Oxygen analyser (ppb) -9182 -

Table of contents

Page

Warnings....................................................................................................................................iii

Chapter 1: Introduction............................................................................................................. 1-1

1.1 Introduction........................................................................................................ 1-1

1.2 Principle of operation........................................................................................... 1-1

1.3 Main characteristics............................................................................................ 1-3

1.4 Technical characteristics..................................................................................... 1-3

1.5 Dimensions........................................................................................................ 1-6

Chapter 2: Description of the analyser...................................................................................... 2-1

2.1 Analytical part .................................................................................................... 2-1

2.2 Hydraulic mounting............................................................................................. 2-2

2.3 Transmitter......................................................................................................... 2-3

2.3.1 Presentation of the transmitter................................................................. 2-3

2.3.2 Application fields .................................................................................... 2-5

2.3.3 Standard mounting possibilities (use of the red clamping bow).................... 2-5

Chapter 3: Installation of the instrument................................................................................... 3-1

3.1 Unpacking.......................................................................................................... 3-1

3.2 Inspection.......................................................................................................... 3-1

3.3 Mounting............................................................................................................ 3-1

3.4 Location............................................................................................................. 3-1

3.5 Electrical connections......................................................................................... 3-2

3.6 Description of the different terminals..................................................................... 3-3

3.7 Mains connection ............................................................................................... 3-4

3.8 Starting the transmitter........................................................................................ 3-4

3.9 Adjusting the display contrast.............................................................................. 3-4

Chapter 4: Using the instrument................................................................................................ 4-1

4.1 Front panel keys................................................................................................. 4-1

4.2 Displays 1 to 4 (live displays)............................................................................... 4-2

4.3 Description of the function keys ........................................................................... 4-3

4.4 Icons ................................................................................................................. 4-3

4.5 Enter or modify a value........................................................................................ 4-4

4.6 Warnings ........................................................................................................... 4-4

Chapter 5: Programming the transmitter.................................................................................. 5-1

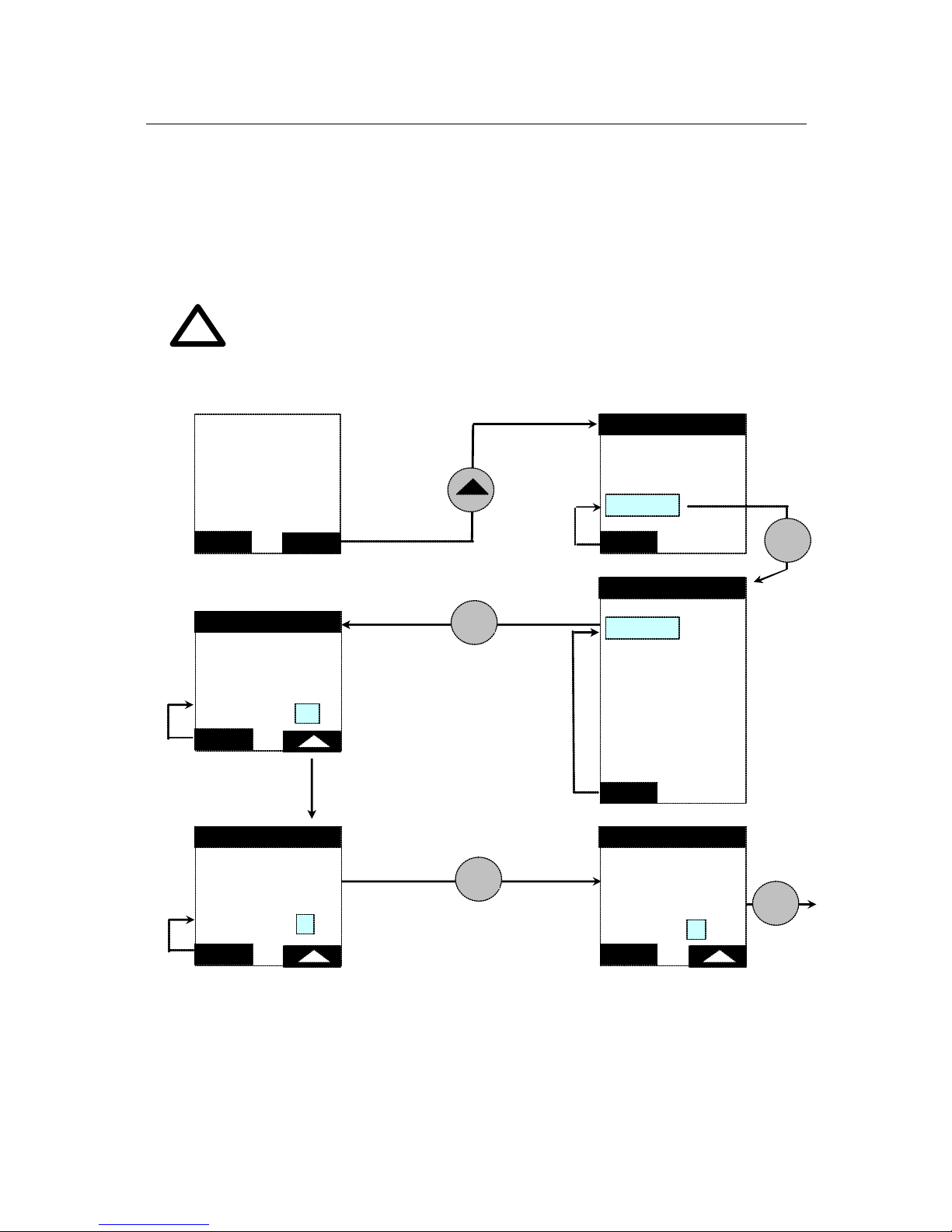

5.1 Main menu......................................................................................................... 5-1

5.1.1 Calibration Menu..................................................................................... 5-2

5.1.2 MAINTENANCE Menu............................................................................. 5-3

5.1.3 PROGRAMMING Menu........................................................................... 5-3

5.1.3.1 MEASURE Menu ....................................................................... 5-4

5.1.3.2 ALARMS Menu.......................................................................... 5-5

5.1.3.3 mA OUTPUTS menu................................................................... 5-8

5.1.3.4 RS485 Menu.............................................................................5-11

5.1.4 SERVICE Menu.....................................................................................5-12

5.1.4.1 AVERAGE Menu.......................................................................5-12

5.1.4.2 DISPLAY Menu.........................................................................5-13

5.1.4.3 CODE Menu .............................................................................5-14