Tecnar Accuraspray CS User manual

User manual

In-line

cold spray

sensor

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 1 of 51

NOTICES

© 2022 Tecnar Automation Ltd.

No part of this manual may be reproduced in any form or by any means (including electronic storage and retrieval

or translation into a foreign language) without prior agreement and written consent from Tecnar Automation Ltd.

MANUAL PART

40101-00075-00 Revision A

The material contained in this document is provided “as is” and is subject to change without notice in future

editions.

Revision: November 17th, 2022

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 2 of 51

Table of Content

TABLE OF CONTENT................................................................................................................................................................2

LASER SAFETY ........................................................................................................................................................................5

GENERAL PRECAUTIONS ........................................................................................................................................................................ 5

AUTHORIZED USE..................................................................................................................................................................................5

CLASS 4LASER SAFETY ........................................................................................................................................................................ 5

DESCRIPTION OF CONTROLS AND SAFETY FUNCTIONS .............................................................................................................................7

SYSTEM DESCRIPTION ...........................................................................................................................................................8

INTRODUCTION......................................................................................................................................................................................8

OVERVIEW ............................................................................................................................................................................................ 8

COMPONENTS DESCRIPTION ................................................................................................................................................9

CONTROLLER ...................................................................................................................................................................................... 10

SENSOR HEAD..................................................................................................................................................................................... 12

CABLES,HOSES AND ANTENNAS ........................................................................................................................................................... 14

SOFTWARE OPERATION.......................................................................................................................................................15

USER INTERFACE OVERVIEW ................................................................................................................................................................ 15

ACCESSING THE USER INTERFACE ........................................................................................................................................................ 16

CONNECTING TO THE SOFTWARE .......................................................................................................................................................... 17

LOGGING IN......................................................................................................................................................................................... 17

NAVIGATION TABS................................................................................................................................................................................ 18

LIVE SCREEN....................................................................................................................................................................................... 19

SELECTING ACTIVE GAUGES ................................................................................................................................................................. 21

ADJUSTING THE TIME SPAN................................................................................................................................................................... 22

ADJUSTING THE Y-AXIS DISPLAY ........................................................................................................................................................... 22

PART TEMPERATURE SCREEN ............................................................................................................................................................... 22

PRODUCTION REPORTS........................................................................................................................................................................ 23

SETUP SCREEN (OPERATOR AND ADMINISTRATOR ONLY) ........................................................................................................................ 24

MIN/MAX ADJUSTMENTS ....................................................................................................................................................................... 25

OPENING/DELETING SETUPS ................................................................................................................................................................ 26

SAVING SETUPS .................................................................................................................................................................................. 27

IMPORTING AND EXPORTING SETUPS ..................................................................................................................................................... 27

SETUP PARAMETERS ........................................................................................................................................................................... 28

SYSTEM SETTINGS............................................................................................................................................................................... 30

CHANGING THE USER PASSWORD ......................................................................................................................................................... 30

ENABLING/DISABLING WI-FI................................................................................................................................................................. 30

CHANGING THE STATIC IP OF THE CONTROLLER ..................................................................................................................................... 30

DHCP IP............................................................................................................................................................................................ 31

CHANGING THE PLC IP........................................................................................................................................................................ 31

REPORT GENERATION MODE ............................................................................................................................................................... 32

CHANGING THE TIME ZONE ................................................................................................................................................................... 32

UPDATING YOUR SYSTEM ..................................................................................................................................................................... 33

.................................................................................................................................................................................................33

PROCESS STABILITY.............................................................................................................................................................34

PHILOSOPHY AND MEASUREMENT PRINCIPLE ......................................................................................................................................... 34

OVERVIEW OF THE STABILITY PANEL...................................................................................................................................................... 35

THE DISTRIBUTION CHART .................................................................................................................................................................... 35

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 3 of 51

THE CALCULATION METHODS ................................................................................................................................................................ 37

ADJUSTING THRESHOLDS BASED ON PREVIOUS RUNS ............................................................................................................................. 37

ADJUSTING THRESHOLDS MANUALLY BASED ON MULTIPLE RUNS.............................................................................................................. 37

TECHNICAL SPECIFICATIONS ..............................................................................................................................................38

SENSOR HEAD..................................................................................................................................................................................... 38

CONTROLLER ...................................................................................................................................................................................... 38

INSTALLATION........................................................................................................................................................................39

INSTALLING THE SENSOR HEAD ............................................................................................................................................................. 39

INSTALLING THE HMI MODULE .............................................................................................................................................................. 42

INSTALLING THE CONTROLLER .............................................................................................................................................................. 42

ADJUSTING THE SPRAY GUN POSITION................................................................................................................................................... 43

SETTING UP THE ACCURASPRAY ON A NETWORK (OPTIONAL) .................................................................................................................. 44

