Tecnar Rotoweld 3.0 User manual

•

MAINTENANCE

MANUAL

Automated welding

work cell for

pipe spool

prefabrication

2

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

1 FLEXIBLE CABLE CARRIER MAINTENANCE .......6

1.1How to replace damaged covers and broken links ................................. 6

2. TRACK SYSTEM MAINTENANCE.........................9

2.1 Chain for motorization maintenance......................................................... 9

3. WELDING CARRIAGE MAINTENANCE............ 10

3.1 Water cooler maintenance ....................................................................... 10

3.1.1 Routine maintenance................................................................................................. 10

3.1.2 Reservoir coolant level............................................................................................... 10

3.1.3 Clean or replace the pump inlet strainer ................................................................ 10

3.1.4 Pump motor ................................................................................................................ 12

3.1.5 Heat exchanger .......................................................................................................... 12

3.2 Gas flow meter maintenance ................................................................... 13

3.3 Wire feeder maintenance......................................................................... 14

3.4 Pressurized flux feed tank maintenance ................................................. 15

3.5 STT arc sensor maintenance .................................................................... 18

3.6 Pyrometer maintenance............................................................................ 19

3.7 Foot pedal maintenance........................................................................... 19

3.7.1 Main & Secondary positioner: .................................................................................. 19

3.7.2 Carriage:...................................................................................................................... 20

3.8 Carriage wheels maintenance ................................................................. 20

3.9 Motorization sprocket maintenance ....................................................... 22

3.10 Welding manipulator maintenance ...................................................... 23

3.10.1 X Y position torch reference ................................................................................... 24

3.10.2 Servo Control timing belt........................................................................................ 24

3.11 Root & Fill torch maintenance................................................................ 28

3.11.1 Nozzle, contact tip, gas diffuser & liner replacement.......................................... 28

3.11.2 How to replace QUICK LOADª liners into retainer pin ..................................... 29

3.11.3 How to replace conventional liners ....................................................................... 30

3.12 SAW fill torch maintenance.................................................................... 31

3.13 Control station Maintenance.................................................................. 32

3.13.1 Monitor and computer enclosure maintenance .................................................. 32

3.13.2 Fan filters maintenance ........................................................................................... 38

4 POSITIONERS MAINTENANCE.......................... 39

4.1 Rotative ground maintenance.................................................................. 39

4.2 Gas cylinder pressure regulator maintenance....................................... 40

4.3 Self centering chuck maintenance .......................................................... 41

4.4 Gears assembly maintenance .................................................................. 41

4.4.1 Gear lubrification........................................................................................................ 42

3

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

4.4.2 Gear box maintenance .............................................................................................. 42

4.4.3 Gear backlash maintenance...................................................................................... 43

4.6 Pillow blocks maintenance ....................................................................... 43

4.7 Root power source maintenance............................................................. 45

4.7.1 STT II Preventive maintenance.................................................................................. 45

4.7.2 STT II input filter capacitor discharge procedure................................................... 46

4.7.3 STT module Power wave S500 Preventive maintenance ...................................... 47

4.8 Fill power source maintenance................................................................ 48

5 PIPE STANDS........................................................ 49

5.1 Hydraulic cylinder, hoses connection maintenance ............................. 50

5.2 Locking hydraulic valve maintenance..................................................... 50

5.3 Wheels maintenance................................................................................. 50

5.4 Flux pan maintenance............................................................................... 50

6 MAINTENANCE SCHEDULE RECOMMENDED51

6.1 Daily............................................................................................................. 51

6.2 Weekly ........................................................................................................ 51

6.3 Monthly ....................................................................................................... 52

6.4 Quarterly..................................................................................................... 52

6.5 Annually ...................................................................................................... 53

4

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

Other Rotoweld documentation:

¥ Rotoweld Startup Manual (40101-00059); requirements, step by step and

startup electrical installation.

¥ Rotoweld Cold Installation Manual (40101-00032); requirements and step by

step mechanical installation.

¥ Rotoweld User interface (40101-00033); detailed information of all the menus

and sub menus.

¥ Rotoweld Operation Manual (40101-00034); detailed information on how to

weld with the system.

¥ Rotoweld Troubleshooting Manual (40101-00035); in case of hardware issues.

¥ Rotoweld Welding Manual (40101-00036); welding program creation plus

welding tips using the Rotoweld.

¥ Rotoweld Technical Description Manual (40101-00037); hardware description.

