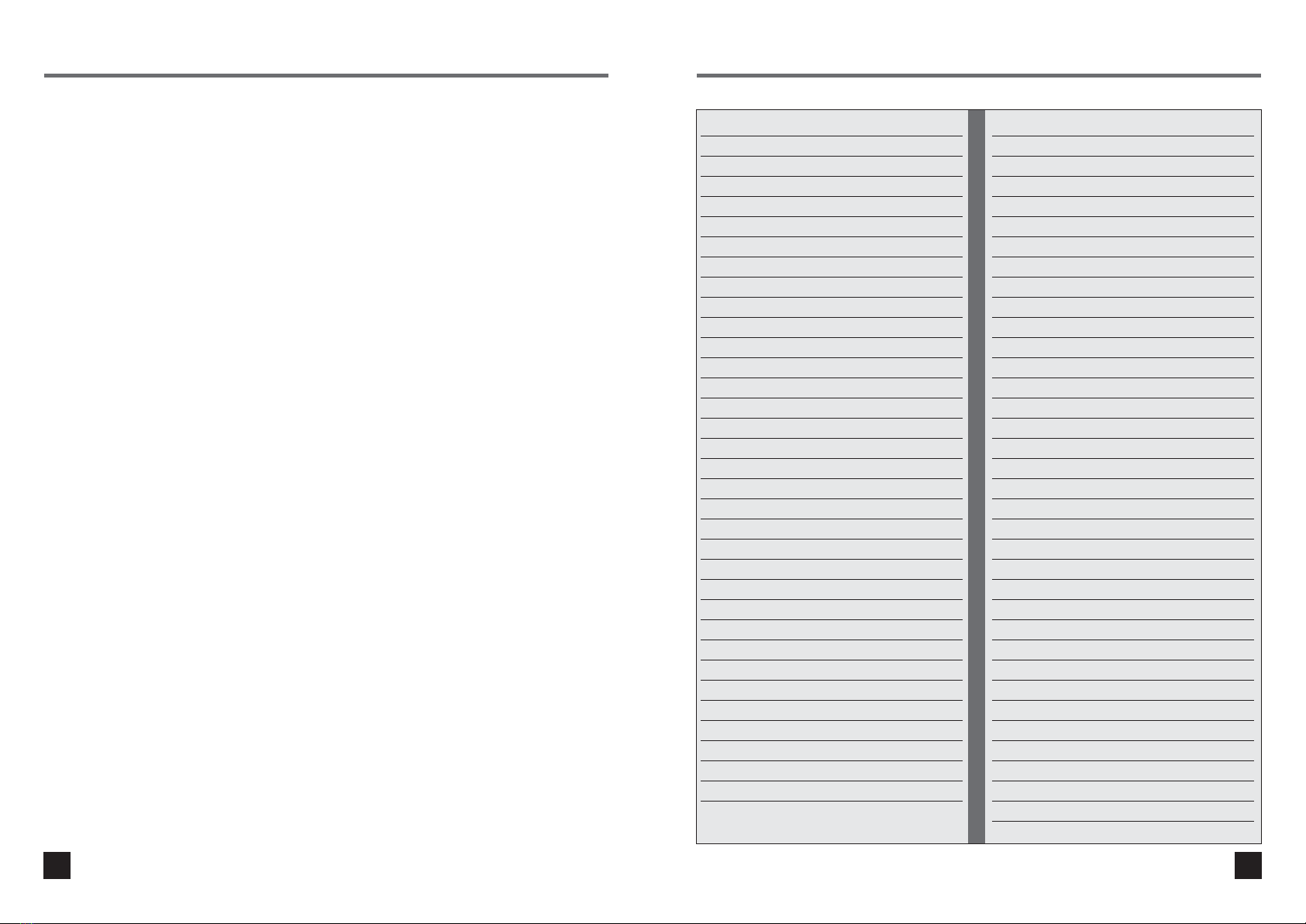

PARTS LIST .........................................................7

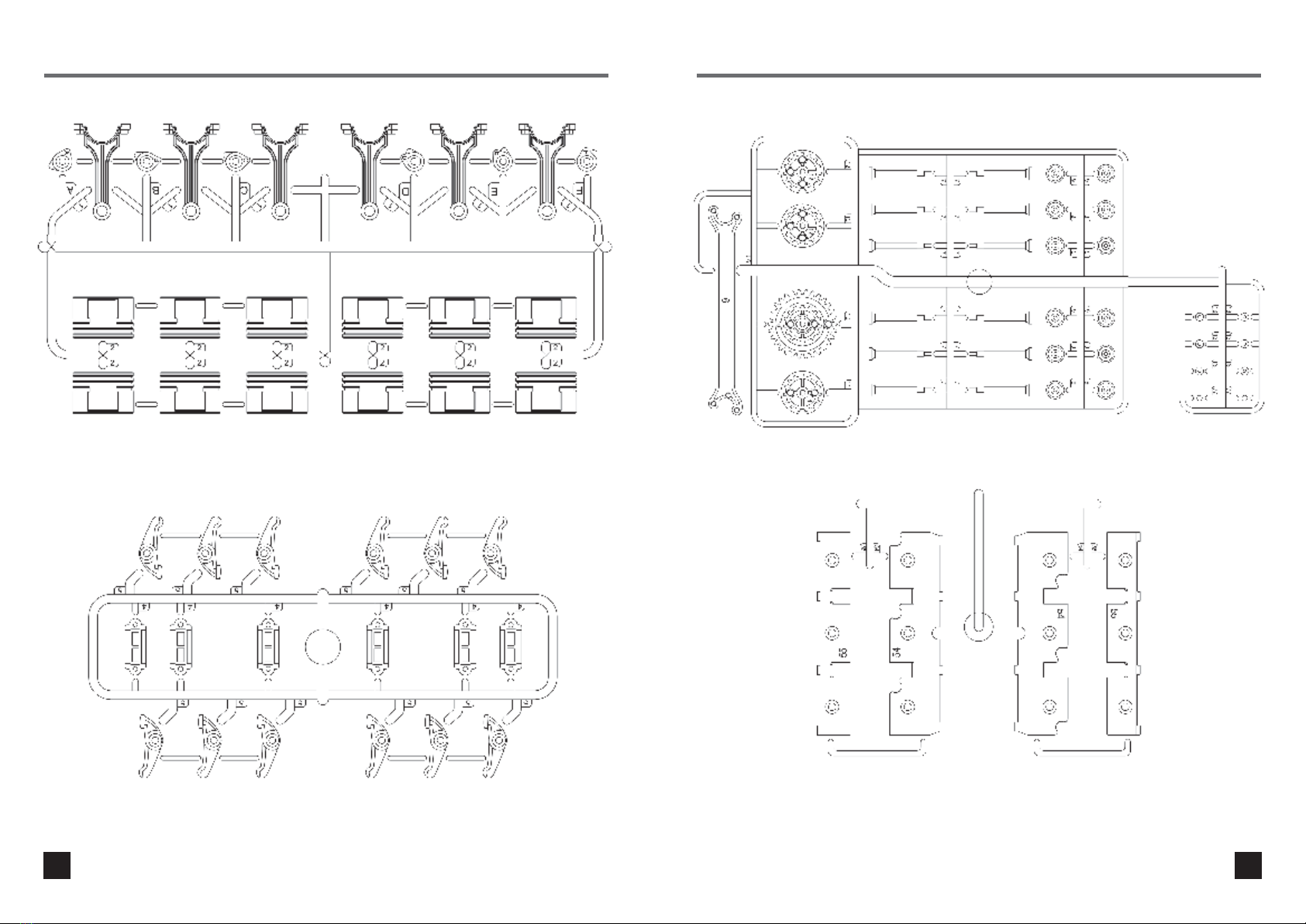

ASSEMBLING THE ENGINE...............................15

Step 1. Pistons.....................................................15

Step 2. Crankshaft................................................15

Step 3. Crankshaft drive gear................................15

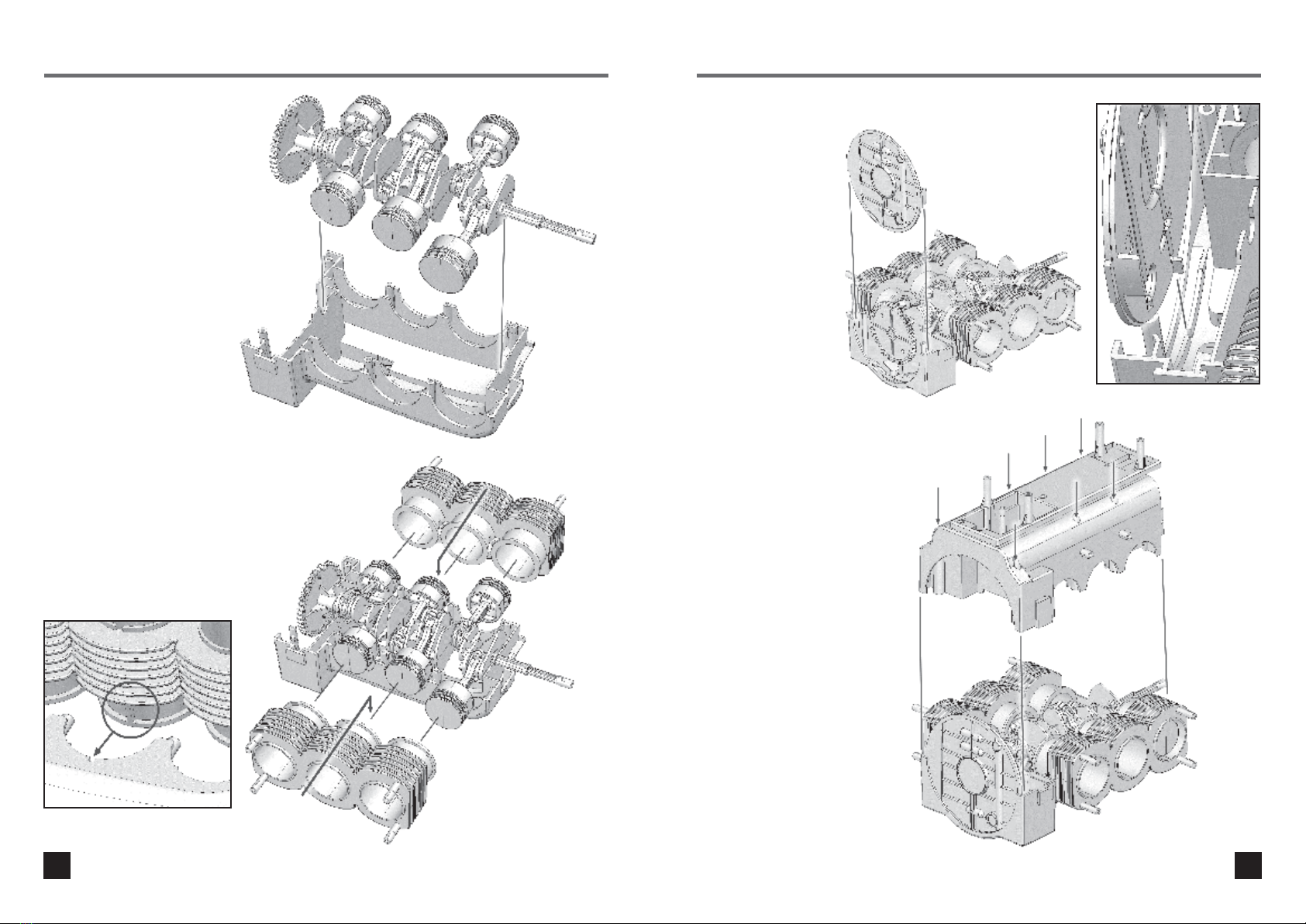

Step 4. Crankshaft assembly ................................16

Step 5. Cylinder barrels........................................16

Step 6. Crankcase rear .........................................17