CONNECTING THE I/OS (OPTIONAL) ....................................................................................................................................................... 44

USING THE INPUT TO GENERATE REPORTS............................................................................................................................................. 44

MAINTENANCE .......................................................................................................................................................................46

MAINTENANCE SCHEDULE .................................................................................................................................................................... 46

MAINTENANCE PROCEDURES................................................................................................................................................................ 47

RECOMMENDED SPARE PARTS.............................................................................................................................................................. 48

TROUBLESHOOTING .............................................................................................................................................................49

LED ERROR CODES ............................................................................................................................................................................. 49

ERROR REPORTING IN THE USER INTERFACE.......................................................................................................................................... 50

SERVICE &SUPPORT ........................................................................................................................................................................... 51

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 4 of 51

TABLE OF FIGURES

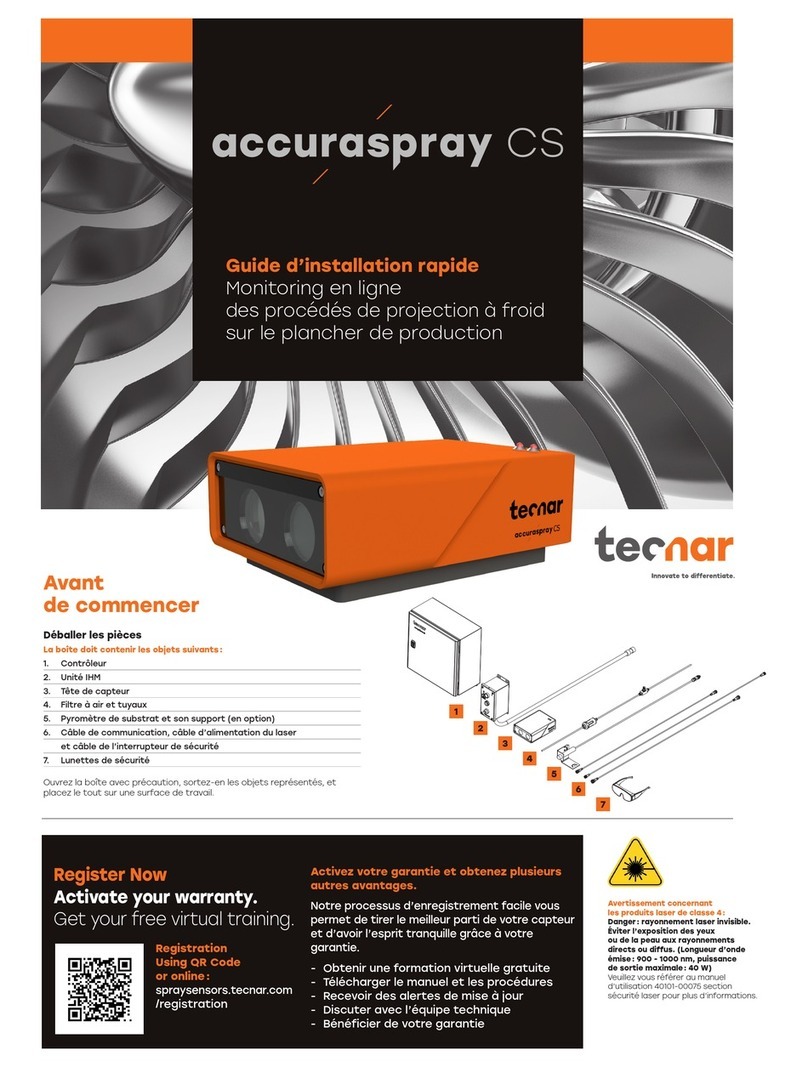

FIGURE 1: SCHEMATICAL DESCRIPTION OF THE SYSTEM ................................................................................................9

FIGURE 2: CONTROLLER (SIDE AND ISOMETRIC) .............................................................................................................10

FIGURE 3: SENSOR HEAD (FRONT).....................................................................................................................................12

FIGURE 4: SENSOR HEAD (BACK)........................................................................................................................................12

FIGURE 5: ACCURASPRAY CS USER INTERFACE .............................................................................................................15

FIGURE 6: ACCURASPRAY 4.0 LIVE SCREEN.....................................................................................................................19

FIGURE 7: ACTIVE GAUGES .................................................................................................................................................21

FIGURE 8: PART TEMPERATURE SCREEN .........................................................................................................................22

FIGURE 9: STRIPCHART BUTTONS BAR .............................................................................................................................23

FIGURE 10: SAVING PRODUCTION FILE..............................................................................................................................23

FIGURE 11: PRODUCTION FILES SCREEN..........................................................................................................................23

FIGURE 12: SETUP SCREEN.................................................................................................................................................24

FIGURE 13: GAUGES PROCESS CONTROL ZONES ...........................................................................................................25

FIGURE 14: OPENING/DELETING SETUPS ..........................................................................................................................26

