Tecnar accuraspray 4.0 User manual

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 2 of 43

User manual Accuraspray4.0

NOTICES

© 2018 Tecnar Automation Ltd.

No part of this manual may be reproduced in any form or by any means (including electronic storage and retrieval

or translation into a foreign language) without prior agreement and written consent from Tecnar Automation Ltd.

MANUAL PART

40101-00024-00

The material contained in this document is provided “as is” and is subject to change without notice in future

editions.

OVERVIEW:

• Table of content at the beginning of the document

• Table of figures at the beginning of the document

This manual contains the following sections:

• Safety

• Product description

• Installation

• Maintenance

• Operation

• Software

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 3 of 43

User manual Accuraspray4.0

TABLE OF CONTENT

1 SYSTEM DESCRIPTION ............................................................................................................................................5

1.1 INTRODUCTION ................................................................................................................................................................................... 5

1.2 GENERAL PRECAUTIONS .................................................................................................................................................................... 6

2 DESCRIPTION ...........................................................................................................................................................7

2.1 CONTROLLER ..................................................................................................................................................................................... 8

2.2 SENSOR HEAD .................................................................................................................................................................................. 10

2.3 CABLES, HOSES AND ANTENNAS ....................................................................................................................................................... 11

3 OPERATION SOFTWARE........................................................................................................................................ 12

3.1 USER INTERFACE ............................................................................................................................................................................. 12

3.2 NAVIGATION ICONS........................................................................................................................................................................... 12

3.3 LOGGING IN AS AN ADMINISTRATOR USER ........................................................................................................................................ 22

3.4 MANAGING SETUPS .......................................................................................................................................................................... 23

3.5 LOADING A SETUP ............................................................................................................................................................................ 24

3.6 TECHNICAL SPECIFICATIONS............................................................................................................................................................. 28

4 INSTALLATION ........................................................................................................................................................ 29

4.1 INSTALLING THE SENSOR HEAD ......................................................................................................................................................... 29

4.2 ACCESSING THE USER INTERFACE .................................................................................................................................................... 34

4.3 SETTING UP THE ACCURASPRAY ON A NETWORK (OPTIONAL)............................................................................................................ 35

4.4 CONNECTING THE I/OS (OPTIONAL) .................................................................................................................................................. 35

5 MAINTENANCE ....................................................................................................................................................... 37

5.1 MAINTENANCE SCHEDULE ................................................................................................................................................................ 37

5.2 MAINTENANCE PROCEDURES ........................................................................................................................................................... 38

5.3 RECOMMENDED SPARE PARTS ......................................................................................................................................................... 39

6 TROUBLESHOOTING .............................................................................................................................................. 40

6.1 SECTION TROUBLESHOOTING (LED ERROR CODES) ......................................................................................................................... 40

6.2 ERROR REPORTING IN THE USER INTERFACE .................................................................................................................................... 41

!

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 4 of 43

User manual Accuraspray4.0

TABLE OF FIGURES

FIGURE 1 SCHEMATICAL DESCRIPTION OF THE SYSTEM .............................................................................................7

FIGURE 2 CONTROLLER (FRONT) ...................................................................................................................................8

FIGURE 3 CONTROLLER (BACK) ......................................................................................................................................8

FIGURE 4 SENSOR HEAD (FRONT) ................................................................................................................................ 10

FIGURE 5 SENSOR HEAD (BACK) .................................................................................................................................. 10

FIGURE 6 ACCURASPRAY 4.0 USER INTERFACE ......................................................................................................... 12

FIGURE 7 CAMERA SCREEN .......................................................................................................................................... 14

FIGURE 8 STRIPCHART SCREEN ................................................................................................................................... 17

FIGURE 9 LOGIN WINDOW ............................................................................................................................................. 20

FIGURE 10 PASSWORD SCREEN ................................................................................................................................... 21

FIGURE 11 DIALS PROCESS CONTROL ZONES ............................................................................................................ 22

FIGURE 13 SETUP SELECTION WINDOW ...................................................................................................................... 24

FIGURE 14 SETUP OVERRIDE WINDOW ........................................................................................................................ 25

FIGURE 15 POSITION OF THE SENSOR HEAD .............................................................................................................. 30

FIGURE 16 SENSOR HEAD MONTING PLATE DIMENSIONS.......................................................................................... 30

FIGURE 17 M OUNTING THE SENSOR HEAD ................................................................................................................. 31

