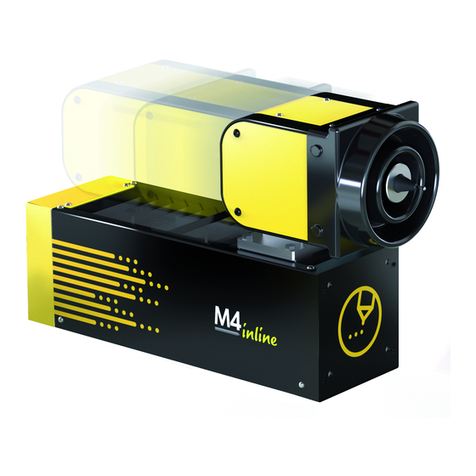

Technomark Multi 4 User manual

®

1 PRODUCT - 4 CONFIGURATIONS

NEW GENERATION!

®

w

w

w

.

t

e

c

h

n

o

m

a

r

k

-

m

a

r

k

i

n

g

.

c

o

m

w

w

w

.

t

e

c

h

n

o

m

a

r

k

-

m

a

r

k

i

n

g

.

c

o

m

On Site

demonstration!

On Site

demonstration!

®

CREATIVE TRACEABILITY

®

PRESENTATION

MULTI4 BENEFITS

• Easier to use : simplied user interface, intuitive

navigation, new and improved features (zooming,

cutting/pasting, test …)

• Resolution : high denition color screen

• Intuitive : icon based navigation menu allows for

quick understanding and operation of the software

• Ergonomics : new design with a second handle

(optional accessory)

• Handling : support foot, controller handgrip and

handle on the marking head (optional)

• Light weight : marking head weight reduced by

around 0.88 lbs (400 grams)

• Robust : use of cast aluminum parts

• Performance : increase of the marking speed by

20% and optimization of the overall X/Y movement,

standard management of 3 axes

• Resourceful : 40Mb of memory can accommodate

up to 20,000 stored, marking les (40 characters,

1 line), serial communication, USB, Ethernet (option)

and Inputs/Outputs

IDI Track :

Real-time Multi4 monitoring for analysis of maintenance needs,

stylus wear and detection faults (auto-diagnosis feature with 5

control points).

TECHNOLOGICAL INTELLIGENCE

IDI Mark :

The quality of marking is ensured, whatever the difference in

height between the part (at or cylindrical) and the stylus. Its

adjustment is managed by the Multi4 software.

(1)

(2) (1) Marking with IDI Track

(2) Marking without IDI Track

Patent n°EP-06 764715.6

Patent No. US-9, 421, 598

mark

®

MULTI4 / QUICK USER GUIDE N°1 USER’S MANUAL

STEP 1 : Read the safety instructions

STEP 2 : Unpacking, assembly and starting up

•Depending on your

application, we

strongly recommend to

wear protective glasses

and gloves, as well as

safety shoes.

•Keep the machine

away from heat,

humidity, and radio

interferences sources

(ex : welding machine).

•Never tighten or

release the knurled nut

of the percussion sub

assembly* using a

plier or any other tool.

Hand tightening is

sufcient (See User’s

guide 1-B-2).

•Avoid violent impact

on the marking head

or the control box.

•Never cover the

control box.

•Do not insert your

ngers between the

stylus and the part to

be marked.

•Never activate the

machine when empty

(without part to mark

under the marking head).

•Think about positioning

stylus between 0.039’’

and 0.37’’ (1mm and

9.5 mm) from the

surface to be marked.

Optimal conguration

is 0.12’’ (3 mm).

•In hand held position,

do not point or position

the active part of the

stylus towards yourself

or anybody else.

Connect the power cable to the

controller.

Tighten the locking handle on the

column (see assembly plan ASC10

included in the packing box).

Unpack the different parts

comprising the machine.

Plug in the power supply cable into

a power socket.

Mount the marking head on the

column (1), using the knurled nut at

the back of the head (2).

Assemble the base and the column

(see assembly plan ASC10

included in the packing box).

