Techkon SpectroDrive User manual

Manual

Scan-Measurement-System

SpectroDrive

Software

ExPresso 4

TECHKON manuals, technical documentation and programs are

copyrighted. Reproduction, translation or transfer to an electronic

medium – in whole or in parts – is prohibited.

TECHKON software is the intellectual property of TECHKON GmbH.

Purchase of the software grants the user a license for the use on one

computer only. Programs may only be copied for back-up purposes.

TECHKON can not be held liable for any damages that may occur by

the use of the software.

The TECHKON team takes great care in producing this manual. Nev-

ertheless, we can not fully guarantee the complete absence of errors.

TECHKON GmbH and the authors can not be held liable neither for

any possibly incorrect statements nor their consequences. TECHKON

can not be held liable for any damages that may occur by the use of

the software.

Products that are not made by TECHKON GmbH are mentioned for

information purposes only and such statements do not represent

trademark infringement. All registered trademarks are recognized.

TECHKON products and product names are registered internationally

under several intellectual patents and trademarks.

Specications can be subject to change without notice.

Version 3.4, January 2021

You can reach us at the following address:

TECHKON GmbH

Wiesbadener Str. 27 • D-61462 Königstein

T +49 (0) 6174/92 44 50 • F +49 (0) 6174/92 44 99

info@techkon.com • www.techkon.com

Welcome

We welcome you among the worldwide community of users of TECHKON products.

We are happy that you have selected this high-quality measurement instrument. It will

be a valuable tool for your day-to-day quality control tasks. With this manual we invite

you to learn how to use SpectroDrive, the software ExPresso 4 and SpectroConnect.

The manual is divided into four chapters:

CHAPTER 1: General description of the measurement system

CHAPTER 2: Installation of SpectroDrive and the software ExPresso 4

CHAPTER 3: How to use SpectroDrive and the software ExPresso 4

CHAPTER 4: How to use the Windows software SpectroConnect

You will be fascinated how easy the system is to use. You will know how to work with

SpectroDrive after having read this manual for only a few minutes. The second chapter

describes the assembly of SpectroDrive and the installation of the software ExPresso 4.

The third chapter describes the operation of SpectroDrive and gives detailed informa-

tion about the measurement functions.

Please get the device registered by using the registration card, which you will nd in

the appendix of this manual. That way we can keep you updated about product news.

Please visit us as well on the internet at www.techkon.com.

You will nd useful information about the complete product range and new software

versions.

Do you have any suggestions for improvements or do you require information that

goes beyond the contents of this manual? We will be glad to hear from you. Your sug-

gestions or questions make an important contribution to the continuous optimization

of our documentation and products.

Your TECHKON Team

Contents

CHAPTER 1: General description of the measurement system

1.1 Product description ............................................................................................................................5

1.2 Packing list ..............................................................................................................................................10

CHAPTER 2: Installation of SpectroDrive and the software ExPresso 4

2.1 Assembly of SpectroDrive ............................................................................................................11

2.2 Installation of the software ExPresso 4 .................................................................................12

CHAPTER 3: How to use SpectroDrive and the software ExPresso 4

3.1 Operation of SpectroDrive ...........................................................................................................13

3.2 Care and maintenance....................................................................................................................16

3.3 Software overview ExPresso 4....................................................................................................18

3.4 Software settings................................................................................................................................21

3.5 Dening and running a print job..............................................................................................41

CHAPTER 4: How to use the Windows software SpectroConnect

4.1 Software description....................................................................................................................... 64

4.2 Installation.............................................................................................................................................. 64

4.3 Overview / Software module: Compare colors.............................................................. 65

4.4 Software module: SpectroDrive settings........................................................................... 66

4.5 Device update ......................................................................................................................................67

4.6 Software module: Export ............................................................................................................. 68

4.7 Software module: ColorCatcher............................................................................................... 69

4.8 Software module: PhotoLab .......................................................................................................70

4.9 Software module: Media Wedge............................................................................................. 73

4.10 Software module: SpectroCheck .............................................................................................75

APPENDIX:

Technical specications

Manufacturer certicate

EC-Declaration of Conformity

Registration card

5

CHAPTER 1 – General Description

Chapter 1

General description of the measurement system

1.1 Product description

High quality and productivity

The new generation of the proven Scan-Measurement System SpectroDrive com-

bines decisive advantages: Precise measurements thanks to an ISO-compliant

measuring head, technical reliability and high measurement speed. It can be fully

integrated into the printing process. The result: a productivity and quality boost

for your printing press.

