Technoton MasterCAN 35 User manual

Contents

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 2

Contents

Contents ...................................................................................................................... 2

Revision history............................................................................................................. 3

Structure of external links .............................................................................................. 4

Terms and Definitions .................................................................................................... 5

Introduction.................................................................................................................. 7

1 General information and technical specifications ........................................................... 11

1.1 Purpose of use, application area, operation principle................................................ 11

1.2 Exterior view and delivery set............................................................................... 12

1.3 Design............................................................................................................... 13

1.4 Technical specifications........................................................................................ 14

1.4.1 Main specifications ........................................................................................ 14

1.4.2 CAN j1939/S6

digital interface protocol and characteristics .................................. 15

1.4.3 Specifications of signals analog inputs ............................................................. 16

1.4.4 Overall dimensions ........................................................................................ 17

2 MasterCAN Display 35 installation ............................................................................... 18

2.1 Exterior inspection prior to starting works .............................................................. 18

2.2 Choosing installation place ................................................................................... 19

2.3 Installation procedure.......................................................................................... 20

2.4 Electrical connection............................................................................................ 21

3 MasterCAN Display 35 configuration ............................................................................ 23

3.1 Connecting MasterCAN Display 35 to PC ................................................................ 23

3.2 Connection parameters for CAN j1939/S6 interface ................................................. 26

3.3 Configuring informational screens ......................................................................... 27

4 Displaying informational screens................................................................................. 31

4.1 Main menu ......................................................................................................... 31

4.2 Screen navigation ............................................................................................... 33

4.3 External Units operability check ............................................................................ 34

4.4 Events monitoring ............................................................................................... 36

5 Packaging ................................................................................................................ 37

6 Storage ................................................................................................................... 38

7 Transportation.......................................................................................................... 39

8 Utilization/re-cycling ................................................................................................. 40

Contacts..................................................................................................................... 41

Annex A SPN of MasterCAN Display 35 Functional modules ............................................... 42

A.1 Self-diagnostics FM ............................................................................................. 42

A.2 Onboard clock FM ............................................................................................... 44

A.3 Vehicle power supply FM...................................................................................... 45

A.4 CAN Monitor FM .................................................................................................. 47

A.5 Analog Gateway FM............................................................................................. 49

A.6 Events registrator FM .......................................................................................... 51

Annex B

Diagrams of pre-set information screens for modifications of MasterCAN Display 35

...... 52

B.1 Screens of MasterCAN Display 35 G (“Truck”)......................................................... 52

B.2 Screens of MasterCAN Display 35 T (“Tractor”) ....................................................... 53

B.3 Screens of MasterCAN Display 35 M (“Vessel”) ....................................................... 54

B.4 Screens of MasterCAN Display 35 U (“Universal”).................................................... 55

Annex C Firmware upgrade ........................................................................................... 56

Annex D Example of onboard equipment connection diagram to MasterCAN Display 35 ........ 57

Revision history

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 3

Revision history

Version

Date

Editor

Description of changes

1.0

06.2018

OD

Basic version.

2.0

12.2018

OD

Changes in the set of parameters displayed on pre-set screens of

different MasterCAN Display 35 modifications are updated and

reflected in diagrams.

Changes in MasterCAN Display 35 delivery set are reflected.

New functional features of MasterCAN Display 35 are included:

- new design of the main menu and information screens;

- monitoring of Units Events and malfunctions;

- menu of settings;

- resetting Counters that can be cleared (for “Marine”

modification);

- switching the display into the “sleeping” (energy-saving) mode;

- displaying electronic passport;

- manual and automatic adjustment of the display backlighting;

- sound signal for incoming messages and pressing buttons.

A table containing a list of equipment that must be connected to

different modifications of MasterCAN Display 35 in order to display

the standard set of specified parameters on pre-set screens is

created.

An example of Units connection diagram to MasterCAN Display 35

using new components of S6 cable system is provided.

Structure of external links

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 4

Structure of external links

CAN j1939/S6 Display MasterCAN Display 35. Operation manual

Document Center

S6 Website

Part S6 Data Base

Part S6 Functional modules

JV Technoton Website

Part Technical support

Part Software/Firmware

Technoton Engineering Website

Page DUT-E

Page DUT-E GSM

Page DUT-E 2Bio

Page CANUp

Page DFM

CAN j1939/S6 Telematics interface.