¥ Rotoweld Prodatalog Manual (40101-00056); viewer for all the welding data

history logged.

¥ Rotoweld Maintenance schedule (40101-00058).

¥ Rotoweld Suggested Welding Parameters (40103-00252 TO 40103-00257);

baseline parameters for welding programs.

5

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

This system is easy to maintain and will deliver many years of operations.

We are proposing the actions required in time in a table at the end of the document.

To begin, components location will be showed with description explanations related

with maintenance.

Furthermore, detailed actions required to perform on each of the sub components.

6

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

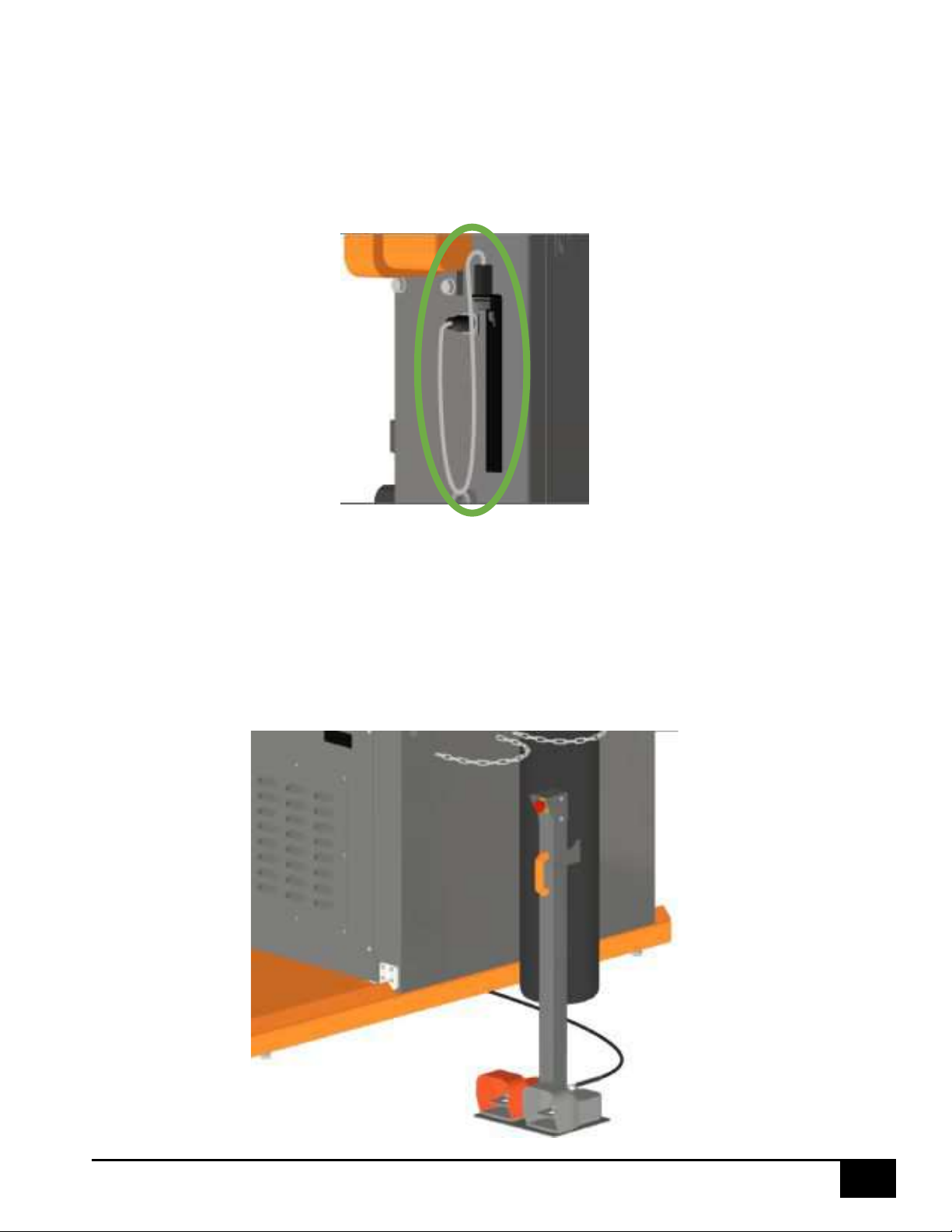

1 FLEXIBLE CABLE CARRIER MAINTENANCE

This is important to keep the base clean where the cable carrier is moving to avoid early

abrasion of the plastic links, also visual inspection for broken covers or links to be

replaced.

