Techno CNC Systems Patriot Operating instructions

TechnoCNC Patriot

Door Lock Troubleshooting

Applies to Control Interface version 1.421 and above.

Version 4

April 2011

Table of Contents

Introduction

Symptoms

Explanation of Tools

Software Requirements

Diagnostics

Tools

Diagnosing Steps

1. Setup Procedure

2. Lock Mounting Procedure

3. heck Sensor Misalignment or Damage

Damaged Sensor

Misaligned Sensor

Behavioral Issues

Door Latch Re-Engages Too Quick

Spindle Doesn't Turn On

Door Locked Always On

Introduction

The Patriot door locking mechanism as designed to prevent unsafe machine operation. When set up

correctly, pressing the “Door” button on the interface ill unlatch the door, but it on't open

automatically. You have to first release the latch, by pressing do n on the door handle. You should hear

the latch click a ay, and the door ill open by lifting on the handle. When you first get your machine,

the gas springs may be a bit stiff; after some use, they should loosen up and allo the door to open

smoothly.

The teachers' key gives an administrator the ability to override the door latch safeties or force the door

open. When the door safety is overridden, the spindle ill operate even if the door is open.

To set up your interlocking mechanism for the first time, follo the first step in Diagnosing Steps.

Symptoms

When setting up the interlock, you may get an INT-1 or INT-2 or INT-3 error or an error message that

begins ith “Interlock not properly detected because...”, depending on the version of your soft are.

These errors refer to a sensor that isn't being detected during the setup process, and can be caused by a

misaligned or damaged sensor, improper setup procedures, or faulty assembly.

Explanation of Tools

Software Requirements

The first step is to make sure you have appropriate soft are. The TechnoCNC Control Interface that

this document references is version 1.421. Anything later than that (1.422) ill ork just fine. You can

do nload the latest version at technorouters.com (click on Control Interface in the menu to the left).

