Techno Control CITY CE516P User manual

TECNOCONTROL S.r.l.

Via Miglioli, 47 20054 SEGRATE (MI) Italy- Tel. (+39) 02 26922890 - Fax (+39)02 2133734

http: www.cpftecnogeca.com e-mail: info@tecnocontrol.it

EN

IST-1516.CE01.02

File: IST-1516.CE01.02_CE516-EN (04.03.2021).docx

GAS CONTROL UNIT

CITY

CE516P

Max no.16 Gas Detectors on RS485 BUS

with proprietary protocol

USER MANUAL

IST-1516.CE01.02 CE516P / User Manual Pag. 2/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

Please read and keep care of this manual and the manual of

installed sensors too.

All documentation relating to gas detection plant should be preserved, because it contains

the procedures to be used during the routines verification and / or during the periodic

calibration. We recommend that you always complete the Setup Memorandum Tables in the

last pages of this manual. This will facilitate any possible change to the configuration and/or

in case of additional sensors, and operations and maintenance service.

INFORMATION AND WARNINGS OF USE

The control unit is suitable for gas alarm systems up to No.16 detection points. The simple

installation and easy configuration via the buttons make the unit suitable for use in many

areas, both civil and industrial.

It should be noted that inappropriate use or lack of maintenance can affect the operation of

the device and thus preventing the proper activation of alarms with potential serious

consequences for the user.

TECNOCONTROL disclaims any responsibility if the product is misused, altered or

not as planned or outside the rated operating limits or put in work incorrectly. The choice

and use of the product are the sole responsibility of the individual operator.

The rules, laws, etc. mentioned, are the ones valid on the date of issue. In any case, must

be observed all applicable national regulations in the country of use.

The information contained in this document are accurate, current at the date of publication,

and are the result of continuous research and development, the specifications of this

product and what is indicated in this manual may be changed without notice.

The Control Unit has a clock with the automatic DST change (Setting for Italy on UTC

+ 01: 00 Time Zone). In the absence of power supply, the clock works with the lithium

battery (on the board in the cover), its life, in normal operation is over 5 years.

If the lithium battery is exhausted and the Control Unit remained completely without power,

at start up, you will need to enter the correct date and time (see chapter Date and Time) and

then the battery must be replaced soon with a new one.

NOTES FOR READING INSTRUCTION

CE516

Control unit up to No.16 gas detectors. Equipped with No.5 relay outputs expandable

to 9 with No.1 ES4014. The unit has also no.1 Logic Input.

ES414

Expansion card with No.4 relay outputs.

ES415

Expansion card with No.1 RS485 serial port Communication via Modbus®RTU binary.

SENSOR

It is the name that, for simplicity, is indicated the Remote Gas Detectors models, which

can be connected via proprietary protocol RS485 BUS, to the CE516.

FIRMWARE

Program inserted into the microcontroller which controls the unit functioning.

Symbol that indicates an important warning in the instructions.

Symbol indicates information or additional explanation in the instructions.

Documento / Document: IST-1516.CE01.02_CE516-EN (04.03.2021).docx

Oggetto / Subject / Objet: CE516 (Bus RS485) Centrale da parete / Wall mount Control Unit / Centrale de

contrôle murale (GIUGIARO design).

Cronologia delle revisioni / Revision History / Historique des révisions

Rev.

Data / Date

Da / By

Note

0

04/03/2021

UT/FG

1° Emissione / 1st Edition / 1ère délivré

IST-1516.CE01.02 CE516P / User Manual Pag. 3/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

SOMMARIO

INFORMATION AND WARNINGS OF USE 2

NOTES FOR READING INSTRUCTION 2

PRODUCT DESCRIPTION 5

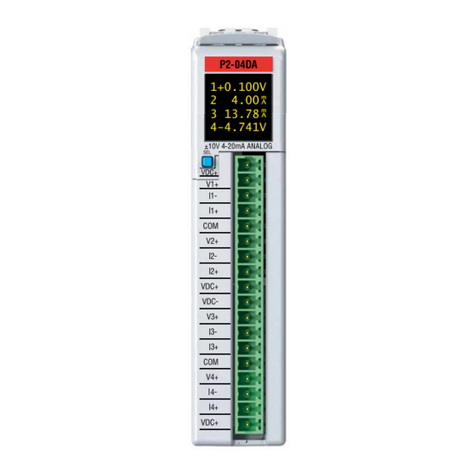

Fig.1 –CE516P - Wall mount housing 5

Fig.2 - Eg installation with TS482 series detectors. 6

CONTROL UNIT INSTALLATION 8

Fig 3 –CE516P Dimensions and Template for wall mounting. 8

OPEN –CLOSING THE HOUSING 8

ELECTRICAL CONNECTIONS 9

Fig.4 –Inputs for cable glands 9

Power connection 10

Fig 5. –CE516P Wiring diagram for Power, Batteries, AUX input and relay output No.9. 10

Connection with Gas Detectors (Sensors) 11

Fig.6 –max No.16 TS482 connected in cascade, max No. 8 per each RS485 port. 11

Fig.7 –Eg.with TS482 (max No.16) connected in cascade 12

Fig.8 –Eg. cable terminated with 120 Ωresistors, one at each end of the cable. 12

Fig.9 –CE516P Wiring diagram COM1 and COM2 RS485 Bus serial ports 13

DETECTOR ADDRESS : Dip-Switch SET-UP 13

Fig.10 –CE516P Wiring diagram - Relay Outputs 14

Expansion Board ES415 - Modbus®15

Fig.11 –ES415 Expansion card with COM3 (RS485) Modbus serial port. 15

USE OF THE CONTROL UNIT 16

Fig.12 –CE516P Keyboard 16

Keyboard 16

LEDs indications 16

Internal Buzzer indication 16

Single digit numeric field (password entry, etc.) 16

Screens 'Enable ...', 'Disable ...', 'Copy ...', 'Delete ...', 'Settings-> Date & Time': 17

Display –All other Screens: 17

Display –Initial Screens 17

Preheating Time 17

Display –Main Screen 17

MAIN MENU 20

List and short description of the accessible menus and the required or Password: 20

RESET 21

SENSORS 21

SENSORS-ENABLE / DISABLE (Level 1): 21

CONFIGURE SENSORS (Level 2): 22

CONFIGURE - PRECONFIGURED SENSOR: 22

Description of items related to the Preconfigured sensor: 24

Description of the items relating to the outputs: 25

CONFIGURE - SEARCH SENSOR: 26

Description of the items relating to the SEARCH SENSORS: 26

SENSORS-COPY (Level 2): 27

SENSORS-DELETE (Level 2): 27

SENSORS-MODIFY (Level 2): 27

SENSORS-DETAILS: 28

LOGIC INPUT 28

LOGIC INPUT - ENABLE/DISABLE (Level 1): 28

LOGIC INPUT –CONFIGURE (Level 2): 28

LOGIC INPUT –DELETE (Level 2): 29

LOGIC INPUT - MODIFY (Level 2): 29

IST-1516.CE01.02 CE516P / User Manual Pag. 4/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