FIGURE 18 SENSOR HEAD INTERFACE ......................................................................................................................... 31

FIGURE 19 CONTROLLER INTERFACE .......................................................................................................................... 32

FIGURE 20 CONTROLLER STATUS LED ........................................................................................................................ 32

FIGURE 21 SENSOR HEAD ALIGNEMENT BUTTON ....................................................................................................... 33

FIGURE 22 SENSOR HEAD WORKING DISTANCE ......................................................................................................... 33

FIGURE 23 CONTROLLER ETHERNET PORT ................................................................................................................. 34

FIGURE 24 ACCURASPRAY 4.0 USER INTERFACE ....................................................................................................... 34

FIGURE 25 I/O PORT ....................................................................................................................................................... 35

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 5 of 43

User manual Accuraspray4.0

!

1 SYSTEM DESCRIPTION

1.1 INTRODUCTION

The present document gives a complete description and principle of

operation of the Accuraspray 4.0 sensor as well as a description of its

components.

1.1.1 OVERVIEW

The main purpose of the Accuraspray 4.0 is to ensure consistent, high-

quality coatings by monitoring the in-flight particles and plume properties

before each spray run. This ensures that the spray properties are within

predetermined acceptance ranges for ideal coating and performance.

To help detect potential issues such as electrode wear, partial clogging of

the nozzle or in the powder injection system, and instability of the powder

feeder before the coating process, the Accuraspray monitors:

• Particle’s temperature and velocity;

• Plume profile and intensity;

• Part temperature (optional);

The Accuraspray 4.0 can also be used to:

• Develop and optimize spray parameters;

• Transfer parameters from one booth to another (anywhere in the world);

• Transfer parameters from one spray gun to another;

• Extend the useful lifespan of hardware;

• Significantly reduce the number of test coupons;

• Troubleshoot day-to-day issues;

!

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 6 of 43

User manual Accuraspray4.0

!

1.2 GENERAL PRECAUTIONS

The following precautions should be observed at all times while operating

the Accuraspray 4.0. Tecnar Automation Ltd. assumes no liability

whatsoever for a user’s failure to comply with these precautions or the

warnings throughout this manual.

To protect your Accuraspray 4.0 from damage, you must:

• Connect it to an unloaded, properly grounded power line (50–60 Hz. 100-

240VAC, 50-60Hz, 1.5 A).

• We also recommend using an additional power line filter to filter out any

power surges or bursts;

• Use it at an ambient temperature between 4 and 45 °C;

• Supply 30 LPM (2CFM) of cooling/cleaning air at 1.7–2.7 bar (25–40 psi)

to the sensor head AT ALL TIMES while the unit is powered on.;

• Use only original spare parts.

All Accuraspray 4.0 users should read this user manual, take the web-based

introduction and training session, and contact Tecnar with any further

questions. We also recommend that a copy of the user manual be kept near

the equipment at all times.

!

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 7 of 43

User manual Accuraspray4.0

!