The system consists of two components: The motorized measurement device scans

the complete color bar on a printed sheet within seconds and simultaneously sends

the spectral measurement data wirelessly to the PC. Here all relevant information for

controlling the printing press is clearly displayed by the TECHKON ExPresso 4 software.

Increase protability

Due to the trend of smaller print jobs and shorter press runs the time from starting a

press to getting it “in color” and running with consistent quality is cost critical. Spectro-

Drive reduces this “non-productive” and therefore expensive set-up time dramatically.

You will increase protability thanks to substantially reducing paper and ink waste and

getting more precious time out of your printing press. The system makes your printing

jobs predictable and calculable. In addition, the complaint rate will go down signi-

cantly and your customers will appreciate the sensible gain and reliability of the print

quality. ISO-compliant printing becomes easier than ever before.

The high rate of return of investment is amazing. The relative low – and only one

time – investment will show in recurring prots almost immediately. Also older print-

ing presses get a productivity boost thanks to SpectroDrive.

Ease of use and high speed measurement

Setting up a printing press can be compared with starting a jet plane. It is a time-

critical process, where the press operator – like a pilot – must observe and perform

a multitude of important tasks at the same time. Hence, during the development of

SpectroDrive great care was taken in delivering a system that is easy to use and fast, to

make working with SpectroDrive even more intuitive and convenient.

6

Manual TECHKON SpectroDrive

For example, a laser beam can be activated to support the exact positioning of the

print control strip. Furthermore the measurement device has only one button to start

the measurement process. Installation is simple as well. After a few minutes the system

is operable and ready to take measurements.

Due to its aluminum unibody case the new SpectroDrive is particularly robust and

reliable. Of course SpectroDrive is able to handle variable scan lengths and ts to any

printing press format. The battery charging is inductive, fast and sustainable.

Two measurement systems in one

This statement relates not only to the technical fact that the spectral measurements

allow displaying densitometric and colorimetric data. It also points out that Spectro-

Drive can be used as a scanning device as well as a hand-held instrument for single

measurements. Just take the device from the horizontal track and position it wherever

you want to take a color measurement. SpectroDrive now also features an integrated

display that shows the measurement values of spot measurements directly at the de-

vice.

Software ExPresso

The Windows software TECHKON ExPresso 4 has a self-explanatory user interface

which can be operated via touch-screen. The software oers a comprehensive tool

set comprising measurement of spot colors, support of up to 16 print units, front-side

and reverse printing, display of color density, dot gain, gray balance, CIE L*a*b*-values

and recommendations on how to adjust the ink on the press. This is only an extract of

the complete functionality.

Thanks to its modularity TECHKON ExPresso 4 is expandable and versatile. The mea-

surement data can be exported into other software applications that connect real-

time to printing presses to enable a “closed loop” turn-key solution. In addition, the

ExPresso software can export measured data to standard applications such as Micro-

soft Excel™.

7

CHAPTER 1 – General Description

All advantages at a glance

Easy to handle

Fast, motorized scanning by pressing

the green measurement button on

the touch-screen or on the device

itself

Automatic white calibration

Windows-software TECHKON

ExPresso 4 can be operated with or

without the touch-screen

The device can easily be used as

hand-held device for spot measure-

ments as well

Modular and compact

Works with any sheet or press format

Horizontal track can be shipped in

any length up to 206 cm

Space-saving measurement device

ts on any table

The mounting table can be inclined

up to 45°

Delivery contains all components

supplied

Easy to install

Installation is made within ve min-

utes without any major assembly

eort

Complete system is maintenance free

Measurement system can be ipped

180°, if the color bar is on the opposite

side of the printed sheet

Wireless, fast data transmission per

WLAN

No vacuum air suction is necessary to

hold down the printed sheet

Complete measurement information

Any color bar can be measured

(patch size has to match aperture size)