Step 7. Crankcase assembly.................................17

Step 8. Valve guides ............................................18

Step 9. Valve assembly........................................18

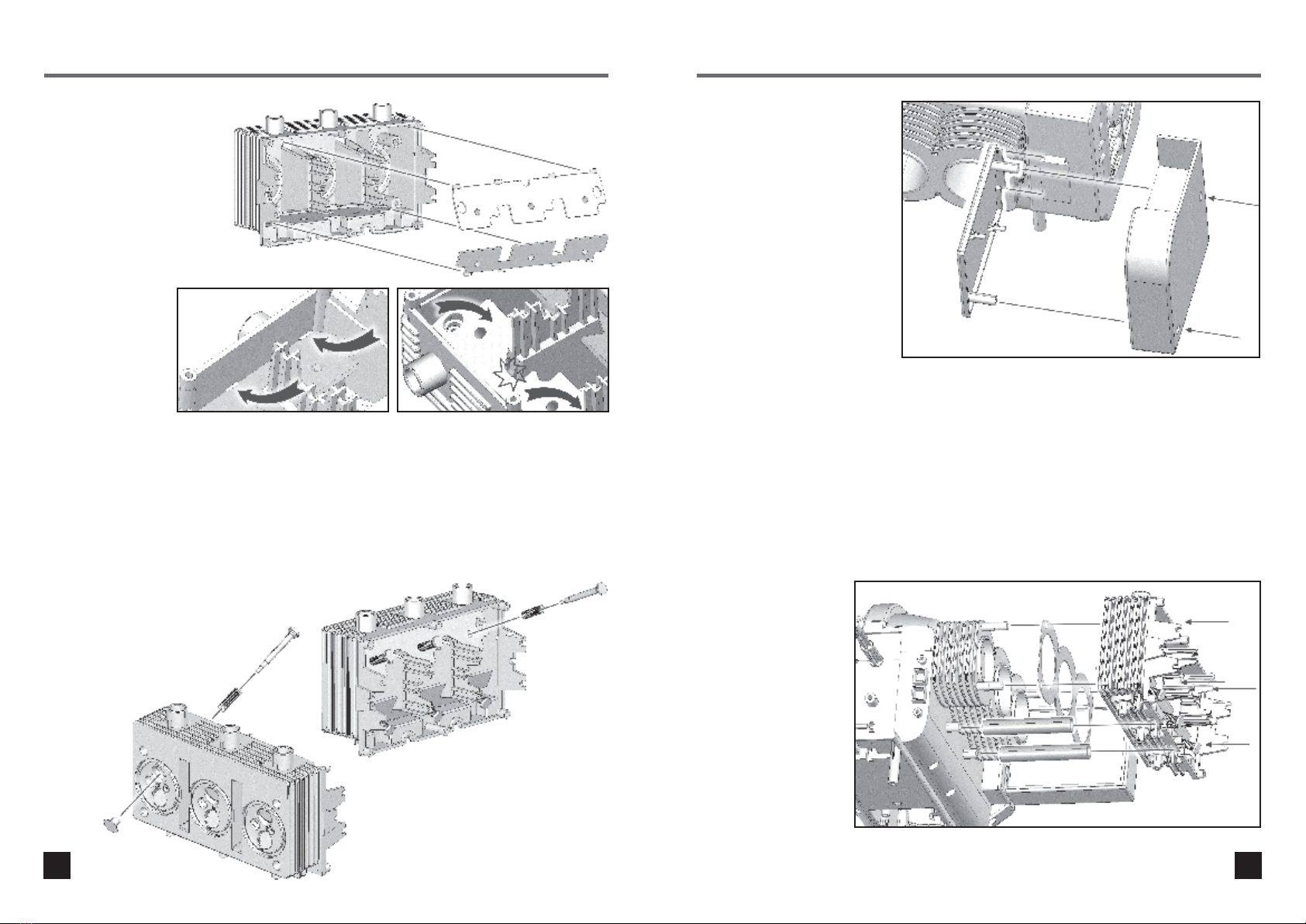

Step 10. Oil cooler...............................................19

Step 11. Cylinder head – right side ......................19

Step 12. Camshaft tunnel – right rear ...................20

Step 13. Cam and rocker shafts – right side .........20

Step 14. Camshaft assembly – right side..............21

Step 15. Rocker shaft assembly – right side .........22

Step 16. Cylinder head – left side ........................23