Operation manual

Pages MasterCAN

Page DFM Marine

Page S6 SK

Terms and Definitions

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 5

Terms and Definitions

IoT Burger is the Technology of creating smart sensors and complex telematics IIoT

devices operating in real time with built-in analytic features

(further on –IoT Burger). The basis of IoT Burger is the software/hardware core, a

set of ready-to-use universal Functional Modules, the database of standartized IoT

parameters.

Particular features of IoT Burger:

•inbuilt analytic features for maximum treatment of signals within the device itself;

•a possibility to design devices with extremely low power consumption;

•doesn’t require programming in the majority of applications, flexible setup;

•using inexpensive industrially manufactured equipment parts;

•measurement and treatment of “quick” processes which is impossible to implement

using cloud technologies;

•an option of ready Reports delivery to the user avoiding server platforms;

•the inbuilt system of data authenticity assurance (self-diagnostics, authorization,

impact control).

The technology provides for the availability of several measurement channels in any device

including pre-set analytical treatment (filtration, linearization, thermal compensation) and the

controlled error of measurement.

Devices created using IoT Burger may be united to form a wire-connected or wireless

connection network. Data may be transmitted to the telematics server, to popular IoT

platforms, by SMS, E-mail, to social networks.

At present, GSM 2G/3G data transmission standards are used in devices with IoT Burger. The

reports transmitted contain data on instant and average values of Parameters, Counters,

Events. The flexible system of Reports setup enables the user to select the optimal ratio of the

data completeness and the volume of traffic.

CAN j1939/S6 Display MasterCAN Display 35 is designed using IoT Burger Technology.

S6 is the Technology of combining smart sensors and other IoT devices within one

wire network for monitoring of complex stationary and mobile objects: vehicles,

locomotives, smart homes, technological equipment etc. The Technology is based

and expands SAE J1939 automotive standards.

Information on cabling system, service adapter and S6 software refer to CAN j1939/S6

Operation manual.

PGN (Parameter Group Number) —is a combined group of S6 parameters, which has common

name and number. Functional modules (FM) of the Unit can have input/output PGNs and setup

PGNs.

SPN (Suspect Parameter Number) —informational unit of S6. Each SPN has determined name,

number, extension, data type and numerical value. The following types of SPN exist:

Parameters, Counters, Events. SPN can have a qualifier which allows qualification of

parameter’s value (e.g. –Onboard power supply limit/Minimum).

Event —relatively rare and sudden change in SPN. For example, the attempt to falsify values

of “Instant fuel consumption” counter by applying electromagnetic field to fuel flow meter will

be recognized as “Interference” Event. An Event can have one or several characteristics.

“Interference” Event has the following: date/time and duration of interference. When the Event

occurs, a terminal unit registers the time of occurrence, which is later mentioned in a report on

the event. Thus, the Event is always attached to exact time and place of occurrence.

Terms and Definitions

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 6

Onboard equipment (OE) —Telematics system elements, directly installed in Vehicle.

Parameter —time-varying or space characteristic of the Vehicle (SPN value). For example,

speed, fuel volume in the tank, hourly fuel consumption, coordinates. Parameter is usually

displayed in the form of graph, or averaged data.

Counter —cumulative numerical characteristics of Parameter. Counter is represented by a

number, which can only grow in time. Examples of Counters: fuel consumption, engine

operation time, total distance and other.

Telematics system —complex solution for vehicle monitoring in real time and trip analysis.

The main monitored characteristics of the vehicle: Route, Fuel consumption, Working time,

technical integrity, Safety. In includes On-board report, Communication channels, Telematics

service ORF 4.

Vehicle an object controlled within Telematics system. Usually Vehicle means a truck, tractor

or bus, sometimes a locomotive or river boat. From Telematics system point of view,

stationary objects are also considered to be vehicles: diesel gensets, stationary tanks,

boilers/burners.

Function module (FM) unit-embedded component of hardware and software combination,

executing a group of special functions. Uses input/output PGNs and settings PGNs.