FIGURE 15: UNSAVED SETUP MESSAGE............................................................................................................................27

FIGURE 16: SAVING SETUPS................................................................................................................................................27

FIGURE 17: IMPORT/EXPORT SETUPS................................................................................................................................27

FIGURE 18: SYSTEM SETTINGS ...........................................................................................................................................30

FIGURE 19: SYSTEM SETTINGS FOR NETWORK OPTIONS. .............................................................................................31

FIGURE 20: IO CONTROL TAB. .............................................................................................................................................32

FIGURE 21: SOFTWARE UPDATE EXAMPLE .......................................................................................................................33

FIGURE 22: STABILITY FEATURE TAB……….....……………………………………………………………………………………34

FIGURE 23: NORMAL DISTRIBUTION………………………………………………………………………………………………...35

FIGURE 24: UNPACKING THE PARTS………………………………………………………………………………………………..38

FIGURE 25: POSITION OF THE SENSOR HEAD ..................................................................................................................40

FIGURE 26: SENSOR HEAD MOUNTING PLATE DIMENSIONS. .........................................................................................40

FIGURE 27: MOUNTING THE SENSOR HEAD. .....................................................................................................................41

FIGURE 28: CABLE CONNECTIONS BETWEEN THE SENSOR HEAD AND THE CONTROLLER......................................42

FIGURE 29: SENSOR HEAD ALIGNMENT BUTTON. ............................................................................................................43

FIGURE 30: SENSOR HEAD WORKING DISTANCE. ............................................................................................................43

FIGURE 31: IO PORTS ON THE CONTROLLER....................................................................................................................44

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 5 of 51

Laser Safety

The following precautions should be observed at all times while operating the Accuraspray CS. Tecnar Automation

Ltd. assumes no liability whatsoever for a user’s failure to comply with these precautions or the warnings

throughout this manual.

General Precautions

To protect your Accuraspray CS from damage, you must:

• Connect it to an unloaded, properly grounded power line (50–60 Hz., 100- 240VAC, 1.5 A).

• We also recommend using an additional power line filter to filter out any power surges or bursts.

• Use it at an ambient temperature between 4 and 45 °C.

• ALWAYS supply 30 LPM (2CFM) of cooling/cleaning air at 1.7–2.7 bar (25–40 psi) to the sensor head while the

unit is powered on.

• Use only original spare parts.

All Accuraspray CS users should read this user manual, take the web-based introduction and training sessions,

and contact Tecnar at servic[email protected] with any further questions. We also recommend that a copy of the

user manual should always be kept near the equipment.

Authorized Use

The Accuraspray CS is intended for use solely for cold spray process monitoring and control. Any other use is

regarded as unauthorized.

The Accuraspray CS has been designed and manufactured according to state-of-the-art technology and

recognized safety regulations. However, unauthorized use can result in danger to the operator or third parties’

body or even life and/or in damage to the product itself or other machinery.

Class 4 Laser Safety

The Accuraspray CS emits Class 4 laser radiation during operation.

Class 4 laser radiation hazards are defined as follows:

“Laser products for which intrabeam viewing and skin exposure is hazardous and for which the viewing of diffuse

reflections may be hazardous. These lasers also often represent a fire hazard.”

The Accuraspray CS contains two class 4 laser diodes with the emission overlapping at the point of measurement.

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 6 of 51

Total laser emission:

Laser wavelength: 940 nm

Duration: Continuous wave

Nominal power: 20 W

Maximum power (fault condition): 40 W

Nominal laser density: 15.7 W/cm2

Beam divergence (each laser source): 3.3° Horizontal / 0.88° Vertical

Maximum permissible exposure: 31 W/m2

Nominal ocular hazard distance: 44 m (10 Second exposure time)

Radiation Pattern:

Both laser sources start near circular and become more elliptical the further away from the source they are.

Beam dimensions at window: 7.3mm horizontal by 6.8mm vertical.

Beam dimensions 200mm from the output: 18mm horizontal by 9mm vertical.

Eye protection:

Optical density: OD >= 4.62

Wavelength range: 900-1000nm

Radiation exposure (fault condition): 40 W

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 7 of 51

Description of Controls and Safety Functions

1. Key Control:

The HMI Remote has a key switch which controls laser emission. When the key is removed laser emission is

disabled. The key must be inserted and turned to the ON position to be able to arm the lasers.

Note turning the key to the ON position does not automatically restart laser emissions, a manual start is required.

2. Remote Interlock Connector:

The controller has a two-channel remote interlock circuit. When the contacts are open-circuited, laser emission is

disabled. Both channels must be closed to be able to arm the lasers.

Note closing the contacts does not automatically restart laser emissions, a manual start is required.

It is recommended to use the interlock to control access to the laser environment. For example, an interlock on

the access door to the laser hazard area.