Power up the machine by switching

the main switch to ( I ).

Connect the marking-head

cable to the controller (1) and

lock it (2).

Fix the xing plate on the column

(see assembly plan ASC10

included in the packing box).

3

6

9

2

5

8

1

4

7

11

22

* Part where the stylus is located.

®

USER’S MANUAL

01 - Return to home page

02 - Character height, position

and marking force

03 - Setting point density,

spacing, ...

04 - Cancel input/operation

05 - Start/stop battery (optionnal)

06 - Space bar

07 - "Shift" key. Allow minuscule

when kept pressed + letter

08 - Marking or test stop button

09 - Insert special characters

10 - File (Open an existing

le, create a new le,

save, adjusting speed,

activate D axis)

11 - Marking simulation function

without marking

12 - Parameters setting (zoom,

time, language, accessory,

window size, …)

13 - Secondary functions

(see step 4 underneath)

14 - Battery and sleep mode

indicator

15 - Erase characters

16 - Conrm input/operation

17 - Marking or test start button

Enter data: text,

gures… Select point density Testing outline of all the

lines (le)

Edit Menu: copy/stick,

insert, ... Setting space between

characters Marking test of all the

lines (le) without impact

Setting marking force Open existing le Users, licences and

password

Modify marking

parameters Select character font Test beginning/end of

the line

File conguration: speed,

accessory and IDI

activation, ... Back to default values Zoom

Adjust characters

height/width New le Interface parameters

(language, ...)

Add mechanical

function: pause, ... Italic mode Marking test of the line

without impact

Manual positioning

of data Save le Setting date and time

Adjustment of slope

angle and radius Import/Export data with

USB key Machine parameters

(maintenance,

window,...)

Centring text X, Y, or XY Testing outline of the

selected line

STEP 3 : Main functions

STEP 4 : Secondary functions (once the main function has been selected)

Yellow buttons open action windows

10

13

11

12

06

09

14

15

16

01

04

02

05

03

08

07

17

®

STEP 5 : Producing a "simple" marking

Press "position" key

Select key: "character dimension" and

adjust height/width with arrows

Position the stylus tip between

0.039’’ and 0.37’’ (1 mm and 9.5

mm); ideally (default value) 0.12’’

(3 mm)

Position part under the marking head

Position marking following X and Y

within the window, using arrows

Enter "data parameters" menu

Enter or modify text, gures; they

are displayed on the screen

Fasten the part to the table

Press "force" key and select 1 to 6

(intermediate setting is 2)

Select "point density" key and select

one of the 4 matrix

Enter the "position" menu

Adjust height of the marking head

(tighten the locking handle (1), adjust

height with the upper wheel (2), release

the locking handle (3)) then lock it

3

6

9

12

2

5

8

11

1

4

7

10

MULTI4 / QUICK USER GUIDE N°1 USER’S MANUAL

02

01-03

®

STEP 6: Reminder of the main technical features

Enter le name and eventually

comments

Start marking

Conrm entered data and

conguration

Conrm entry

Select "le" menu

Select "test" menu

Turn off the mains switch ( o)

Press "save" key

Test marking (choose from: line outline

(1), le outline (2), beginning-end

line (3), line without impact (4), le

without impact (5))

15

18

21

14

17

20

13

16

19

• Power: 250 VA

• Frequency: 50 or 60 Hz

• Controller dimensions (L x W x H): 145.67’’ x 84.65’’ x 54.72’’ (370 x 215 x 139 mm)

• Electrical supply: 90 to 240 V

• Range of working temperature: 0°C to + 45°C (32°F to 115°F)

USER’S MANUAL

1 32 4 5

®

MULTI4 / QUICK USER GUIDE N°2 TECHNICAL HELP

STEP 1: Safety instructions

For safety reasons, you must unplug the power cable before performing any maintenance or service

operation on the machine.

The new Multi 4 generation was designed to keep maintenance as low as possible.

Only the mechanical part (marking head) requires minor maintenance.