Color bar can be at any location on

the printed sheet

No limitation in paper thickness

Automatic polarizing lter function for

densitometric and colorimetric mea-

surements

8

Manual TECHKON SpectroDrive

Accurate

Precise spectral engine with automa-

tically insertable polarizing lter

Patented measurement head for easy

positioning conforming to ISO 13655

Solid aluminium unibody case for reli-

able function in a harsh industrial

environment

Fast

High resolution spectral measure-

ment of a complete color bar within

seconds (e.g. 500 mm sheet length in

about 3 seconds!)

Wireless data transmission to the PC

during scan in real-time

Information overview displays all rel-

evant parameters for quality control

Using SpectroDrive as a hand-held unit is

simple. Just position the compact mea-

surement head above the sample and

press the green measurement button.

The measurement value is transmitted

instantly to the PC.

TECHKON SpectroDrive is delivered as a

complete turn-key system. Within a few

minutes the system is up and running.

One unique feature of SpectroDrive is its

exibility to be used with any press type

or format.

Formats

52: for printed sheet 00 (B3+, 370 x 520 mm)

74: for printed sheet 0B (B2+, 520 x 740 mm)

102: for printed sheet 3B (B1+, 720 x 1020 mm)

105: for printed sheet 3B+ (B1+, 780 x 1050 mm)

Special formats (up to 2100 mm system length/ 2060 mm scan length) on request

9

CHAPTER 1 – General Description

Dimensions

Performance packages

The scan-measurement device SpectroDrive and the Microsoft Windows software Ex-

Presso form a complete quality control system for increasing productivity and quality

of a printing press. There are two dierent versions available:

SpectroDrive + ExPresso Basic

consists of the spectral measuring

device SpectroDrive and the Microsoft

Windows software ExPresso Basic with

the following functions:

Ink zone specic density display

Color density for CMYK and spot

colors (spectral density)

Densitometric gray balance

Dot gain, dot area, printing contrast

Slur/doubling value

Target values, tolerances, OK-sheet

Front- and reverse-printing

Works with any color bar length

Display of single measurements when

used as a hand-held device

Measurement data export (e.g. JDF-

format)

Statistical analysis, report generator

Supports up to 6 printing units

SpectroDrive + ExPresso Pro

contains the same functions as the Basic

package and additionally:

Ink zone specic colorimetric CIE

L*a*b*and ∆E*a*b* display

∆L*a*b*, CIE L*C*h*, ∆L*C*h*

InkCheck: recommendation for ink

key setting

Display and evaluation according to

ISO 12647 (PSO)

GrayGuide (gray balance) according to

Gracol G7™

OBA-Check

Supports up to 16 printing units

A post-purchase software-upgrade

from the Basic- to the Pro-version can

be done easily.

52: 750 mm, 74: 970 mm,

102: 1250 mm,105: 1280 mm

96 mm

52: 370 mm

74: 530 mm

102: 720 mm

105: 780 mm

170 mm

10

Manual TECHKON SpectroDrive

1.2 Packing list

Contents of delivery

Measurement device SpectroDrive

Left holder incorporating charging console with white standard and

AC adapter with universal plugs

Horizontal track, right holder, two vertical bars

WLAN-module for wireless data transmission, USB cable

Manual with ISO 9000 compliant certicate (pdf on CD),

Manufacturer certicate

Screwdriver, 4 screws

Optional: Data media with Windows software TECHKON ExPresso 4,

USB-dongle (software protection key)

System requirements: for TECHKON software:

Microsoft Windows 10; 64-bit, minimum: IBM-compatible PC with Intel Core Duo

or comparable processor, 4 GB RAM, 2 USB ports; screen resolution for TECHKON

ExPresso: minimum 1280 x 1024 pixel

Optional accessories

Color reference SpectroCheck for checking the measuring accuracy

Print control strips TECHKON TCS, available as EPS- and pdf-les on CD

(can be downloaded free of charge at www.techkon.com)

Software-upgrades from ExPresso Basic to ExPresso Pro

Replacement parts

Left holder with charging console and white standard Horizontal track

AC adapter Rechargeable battery WLAN-module

(All parts are easy to exchange.)