3. Sensor Head Beam Stop:

On the sensor head, a safety switch is provided. When the switch is turned to the vertical OFF position laser

emission is disabled. The switch must be turned to the vertical ON position to be able to arm the lasers.

Note turning the switch to the ON position does not automatically restart laser emissions, a manual start is required.

4. Manual Start and Stop Controls

The HMI Remote has two buttons to start and stop laser emission. If all the safety devices are clear to allow laser

emission, pressing the green button will start laser emission, and pressing the red button will stop laser emission.

The green button must be pressed to restart laser emission after any safety device has stopped emission or after

mains power to the controller has been lost.

5. Laser emission warning

The sensor head and the HMI Remote are both equipped with redundant indicator lights to indicate that the laser

is armed, and emission is possible. The lights remain on as long as the power to the laser is not completely

discharged, even if laser emission has stopped.

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 8 of 51

System Description

Introduction

The present document gives a complete description and principle of operation of the Accuraspray CS sensor as

well as a description of its components.

Overview

The main purpose of the Accuraspray CS is to ensure consistent, high-quality coatings by monitoring the in-flight

particles and plume properties before each spray run. This ensures that the spray properties are within

predetermined acceptance ranges for ideal coating and performance.

To help detect potential issues such as partial clogging of the nozzle or in the powder injection system, and

instability of the powder feeder before the coating process, the Accuraspray CS monitors:

•Inflight particle velocity

•Relative powder feed rate

•Process Stability

•Standard deviation of all measurements

•Substrate temperature (optional)

The Accuraspray CS can also be used to:

•Develop and optimize spray parameters

•Transfer parameters from one booth to another (anywhere in the world)