Diagnostics

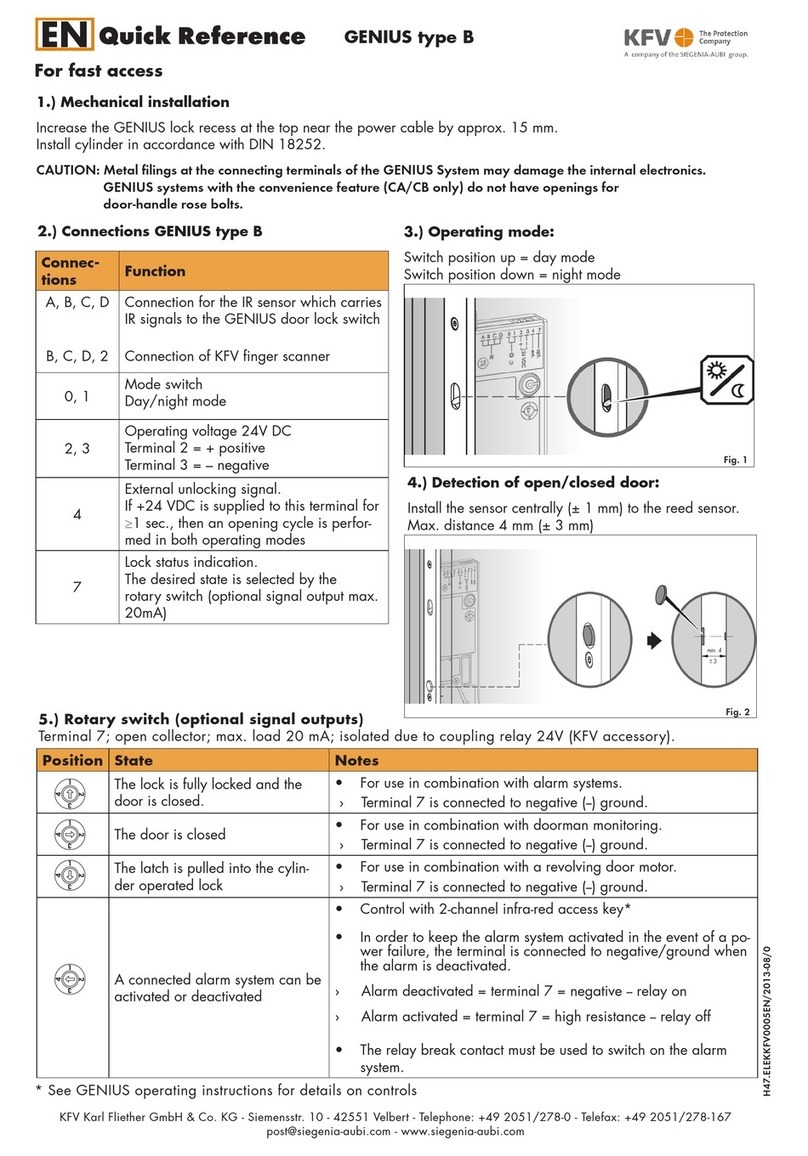

The tool you'll use to help diagnose the problem can be found under Setup -> Diagnostics. The

Diagnostics screen sho s the status of the “door open” and “door locked” sensors under Ctrl Inputs.

Note that the lock is ired such that it is impossible to have the door locked sensor be active ithout

the door closed. In other ords, it's impossible for the door to be locked, but not also closed.

Secondly, hen the s itch is activated, the door closed and door locked boxes ill NOT be checked.

These s itches are flipped from normal input, so the absence of a red check box means the sensor has

been activated. See images belo for clarification.

Lastly, there is a check-box option under CtrlReg called “Override Door”. This ill force the lock open

or closed, regardless of the state of the interlock. Note that if you click on it, it ill arn you before

preceding. If you use the space bar to toggle the state of the check box after you've clicked once, it

on't prompt you.

Tools

You may need a 3 mm hex rench to remove the door lock assembly.

Illustration 1: On the left, the door is open and unlocked. On the right, the

door is closed and locked. Note that Override Door needs to be checked to

release the door latch and open the door.

Diagnosing Steps

While there are multiple causes of these errors, some causes are more common than others.