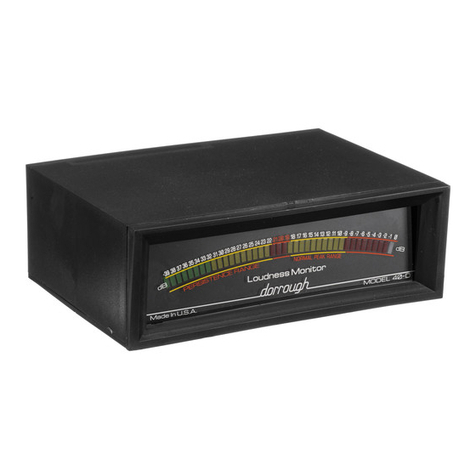

Measurement device SpectroDrive and the supplied

system components

11

CHAPTER 2 – Installation

Connect the horizontal track with the left

and right holder as shown on the images. Be-

fore placing the holders upside down, put a soft

material underneath to avoid scratches. Before

tightening the rst screw, insert the second

screw and assure that the holder is correctly

aligned.

The two vertical bars are attached vertically

at the right and left side on a at table. Before

adhering them, it is important to check that

they are parallel and have the right distance to

each other. We advise to mark the position with

a pencil rst. Now attach the two vertical bars,

which have self-adhesive tape on the backside

to the table or console. Assure, that the verti-

cal bars are parallel and well aligned in order to

hold the left and right holder which will attach

magnetically to the vertical bars. Preferably the

table will have a lay-on edge for positioning the

printed sheet.

Connect the plug of the AC adapter with the

charging console. The AC adapter can be used

universally for 100 – 240 V.

There are three adapter plugs for dierent coun-

tries. To change an adapter plug, just unlock the

lock, pull the plug o the AC adapter and push

in the new one. Make sure it is connected rmly.

Connect the mains plug to the power socket.

The socket must be located near the facility and

must be easily accessible. Do not use the power

plug if the power cord is damaged. Always use

the original TECHKON Spectro-Dens AC adapt-

er. The use of other power sources is hazardous.

Chapter 2

Installation of SpectroDrive and the software ExPresso 4

2.1 Assembly of SpectroDrive

12

Manual TECHKON SpectroDrive

WLAN-module for wireless data transmission

PC

2.2 Installation of the software ExPresso 4

System requirements

Microsoft Windows 10; 64-bit, minimum:

IBM-compatible PC with Intel Core Duo or com-

parable processor, 4 GB RAM, 2 USB ports;

screen resolution for TECHKON ExPresso:

minimum 1280 x 1024 pixel

The software is optimized to be operated

with a touch sensitive screen.

However, working without a touch-screen by

using a conventional mouse / trackpad and

keyboard is also possible.

Recommended color bar:

Print control strip TECHKON TCS Digital

(included in delivery).

Installation

It is important to carry out the following steps

in the right order to make sure that the USB

device drivers will be installed properly.

1. Plug the TECHKON data media into the USB

port of the running computer. Make sure

that the USB-dongle (software protection

key) and the module for wireless data

transmission are not connected to the PC.

2. Select starter.exe and choose Install

TECHKON ExPresso. The installation rou-

tine will start automatically. Follow the

steps of the installation, until it is completed.

3. After the installation is nished successfully

you can connect the module for wireless

data transmission with the USB cable and

the USB-dongle to the PC.

4. TECHKON ExPresso can now be launched.

Module for

wireless data

transmission

13

CHAPTER 3 – How to use SpectroDrive

Place the measurement device on the hori-

zontal track.

The module for the wireless data transmis-

sion has to be positioned as close as possible

to the measurement device with the front

pointing to the measurement system as

shown on the image. Please connect it to the

PC via the USB cable AFTER the installation of

the software

By pressing the green measurement but-

ton the device will move into the charging

station at the left, where it is automatically

charged, which is indicated by an animated

battery symbol in the device display.