•Transfer parameters from one spray gun to another

•Extend the useful lifespan of hardware

•Significantly reduce the number of test coupons

•Troubleshoot day-to-day issues

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 9 of 51

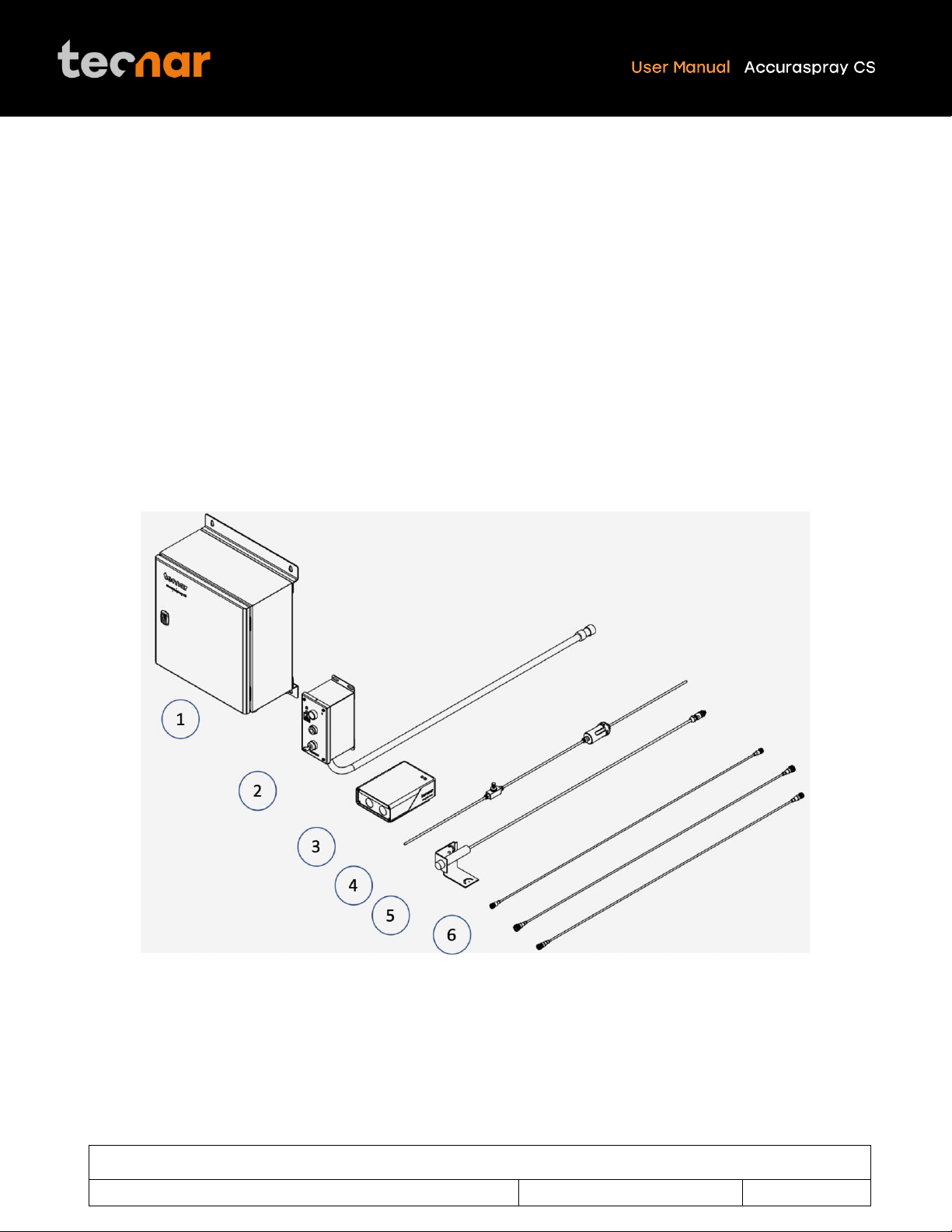

Components Description

The Accuraspray CS system includes the following elements:

1. Controller

2. HMI unit

3. Sensor head

4. Air filter and hoses

5. Substrate pyrometer and its support bracket (optional)

6. Communication cable, laser power cable and safety switch cable

Each element is described in detail on the following pages.

FIGURE 1: SCHEMATICAL DESCRIPTION OF THE SYSTEM

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 10 of 51

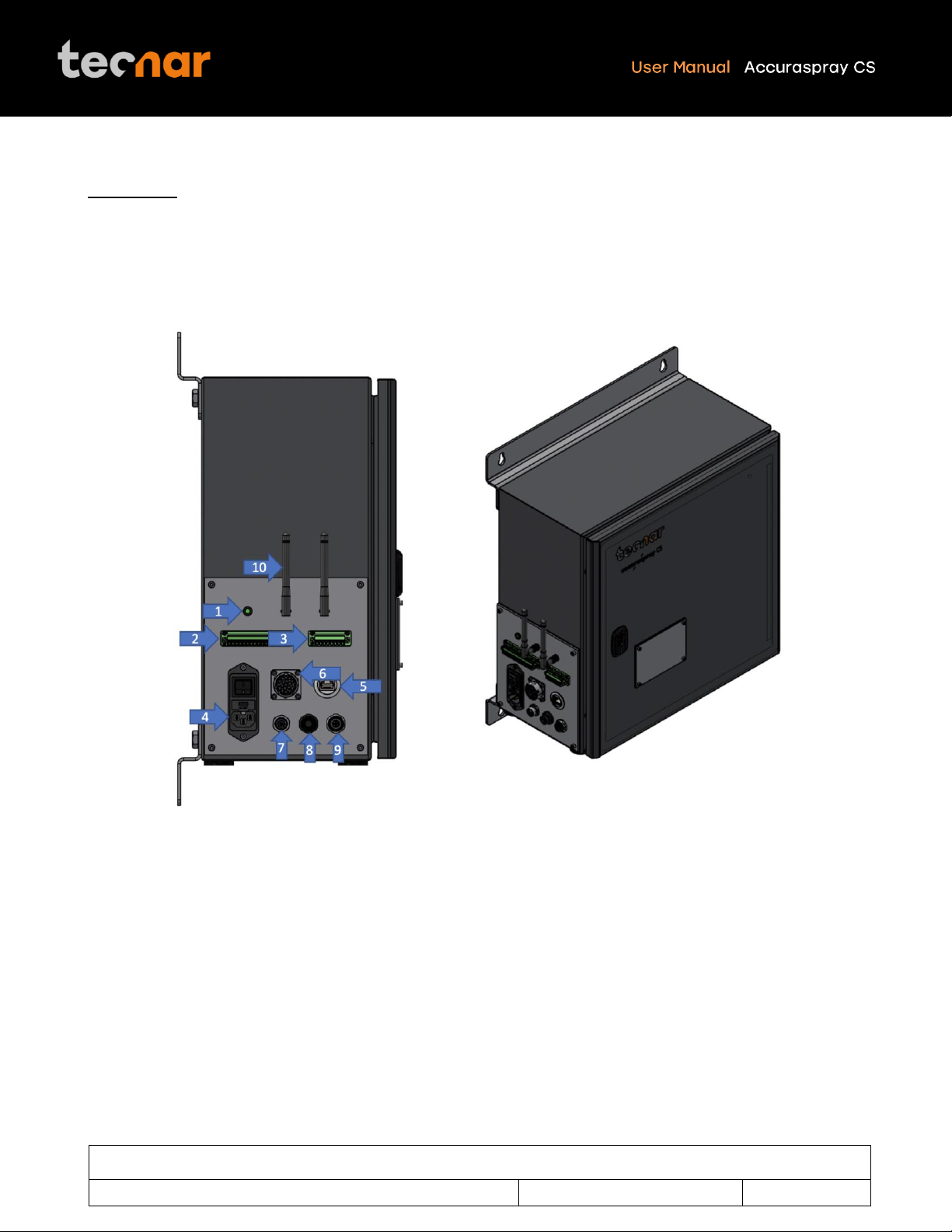

Controller

The controller must be kept in a ventilated area to reduce the risk of overheating.