LOGIC INPUT –DETAILS: 29

ZONES 29

ZONES - ENABLE/DISABLE (Level 1): 29

ZONES - CONFIGURE (Level 2): 30

Description of items related to the Zone: 30

Description of the items relating to the outputs: 30

ZONES-DELETE (Level 2): 30

ZONES-MODIFY (Level 2): 31

ZONES-DETAILS: 31

EVENTS 31

EVENTS - ALARMS / FAULTS 31

EVENTS - ALL 31

SETTINGS 32

SETTINGS-LANGUAGE (Level 1): 32

SETTINGS-DISPLAY CONTRAST 32

SETTINGS-BUZZER (Level 1) 32

ALARMS 32

FAULTS 32

SETTINGS-DATE and TIME (Level 1): 33

SETTINGS-Modbus® (Level 2): 33

Function Codes and Reading 33

SETTINGS-INFO 34

ACCESS MENU 34

ENABLE LEVEL: 34

DISABLE LEVEL 35

CHANGE PASSWORD: 35

SERVICE 35

SERVICE-ELECTRIC TEST (Level 2): 35

SERVICE-BATTERY (Level 2): 36

SERVICE-FACTORY TEST (Level 3) 37

SERVICE-SD CARD 37

UPDATE FW. (Level 2): 37

Fig.12-SD Card insertion 37

COPY CONF. FROM (Level 2): 38

COPY CONF. ON (Level 2) 38

COPY EVENTS ON (Level 2): 38

DATA LOGGING (Level 1): 39

DELETE SD (Level 2): 39

APPENDIX 41

TECHNICAL SPECIFICATIONS 41

Summary of the list of Fault and Alarm messages 42

TABLES with List of PRECONFIGURED Gas Detectors 43

TABLE 1 - Models with RS485 BUS and Replaceable Sensor Cartridge. 43

TABLE 3 - Models and Values of TLVs 44

TABLE 4 - Pre-configured values for PARKING-EN (EN50545-1) 44

TABLE 5 - USED ONLY IN ITALY - Values to be set to use with PARKING-ITA 44

TABLE 6 - PRECONFIGURED Parameters of Relay Output Operation 45

Configuration Reminder Tables 46

EN

Diagram Menu with access without password 50

IST-1516.CE01.02 CE516P / User Manual Pag. 5/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

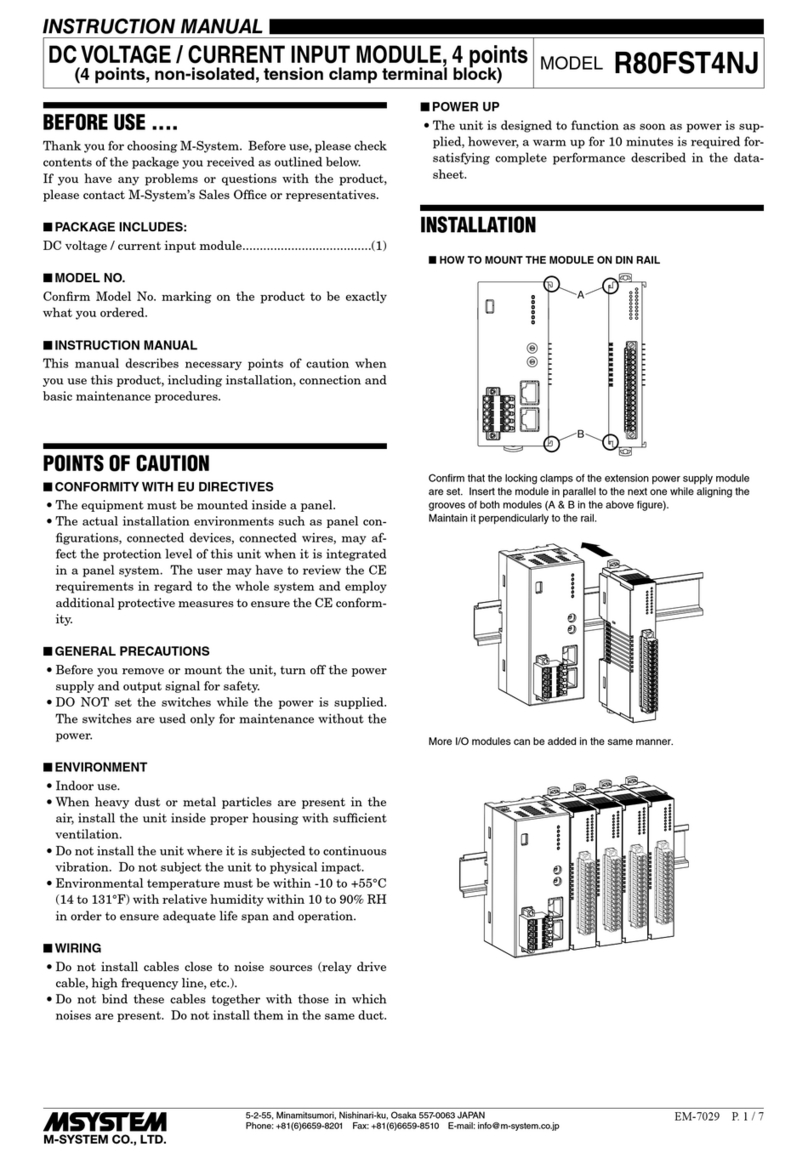

PRODUCT DESCRIPTION

The Control unit is wall mount, GIUGIARO DESIGN housing 379x241x133 mm.

The CE516P can only manage our Gas Detectors with proprietary RS485 BUS:

The Control Unit can manage up to 16 remote gas detectors (Sensors) (see list in Table 1)

RS485-Bus output models with “Replaceable Cartridge Sensor” for:

Flammable gases with Catalytic sensor (20% LFL range) TS482K (IP65) series.

Flammable gases with Pellistor sensor (100% LFL range) TS482P (IP65) series.

Toxic gases with electrochemical cell TS482E (IP65) series.

Oxygen with electrochemical cell (25% volume range) TS482EO (IP65) .

Available gas detectors: some models of detectors or calibrations for some gases may

not yet be available. We recommend that you contact us for confirmation or for specific

requests. e-mail: info@tecnocontrol.it

THE CE516P IS COMPATIBLE,ONLY WITH OUR DETECTORS,WHICH COMMUNICATE VIA RS485 BUS

WITH A PROPRIETARY COMMUNICATION PROTOCOL.

TO EACH SINGLE SERIAL PORT (COM1 AND COM2) CAN BE CONNECTED,ONLY 8DETECTORS

SUPPLIED DIRECTLY FROM THE CONTROL UNIT.

NO LIABILITY IS DISCLAIMED FOR MALFUNCTIONS,FAILURES OR DAMAGES CAUSED BY PRODUCTS

THAT ARE NOT COMPATIBLE OR NOT OF OUR PRODUCTION.

La Unit has No. 2 serial ports with RS485 proprietary BUS input (COM1 e COM2):

On each single serial port, max 8 detectors type TS482 can be connected, using 4-Wires, 2- wires for

the 24VDC power supply and 2 wires for the Bus.

The Unit has No.1 AUX input, which can be associated with a relay output:

It can be configured to activate one of the available relays and can be used by devices with NO or NC

contact outputs (gas sensors with a relay contact, smoke sensors, buttons, etc.).

Each Sensor can be configured in two ways quickly and easily:

Preconfigured Setup: Here you can choose one of the models of our production, (See list in Table 1),

which is then automatically set in the configuration recommended by the respective thresholds and

relay outputs. Is enough set the output number (relay) to complete the configuration.

Modifications of the other values are however allowed.

Search Sensors: here you can semi-automatically search and configure sensors if connected and

only if set with the correct address (from 1 to 16). In this case it will be necessary to enter only a few

parameters such as the number of the relay to be associated with the alarm thresholds.

Modifications of the other values are however allowed.