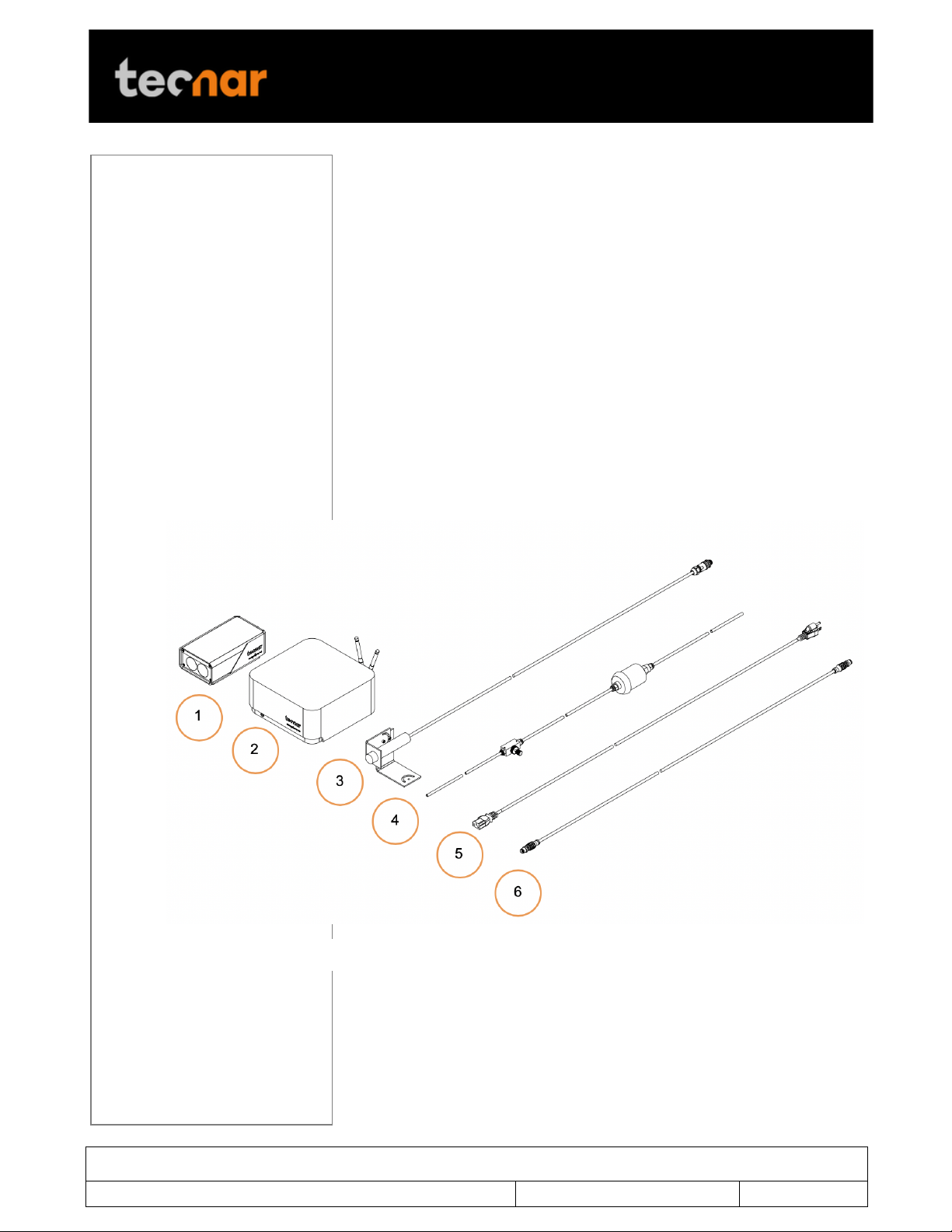

2 DESCRIPTION

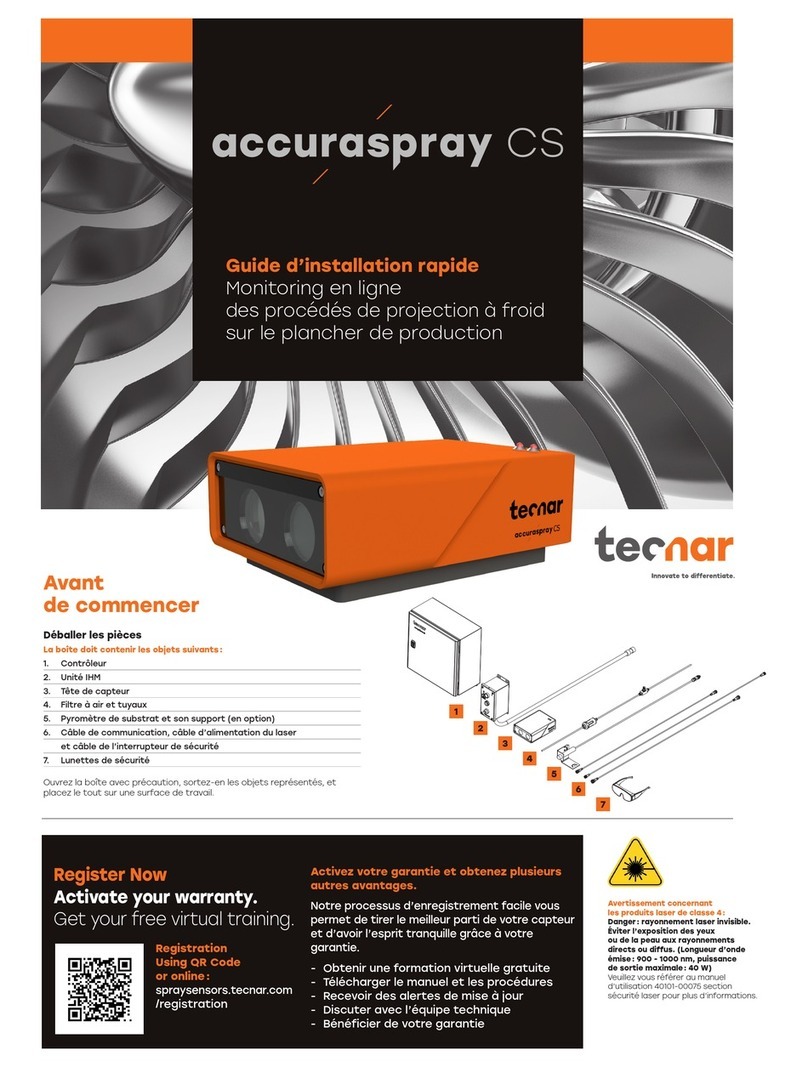

The Accuraspray 4.0 system includes the following elements:

1) A sensor head;

2) A controller;

3) A substrate pyrometer (optional);

4) Air hoses and filter;

5) Controller power cable;

6) Sensor head power and communication cable;