The controller receives readings from the sensor head. It processes the data and broadcasts the results to the

user interface(s).

FIGURE 2: CONTROLLER (SIDE AND ISOMETRIC)

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 11 of 51

Component

Description

1. LED

LED

Off: Power supply is OFF

Green: The system is ON

2. I/O interface

Used to interface the Accuraspray CS to the

user’s spray controller via digital I/O ports.

3. Safety interlock

Used to setup safety interlocks with the booth

access points

4. Power switch and

inlet

Used to activate the unit. Connect it to an

unloaded, properly grounded power line (100-

240VAC, 50-60Hz, 1.5 A).

5. Ethernet port

Used to access the Accuraspray CS user

interface through a wired network connection

(either static or DHCP).

6. HMI cable port

Used to connect the HMI unit with the

controller.

7. Laser power port

Used to power the lasers in the sensor head

8. Safety switch port

Used to display the status of the laser beam

stop on the UI.

9. Communication

cable port

Used to communicate with the sensor head.

10. Wi-Fi antennas

Used to access the Accuraspray CS user

interface through a wireless network

connection. The Wi-Fi connection acts as a

hotspot. It can be disabled but not

reconfigured.

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 12 of 51

Sensor head

The sensor head measures the following particles and spray plume properties:

•Particle’s velocity

•Relative feed rate

•Process Stability

FIGURE 3: SENSOR HEAD (FRONT)

FIGURE 4: SENSOR HEAD (BACK)

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 13 of 51

Component

Description

1. Air knife

The air knife is used to keep the sensor head

windows cleaned and free of dust.

2. Laser Illumination

Laser illumination chamber for the illumination

of the plume.

3. Detector viewport

Viewport of the detectors used to characterize

the velocity and feed rate.

4. Safety switch

connector

Used to relay information about the

mechanical shutter in the sensor head to the

controller.

5. Substrate

pyrometer

connector

Used to power and communicate with the

optional substrate pyrometer sensor.

6. Communication

port connector

Used to power the sensor head and

communicate with the controller.

7. Laser power port

connector

Used to connect the laser diodes with power.

8. Alignment beam

switch

Activation switch for the alignment beam.

9. Compressed air

port connector

Compressed air is used both as active cooling

for the head’s internal components, and as it

is exhausted from the head, to generate an air

knife that keeps the viewport windows clean.

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 14 of 51

Cables, hoses and antennas

The Accuraspray CS is delivered with several cables, hoses, and antennas, which are described in the following

table.

Cables/Hoses/Antennas

Description

1. IEC power cable

Used to connect the Accuraspray to a

power outlet.

2. Communication cable

Communication between the controller

and the sensor head.

3. Antennas

Used for Wi-Fi communication to the

controller.

4. Safety switch cable

Used to communicate the status of the

beam stop in the sensor head

5. Laser power cable

Used to power the lasers in the sensor

head through the controller

6. Compressed air hoses

Provide compressed air to the sensor

head for cooling and purging purposes.

•One hose connects the

compressed air supply to the air

filter

•One hose connects the air filter to

the pressure regulator

•One hose connects the regulator

to the sensor head

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 15 of 51

Software Operation

User interface overview

The Accuraspray CS user interface is accessible through a web browser, but it is not actually hosted on the

internet. It is streamed from the Accuraspray CS controller. Tecnar recommends using Google Chrome or

Microsoft Edge (chromium based) browsers.

Any modern computer with at least 4GB of RAM should be sufficient to run the user interface smoothly. Connect

the PC to the controller via an Ethernet cable or through the built-in Wi-Fi.

FIGURE 5: ACCURASPRAY CS USER INTERFACE

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 16 of 51

Accessing the user interface

To connect to the UI through the Wi-Fi use the following steps:

1. Open the Wi-Fi menu on your computer or tablet

2. Look for “Accura CS –serial number”.

3. The password to access the Wi-Fi is “accura.wifi”.

4. Follow the procedure in the section “Modifying Windows “hosts” file” of the “40107-00047” document.

To connect to the UI through static IP use the following steps:

1. Connect the Accuraspray controller directly to your PC with an Ethernet cable.

2. Click on the Windows icon, type “View Network Connections”.

3. In the connection window, identify the connection connected to the Accuraspray.

4. Right-click on the connection and click “properties”.

5. Double-click on “Internet Protocol Version 4 (TCP/IPv4).

6. Click on “Use the following IP address”.

7. Enter the following:

IP address: 192.168.101.254

Subnet mask: 255.255.255.0

Default gateway: (leave blank)

7. Follow the procedure in the section “Modifying Windows “hosts” file” of the “40107-00047” document.

8. You are now ready to connect to the software, please refer to the section “Connecting to the software”.

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 17 of 51

Connecting to the software

To connect to the software, use the following steps:

1. Open your browser

2. Enter the URL: http://accuracs-00000000/ to connect to the Accuraspray CS user interface. Replace the

zeros with the serial number of the unit you are trying to reach. The serial number is composed of 8 digits

which can be found in the Wi-Fi network name or under the controller.