Mains Supply 90÷264 VAC

Fig.1 –CE516P - Wall mount housing

No.2 RS485 proprietary Bus

COM1 max No.8 Detectors

COM2 max No.8 Detectors

SD-CARD

Max No.16 Detectors

No.5 or No.9 Relay

No.1 RS485 (COM3)Modbus

(with ES415 optional card)

No.1 Logic Input

Internal Batteries (optional)

IST-1516.CE01.02 CE516P / User Manual Pag. 6/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

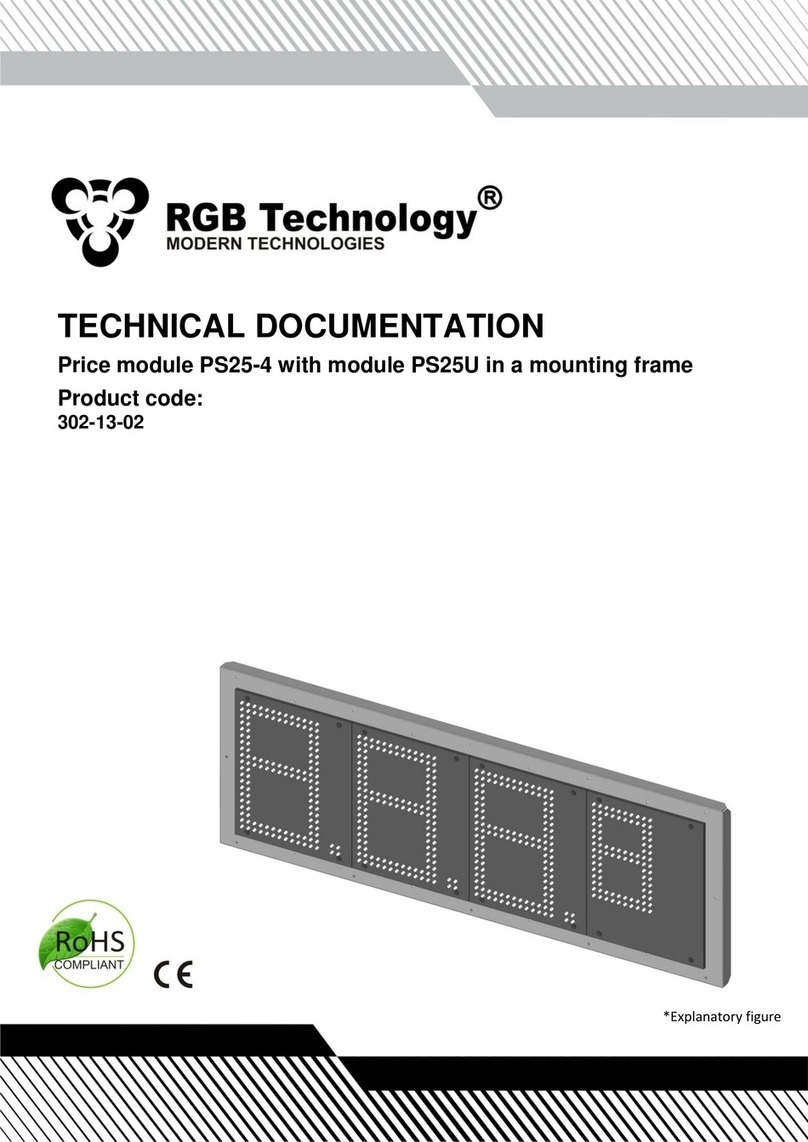

Fig.2 - Eg installation with TS482 series detectors.

Each Sensor is protected and has a FAULT signal:

The Sensors COM Ports, are protected against short-circuit or wire breakings. If a short-circuit occurs,

the COM Port power supply is automatically stopped, and therefore also all the sensors (max n.8),

connected to it, switch off. At the same time, the FAULT signal is activated.

Each Sensor may be associated with a ZONE:

The sensors can be grouped into Zones (Max No.4), which can associate up to No.2 relay outputs

different for each alarm level and No.1 for the FAULT.

Each ZONE can be set according to operating LOGIC:

The logic used are the typical logic functions (OR, AND), management of adjacent sensors

(CORR.CON, CIRC.CON). Note that PARK-ITA is a function only for Italy standard (Italian Ministerial Decree DM

01/02/1986 replaced by DM 08/03/2015 and subsequent updates).

The Unit can manage up to No.5, or No.9 Alarm relays:

Each sensor has three alarm levels (Threshold 1, Threshold 2 and Threshold 3) and a FAULT,

freely addressable to any relay output. The control unit has no.5 relay already installed, which can be

increased to No.9 with the expansion card ES414.

The alarm thresholds can be configured with special mode of operation:

For use in car parking "PARKING EN" (EN 50545-1) or to the workplace, such as exposure limit value

TLV.

Each output (relay) can be configured as follows:

- Silenceable: the output is disabled for the Silence time, when RESET is carried out and the sensor

is above the set threshold. This function can, for example, be used for the outputs connected to

audible warning devices.

- Silence Time: is the time, adjustable from 0 to 300 seconds, so Silenceable output (e.g. relay connected to

a siren) is disabled when the RESET is performed and a sensor is above the set threshold

- Hysteresis ON: is the delay, adjustable from 0 to 300 seconds, of the relay, associated with an alarm

threshold.

- Hysteresis OFF: is the delay, adjustable from 0 to 300 seconds, of the relay to return to normal condition,

when it ends the alarm.

- Time ON: is adjustable from 0 to 300 seconds. This function can only be used if you want to stop the alarm

output after a finite time, even if the sensor remains above the alarm threshold set (This function

cannot be used in conjunction with Hysteresis OFF delay). For example you can use it to enable

devices that cannot be powered down, or to send a pulse to a phone dialer.

- Memorized: the relay remains in alarm, even if the sensor returns below the threshold (this function

does not work if the Time ON or into Hysteresis OFF has already been inserted a value other than

zero), to return to normal conditions must be done RESET. Serves, for example, to prevent the

accidental or unauthorized resetting of a block valve of the gas, without first checking the cause of

the alarm.

-Positive Logic: the operation of the relay can be set normally activated or in positive logic,

therefore, if the relay fails, or is completely out of power, automatically moves into the Alarm

position, the NC contact becomes NO.

The Control Unit has a BUZZER inside:

The internal Buzzer sounds a Beep every touch of the keyboard. It can also be set to sound in case of

Fault and / or Alarm.

Ingresso Logico AUX (es. PULSANTE)

AUX Logic input (eg. BUTTON)

Entrée logique AUX (par ex. BOUTON)

COM1 RS485

Elettrovalvola intercettazione gas / Gas cut-off

solenoid valve / Électrovanne de coupure du gaz

SE301 SIRENA / SIREN

RILEVATORI (es.TS482) / DETECTORS (e.g.TS482) / SONDES (par ex.TS482)

Lunghezza MAX cavi MAX cable lenght / Longueur de câble maxi

COM2 RS485

S9

S16

S15

S14

S10

S11

S12

S13

S1

S7

S8

S6

S3

S5

S4

S2

CE516P

IST-1516.CE01.02 CE516P / User Manual Pag. 7/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

The Control Unit can store the Events:

The system can store up to 100 events comprising Alarms, Faults, Power ON, Mains blackout and

Resetting, that can be re-called at any time.

The Control Unit has an SD-CARD slot, it can be used for:

Future updates of the Control Unit firmware.

Loading or Saving the control unit configuration and the events.

Transfer of a copy of the configuration from a CE516, to another CE516.

Data Logger (Storing in time, of the values read by the sensors, in text format).

The Control Unit has 1 Modbus®RS485 serial port (COM3):

With the expansion board ES415 (Optional PC-Card Modbus output) you can connect the Control Unit to

a Building or Industrial Management Systems, using the Modbus RTU binary protocol.