Unit is an element of vehicle on-board equipment compatible with S6 bus, which uses

S6 Technology.

Introduction

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 7

Introduction

Recommendations and rules set out in this Operation Manual apply to

MasterCAN Display 35 CAN j1939/S6 Display (further on —MasterCAN Display 35),

model code —04, manufactured by JV Technoton, Minsk, Republic of Belarus.

Model code of MasterCAN Display 35 is defined by first two digits of serial number, which is

printed on nameplate placed in the lower part of back cover or printed on package label

(see figure 1).

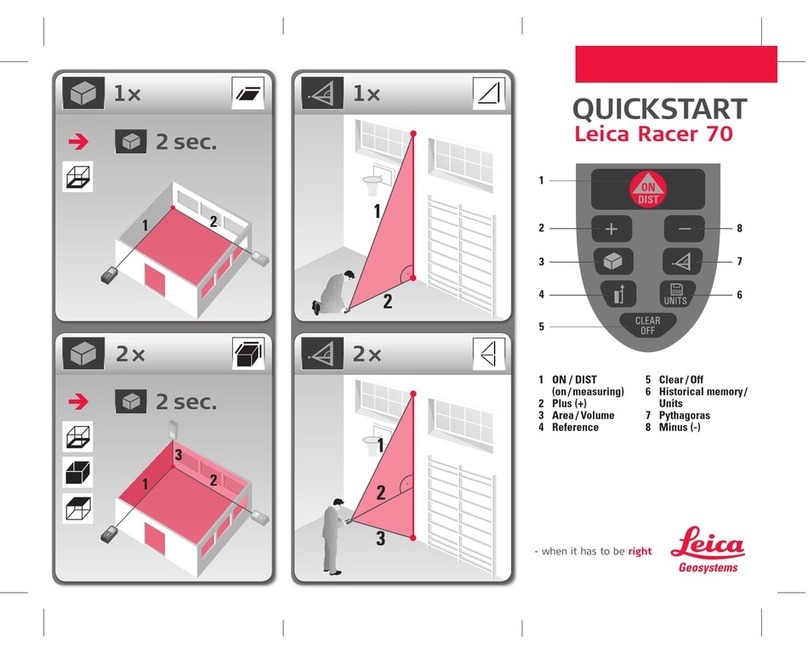

Figure 1 —Finding out model code of MasterCAN Display 35

The manual contains information on design, operation principle, specifications and instructions

on connection, configuration and use of MasterCAN Display 35.

—a tool for supervising operation parameters of complex

vehicles and stationary machines.

MasterCAN Display 35 key features:

possibility to display selected Vehicle operation parameters from total 3500+ received

via CAN j1939/S6 interface;

converting voltage/frequency signals of analog sensors into digital messages (SPN) and

displaying it on the screen;

flexible configuration of display of parameters (up to 21 group, 10 screens in each

group, 1 or 2 parameters on each screen);

special modifications of MasterCAN Display 35 —“Truck”, “Tractor” and “Vessel”have

pre-set information screens displaying performance parameters of primary interest for

specific types of equipment;

compliance with Units, Database and cabling system S6 Technology;

based on IoT Burger Technology, which ensures data processing by electronic module of

MasterCAN Display 35 with no need of additional data processing units;

unique diagnostics functions, allowing to check operability of MasterCAN Display 35

itself and Units connected using S6 Technology;

signal cables and fasteners included in delivery set;

automatic display brightness adjustment;

conformity with European and national automotive standards.

For MasterCAN Display 35 configuration using cable connection to the PC you should use S6 SK

service adapter (to be purchased separately) and the Service S6 MasterCAN service software

(the software current version can be downloaded at https://www.jv-technoton.com/, section

Software/Firmware).

Introduction

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 8

Features of different modifications of MasterCAN Display 35:

1) MasterCAN Display 35 U (“Universal”)—Display modification with extended user rights

regarding configuration of information screens. It is designed for monitoring parameters of any

fixed/mobile objects equipped with a standard CAN-bus, S6 Units, analog sensors.

It has 27 pre-set screens with SPN values received via CAN j1939/S6 interface and one screen

with converted signals from analog inputs (see B.4).