The articulated cable carrier is a flexible conduit that contains the electrical cables, gas

lines and connectors required between the welding carriage and the main positioner.

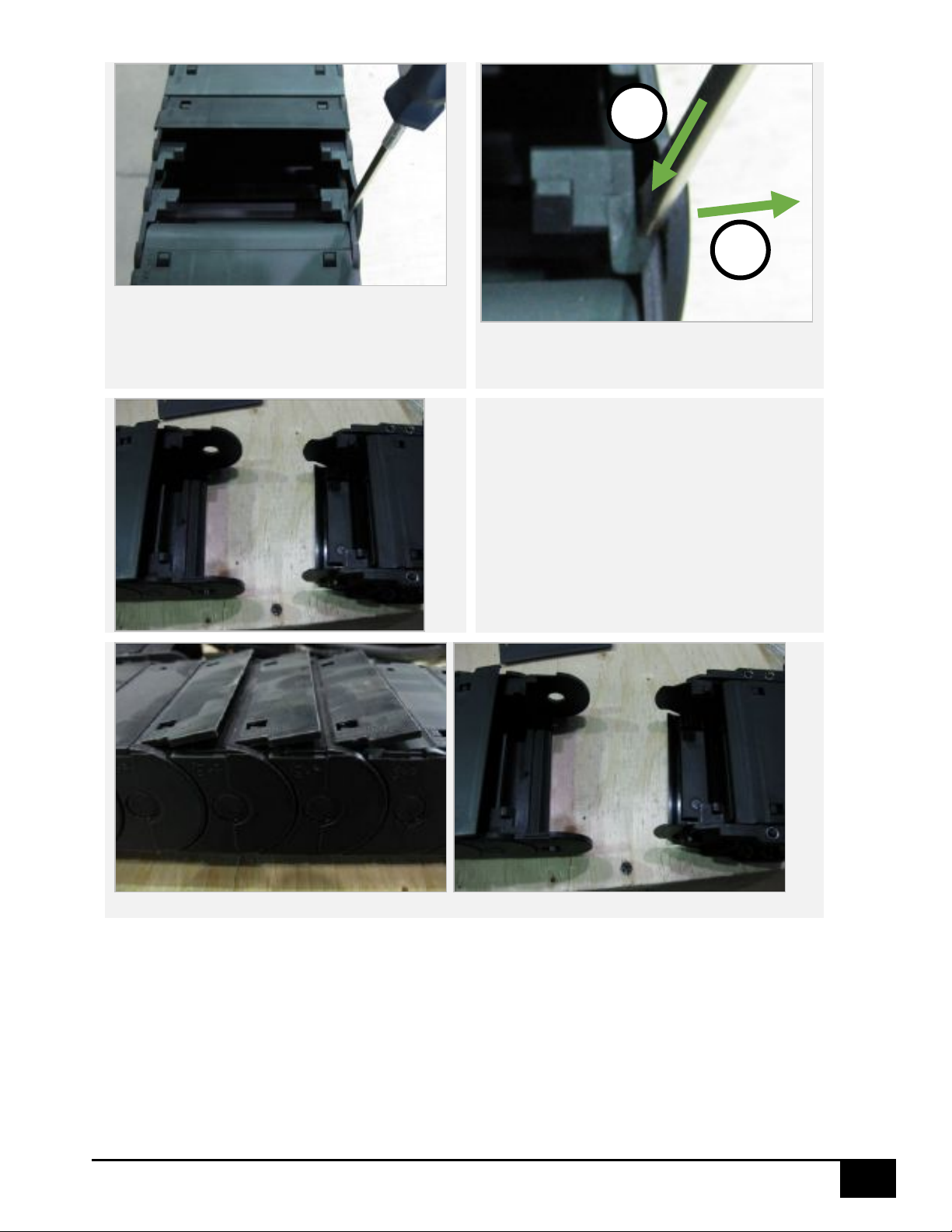

1.1How to replace damaged covers and broken links

1. To raise the lids of the Cable track

management system, insert a flat

screwdriver in the appropriate hole

(see picture) and pull down at each

extremity of the lid.

2. Pull down at each extremity of the

lid

3. For removing a section raise at least 3 lids and remove two of them.

7

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

4. Insert flat screwdriver in the side

panel between the two sections and

push carefully to the outside and pull

out the two sections from each other.