Each elements are described in details on the following pages.

!

FIGURE 1 SCHEMATICAL DESCRIPTION OF THE SYSTEM

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 8 of 43

User manual Accuraspray4.0

!

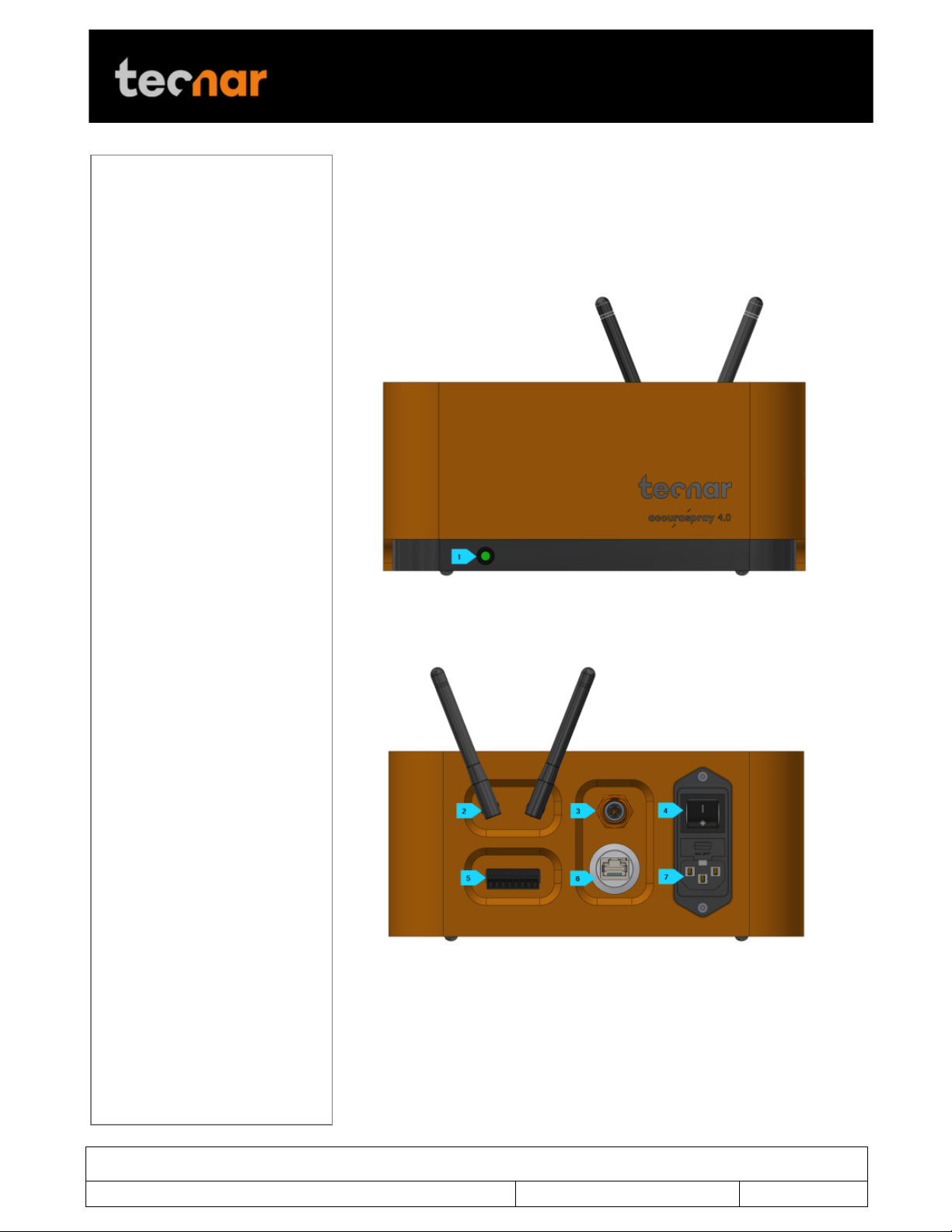

2.1 CONTROLLER

The controller must be kept in a ventilated area to reduce the risk of

overheating.