The Control Unit is protected by 3 LEVELS of PASSWORD:

Some menus are accessible up to three password levels, with a code composed of 4 numbers. The

levels are for access to functions, used by the respective authorized persons:

LEVEL 1: for the User

LEVEL 2: for the Installer or Maintenance technician.

LEVEL 3: Reserved - Only accessible for factory settings.

IST-1516.CE01.02 CE516P / User Manual Pag. 8/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

CONTROL UNIT INSTALLATION

THE FOLLOWING INSTRUCTIONS DESCRIBES ALL THE CONTROL UNIT

SYSTEM SETUP PROCEDURES AND THE INSTALLATION PROCEDURES TO

BE EXECUTED ONLY BY AUTHORISED AND EXPERIENCED STAFF.

WARNING: The unit is to be installed in an area protected from direct sunlight

and rain. Please note that for safety the unit is to be installed in safe areas

where there are present or can form flammable atmospheres and

concentrations exceeding 24% volume of oxygen.

CLEANING: To clean the exterior of the enclosure, use a soft damp cloth with water; do not use

solvents or abrasive cleaners.

POSITIONING: The unit should be mounted on the wall using 4 screws and wall plugs (Ø 6 mm) or 4

M4 screws and nuts, if the wall is not in masonry. The housing's base must be fixed through the 4

holes, on the sides of the base (Fig.3). The electrical connections should be executed all on the

housing base.

Fig 3 –CE516P Dimensions and Template for wall mounting.

The cover unlocks (with a coin) by turning 90° the 4 buttons located above and below the enclosure. It

is opened by pulling and then rotating it up until it rests at the base.

OPEN –CLOSING THE HOUSING

The housing has two sliding internal hinges. To open the case, you must:

1- With a coin or screwdriver (blade 10-12 mm), unlock the 4 closing buttons, turning them 90°

clockwise.

2- Gently, pull the cover outwards of about 4 cm and then rotate it up and place it on the upper edge

of the base housing, in this way remain in the open position.

To close the housing act in reverse order. Pay attention that the cover and the locking mechanism

enter into place. Finally block 4 buttons, turning 90 ° counterclockwise. To facilitate the closure, press

on the lid, the buttons, which are eccentric, will bring the lid to adhere to the base housing.

APRE

OPENS

OUVERT

CHIUDE

CLOSES

FERME

DIMA DI FISSAGGIO A PARETE

n.4 Fori per Tasselli a muro Ø 6mm

TEMPLATE FOR WALL MOUNTING

No.4 holes for wall plugs Ø 6mmn.

PATRON DE FIXATION AU MUR

4 Trous pour chevilles Ø 6mm

130 mm

342 mm

IST-1516.CE01.02 CE516P / User Manual Pag. 9/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

ELECTRICAL CONNECTIONS

The electrical connections should be executed all on the housing base.

The details of the connections to the mains, the two batteries, the AUX input and relay output

R9 are illustrated in Figure 4. While the details of the connections to the sensors and the other

outputs are illustrated in Figure 5.

The terminals are of "polarized inlet" type (1). We suggest to use

lugs adequate to the conductors (2) and to fix the wires to the box

structure to avoid excessive stress to the circuits and to the

terminals. Use a screwdriver (3) with the right dimensions.

3

1

2

Input terminal,

plug-polarized.

Considering that, it should be normal procedure disconnect power to the electronic equipment when

installing, or changing the connections, or when disconnecting or connecting expansion cards.

IMPORTANT:TO AVOID IRREVERSIBLE DAMAGE,DISCONNECT THE POWER SUPPLY TO

THE CONTROL UNIT,MAINS POWER AND BATTERY (IF PRESENTS)DURING INSTALLATION

(WIRING CABLES)OR BEFORE YOU INSTALL ANY EXPANSION BOARDS OR UNPLUG OR RE-

CONNECT THE FLAT CABLE.

Only if necessary, for maintenance or installation requirements, the housing cover can be

separated from its base, first remove mains power and remove the batteries, then disconnect

the flat cable, press on the two side tabs as shown in Fig. 3.Then you need to release the cover

from sliding hinges (press fit). To reconnect it, proceed in reverse order and after hanging up

the lid hinges, push the flat cable into the connector, respecting the polarization, the two levers

close automatically locking it. Only then you can reconnect power supply.

BATTERIES:Inside the housing, it can also accommodate two 12V/1.3Ah Lead batteries connected

in series (Fig.5) to assure the system powering in case of mains blackout.

The battery life is about 50 minutes with No.16 sensors, but each detector in less increases the

autonomy of about 4 min.

(The batteries are not included in the delivery, but are available on request). If required, to

increase the autonomy, No.2 12V, 3Ah or 7Ah batteries connected in series can be used,

but due to their size, they must be installed outside the control unit.

Considering that each detector absorbs 0.08A/h from the battery, the autonomy, with 16

detectors, becomes: about 2.5 hours with 3Ah batteries (each sensor less increases the

autonomy by about 9 min) and about 5.5 hours with 7Ah (each sensor less increases the

autonomy of about 20 minutes).

CABLE GLANDS: the lower side of the housing has 13 inputs designed for metric cable glands (ISO

pitch 1.5 mm). No.10 are for glands M16x1.5 mm (that accept external cables Ø 4÷8 mm) and n.3 are

for glands M20x1.5 mm (that accept external cables Ø 6÷12 mm).

These passages are closed, but they are not manually breakable, according to the installation

requirements, they must be drilling. To facilitate the operation, they have a centering for the drill bit.

Please, pay attention not touch the tip of the internal circuits or the power supply cables

To guarantee the degree of protection of the enclosure, it is recommended to use cable glands with

protection IP55 or higher.

Fig.4 –Inputs for cable glands

Altri ingressi

Other Inputs

Autres entrées

Centro guidapunta

Center for the drill bit

Centre de guidage

Ingresso Alimentazione di Rete

Mains power supply Input

Entrée Alimentation Reseau

IST-1516.CE01.02 CE516P / User Manual Pag. 10/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

Power connection

The installation must include a power line protection device. To the mains line, a bipolar disconnecting

switch dedicated for the gas detection system. The device, clearly identified, must act only on Phase

and Neutral, but not on the Earth. It is advisable to also provide for a surge protector, lightning etc.

Mains Power Supply (90÷264Vdc / 47÷63Hz) should be connected to terminal L, Nand Earth at the

right of the housing base. The terminal has a protective fuse (5x20) 2A.

The two 12V/1.3Ah Lead internal batteries if required should be connected in series to BAT+ (Red)

and BAT- (Black) terminals. For the series connection, use the black cable supplied with two terminals

(4.8 mm Fastens).

The auxiliary input (AUX) can be used to connect devices with a NO or NC contact (gas sensors with

relay contacts, smoke sensors, buttons, etc.). It can be configured to activate one of the available

relays. It can be connected to multiple devices if it’s are homogeneous. (If the device has an NC contact

must be connected in series or in parallel if it’s have all a contact NO).

Output Relay No.9 has the same characteristics and use of those described on the next page.

Fig 5. –CE516P Wiring diagram for Power, Batteries, AUX input and relay output No.9.

N T L

B

-

B+

B-

NC

C

NC

A

A

B-

Black

B+

Red

n.2 12V / 1,3Ah Batteries

Connected in Series

Relay no.9 output terminal

LED ON = Relay OUT no.9 NC

Press to Open

Neutral

Earth

Line

-+- +

Fuse (5x20) 2A

TO AVOID IRREVERSIBLE DAMAGE,

DISCONNECT THE POWER SUPPLY TO

THE CONTROL PANEL,MAINS POWER

AND BATTERY (IF PRESENTS)BEFORE

YOU UNPLUG OR RE-CONNECT THE

FLAT CABLE.