Logging in

The Accuraspray CS user interface interface allows multiple, simultaneous users (up to 5). For instance:

•One user or “the operator” can be using the system for measurement (will need to “take control” as covered

in subsequent sections).

•Another user can be “watching” the “operator” from the engineering office via the network or wireless.

•Another user can be viewing saved files from previous runs in the QC department.

When accessing the Accuraspray CS interface, users that are not logged in are in viewer mode and can only

visualize the sensor’s readings from the live screen or the strip charts screen.

To make changes to the setup and record sequences it is necessary to log in by clicking the designated icon.

Users can log in either as operator or administrator.

•Operators (username: operator) can change (load) the setup used by the sensor and record

measurement sequences. Operators cannot modify setups. The default password for operators is:

accura.operator

•Administrators (username: admin) have the same rights as the operators and can also create,

modify, and delete setups. The default password for administrator is: accura.admin

Users’ passwords can be changed in the settings tab.

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 18 of 51

Navigation tabs

The navigation icons are displayed on the he left of the Accuraspray CS user interface to access the different tabs.

The following table describes those icons.

Icons

Description

Access the main measurement screen (live).

Access the production files screen.

Access the setup screen (spray parameters).

Access the IO settings.

Access the substrate pyrometer screen.

Access system settings.

Take control and access the setup settings.

This document contains information considered proprietary and confidential to Tecnar Automation Ltee