You can align the measurement system in

vertical direction. By keeping the black but-

tons on the left and right holder pressed you

reduce the magnetic adhesion of the holders.

First, position the printed sheet at the low-

er lay-on edge.

Then move both holders vertically, so that

the measurement head is exactly on top of

the color patches. You can use a red laser

beam for the adjustment. Press the Laser-

button on the charging console. If the laser

beam turns o before you could nish the ad-

justment of the print control strip, just press

the Laser-button again.

Warning: To protect your eyes, do not stare

into the laser beam.

Chapter 3

How to use SpectroDrive and the software ExPresso 4

3.1 Operation of SpectroDrive

Automatic measurements

Measurement area

WLAN-module

1.

2.

14

Manual TECHKON SpectroDrive

Spot measurements

It is important that the measurement aper-

ture always covers the color patches com-

pletely during the entire scan.

When using color bars with a patch height

smaller than 4,5 mm, the edge of the mea-

surement head of the device has to be placed

exactly at the upper edge of the color bar, to

ensure that the measurement head is posi-

tioned correctly on the patches.

When using color bars with a patch height

higher than 4,5 mm, the measurement head

has to be placed with the measurement aper-

ture at the bottom edge of the color bar.

To carry out a spot measurement just re-

move the measurement device from the hori-

zontal track, position it with the measurement

head on a single measurement patch and

press the green measurement button shortly.

The measurement data are shown in the de-

vice display as well as in the window Spot

measurement of the ExPresso software.

Display modes of the device display

Results of a spot measure-

ment; densities CMYK and

CIE-Lab values; display of the

measurement conditions

Warning: the unit has been

blocked while driving

Scan is in progress

Paper white calibration is

performed

After a few minutes of

inactivity on the charging

station the device goes into

the stand-by mode

Absolute white calibration

is performed

15

CHAPTER 3 – How to use SpectroDrive

How to measure

Please ensure that the sample is located on a solid and at surface. There must not be

a distance between the measurement head and the sample where light could pass

through, because this can inuence the measurement. The color of the background

material underneath the measurement sample can have an inuence on the measure-

ment result. Dierent technical standards describe which backing material to use. In

the printing industry the following procedure is widely used: White backing for single

printed papers and black backing for double printed sheets in order to avoid that the

back printed side might shine through the paper and inuence the measurement.

Paper white calibration

A paper white calibration can be carried out by keeping the green button pressed for

a few seconds. The measurement aperture has to be on top of a non-printed area of

the sheet.

When SpectroDrive is on the track, the paper white calibration is performed by soft-

ware command (see p. 34).

Charging

Completely charging an empty battery will take approximately four hours. Spectro-

Drive has a regulated charging management. This means it will power-charge an emp-

ty battery, so the device can be used again after a few minutes. On the other hand,

there is no overcharging of full batteries.

Disposal instructions: Please dispose of the battery only in a designated recycling cen-

ter.

Automatic turn o

When the device is not located at the left holder in the charging position and is not in

use, it will switch o automatically after three minutes. It can be reactivated by press-

ing the green button on the device.

Device information and safety instructions

The use of this device in a dierent way than recommended by TECHKON GmbH

can endanger the device safety.

WARNING: This device may not be used in potentially explosive atmospheres.

16

Manual TECHKON SpectroDrive

Please protect your eyes and do not look directly into the optics when the device

is switched on.

Operating conditions: Ambient temperature: 10 to 35 °C, max. 30 to 85 % rel. humidity

(non-condensing); storage temperature: -20 to 50 °C.

3.2 Care and maintenance

Cleaning

SpectroDrive is a highly-precise optical instrument. It is designed to work in harsh,

industrial environments. However, it should be handled with care. Avoid mechanical

shocks, heat, dusty or humid environments.

The measurement head with the optical system is sealed against dust and dirt. Nev-

ertheless take care that the visible, open measurement aperture is always free of dust.

You can clean the measurement aperture with oil-free, clean compressed air and a

brush used for cleaning photographic equipment. Clean the device casing only with

a soft cloth and a non-aggressive plastic cleaner. Never use alcohol or chemically ag-

gressive solvent-based cleaners which can destroy the surfaces.

