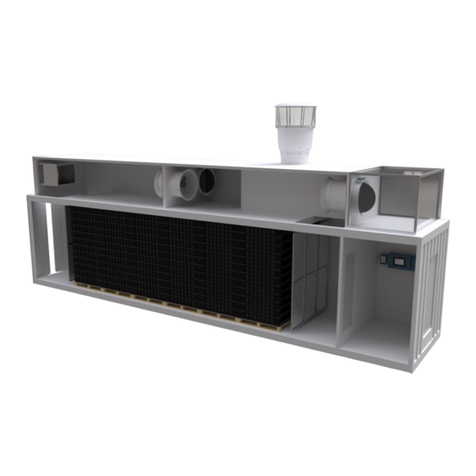

DA 60-820

Technical User Guide

1 Product description ....................................................................................................................................... 6

2 Product survey ............................................................................................................................................... 7

2.1 Above roof .................................................................................................................................. 8

2.2 Lead-through.............................................................................................................................. 9

2.3 Attic/section ............................................................................................................................... 9

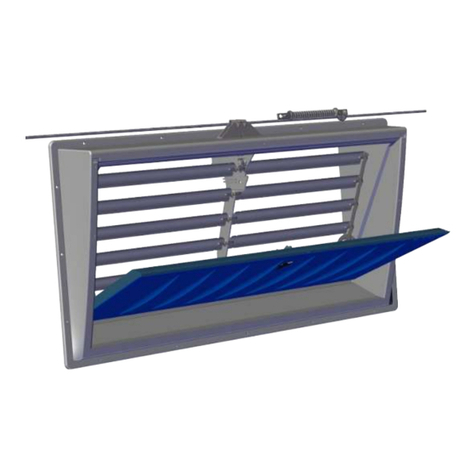

2.4 Inlet............................................................................................................................................ 11

3 Mounting guide............................................................................................................................................. 13

3.1 Recommended tools................................................................................................................ 13

3.2 Installation examples............................................................................................................... 15

3.2.1 Placement .................................................................................................................................. 15

3.2.2 Select adhesive air jet or free air direction................................................................................. 15

3.3 Placement in the livestock house .......................................................................................... 16

3.4 Examples of placement in the house..................................................................................... 16

3.5 General drawing with roof cap ............................................................................................... 17

3.6 General drawing in the attic.................................................................................................... 18

3.7 Mounting the duct.................................................................................................................... 19

3.7.1 Shortening ducts ........................................................................................................................ 19

3.8 Mounting of roof duct and duct.............................................................................................. 20

3.9 Mounting the fan ...................................................................................................................... 21

3.10 Lead-through in ceiling ........................................................................................................... 22

3.11 Mounting in the attic................................................................................................................ 23

3.11.1 Mounting the anchorage ............................................................................................................ 23

3.11.2 Mounting the bell mouth............................................................................................................. 24

3.11.3 Mounting the net ........................................................................................................................ 24

3.12 Mounting roof sheet ................................................................................................................ 25

3.12.1 Roofing sheet in a corrugated roofing sheet construction.......................................................... 25

3.12.2 Flat roofing sheet in a sandwich panel roofing sheet construction ............................................ 25

3.13 Roof duct in roof ...................................................................................................................... 27

3.13.1 Flat roofing sheet in a corrugated steel plate construction, ridge .............................................. 28

3.13.2 Flat roofing sheet in a corrugated steel plate construction, side................................................ 29

3.13.3 Check if the top is level .............................................................................................................. 31

3.14 Mounting the roof cap ............................................................................................................. 31

3.15 Mounting the duct unit on the roofing sheet......................................................................... 33

3.16 Mounting storm protection kit on roof duct .......................................................................... 34

3.17 Foaming and sealing of the duct unit .................................................................................... 35

3.18 Mounting the outlet funnel on the adapter ............................................................................ 35

3.19 Mounting adapter on the duct ................................................................................................ 37

3.20 Mounting the intermediate and bottom plate ........................................................................ 37

3.21 Mounting the recirculation fan ............................................................................................... 39

3.22 Mounting the insulation .......................................................................................................... 40

3.23 Mounting the pull rod/suspension ......................................................................................... 41

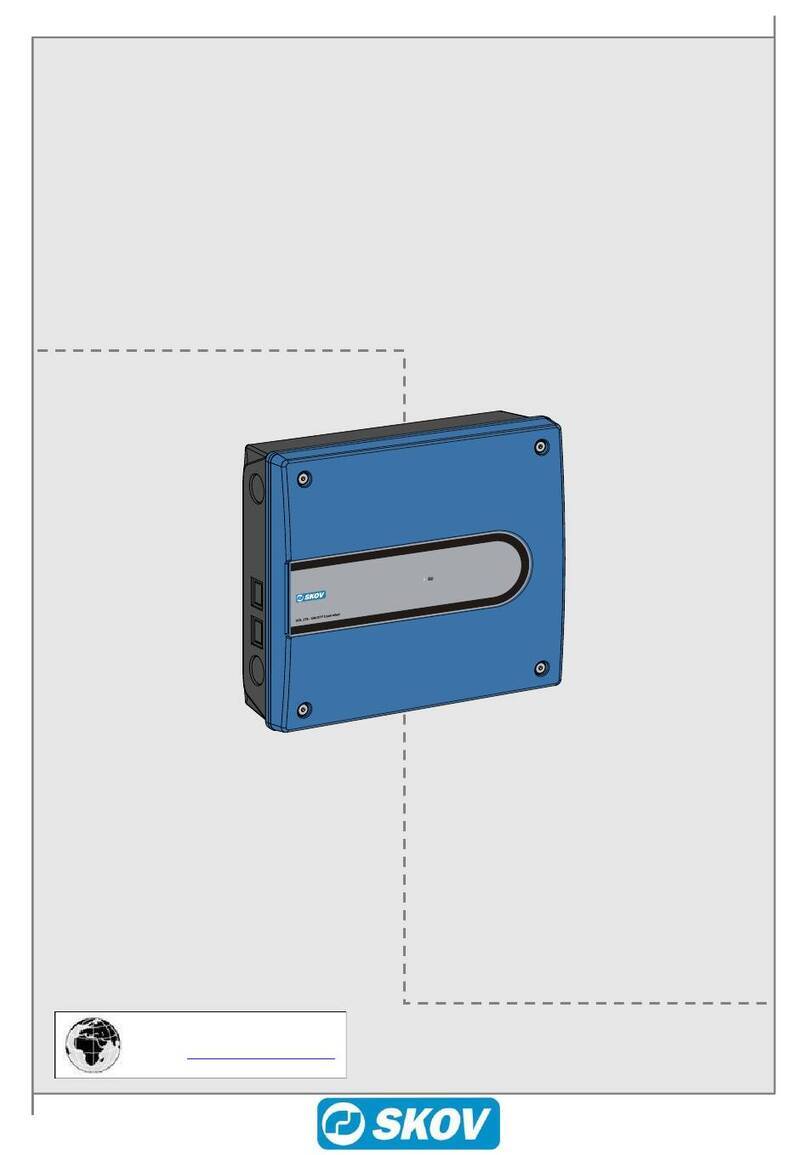

3.24 Mounting the motor controller................................................................................................ 42

3.24.1 Position of motor controller/frequency converter ....................................................................... 42

3.24.2 Mounting distances for the motor controller/frequency converter .............................................. 42

3.24.3 Position of motor controller ........................................................................................................ 43

4 Installation guide.......................................................................................................................................... 44

4.1 Electrical connection............................................................................................................... 44

4.1.1 Mains supply dimensioning regarding harmonic distortion ........................................................ 44