A user of MasterCAN Display 35 U can:

delete and edit pre-set screens;

configure displaying any of 3500+ parameters (SPN) of S6 Database;

create and configure the maximum possible number of information screens (200 screens

with SPN received via CAN j1939/S6 interface and one screen with converted signals

from analog inputs);

conduct flexible configuration of parameters displayed (one/two SPN on the screen,

change SPN name and designation).

2) MasterCAN Display 35 G (“Truck”)—Display modification designed to monitor

parameters of tractor trucks equipped with a standard CAN-bus, S6 Units, analog sensors.

It has 27 pre-set screens with SPN values received via CAN j1939/S6 interface and one screen

with converted signals from analog inputs (see B.1).

A user of MasterCAN Display 35 G can:

add the number of screens up to 10 in each of the pre-set groups;

edit the screen with converted signals from analog inputs;

load SPN designation.

A user of MasterCAN Display 35 G cannot:

delete and edit pre-set screens;

create new groups of screens;

change SPN name.

3) MasterCAN Display 35 T (“Tractor”)—Display modification designed to monitor

parameters of farming machinery equipped with a standard CAN-bus, S6 Units, analog

sensors.

It has 23 pre-set screens with SPN values received via CAN j1939/S6 interface and one screen

with converted signals from analog inputs (see B.2).

A user of MasterCAN Display 35 T can:

add the number of screens up to 10 in each of the pre-set groups;

edit the screen with converted signals from analog inputs;

load SPN designation.

A user of MasterCAN Display 35 T cannot:

delete and edit pre-set screens;

create new groups of screens;

change SPN name.

Introduction

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 9

4) MasterCAN Display 35 M (“Vessel”)—Display modification designed to monitor

parameters of sea and river vessels equipped with S6 Units.

It has 39 pre-set screens with SPN values received via CAN j1939/S6 interface (see B.3).

A user of MasterCAN Display 35 M can:

add new groups to the pre-set groups of screens to the maximum possible number (21);

add the number of screens up to 10 in each of the pre-set groups;

reset flow meter counters (counters that can be reset) while viewing the corresponding

screens;

load SPN designation.

A user of MasterCAN Display 35 M cannot:

delete and edit pre-set screens;

change SPN name.

Diagrams of pre-set information screens for all modifications of MasterCAN Display 35 are

provided in annex B.

Table 1 —Equipment that should be connected to MasterCAN Display 35 in order to display a

standard set of parameters on pre-set screens

Designation of Equipment

Number for modifications of

MasterCAN Display 35, pcs.

Note

G

T

M

U *

DFM CAN **/ DFM D CAN

Fuel flow meter

1

1

2

1

Connection using S6 Technology

(to S6 connector).

DFM Marine CAN Fuel flow meter

-

-

2

-

Connection using S6 Technology

(to S6 connector).

DUT-E CAN / DUT-E 2Bio /

DUT-E GSM Fuel level sensor

2

2

2

2

Connection using S6 Technology

(to S6 connector) in any

combination of fuel level sensors.

MasterCAN CC

Vehicle data interface

1

1

-

1

To connect to standard vehicle

CAN-bus, you may use any of

these Units. We recommend to

connect MasterCAN CC to CAN-

bus using CANCrocodile or

CANCrocoLITE contactless

readers.

FMSCrocodile CCAN

Contactless reader-converter

MasterCAN DAC2113

J1939 i/o module

2

-

-

1

Connection using S6 Technology

(to S6 connector).

CANCrocodile / CANCrocoLITE ***

Contactless reader

1

1

1

1

Connection to S6 connector,

operation in the snuffer mode.

GNOM DDE / GNOM DP

Axle Load Sensor

2

-

-

2

Connection to SENS connector in

any combination of models and

types of sensors used.

DUT-E AF Fuel level sensor

*In case of pre-set groups of screens, replacement by groups of screens with parameters specified

by the user; see the number of Units available for connection by means of S6 Technology in table

3.

** In case of connection of one-chamber flow meters, SPN values that can be displayed only by

differential flow meters are not shown.

*** In case of CANCrocodile / CANCrocoLITE connection, data display is only possible on the screens

for T-CAN source of input data. In this case, simultaneous connection of other Units to

S6 connector is not allowed.