The controller receives readings from the sensor head. It processes the data

and broadcasts the results to the user interface(s).

FIGURE 2 CONTROLLER (FRONT)

FIGURE 3 CONTROLLER (BACK)

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 9 of 43

User manual Accuraspray4.0

!

Component

Description

1. LED

LED

Off: Power supply is OFF;

Green: The system is working properly;

Yellow: Sensor head is not connected;

Red: Unit power up but an error is detected.

2. Wi-Fi antenna

Used to access the Accuraspray user interface

through a wireless network connection. The

Wi-Fi connection acts as a Hotspot. It can be

disabled but not reconfigured.

3. Sensor head port

Used to power and communicate with the

sensor head.

4. Power switch

Used to active the unit.

5. User interface

port

Used to interface the Accuraspray to the user’s

spray controller via digital I/Os.

6. Ethernet

Used to access the Accuraspray user interface

through a wired network connection.

7. Power inlet

Provides power to the Accuraspray.

Connect it to an unloaded, properly grounded

power line (100-240VAC, 50-60Hz, 1.5 A).

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 10 of 43

User manual Accuraspray4.0

!

2.2 SENSOR HEAD

The sensor head measures the following particles and spray plume

properties:

• Particles velocity;

• Particles temperature;

• Spray plume geometry (width, position) and intensity.

FIGURE 4 SENSOR HEAD (FRONT)

!

FIGURE 5 SENSOR HEAD (BACK)

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 11 of 43

User manual Accuraspray4.0

!

Component

Description

1. Air knife

The air knife is used to keep the Accuraspray

windows clean and free of dust.

2. Optical system

viewport

Viewport of the temperature and velocity

measurement sensor.

3. Camera viewport

Viewport of the camera used to characterize

the plume geometry.

4. Air supply port

Compressed air is used both as active cooling

for the head’s internal components and, as it is

exhausted from the head, to generate an air

knife that keeps the viewport windows clean.

5. Alignment beam

switch

Activation switch for the alignment beam.

6. Substrate

pyrometer port

Used to power and communicate with the

optional substrate pyrometer sensor.

7. Communication

port

Used to power the sensor head and

communicate with the controller.

2.3 CABLES, HOSES AND ANTENNAS

The Accuraspray 4.0 is delivered with several cables, hoses and antennas,

which are described in the following table.

Cables/Hoses/Antennas

Description

IEC power cable

Used to connect the Accuraspray to a

power outlet.

Communication cable

Communication between the controller

and the measurement head.

Antennas

Used for WiFi communication.

Compressed air hoses

Provide compressed air to the

measurement head for cooling and

purging purposes.

• One hose connects the

compressed air supply to the air

filter;

• One hose connects the air filter to

the pressure regulator;

• One hose connects the regulator

to the measurement head;

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 12 of 43

User manual Accuraspray4.0

!

3 OPERATION SOFTWARE

3.1 USER INTERFACE

The user interface can be accessed with most internet browsers. It connects

to the controller via an Ethernet cable or Wi-Fi network.

3.2 NAVIGATION ICONS

Different icons are displayed at the top of the Accuraspray user interface in

order to navigate between the different screens. The following table

describes those icons.

Icons

Description

Access the main measurement screen.