1 Setup Procedure

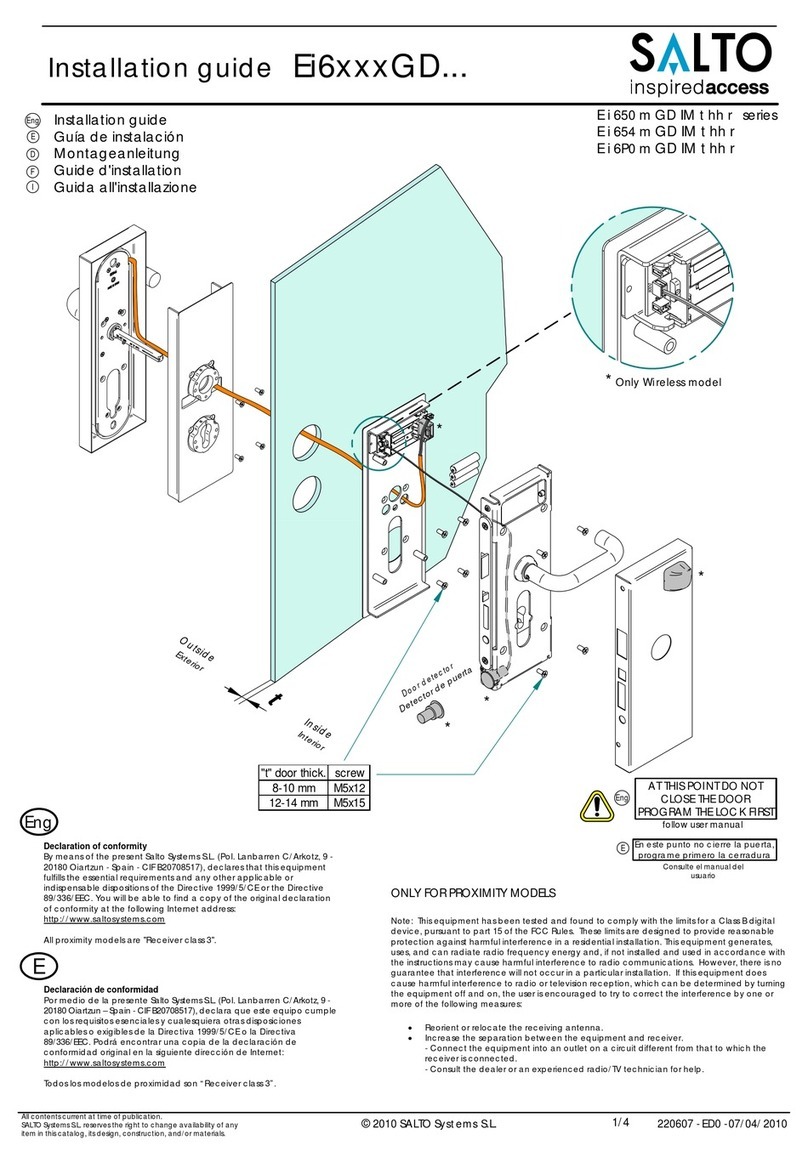

The procedure for detecting the interlock can be difficult to follo if you're in a rush. Be sure to read

all the prompts, and follo the instructions properly.

Go to Setup > Advanced > Hard are S itches and make sure Use Interlock is checked, and Auto

Relatch is checked. Click on the Detect Interlock button to set up the interlock.

2 Lock Mounting Procedure

Go to Diagnostics and un-check the Override Door checkbox. This ill force the lock to move for ard,

into the lock position. Push the door do n into the lock. Did the door properly push the lock aside, and

settle in to the closed position, or did the lock get in the ay?

If the door properly closed

The lock assembly is properly mounted. Go on to the next step.

If the lock got in the way

Loosen the four hex bolts that mount the lock in position, and slide the hole lock assembly to ard the

back of the machine. Tighten the bolts, making sure that the lock is as far back as it ill go. Repeat the

procedure above. If the lock still hits the bottom of the door and doesn't allo the door to close, take

note of ho far back the lock should be to allo the door to close properly. It's probably on the order of

a fe millimeters.

Unbolt the four hex bolts, and remove the lock assembly through the bottom of the machine. If you

have a stand, you can open the dra er to provide access. The lock assembly is connected via a hite

connector that you can disconnect if you need more room.

When you have the lock assembly out of the machine, take note of the small scre in the front. The

more you tighten it, the further back the lock sits hen it's in the locked position. For the door to close

properly, the scre should be tightened so that the lock moves back a fe millimeter or so. Move the

lock back to a position you believe is adequate.

Remount the lock assembly. Be sure to reconnect the assembly to the controller! Slide the assembly as

far to ard the back of the machine as the four bolts ill allo , and tighten them. When the lock is

Illustration 2: Interlock Setup. Note that the text on

the right ay be cut off, depending on the version of

the software you use.

properly seated, you should be able to close the door easily, even if the lock is in the locked position.

The door ill simply push the lock out of the ay as it closes.

Try the interlock setup again. While the procedures above may not fix the problem, it's critical that the

lock assembly be properly mounted because sensor adjustment relies on it.

3 Check Sensor Misalignment or Damage

The door closed sensor is a black tubular scre , that pokes up a bit above the surface of the lock

assembly. There is a magnet mounted in the bottom of the door that activates the door sensor. T o

things can go rong here: either the sensor is damaged, or the sensor is simply misaligned.

Damaged Sensor

If the sensor is damaged, you may find scrapes and gashes in the top of the sensor, here it as

knocked. A damaged sensor ill exhibit strange behavior. In Diagnostics, you may find the door closed

signal activated even hen the door isn't closed. But then magically become deactivated for no

apparent reason. Lightly flicking the top of the sensor ith a finger can cause a damaged sensor to

s itch states. If you find this behavior, call Techno to get a replacement.

Misaligned Sensor

Because the door sensor is triggered by a magnet, all magnets in the area can potentially trigger the

sensor. There are t o other magnets; one inside the locking latch itself, and another in the solenoid that

moves the lock into position. When the lock is in the for ard position, the magnet in the latch can

influence the door closed sensor. This on't be a problem if a) the magnet in the door is strong and

properly mounted, and b) if the door closed sensor is mounted high enough to be above the influence of

the lock magnet. Note that it can also be triggered because the lock moves for ard too far, but if you've

follo ed the steps in Section 2, this on't be a problem.