Flat-cable connector for cover

connection

V1+

GND

H1

L1

V2+

L1

GND

H2

L2

H1

LED: Batt TEST ON

The LED lights up when

checking functioning of

batteries (if installed).

Auxiliary Input Terminal AUX

RS485 BUS Card

(COM1 and COM2)

Outputs board

(Relays 1÷4)

Main Board

Input AUX and

Outputs Relay 9

RS485 BUS

INPUTS

Battery

n. 1

Battery

n. 2

Position Expansion

board

ES414 (Relays 5÷8)

90÷ 264 Vac / 47÷63Hz Mains power supply terminal

IST-1516.CE01.02 CE516P / User Manual Pag. 11/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

Connection with Gas Detectors (Sensors)

Please always refer to the specific instructions supplied with detectors.

Please note that the Control Unit has a card with no.4 outputs. An ES414 board can be

installed to have a total of 9 outputs. In the diagrams, for simplicity, they are always indicated

with all the Outputs.

Connection cables: Cables must be shielded and suitable both for powering the detectors (sensors)

with 2 wires, section of at least 0.75mm2, both for industrial RS485 communications, the twisted pair

type with an impedance of 120 Ω section and at least 22 AWG (0.35mm2) or higher.

E.g. Twisted pairs signal Cable Shielded with double

jacket.

E.g. Shielded Signal Cable with 1 straight pair (24Vdc

power supply) and 1 Twisted pair (RS485 Bus)

Distance between Control Unit and Sensors and cable section: To determine the maximum cable

length, it is necessary to measure the CE516 distance from the last detector (it must be the farthest

sensor). The distance depends mainly on the absorption of the installed sensors and therefore on the

conductor section. Each sensor absorbs about 2W (Power +and -on two wires), considering that the

sensors are powered in parallel, (max 8 on the COM1 input and 8 on the COM2) each cable must

support 16W. Therefore, to ensure that the last sensor is supplied correctly, the distance between the

CE516 and the last sensor is indicated in the table according to the cable section.

Max distance of the farthest detector from the CE516

Twisted pairs signal (TW) Cable Shielded

Max 300 meters

2 x0.75 (Power supply) + 2 x0.5 TW (BUS RS485) mm2Shielded

Max 400 meters

2 x1,0 (Power supply) + 2 x0.5 TW (BUS RS485) mm2Shielded

Max 600 meters

2 x1,5 (Power supply) + 2 x1 TW (BUS RS485) mm2Shielded

Detectors connections: The connection of the detectors (Sensors from No.1 to No.16) should be

performed on the RS485 BUS INPUT BOARD, mounted in the housing base, using the COM1

terminals (V1 +, GND, H1 and L1) and / or the COM2 terminals (V2 +, GND, H2 and L2).

On each single COM port, can be connected in parallel (in cascade) up to no.8 gas detectors TS482

series. As indicated in the table above, a cable with 4-Wires, no.2 wires for powering the sensors

(24Vdc) and no.2 wires for the RS485 communication bus must be used.

The cable shield must be connected only from the Control Unit side and on a single "EARTH" point

which must be equipotential. On each detector (sensor) it will be necessary to use two cable glands,

one for the input and one for the output.

Fig.6 –max No.16 TS482 connected in cascade, max No. 8 per each RS485 port.

CE516P

COM2

Bus + Alimentazione (max 8 Rilevatori)

Bus + Power supplt (max 8 Detectors)

Bus + alimentation (max 8 détecteurs)

S9

S10

S11

Sn

S16

S1

S8

S2

S3

Sn

Eg. with shielded cable

2x0.75mm2(Power supply) +

2x0.5 mm2Twisted (Bus RS485),

each cable length is Max 300

meters.

MAX Lunghezza dei cavi / MAX Cables Length / Longueur maximum des câbles

COM1

Bus + Alimentazione

(max 8 Rilevatori)

Bus + Power supplt (max 8 Detectors)

Bus + Alimentation (max 8 détecteurs)

IST-1516.CE01.02 CE516P / User Manual Pag. 12/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

If alternatively, separate power supplies are used from the control unit, we recommend the use of

type feeders SELV (Safety Extra Low-Voltage)and it will be necessary to use a third cable gland for

the power supply. In this case the cable for the RS485 Bus will be a shielded twisted pair, with an

impedance of 120Ω, but the section must be at least 22 AWG (0.35mm2).

Fig.7 –Eg.with TS482 (max No.16) connected in cascadeon RS485 Bus cable, with a maximum length

of 600 meters and with each Detectors supplied with local 24VDC power supplies

The RS485 data transmission lines must (should) always be terminated and the stubs must be as

short as possible to avoid reflections of the signal on the line. The value of the termination resistors

must correspond to the impedance of the transmission cable (for RS485 is recommended by 120Ω).

The cable must be terminated with 120Ωresistors, one for each end of the cable.

Fig.8 –Eg. cable terminated with 120 Ωresistors, one at each end of the cable.

V1+

GND

H1

L1

V2+

GND

H2

L2

H1

ULTIMO SENSORE

LAST SENSOR

DERNIER CAPTEUR

SENSORE n.1

SENSOR No.1

SONDE 1

+

H

L

GND

L2

H1

+

H

L

GND

L2

H1

Troncone (stub)

più corto possibile

Stubs must be as

short as pssible.

Stubs aussi court

que possible

Resistenza 120 Ω

120 Ω Resistor

Résistance 120Ω

Resistenza 120 Ω (Vedi anche Fig.9)

120 ΩResistor (See also Fig. 9)

Résistances de 120Ω(Voir aussi la figure 9)

Power Supply

Alimentation

Alimentatore

24Vcc/24VDC

Power Supply

Alimentation

Alimentatore

24Vcc/24VDC

S16

S no

S1

S no

Power Supply

Alimentation

Alimentatore

24Vcc/24VDC

CE5161

IST-1516.CE01.02 CE516P / User Manual Pag. 13/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

DETECTOR ADDRESS : Dip-Switch SET-UP

INDIRIZZO

ADDRESS

ADRESS

1

2

3

4

INDIRIZZO

ADDRESS

ADRESS

1

2

3

4

1

OFF

ON

ON

ON

9

OFF

ON

ON

OFF

2

ON

OFF

ON

ON

10

ON

OFF

ON

OFF

3

OFF

OFF

ON

ON

11

OFF

OFF

ON

OFF

4

ON

ON

OFF

ON

12

ON

ON

OFF

OFF

5

OFF

ON

OFF

ON

13

OFF

ON

OFF

OFF

6

ON

OFF

OFF

ON

14

ON

OFF

OFF

OFF

7

OFF

OFF

OFF

ON

15

OFF

OFF

OFF

OFF

8

ON

ON

ON

OFF

16

ON

ON

ON

ON

N T L

TO THE

SENSORS

fron no.2

to no.8

+

H

L

GND

L2

H1

SENSOR no.9

ON

OFF

1

2

3

4

+

H

L

GND

L2

H1

SENSOR no.1

ON

OFF

1

2

3

4

V2+ = Power Supply 24VDC-8W max

Dip-Switch for sensor Address

< RS485 INPUT BOARD (COM1 /COM2)

LED Rx/Tx

COM 2

LED Rx/Tx

COM 1

A

V1+

GND

H1

L1

V2+

L1

GND

H2

L2

H1

COM 2 - RS485

BUS INPUT

COM 1 - RS485

BUS INPUT

GND = Negativ 24VDC Power Supply

H2 BUS RS485 Signal

L2 BUS RS485 Signal

H1 BUS RS485 Signal

L1 BUS RS485 Signal

V2+ = Power Supply 24VDC-8W max

GND = Negativ 24VDC Power Supply

LED 24VDC

COM 1

LED 24VDC

COM 2

EARTH SHIELDING

(control unit side only)