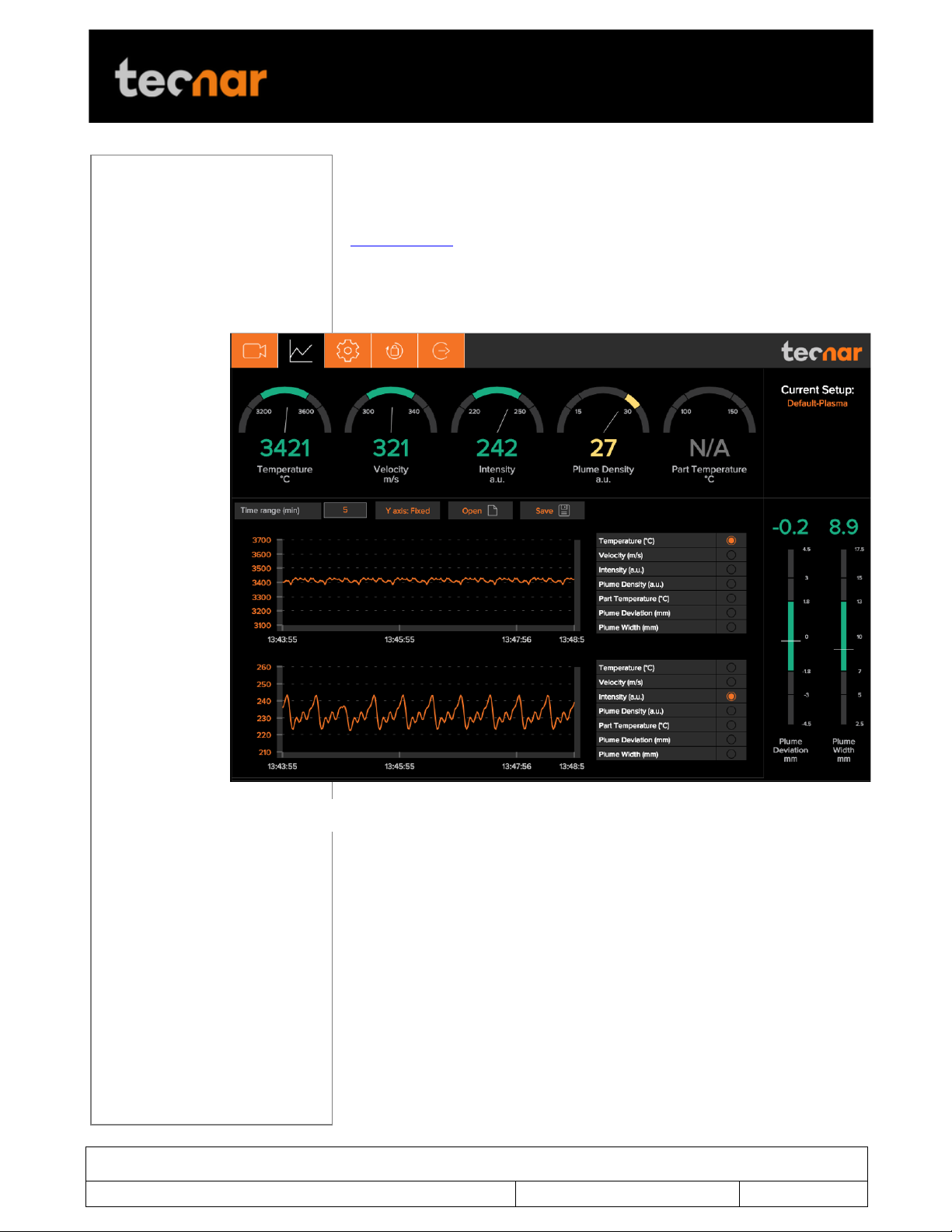

FIGURE 6 ACCURASPRAY 4.0 USER INTERFACE

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 13 of 43

User manual Accuraspray4.0

!

Access the charts screen.

Access the setup screen (Only when logged in as

Operator or Administrator)

Access the menu to change user’s passwords.

Take control and access the configuration screen

(Operators and Administrators only)

Log in.

Log out.

! !

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 14 of 43

User manual Accuraspray4.0

!

3.2.1 CAMERA SCREEN

The camera screen displays, in real time, all measurements taken by the

Accuraspray.

The measurements, are displayed at the top and to the right of the screen.

Color codes indicate whether or not the measurements are within the

acceptance range as defined in the setup by the process engineer. A

measurement fully within the acceptance range is shown in green, a

measurement just barely within the acceptance range is shown in yellow,

and a measurement outside the acceptance range is shown in red.

Corrective actions should be taken to ensure that all measurements are

within the acceptance range and displayed in green.

In the middle of the screen, in the camera view, an orange bullseye

represents the position where the particle’s temperature and velocity are

being measured. The distance between the bullseye and the tip of the spray

gun, called the standoff distance, is represented by the dotted horizontal

orange line. The green curve shows the plume intensity profile as measured

by the sensor along the vertical line.

FIGURE 7 CAMERA SCREEN

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 15 of 43

User manual Accuraspray4.0

!