To align the door closed sensor, open the Diagnostics screen so you can see the status of door closed

and door locked sensors. Open the door, and check Override Door such that the latch is in the locked

position (for ard). Reach under the door lock assembly, and find the black plastic nut that holds the

door closed sensor in place. Unscre this nut, and back the sensor out until the top of the sensor sits at

the surface of the case floor. You ill probably see both door closed and door locked sensors triggered.

This is because the door closed sensor is being activated by the door locked magnet. Slo ly scre the

sensor until it starts moving up. At some point (perhaps a quarter inch above the floor), both door

closed and door locked signals ill turn off. This means that the door closed sensor is no positioned

high enough to be out of the influence of the latch magnet. Scre the sensor up a tiny bit extra (just to

be safe), and lock it into position using the black plastic nut.

No close the door so that it is latched, but you aren't pushing on it. Verify that both the door closed

and door latched signals indicate the door is closed and latched. If the door closed signal isn't being

activated, keep the door closed hile you scre the sensor up. Bring it up until it is activated (and then

an extra bit just to be safe). Tighten the black nut to hold the sensor in place.

Press the door do n and verify the sensor signals do not change. If they do change, you may need to

prevent the door latch from moving too far for ard. Tighten the scre that pushes back on the door

latch, but not so far that the latch can't grab the door or activate the door locked sensor.

There's a good chance you've fixed your problem no . Rerun the Detect Interlock setup. If it fails ith

an error, there are a fe more possibilities that need checking. If it passes, verify the Door button on

the front interface properly disables the latch, and that pushing do n on the door releases the latch and

allo s the door to open. If you have Auto Relatch enabled, pushing the door closed ill automatically

engage the door latch.

Behavioral Issues

Door Latch Re-Engages Too Quick

If the latch releases, but then re-engages too quickly for the door to be released (you'll hear it clicking

back and forth), the door closed sensor is disengaging hen you push the door do n, and then re-

engaging hen it moves back up, causing the soft are to believe the door as pushed closed. Raise the

door closed sensor ith the door in the fully locked and closed position, until the door closed signal is

triggered. Push do n on the door, and verify that the door closed signal does not go out.

There is a perfect area bet een the latch magnet triggering the door closed sensor (door closed sensor

too lo ), and the door magnet passing by the door closed sensor (door closed sensor too high). This is

the area here the door closed sensor should be mounted. When it's properly aligned, the door closed

signal ill be triggered hen the door is closed, and hen the door is pushed do n to release the lock.

Spindle Doesn't Turn On

The spindle has been ired to operate only under safe conditions. If the interlock key is set in the

Normal position, but the spindle doesn't turn on even hen the door is closed and locked, the door

closed sensor is likely not being seen. This is caused by the door closed sensor mounted too lo for the

magnet to trigger the sensor hile it's hooked to the door latch. Moving the door closed sensor higher

ill fix this.

Door Locked Always On

If the door locked sensor is al ays on, regardless of the door and lock position, the lock assembly may

have a diode installed incorrectly. This is a rare problem, but it's conceivable. The easiest thing to do in

this case is have the entire lock assembly replaced.

I Can't Get It To ork!

The Patriots have gone through a fe revisions since their introduction, and a fe revisions to the door

latch and magnet assembly ere performed to make it easier to install. While all versions have been

tested to ensure they ork properly, shipping may cause misalignment or damage. As the machine is

used, components can ear do n, be misaligned or damaged. If you can't get the door to properly

latch, or to properly detect the interlock, you may have damaged sensors, magnets, or even cable

assemblies under then machine. In all these cases, it's best to call Techno for help. We'll help guide you

through these instructions, and ill be able to further diagnose damaged equipment.

Before you call, please double-check to make sure nothing is obstructing a sensor or other component,

and that no component appears damaged.

Table of contents

Popular Door Lock manuals by other brands

Dorma

Dorma SVP 22 DCW Series Mounting instructions

Gainsborough

Gainsborough SD8 ILLUSTRATED FITTING INSTRUCTIONS

Kaba

Kaba Simplex 7104 Series installation instructions

Ingersoll-Rand

Ingersoll-Rand Schlage BE365 user guide

G-U

G-U BKS B-2193 Series installation instructions

Simplex

Simplex 3000 Series Assembly instructions