EARTH SHIELDING (control unit side only)

Fig.9 –CE516P Wiring diagram COM1 and COM2 RS485 Bus serial ports

TO THE

SENSORS

from no.10

to no.16

FUSE 2A (5x20)

Outputs board

(Relays 1÷4)

Position Expansion board

ES414 (Relays 5÷8)

Main Board Input

AUX and

Outputs Relay 9

RS485 BUS

INPUT BOARD

Battery

no. 2

Es. INDIRIZZO n.1

Eg.ADDRESS no.1

Ex. ADRESSE 1

1

2

3

4

ON

OFF

SET

Es. INDIRIZZO n.9

Eg.ADDRESS no.9

Ex. ADRESSE 9

1

2

3

4

ON

OFF

SET

IST-1516.CE01.02 CE516P / User Manual Pag. 14/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

IMPORTANT ADVICE: before installing and configuring the control unit,

evaluate how many alarm devices are connected to the relays to determine how

many relays are needed and how they should act. Please see in SENSORS>

Configure> Description of the items related to the relay outputs.

Please note that the unit has No.5 outputs (relays) that can be increased by installing the

ES414 expansion board to have a total of 9 outputs. The diagrams, for simplicity, show all

relays outputs.

The connection to the internal outputs (relays 1 to 9) should be performed on the outputs board,

mounted in the base, on the right. The relay output no.9 is located on the central board, see Figure 5.

The relays nominal load is 250 VAC - 2 A or 30 VDC –2 A (resistive load).

NOTE: in Italian the indication NA means NO (Normally Open) while the others are the same.

The relay have changeover free voltage contacts, on the boards, the indications NO (Normally Open),

NC (Normally Closed), C (Common), refer to the relays in the normal position (not powered). If an output is

configured as POSITIVE LOGIC, the NO contact will become NC and NC will become NA.

NC

C

NC

A

A

Outputs board with relays 1÷4

NA

C

NC

NA

C

NC

NA

C

NC

NA

C

NC

Terminal Relay

Output no.1

Terminal Relay

Output no.2

Terminal Relay

Output no.3

Terminal Relay

Output no.4

LED: ON

Fig.10 –CE516P Wiring diagram - Relay Outputs

NA

C

NC

NA

C

NC

NA

C

NC

NA

C

NC

ES414 - Expansion board with relays 5÷8

NA (in Italian) means NO (normally open)

Terminal Relay

Output no.7

Terminal Relay

Output no.5

Terminal Relay

Output no.6

Terminal Relay

Output no.8

LED OUTPUT relay no.9

Terminal of Relay no.9

See also Fig.3

Position Expansion board

ES414 (Relays 5÷8)

Outputs board

(Relays 1÷4)

Main Board

Input AUX and

Outputs Relay 9

Battery

no. 1

Battery

no. 2

RS485 BUS

INPUT BOARD

LED: ON

IST-1516.CE01.02 CE516P / User Manual Pag. 15/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

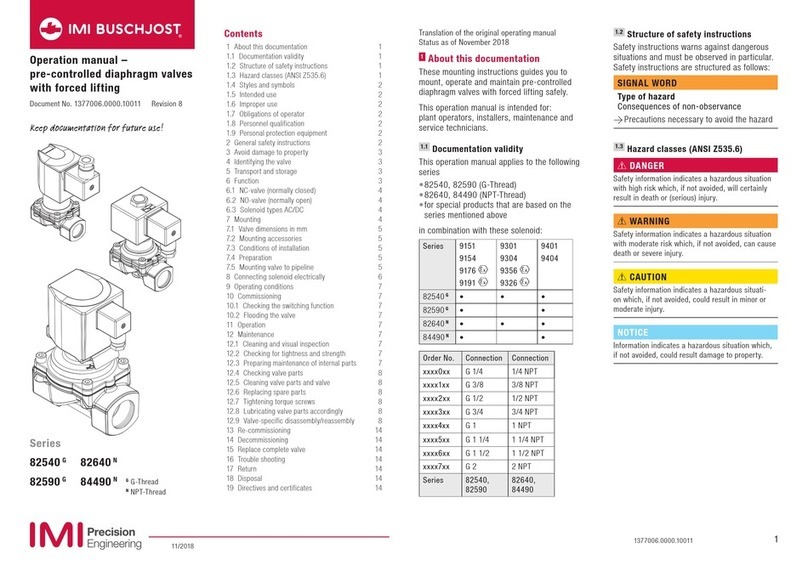

Expansion Board ES415 - Modbus®

The connection to a monitoring system via Modbus RTU binary protocol (COM3) is carried on the

optional expansion board ES415 (PC-Card Modbus output).

The ES415 board is mounted on the main board, placed in housing cover. (See Figure 11).

Pay attention, to put the terminals into the connector on the motherboard, making the first, matching

the three click columns with the corresponding holes and then pressing to insert them.

The "H3 (D1)", "GND (Common)," and "L3 (D0)" terminals of the RS485 serial port (COM3) are to be

connected to the supervision system (Master) or dedicated isolated converter (not included).

On standard MODBUS system, all devices are connected (in parallel) on a distribution cable with 3

shielded wires. Two form a balanced pair of twisted conductors, on which the bidirectional data,

typically at 9600 bits per second are transmitted. The third conductor (if used) is the common to all of

the bus devices.

TO AVOID IRREVERSIBLE DAMAGE,DISCONNECT THE POWER SUPPLY TO THE

CONTROL UNIT,MAINS POWER AND BATTERY (IF PRESENTS)BEFORE YOU UNPLUG

OR RE-CONNECT,ANY EXPANSION CARD.

Fig.11 –ES415 Expansion card with COM3 (RS485) Modbus serial port.

H3 (D1) = Segnale ModBus / ModBus Signal / Signal ModBus

LED Tx COM 3

LEd Rx COM 3

Morsetto / Terminal / Bornier

COM 3 - RS485- Modbus

Posizione scheda (Interno coperchio custodia aperto verso l’alto)

Card location (Internal housing cover opened up)

Emplacement de la carte (couvercle du boîtier interne ouvert)

L3 (D0) = Segnale ModBus / ModBus Signal / Signal ModBus

GND = Negativo (facoltativo) / Negativ (optional) / négatif (facultatif)

Cavo per comunicazioni Modbus, del tipo a doppino intrecciato (twisted pair)

schermato con SCHERMO a TERRA (solo lato centrale)

Modbus communications cable, twisted pair type shielded with GROUND

SCREEN (control unit side only.

Câble de communication Modbus, type paire torsadée blindé avec GROUND

SCREEN (côté unité de contrôle uniquement).