The different measurements provided by the Accuraspray are described in

details in the table below.

Parameters

Description

Temperature

Average particles temperature that are passing

through the sensor’s measurement volume

(bullseye).

Velocity

Average particles speed that are passing through the

sensor’s measurement volume (bullseye).

Intensity

Intensity of the spray plume.

This measurement is very sensitive to minute

changes in the spray conditions. The parameters that

have the strongest effect on the plume intensity are:

• Particles temperature;

• Average particles diameter;

• Feedstock emissivity;

• Feed rate.

Plume density

Provides an indication of the particles flow rate.

Part temperature

Temperature of the substrate on which the coating is

applied.

Plume deviation

Deviation of the plume position against the bullseye.

Plume width

Width of the spray plume.

3.2.1.1 Zoom in / out

It is possible to zoom in on the center of the image where the bullseye is

located.

To do so, click on the magnifying glass icon. This will enlarge the image so

that the sampling line, the dotted vertical line overlaid on the camera image,

takes 50% of the screen. To return to the full screen click on the magnifying

glass again.

This feature is especially useful for HVAF/HVOF where the plume is quite

narrow and can be difficult to see when viewing the full camera frame.

3.2.1.2 Recording a video sequence

Sequences can be recorded and recalled using the icons on the top left

corner of the video. The camera icon is used to launch a recording.

Once the Accuraspray is recording, the letters in the camera will turn red to

indicate that the Accuraspray is recording.

To stop recording, click on the square icon next to the camera. This will

automatically download the sequence to your computer in your web browser

default download directory.

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 16 of 43

User manual Accuraspray4.0

!

Recorded video sequences are not stored on the Accuraspray Controller.

3.2.1.3 Playing back a video sequence

To open a saved sequence, click on the folder icon, select the sequence

that you want to replay.

As mentioned previously, the video sequences are not stored on the

Accursaspray controller. You will find them on your computer in your default

download directory or wherever you have stored them.

When replaying a sequence an X icon will appear. It is used to exit replay

mode and return back to live mode.

It is possible to pause a sequence using the Pause icon and resume

playback using the Play icon.

!! !

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 17 of 43

User manual Accuraspray4.0

!

3.2.2 STRIPCHART SCREEN

The stripchart screen displays the evolution over time of measurements

available on the camera screen. For the measurement descriptions, see the

camera screen section.

In the middle of the screen are two graphs, each displaying one

measurement. It’s possible to select which measurement to display from the

table located to the right of the graphs.

3.2.2.1 Adjusting the time display

The time duration displayed on the strip charts can be adjusted using the

text box at the top of the page. The charts can display up to 60 minutes of

measurements.

The last 60 minutes are stored in the database and can be recalled at any

time.

3.2.2.2 Adjusting the Y-axis display

The range of the strip charts Y axis can be adjusted in two ways:

• Fixed - Sets the Y-axis limits (min and max values) according to the

Acceptance Ranges as defined by the setup.

FIGURE 8 STRIPCHART SCREEN

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 18 of 43

User manual Accuraspray4.0

!

• Auto – Sets the Y-axis limits (min and max values) according to the full

scale of the values captured by the sensor.

3.2.2.3 Production Reports

Production reports can be generated from the Strip Chart screen. When

users select “Save” the data contained in the strip charts and a screen

shot of the camera screen will be copied into a .pdf and .csv files.

The production reports are stored on the Accuraspray controller’s hard

drive. The directory where the files are stored is accessible by clicking on

the “Open” icon. It also contains all the strip charts. The duration of the

strip charts in the production report is the same as what was displayed in

the User interface at the time when the production report was generated.

If desired you can take the strip charts .csv file and generate your own

graphs to manipulate the data.

!! !

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 19 of 43

User manual Accuraspray4.0

!