Introduction

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 10

ATTENTION: It is strongly recommended to follow strictly the instructions of the

present Manual when using, mounting or maintaining MasterCAN Display 35.

The Manufacturer guarantees MasterCAN Display 35 compliance with the requirements of

technical regulations subject to the conditions of storage, transportation and operation set out

in this Manual.

ATTENTION: Manufacturer reserves the right to modify MasterCAN Display 35

specifications that do not lead to a deterioration of the consumer qualities without

prior customer notice.

General information and technical specifications

/

Purpose of use, application area, operation principle

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 11

1 General information and technical specifications

1.1 Purpose of use, application area, operation principle

is designed for displaying current values of:

SPN received from Units using S6 Technology (see table 3);

SPN received from standard automotive CAN bus;

Voltage/frequency signals (see 1.4.3) of standard and additional automotive sensors.

Application areas:

1) MasterCAN Display 35 CAN j1939/S6 Display can be used within Telematics system as a

tool for supervising operation parameters “on board” of complex vehicles, railroad machinery

and water vessels.

MasterCAN Display 35 is installed on a Vehicle and can simultaneously receive data (SPN) from

standard automotive CAN bus and Units connected using S6 Technology.

Also MasterCAN Display 35 can convert output signals of standard or additional

voltage/frequency sensors into digital data (SPN). Depending on model (see page 9) and user

configurations, MasterCAN Display 35 can show up to 201 screens containing SPN values

(maximum 2 parameters per screen) (see figure 2).

Figure 2 —Example of using MasterCAN Display 35 within Telematics system

for supervising operation parameters of a Vehicle

2) MasterCAN Display 35 CAN j1939/S6 Display can be used independently of any telematics

system for supervision of operation parameters of stationary machines –sets of diesel

generators, boilers, technological equipment and complex objects like granaries etc.

(see figure 3).

Figure 3 —Example of using MasterCAN Display 35 independently of Telematics system

for supervising operation parameters granary

General information and technical specifications / Exterior view and delivery set

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 12

1.2 Exterior view and delivery set

1MasterCAN Display 35 –1 pc.;

2Passport containing an enclosed information sheet

with factory settings and information on

navigation between the screens –1 pc.;

3S6 signal cable (2 m) –1 pc.;

4Mounting kit (1 pc.) including:

a) SENS signal cable (1.4 m) - 1 pc.;

b) cable tie - 2 pcs.;

c) fuse with holder (2 A) - 1 pc.;

d) wing screw - 1 pc.;

e) self-tapping screw 2.9x9.5 - 6 pcs.;

f) mounting plate - 1 pc.;

g) plate fixator - 1 pc.

Figure 4 —MasterCAN Display 35 delivery set

1

3

2

4 a

4 d

4 e

4 f

4 g

4 b

4 c

General information and technical specifications / Design

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 13

1.3 Design

a) front view b) back view

1–body with electronic module inside;

2–LCD with backlight;

3–ambient light sensor for automatic adjustment of LCD brightness;

4–horizontal selection buttons;

5–vertical selection button;

6–confirmation button;

7–escape (cancel) button;

8–S6 socket (for connecting to CAN j1939/S6 interface and onboard electrical

network of Vehicle);

9–SENS socket (input for connecting voltage/frequency automotive sensors);

10 –groove for fixing mounting plate to back cover.

Figure 5 —MasterCAN Display 35 design

8

9

10

3

1

2

4

6

5

7

General information and technical specifications

/

Technical specifications

/

Main specifications

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 14

1.4 Technical specifications

1.4.1 Main specifications

Table 2 —MasterCAN Display 35 main specifications

Parameter, measuring unit

Value

Digital interface

CAN j1939/S6

Physical signal inputs (2 pcs.)

Analog/Frequency

Power supply voltage range, V

9…45

Maximal current consumption at supply voltage

12/24 V, mA, not more than

100/50

Temperature range, °C

-10*…+60

Ingress protection rating

IP40

Liquid-crystal display (LCD)

128x64

monochrome, with automatic and

manual adjustment of backlighting

Weight, kg, not more than

0.25

Overall dimensions, mm, not more than

see figure 6

*If the ambient temperature is below -10 °С, LCD display of MasterCAN Display 35

switches off automatically, but the device itself is active and operative. If the temperature

rises above -10 °С, LCD display switches on automatically.