IST-1516.CE01.02 CE516P / User Manual Pag. 16/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

USE OF THE CONTROL UNIT

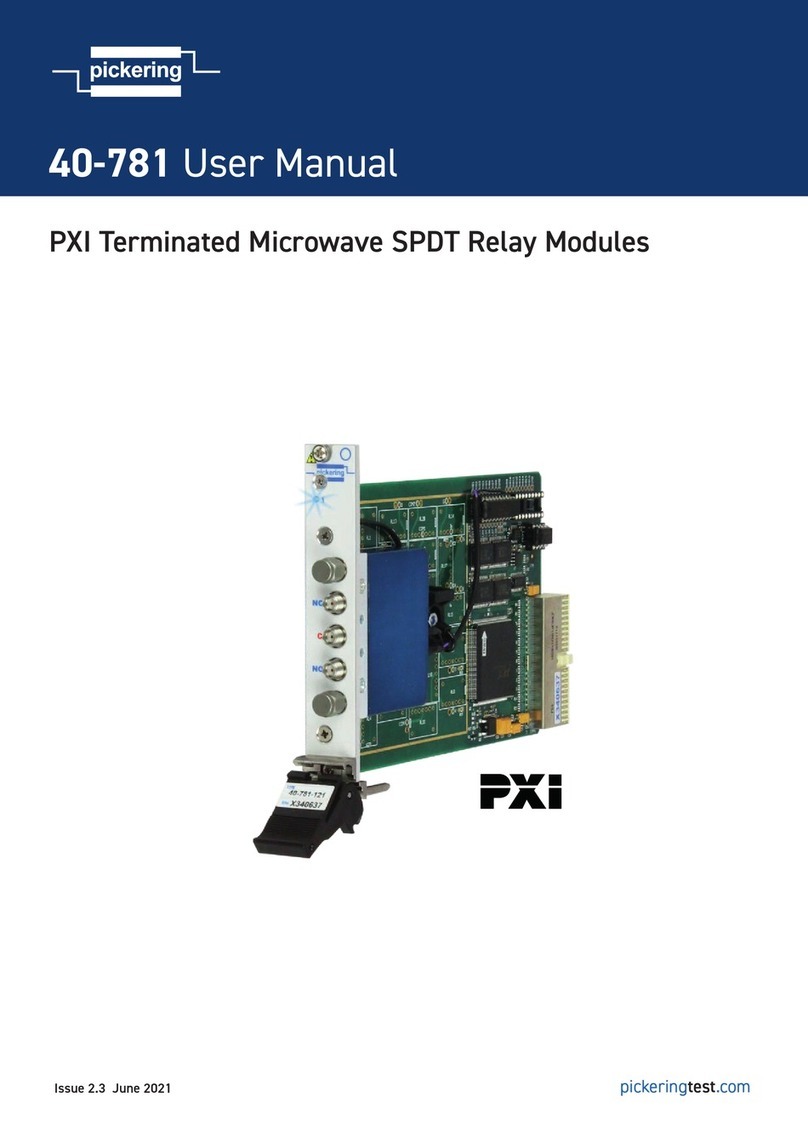

Fig.12 –CE516P Keyboard

Keyboard

The keyboard is backlit. To save energy, the brightness is reduced to half after 10 seconds of non-use.

RESET

Can only be used on the main screen, it is used to reset the latched outputs to normal

operation, but only if the Sensor or Zone or Input has returned from the alarm condition. If

there are active alarms, outputs configured as Silenceable (e.g. alarm) returns to normal

operating conditions only for the time of silencing by default.

Scroll through the display screens and the numeric digits up and down.

Keeping the key pressed increases the values' speed scrolling. In the main screen

changes to display the status of sensors, Logic Input and configured zones.

MENÙ

Call up the Main Menu from any screen.

ENTER

Confirm the inserted data and in the Main Screen allows you to select the detail’s sensors.

Scroll through the pages (6 sensors at a time and 7 events at a time), and input fields.

Keeping the key pressed increases the speed scrolling.

ESC

Cancel an operation and in the main screen is used to enter to Main Menu.

LEDs indications

The unit has 3 LEDs that show the operating status of the control unit (see also appendix).

FAULT

(Yellow LED)

Flashing = Preheat (Start Unit) or Firmware Update.

Fixed ON = Fault (Sensor or Areas) + Buzzer if enabled.

Short flashing = Output relay associated with a latched Fault.

Rapid flashing = Batteries Faulty or Disconnected.

ON

(Green LED)

Fixed ON = Operation with mains power.

Flashing = Operation with the batteries.

ALARM

(Red LED)

Fixed ON = Alarm 3 is active (Sensor or Zone) + Buzzer if enabled.

Flashing = Alarm 1 and / or 2 active (sensor or area or logic input).

Short flashing = Alarm latched (indented) (sensor or area or logic input).

Internal Buzzer indication

The unit has an internal buzzer that emits a beep when a key is pressed. It can also be configured to

sound in the event of a Fault and / or an Alarm.

Sound short (0.1s)

is always active

Confirms the pressing of a key

Continuous sound

if configured

Fault (Sensor or Zone)

Continuous sound

if configured

Alarm 3 is active (Sensor or Zone)

Single digit numeric field (password entry, etc.)

By pressing

and

key, the number is displayed in the field.

Tastiera

Keyboard

Clavier

Display

Ecran

LED

IST-1516.CE01.02 CE516P / User Manual Pag. 17/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

Screens 'Enable ...', 'Disable ...', 'Copy ...', 'Delete ...', 'Settings-> Date & Time':

Pressing the first time,

key, the number is displayed in its field (deleting any existing number), and

the next digits will be always inserted to the right of the number.

Example: to enter the number “12”, press

once, then press

to

move to the right and then press

twice.

If the number exceeds the maximum acceptable value, message will

appear "PARAMETER OUT OF RANGE".

Display –All other Screens:

As above, but in addition, when you press the

key, the last digit entered will be erased and you

can continue to enter additional digits.

Example: If you have entered the number "23", and then you want to change it to "25", simply press

the

then press

5 times. If you have already entered a single digit, pressing

will display

the minimum value accepted by the field. Then, by pressing

or

key, the value already present

is deleted and replaced with the new one.

Display –Initial Screens

The unit, when powered, for 5 seconds shows the model name and the

installed firmware version.

This information shall be accessible also in the menu SettingsGeneralInfo.

For more information read the chapter Settings.

Only at first power (and only then) will be asked to choose

your language and to indicate if the battery is present. Use the

key

and

to scroll through the languages and pressing

the key

ENTER

to confirm the choice.

If necessary, these choices can be changed. Please see forward

Service

Battery.

Preheating Time

At each start-up, a decreasing count of 90 seconds will always start, it

is the time necessary for the control unit to start up and allow the

Sensors to stabilize.

Display –Main Screen

After the preheating time, appears the main screen that the control unit

displays in normal operation. The date is shown in the top row, the first 6

sensors (with the measured concentration and its state) and in the last

line, the battery status of charge (if installed) and presence of the mains.

PSW (PASSWORD) followed by a number, at the bottom left indicates the

current access level (eg PSW 2 indicates that Level 2 is enabled).

The word 'SD' at the bottom right indicates that the SD-Card is inserted.

If the word 'DATA LOG' is also present, data storage is enabled (Data Logger).

Symbols used to indicate the status of the battery (if installed):

Full Charge

Half Charge

Low Charge

Discharge

Flashing =

Faulty or Disconnected

If by mistake, the battery (configured present) being disconnected and/or connected with

the control unit, mains powered the yellow LED lights up on fast blinking.

Symbols used to indicate the presence of mains power:

= mains operation (is absent, when the power is by the batteries).

12:00 fri. 08/07/2020

1) 2 % LFL NORM

2)10.2 ppm AL.1

3) 300 ppm AL.3

4) - - - -

5) - - - -

6) - - - -

PSW 2 DATA LOG SD

WARM UP

90

Wait . . .

PRESENCE BATTERY

1 - > NO

2 - > YES

L I N G U A - L A N G U A G E

L A N G U E - I D I O M A

1 - > ITALIANO

2 - > ENGLISH

3 - > FRANCAIS

4 - > ESPAÑOL

CE516

ver.

2.0X

PARAMETER

OUT OF SCALE

IST-1516.CE01.02 CE516P / User Manual Pag. 18/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

If the control unit, had lost the date and time, due to a malfunction or discharge of the clock

backup battery, screen will be displayed for entering updated values (The unit's safety

functions are guaranteed, except those involving the use of date that will be wrong). By

changing these parameters, see below, the section SETTINGSDATE and TIME.