Step 17. Timing pin .............................................24

Step 18. Crankshaft sprocket................................24

Step 19. Valve timing tool ....................................25

Step 20. Cam belt – left side................................25

Step 21. Cam belt cover – left side ......................26

Step 22. Distributor drive gears............................26

Step 23. Cam drive sprocket – right side..............27

Step 24. Cam belt – right side..............................27

Step 25. Cam belt cover – right side ....................28

Step 26. Distributor..............................................28

Step 27. Engine front ...........................................29

Step 28 Crankshaft pulley wheel...........................29

Step 29. Drive motor............................................30

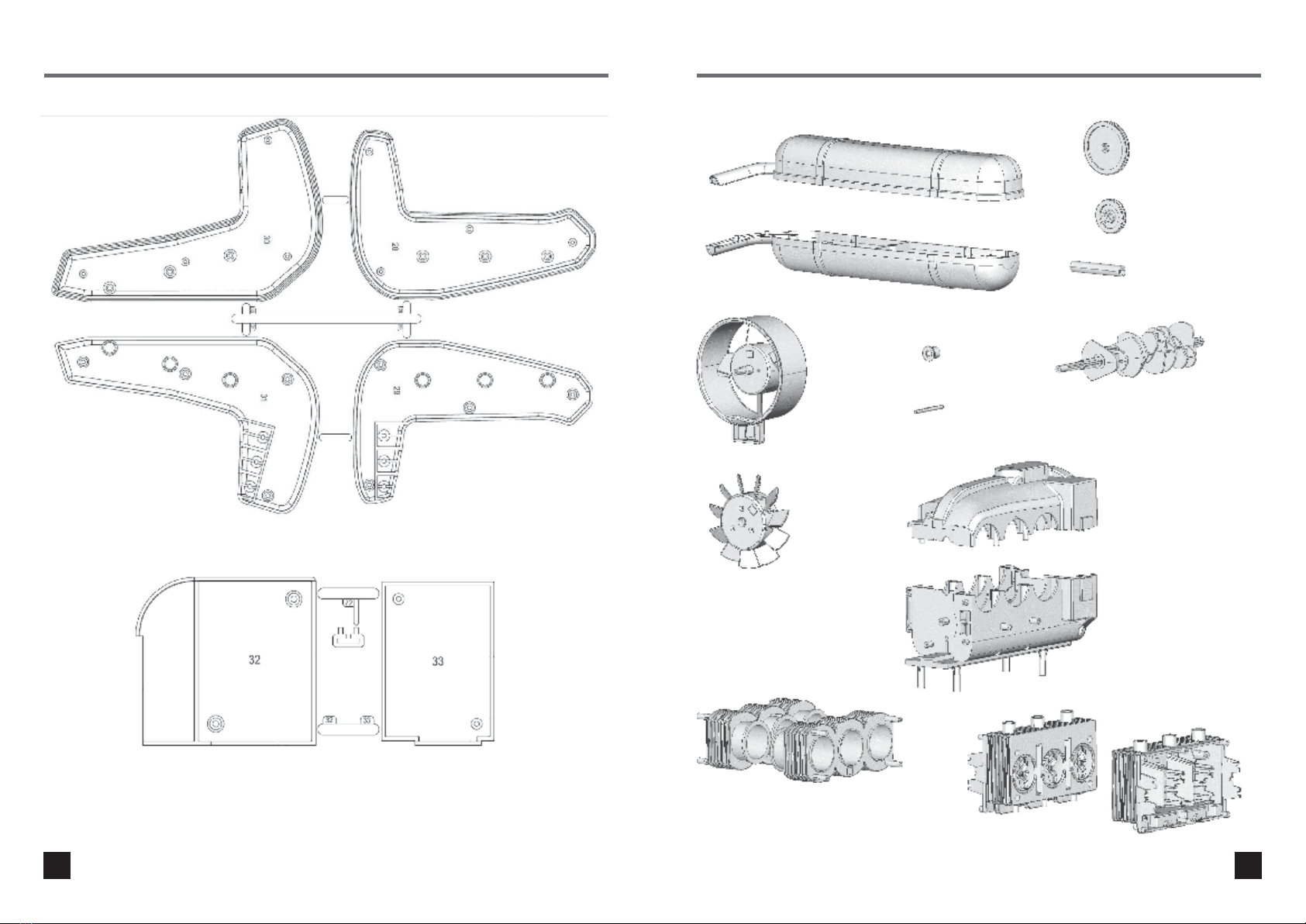

Step 30. Cylinder head covers..............................30

Step 31. Exhaust manifolds ..................................31

Step 32. Exhaust pipes.........................................31

Step 33. Exhaust muffler ......................................32

Step 34. Base - battery installation .......................34

Step 35. Base label..............................................35