The same procedure is valid for the white standard which is integrated in the charg-

ing console. A soft cloth made of micro-bers is especially well suited for cleaning

the white ceramic tile. If the white standard should be defective, it has to be replaced

completely.

Please do not stick any labels at the bottom of the device. This could lead to faulty

measurements, because the dened distance – which is important for the correct op-

tical eld of depth – might not be maintained.

Error handling

Should SpectroDrive do not work properly, rst check, if the ExPresso software is

running correctly.

The status bar in the lower right corner will display, if the device, the module for

wireless data transmission and the USB-dongle communicate correctly with the PC.

It can be helpful to plug-o and re-connect the module for the wireless data trans-

mission from the USB connection when problems occur.

Restarting the software ExPresso is also recommended to solve software problems.

17

CHAPTER 3 – How to use SpectroDrive

Check that the right measurement device is selected in the software settings.

If SpectroDrive Simulator is selected, no real measurements will be carried out.

Check if the AC adapter is connected correctly to the mains plug and the charging

station. Check if SpectroDrive is charged in the home position (The battery symbol is

animated during charging).

If the device does not communicate with the software and does not work by press-

ing a button, but the device display is on, move it manually from the charging position.

Now, wait until it switches o automatically after three minutes. Then, turn it on again

by pressing the green button.

Warranty and service

The warranty for TECHKON products is 24 months starting with the date of purchase.

Consumable and wearing parts are excluded from this. The invoice is the certicate

of warranty. The warranty is invalid if the damage is caused by inadequate use of the

device.

Should a TECHKON product do not work according to the specication, please contact

us before sending us the device. In most cases we can solve the problem over the

phone or via E-mail.

Inspection intervals

TECHKON SpectroDrive is to a large extend maintenance free. Nevertheless we rec-

ommend to validate the complete functionality of the devices in a 24 months time

interval in the TECHKON service center. We oer a complete device check as a service

package. Please contact us for details.

For a at fee the device will be cleaned, checked and recalibrated. In case a repair or

exchange of components should be necessary we will inform you. Please send the

device always securely in the carrying case with complete accessories.

18

Manual TECHKON SpectroDrive

3.3 Software ExPresso 4 overview

The software ExPresso is clearly structured. The menu bar comprises the four sections

Print job (blue buttons), Settings (red buttons), Exit (blue button) and Scoring (when

active). The appropriate submenu layers follow this color system.

PRINT JOB:

P. 41

P. 42

P. 4 8

P. 57

P. 42 P. 43

P. 44 P. 46

P. 48 P. 51 (GrayGuide P. 52)

P. 53* P. 54*

P. 57* P. 58*

P. 60 P. 61

P. 62 P. 63

19

CHAPTER 3 – How to use SpectroDrive

SETTINGS:

EXIT:

P. 24 P. 25

P. 27

P. 29 P. 31

P. 33 P. 37

P. 38

P. 39

P. 24

P. 29

P. 39

P. 63

20

Manual TECHKON SpectroDrive

By clicking on the device icon in the right section of the menu bar (1.), one gets a

direct access to important device settings. A window is displayed with the submenus

Measurement device,Measurement settings, Export to other applications and Up-

date (see p. 33 – 36).

Below the menu bar the program window (2.) is displayed which is activated by the

appropriate menu item.

The following example shows the program window Density after a measurement was

carried out. In this program window a click on the bar graph opens a second window

displaying detailed measurement data of the ink zones.

The command line (3.) of the active program window is located at the bottom of the

program window.

The bottom area of the screen is a status line (4.), showing at the right side the con-

nection status of the module for wireless data transmission, of the measurement

device (SpectroDrive, SpectroDrive Simulator or SpectroJet) and of the USB-dongle.

When moving the mouse pointer on the icons of one of these components, you get

additional information, e. g. the density- and colorimetric-settings of the device or the

software version.

1.

2.

3.

4.

Other manuals for SpectroDrive

3

Table of contents

Other Techkon Measuring Instrument manuals