General information and technical specifications / Technical specifications / CAN j1939/S6 digital interface protocol and characteristics

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 15

1.4.2 CAN j1939/S6

digital interface protocol and characteristics

Specifications of CAN j1939/S6 MasterCAN Display 35 digital interface correspond to

S6 Technology. The data transfer protocol is based on SAE J1939 standard and meets its

requirements.

Configuration of MasterCAN Display 35 connection to CAN j1939/S6 interface and selection of

SPN for displaying on screens is carried out using Service S6 MasterCAN software via K-line

interface (ISO 14230). The software current version can be downloaded at

https://www.jv-technoton.com/, section Software/Firmware.

MasterCAN Display 35 mode of data reception/transmission is automatic. Baud rate values list

100; 125; 250; 500; 1000 kbit/s (by default —250 kbit/s).

Any SPN from S6 Database except those in text format can be selected to be displayed.

To identify Units when connecting MasterCAN Display 35 using S6 Technology, choose unique

network address (SA) using Service software and following the table 2 below.

Table 3 —Allowed network addresses for S6 Units connected to MasterCAN Display 35

S6 Units

Maximum

number on one

Vehicle

Allowed network

address (SA)

Type

Model

CAN j1939/S6 Display

MasterCAN Display 35

2

109, 110

Online telematics

gateway

CANUp 27

1

100

Fuel flow meters

DFM CAN

8

111…118

DFM Marine CAN

Fuel level sensors

DUT-E CAN

8

101…108

DUT-E GSM

DUT-E 2Bio

Vehicle data interfaces

MasterCAN CC

2

122, 142

MasterCAN C232/485

2

124, 144

MasterCAN V-Gate

2

125, 145

Contactless reader-

converter

FMSCrocodile CCAN

1

122

J1939 i/o modules

MasterCAN DAC15

2

126, 146

MasterCAN DAC2113

127, 147

General information and technical specifications / Technical specifications / Specifications of signals analog inputs

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 16

1.4.3 Specifications of signals analog inputs

MasterCAN Display 35 has two configurable analog inputs (see table 4).

Table 4 —Specifications of signals of MasterCAN Display 35 analog inputs

Signal type, measurement units

Value

Voltage, V

0.5…10

Frequency, kHz

(amplitude 8…10 V)

0.01…10

Note –Input resistance of analog input is 140 kOhms.

Selection of necessary type of input signals (voltage/frequency) and configuration of

convertion of their levels into SPN values is carried out using Service S6 MasterCAN

(see A.5).

The software current version can be downloaded at https://www.jv-technoton.com/, section

Software/Firmware.

MasterCAN Display 35 installation / Exterior inspection prior to starting works

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 18

2 MasterCAN Display 35 installation

ATTENTION:

1) When mounting MasterCAN Display 35, strictly follow safety rules of car repair

works as well as local safety rules of the customer’company

2) Before the start, it is recommended to carefully study through the electrical circuit

diagram and Operation manual for the Vehicle, where MasterCAN Display 35

is mounted.

For MasterCAN Display 35 correct operation its mounting and configuration should be carried

out by certified specialists who have passed corporate technical training.

2.1 Exterior inspection prior to starting works

It is required to conduct MasterCAN Display 35 exterior inspection for the presence of the

possible defects of body or connectors arisen during transportation, storage or careless use.

Contact the supplier if any defects are detected.

MasterCAN Display 35 installation / Choosing installation place

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 19

2.2 Choosing installation place

MasterCAN Display 35 installation should be done in a dry location protected from aggressive

impact of the environment. MasterCAN Display 35 should not be mounted near heating and

cooling devices (e.g. the climate control system). Also, it is not recommended to mount

MasterCAN Display 35 close to the vehicle electrical circuits.

We recommend installing MasterCAN Display 35 in driver’s cab. To make sure the display is in

the eyesight of a driver, it is recommended to place the display on the top of the panel

(see figure 7).

