PROGRAM LOCK CODES:

11

Code Functions:

The MPC Cobra is manually programmable to have up to 100 codes. The codes can have different functions as

described below. Several types of functions have factory default values which are operational as soon as the lock is

installed. It is highly recommended that the Programming Code be changed (this will delete all factory default codes)

and new codes be added. In addition, it is recommended that at least one Freeze/Lockout Code be added - in case

the batteries get completely drained. (See “Battery Information” on below.) All codes can be 3-8 digits in length

(except the Programming code which must be 5-8 digits.) Keep a log of all issued codes. Issue codes exclusively with

all odd or all even numbers - this practice will make it easier to spot duplicate codes, since each keypad button repre-

sents two numbers (for example, code 246 is identical to code 135.)

FUNCTION: FACTORY DEFAULT: DESCRIPTION:

PROGRAMMING

NORMAL

9 7 5 3 1

1 3 5 7 9

1 3 5 1 3 5

9 1 1 5

NONE

NONE

NONE

TOGGLE

ONE USE

SUPERVISED

PASS THRU

FREEZE/LOCKOUT

The programming code puts the lock into a programming mode. It will

not unlock the lock. When a Programming code plus “*” is entered the

LEDs alternately flash several times indicating the lock is in a program-

ming mode. If more than 30 seconds pass in between programming

entries, the lock returns to a normal operational state.

Normal codes unlock the lock for the relock time delay. While the lock is

unlocked the green LED will flash. The LED will stop flashing and the

lock will relock.

Toggle codes unlock the lock indefinitely. When the same (or another)

toggle code is entered, the lock will immediately relock. When a toggle

code is entered, the green LED will flash once. The LED will stop flash-

ing and the lock will relock. .

Freeze/Lockout codes prevent other codes from working. The lock can

be locked or unlocked when one is entered. If it is locked, a Pass Thru

code will unlock it but all other codes will not. Only another Lockout code

will reverse the effect.

One Use codes unlock the lock for the relock time delay. They will only

work once and then are deleted from memory. They can used again if

they are programmed (added) into memory again.

Supervised codes require that two different supervised codes entered in

order to unlock the lock for the relock time delay.

Pass Thru codes will unlock the door for the relock time delay even if

the door is in the lockout mode.

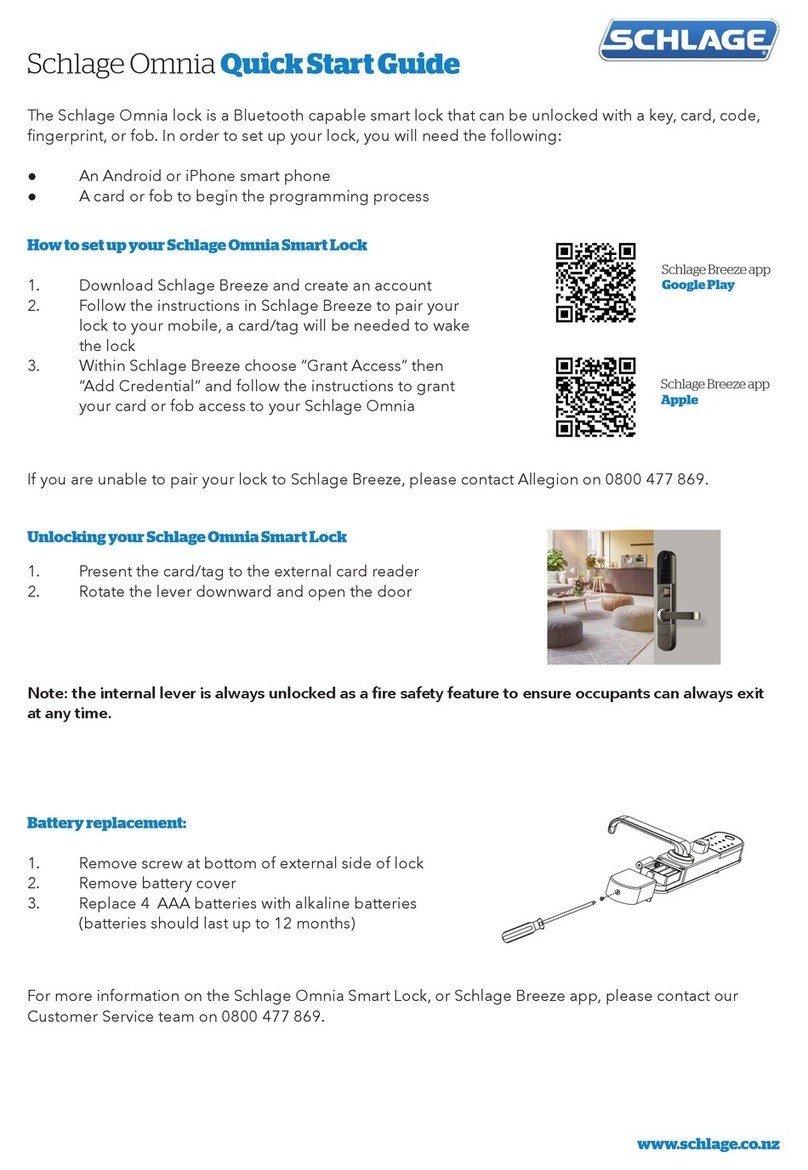

BATTERY INFORMATION:

The MPC Cobra uses four, standard AA batter-

ies. The batteries should provide enough life for

approximately 80,000 lock/unlock cycles. When

the batteries are running out the lock provides

two different modes of low battery indication:

First, when a code is entered, the red LED will

flash twelve times before the lock executes the

command of the code. This is an indication that

it is time to replace the batteries. The lock will

go for about 500 cycles in this condition. After it

reaches a certain point the lock will go into “Low

Battery Lockout” mode. A Freeze/Lockout code

will need to be entered in order gain access. If

the batteries are not changed, the lock will even-

tually not work and manual key override (if

installed) will need to be used.

CLEARING MEMORY:

Clearing memory will delete all programmed codes and restore

factory default codes. If the memory ever needs to be erased fol-

low the steps below:

1. Remove the inside escutcheon. Remove one of the batteries.

2. Press any key.

3. Hold down the “*” key and reinstall the battery. Continue holding

the “*” key down. The red LED will flash a few times and then stay

on.

4. Release the “*” key.

5. Install the inside escutcheon.

Note: to return the lock to the factory default relock time delay, do

steps 1-4 twice in a row.

FORM 57018 Rev. B 02-10-2005PAGE 7