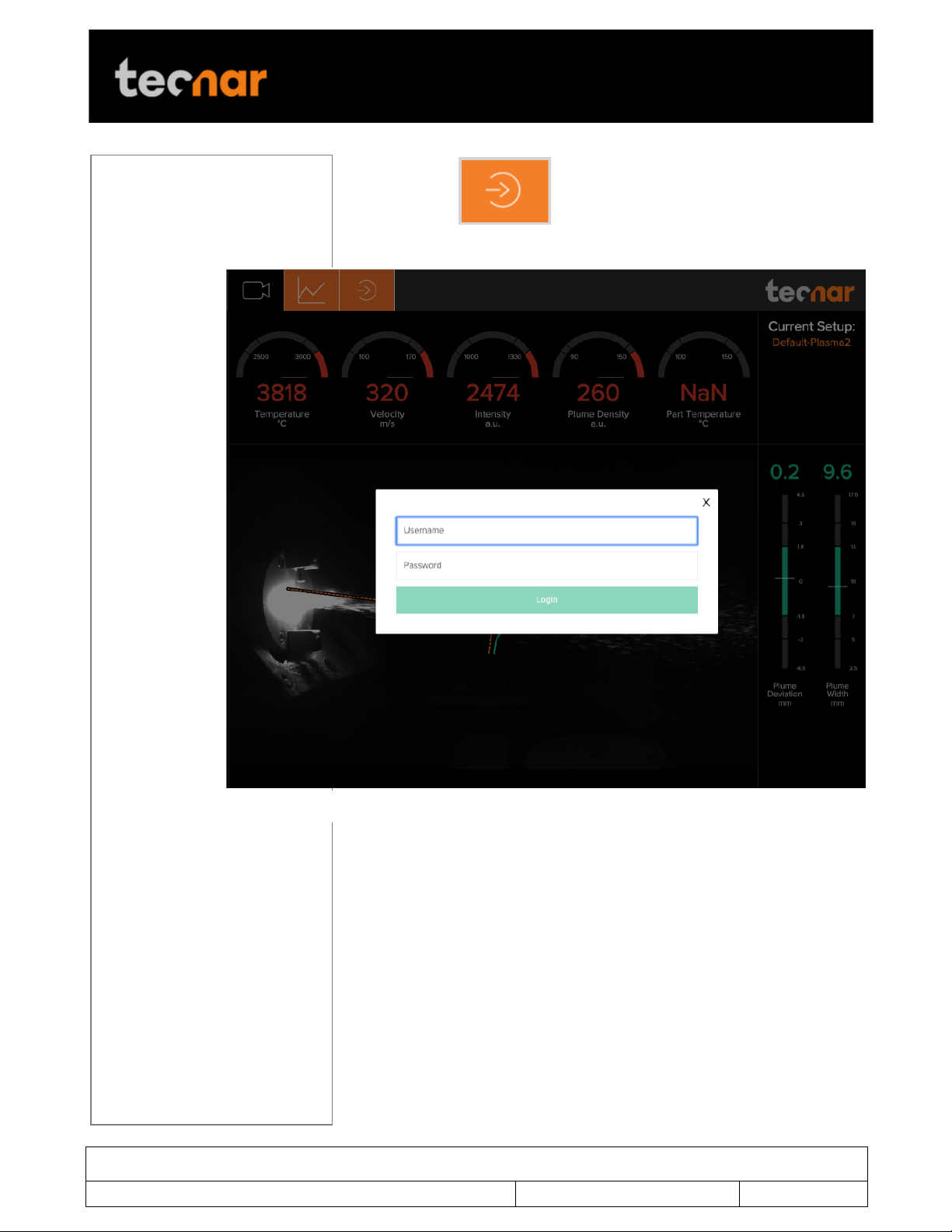

3.2.3 LOGGING IN

The power of this interface is the ability to have multiple, simultaneous,

users (up to 5) of the software. For instance:

• One user or “the operator” can be actually be using the system for

measurement (will need to “take control” as covered in subsequent slides)

• Another user can be “watching” the “operator” from the engineering office

via the network or wireless

• Another user can be viewing saved files from previous runs in the QC

department

When accessing the Accuraspray interface, users are in viewer mode and

can only visualize the sensor’s readings like the engineer or QC person

discussed earlier.

In order to actually use the sensor and record sequences it is necessary to

log in by clicking the designated icon. Users can Log in either as Operators

or Administrator.

• Operators (user name: operator) can change the setup used by the

sensor and record measurement sequences. The default password for

operators is: accura.operator

• Administrators (user name: admin) have the same rights as the

Operators and can created, modify and delete setups. The default password

for administrator is: accura.admin

This document contains information considered proprietary and confidential to Tecnar Automation Ltd

40101-00024-00– Rev E

Revision date: 2019-03-17

Page 20 of 43

User manual Accuraspray4.0

!

To log in click to display the login window and enter your

credentials

! !

FIGURE 9 LOGIN WINDOW

Other manuals for accuraspray 4.0

3

Table of contents

Other Tecnar Accessories manuals