01 - Unplug the power cable from the machine, to remove all power.

02 - Refer to the user’s manual.

03 - Contact our after sale customer service team by either:

• Telephone: (936) 270-7180 or (888) 610-0151

Our technicians are committed to helping you identify and rectify the malfunction as quickly as

possible.

04 - If the problem cannot be solved directly, we ask you to return the complete machine

(controller + head).

If required, and depending on the guarantee conditions, our company will supply FREE of

charge a loan machine during the period your equipment is unavailable.

We are committed quotation a repair estimate within 48h from the time we receive the machine.

STEP 2: Maintenance and Daily Service

STEP 3: What to do when faced with a malfunction?

Check if there is no dirt in

the mechanic parts, and

clean as necessary using a

compressed air nozzle.

Check the sharpness of the

stylus (Standard 90°). It can

be sharpened or replaced

as necessary.

Check the spring condition.

It should not be shorter than

51 mm!

Think about cleaning

and lubricating the stylus,

following the disassembly

instructions as explained in

the user’s manual (6-C).

Regular maintenance with manufacturer origine pieces ensures marking equipment lifetime

of 20% gain. Over a 5-year period, the average operating cost of the product was

reduced by 14% (excluding warranty period)

®

TECHNICAL HELP

STEP 4: Trouble shooting

• Ensure the part is correctly xed in

place

• Check sharpness of the stylus

• Adjust:

- Character height

- Impact force

- Part to stylus distance

The marking quality is bad and/or

the characters are not well formed.

• Check if stylus is moving freely

• Check if force and/or distance are

compatible

• Check position and tightening of the

stylus assembly

• Check if the purple electro-magnet

cable is damaged

The part is not marked.

• Check the main power supply

• Check the On/off switch

The control screen does not work.

• Clean and oil the stylus

• Change the stylus spring

(See user’s manual 6-C)

• Replace the stylus

The stylus stays stuck, tip downwards.

• Check alignment and cleanliness of

X and Y axis (see user’s manual 6-F)

• Check the connection and locking

of the marking head cable on the

controller

The percussion assembly is not moving

or makes a strange noise during the

marking cycle and/or as it returns to

its origin.

For any other malfunction, please refer to the user’s manual.

®

ADMINISTRATIVE

Your support

Many services are available to satisfy all your requirements. Our teams are at your service.

COMMERCIAL DEPARTMENT

For all inquiries concerning:

• Machine and accessory sales

• Maintenance and loan contracts

• Our product offers

LOGISTIC DEPARTMENT

For all inquiries concerning:

• Shipping policy

• Transport

• Return of equipment

ADMINISTRATIVE DEPARTMENT

For all inquiries concerning:

• Invoicing

• Payment facilities

• Contract follow up

AFTER SALES SERVICE

For all inquiries concerning:

• Technical service

• Maintenance

• Loan equipment

• Repairs

MULTI4 / QUICK USER GUIDE N°3

®

Plate support Transport trolleyPart support

Powered Z column base for

automatic part detection

Maintenance kit Bar-end tool

Standard rotary D axisHeavy duty rotary D axis Automatic plate feeder

MAIN ACCESSORIES

photo credit 3D © Comète 2012

Version 2.0 US

Our whole team thank you for choosing Technomark and wish you many good markings!

Magnetic head support Reading systemSoftware

Technomark North America

13626 Poplar Circle, Suite 502 - Conroe, TX 77304

Tel: (936) 270-7180 or (888) 610-0151 / Fax : (936) 230-5679

E-mail : [email protected]

www.technomark-inc.com

®

Table of contents

Other Technomark Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Swann

Swann AMI Phosphate-II Operator's manual

TESTO

TESTO 300 XXL instruction manual

LaserLiner

LaserLiner DampFinder Home manual

Velleman Instruments

Velleman Instruments HPS40 Technical documentation

Hansen

Hansen VPIF Specifications, Applications, Service Instructions & Parts

geo-FENNEL

geo-FENNEL FL 105H user manual