Figure 7 —Recommended place of installation MasterCAN Display 35

MasterCAN Display 35 installation / Installation procedure

MasterCAN Display 35 CAN j1939/S6 Display. Operation manual. Version 2.0

© Technoton, 2019 20

2.3 Installation procedure

IMPORTANT: When installing MasterCAN Display 35 it is strongly recommended to

use installation elements from delivery set.

1) Put fastening plate into groove on the back cover of MasterCAN Display 35 (see figure 8)

and fix it with two crews.

2) Fasten the clamp of the mounting plate to a selected place on the panel with two self-

tapping screws.

3) Put fastening plate under the fixator and fasten in using wing screw.

Figure 8 —MasterCAN Display 35 fixed using elements from delivery set

This manual suits for next models

1

Table of contents

Other Technoton Analytical Instrument manuals

Popular Analytical Instrument manuals by other brands

Calculated Industries

Calculated Industries Pocket Dimension Master 3310 user guide

Omron

Omron F300 installation manual

Ryobi

Ryobi LDM-32 Owner's operating manual

Extech Instruments

Extech Instruments HDV-WTX2L quick start guide

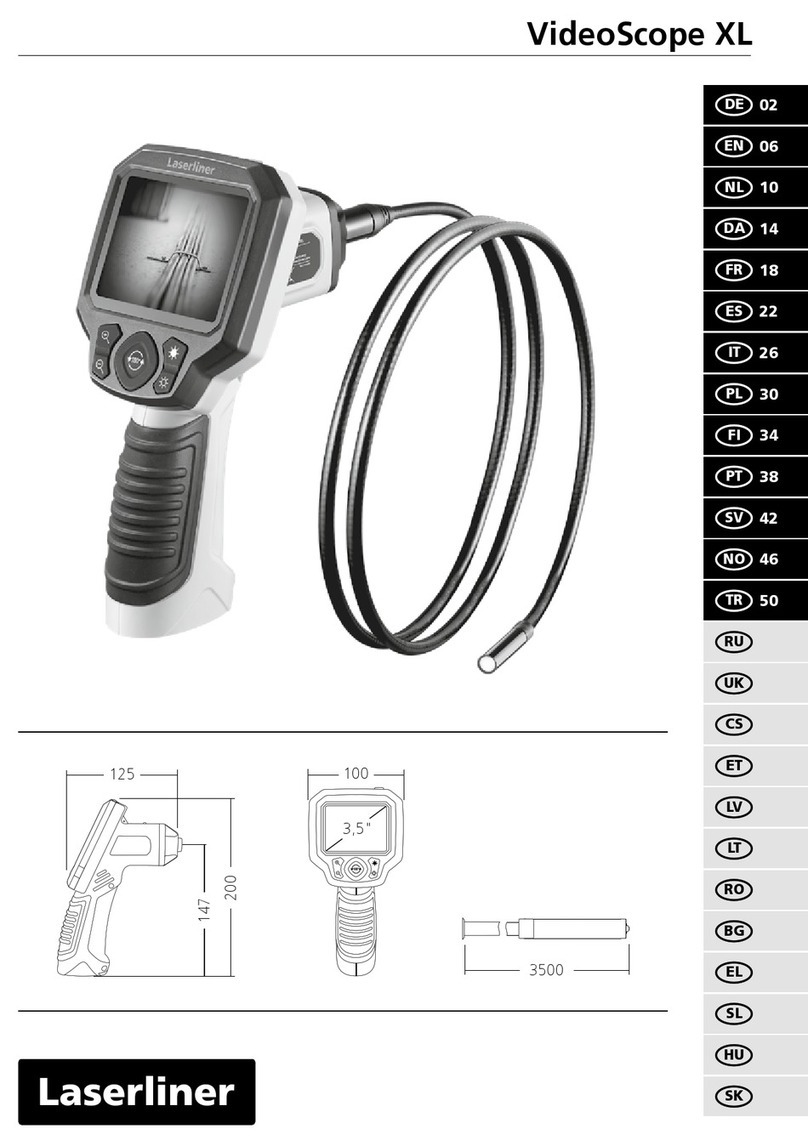

LaserLiner

LaserLiner 082.114A manual

Hach Ultra

Hach Ultra POLYMETRON 9182 Operator's manual