40101-00075-00 –Rev A

Revision date: 2022-11-17

Page 19 of 51

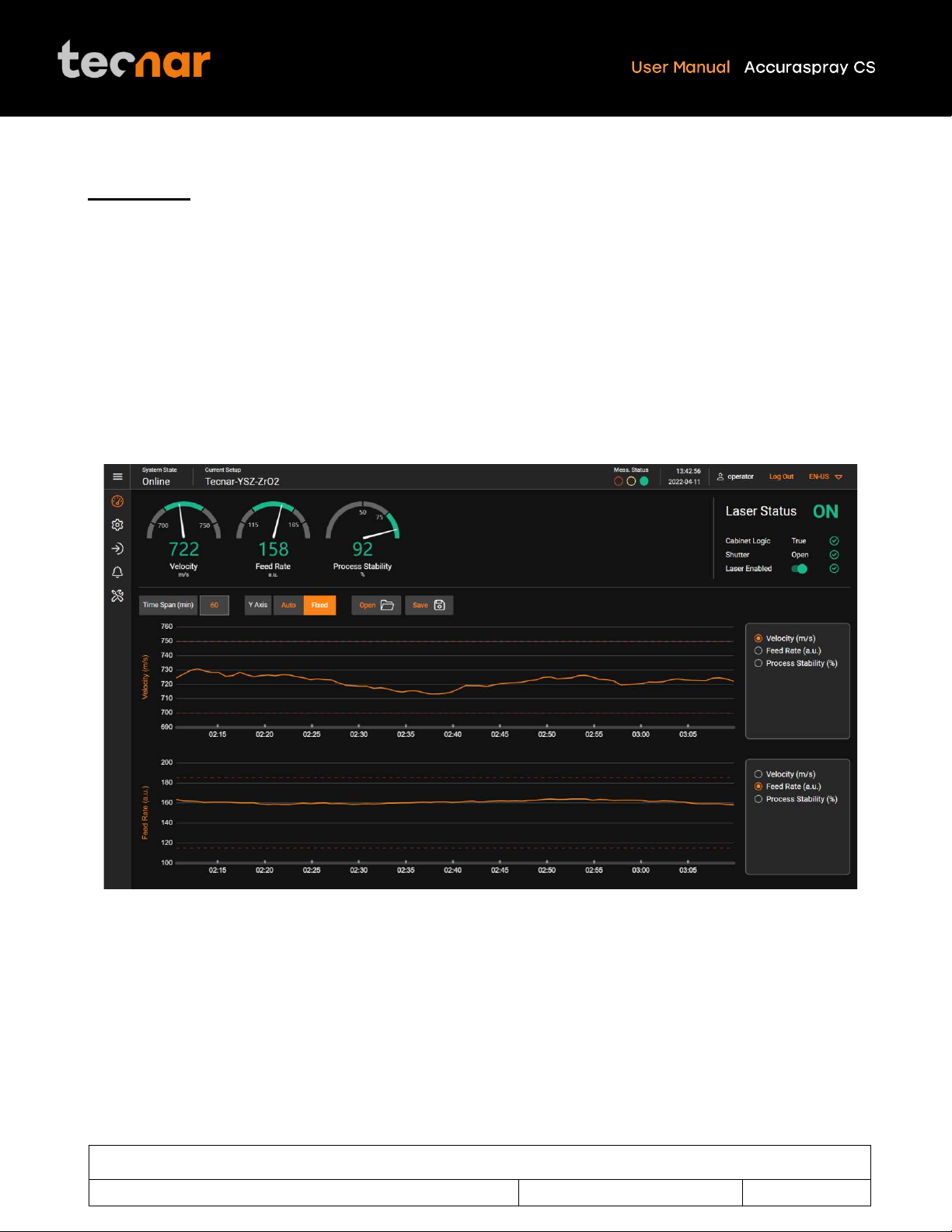

Live screen

The live screen displays in real time all measurements taken by the Accuraspray CS.

The measurements are displayed at the top of the screen.

Color codes indicate whether the measurements are within the acceptance range as defined in the setup by the

process engineer. A measurement fully within the acceptance range is shown in green, a measurement just barely

within the acceptance range is shown in yellow, and a measurement outside the acceptance range is shown in

red. Corrective actions should be taken to ensure that all measurements are within the acceptance range and

displayed in green.

In the middle of the screen, you will find two graphs, each displaying one type of measurement. It is possible

to select which measurement to display from the table located to the right of the graphs .

FIGURE 6: ACCURASPRAY 4.0 LIVE SCREEN

Table of contents

Other Tecnar Accessories manuals

Popular Accessories manuals by other brands

Polaroid

Polaroid PLAY PL-2000-00 quick start guide

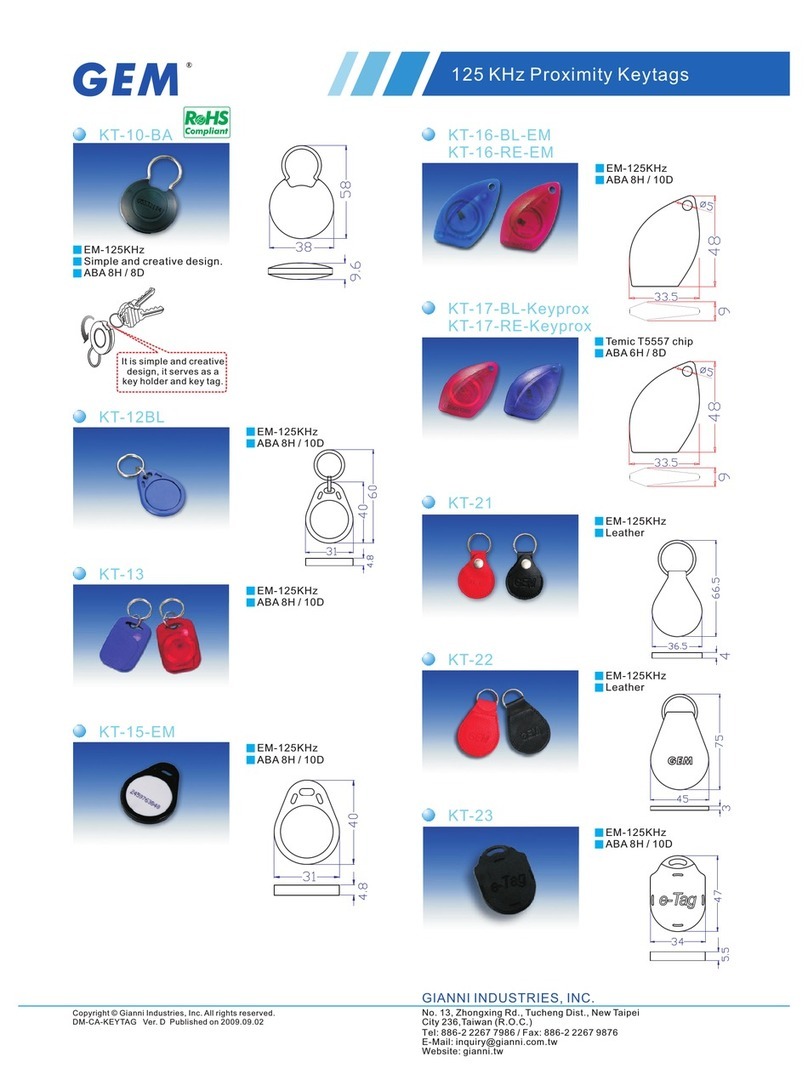

GEM

GEM GEM KT-10 Specification sheet

Essence

Essence CareHome ES700MGLS user guide

active fun

active fun Infinity Leap TP499 Instructions for assembly, maintenance and safe use

elobau

elobau 2UF Assembly instructions

Manitowoc

Manitowoc 7626213 Replacement manual