Step 36. Base ......................................................36

Step 37. Cooling fan assembly.............................34

Step 38. Cooling fan installation...........................34

Step 39. Spark plugs............................................35

Step 40. Carburettors...........................................36

Step 41. Operation...............................................36

HOW AN ENGINE WORKS.................................37

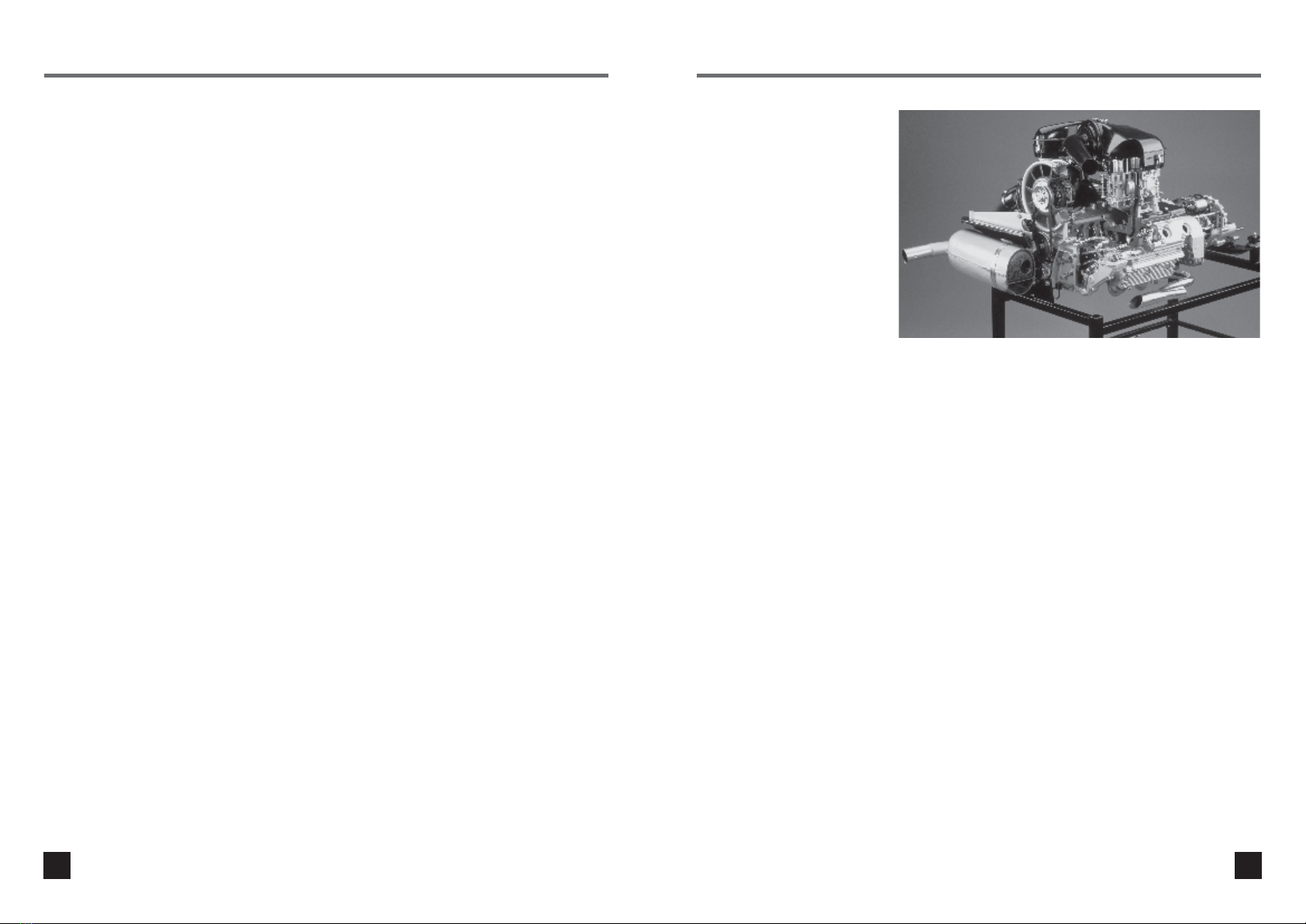

PE01 Porsche Flat-Six Boxer Engine

© Franzis

All rights reserved. No part of this

publication may be reproduced, stored in a

retrieval system or transmitted, in any form

or by any means, electronic, mechanical,

photocopying, recording or otherwise,

without prior permission in writing from the

publisher.

Printed in China

Please retain the information in

this manual for future reference.

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions:

(1) this device may not cause harmful interference

(2) this device must accept any interference received,

including interference that may cause undesired operation.

Caution: Changes or modifications not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

32

Flat-Six Boxer Engine

Build your own working, classic Porsche 911 flat-six engine model!

Contents

PORSCHE 911