The status of a sensor, which appears on the main screen, may be:

- - - -

Not configured

The detector is not Configured

* * * *

Disable

Detector is disabling. The outputs (relay) are not activated if an alarm occurs.

FAULT

Sensor failure

General information, of a faulty detector

OFF LINE

No Response

The detector does not respond or is disconnected from the Bus.

E001

Cartridge failure

The Sensor Cartridge is faulty.

E002

Cartridge failure

The Sensor Cartridge is not connected or its sensor may be faulty.

NORM.

Normal

There is no gas and there are no active alarms. The text blinks when

relay output is latched (Detector or Zone, returned to normality after an alarm or

a fault).

AL.1

Alarm 1

The first alarm threshold has been exceeded

AL.2

Alarm 2

The second alarm threshold has been exceeded

AL.3

Alarm 3

The third alarm threshold has been exceeded.

F.S.

Full Scale

The gas concentration is over the full scale or the detector may be

faulty.

When a detector, a logic input or a zone, activate a relay output, the summary screen of the status of

the Alarms and Faults appears. This allows checking quickly, the total number of active relays and

their relative alarm level.

The details of the individual items is as follows:

FAULT

Indicates the number of active relays, relative to the Fault, of a sensor or a group of

sensors that belong to a zone.

AL. 1

Indicates the number of active relays, relating to exceeding the threshold of alarm 1, of a

sensor or a group of sensors that belong to a zone.

AL. 2

Indicates the number of active relays, related to exceeding the threshold of alarm 2, of a

sensor or a group of sensors that belong to a zone.

AL .3

Indicates the number of active relays, relating to exceeding the alarm threshold 3, of a

sensor or a group of sensors that belong to a zone.

INPUT

Indicates the number of active relay, logic input.

O.L.

Indicates the number of the OUT OF LINE detectors.

The screen can be closed by pressing

ESC

or

RESET

key. If the alarms

persist, the screen reappears after 10 minutes. If a new alarm occurs

the screen will appear again automatically.

From the Main screen, by pressing

and

keys, to scroll through

the sensors, displayed in groups of 6 at a time. Pressing

ENTER

, key

highlights the sensor in the first row. While, using the keys

and

to scroll through the sensors (in the page) shown on the display.

Pressing the

ENTER

key again, you view the details of the highlighted

sensor, (of course only if it is configured).

Explanations of the details are as follows:

1st row

Shows the number of the sensor (Gas Detector).

2nd row

Shows the name of the gas or its CAS Number being measured.

CAS No. is a unique numerical identifier assigned by the Chemical Abstracts Service

(CAS) to every chemical substance.

3rd row

Shows the currently measured gas concentration and the unit of measure.

4th row

Indicates the Zone.

N. 1

GAS:

METHANE

2 % LFL

ZONE:

0

OUTPUT

0 1 29

ALARM STATUS

FAULT:

00

AL 1:

01

AL 2:

00

AL 3:

03

INPUT:

00

O.L.

00

IST-1516.CE01.02 CE516P / User Manual Pag. 19/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

5th-6throw

Indicates the output number (Relay), corresponding respectively to:

1st Threshold (AL1) 2nd Threshold (AL2) 3rd Threshold (AL3) FAULT.

Value 0(zero) indicates, at that threshold, the output not been assigned, while the

highlighted value indicates that output relay is currently active (alarm). The values are

real time updated.

Pressing

ESC

key it returns to the screen of the sensors. Press

ESC

again, to return to the Main

Screen.

Using the keys

and

is displayed, in cyclic mode, the situation of

the Zones (from Z1 to Z4) and the Logic Input AUX (I1).

The status of a LOGIC INPUT can be configured LOW (normally open

contact) or HIGH (normally closed contact) it can only be ACTIVE or

DEACTIVE, while a ZONE has the same states as a Sensor, except the

full scale.

Press

ESC

to enter the Main Menu.

The Control Unit has No.4 Zones and No.1 Logic Input.

12:00 fri 08/07/2020

I1) LOW DEACTIVE

PSW 2 DATA LOG SD

12:00 fri 08/07/2020

Z1) NORM.

Z2) - - - -

Z3) - - - -

Z4) - - - -

IST-1516.CE01.02 CE516P / User Manual Pag. 20/50

TECNOCONTROL S.r.l. - Via Miglioli, 47 20054 SEGRATE (MI) - Tel. 02. 26 92 28 90 - Fax 02. 21 33 734

MAIN MENU

The Control Unit is provided with a main menu from which you can

manage all of its functions.

The name of each line indicates the thematic area on which we can take

action, by accessing the corresponding submenus.

Pressing

and

key to scroll through the menus.

Than press

ENTER

to enter in the corresponding submenus.

The Submenu 2-RESERVED, is not accessible, is not currently enabled,

is reserved for other functions.

Some submenus are protected by Level 1 or Level 2 passwords, indicated by the

“padlock” symbol visible when the level was not enabled.

When a protected menu is selected, the request to enter the specific Password

appears. When a menu is enabled, all others of the same level will be enabled and the

"locks" disappear. Further information can be found in the Access menu section.

With

and

you can enter the value, with

and

keys you

can move from one number to another.

After entering the Password, move to OK and press

ENTER

.

If the password entered is correct, the window will confirm the operation.

If an incorrect password was entered, the window alerts you of the error

and return to the screen ENTER PASSWORD

The required access level is indicated, when necessary, to the left of the individual items of the

manual.

List and short description of the accessible menus and the required or Password:

1-RESET

Performs silencing or Resetting the alarms and faults, not active and return to

the main menu.

2-RESERVED

Submenu currently not active, reserved for further functions.

3-SENSORS

Enter a submenu where you can enable , disable , configure , modify ,

copy , delete and view the details of the sensors.

4- INPUTS

Enter a submenu where you can enable , disable , configure , modify ,

copy , delete and view the details of the logic input.

5-ZONE

Enter a submenu where you can enable , disable , configure , modify ,

delete and view the details of the zones.

6- EVENTS

Enter a submenu where you can view, all events or ones related only to faults /

alarms.

7- SETTINGS

Enter a submenu where you can change, the language , the display Contrast,

the buzzer settings , date and time settings the Modbus protocol and

display Info (model, version and business address).

8- ACCESS MENU

Enter a submenu where you can enable, disable, modify, the password, of the

relative access levels and . The level is not accessible, is factory

reserved.

9-SERVICE

Enter a submenu where you can perform electrical testing of the control unit

manage the battery . Factory Test is factory reserved.

0-SD CARD

Enter a submenu where you can update the Firmware of the control unit via

an SD Card, upload or save the configuration , save the events or store the

values read by the detectors (Detectors’ data logger) on the SD card (if

inserted).

ENTER PASSWORD

LEVEL 1

0000

OK

CE516

1 RESET

2 RESERVED

3 SENSORS

4 INPUTS

5 ZONES

6 EVENTS

7 SETTINGS

8 ACCESS MENU

9 SERVICE

0 SD CARD

Table of contents

Popular Control Unit manuals by other brands

Automationdirect.com

Automationdirect.com Productivity 2000 P2-04DA manual

Wetco

Wetco Water Specialist 1.5EI Programming and Drawings Manual

RGB Technology

RGB Technology PS25-4 Technical documentation

IMI BUSCHJOST

IMI BUSCHJOST 82590G Series Operation manual

GBD

GBD BA100 Instructions for installations

Pickering

Pickering 40-781 user manual