5. Push carefully to the outside

6. Pull out the two sections from each

other.

7. For the installation of the flange, raise 3 lids and remove 2 of them.

1

2

8

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

8. To insert the flange in the chain, insert one side at the time. Make sure the

sections are correctly inserted.

Regular lids

Flange lids

Note:

We have included with the Nylatube 12

regular and 2 flange spare lids. You

have two different lids. The one without

the little ears is the one for the flange

and the other one is for the regular

chain.

9

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

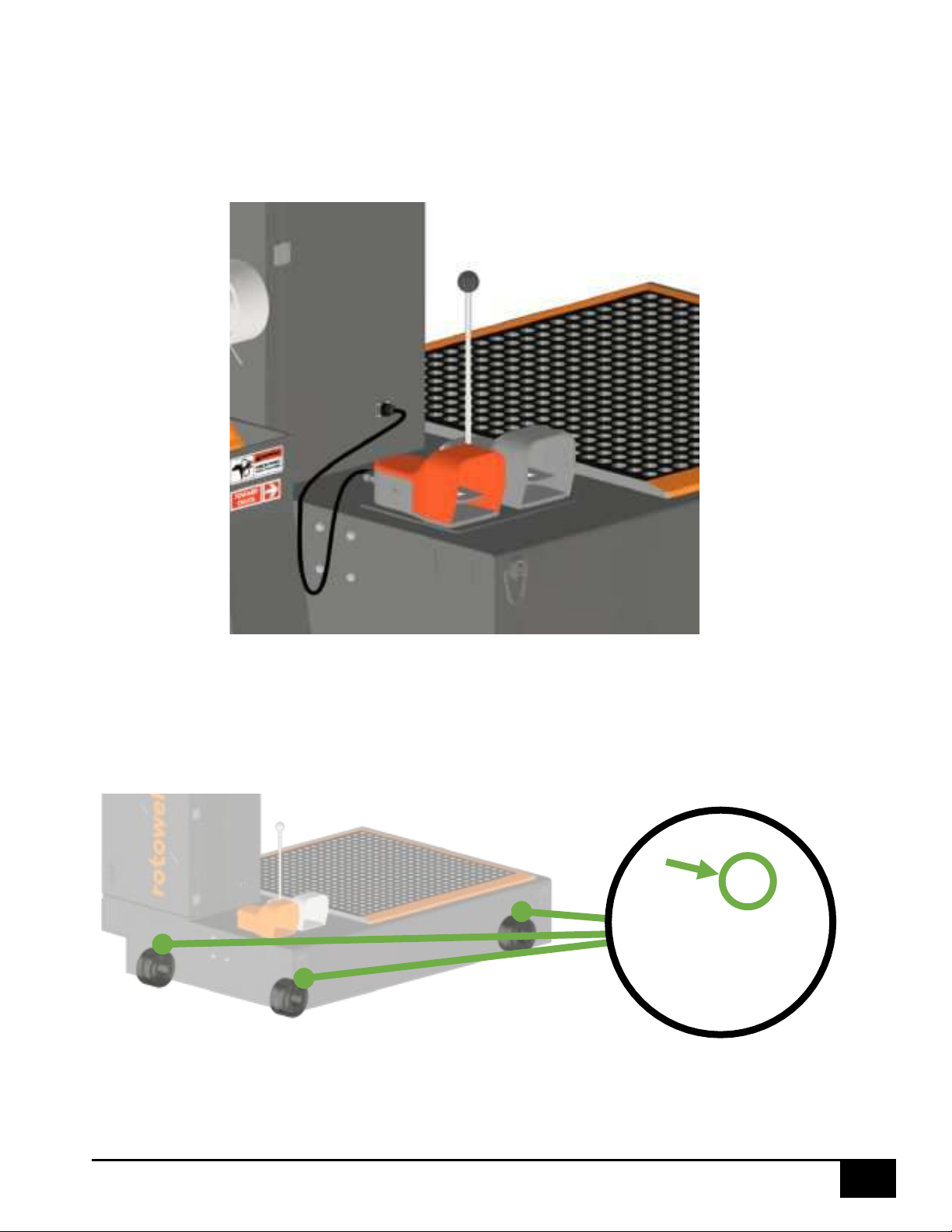

2. TRACK SYSTEM MAINTENANCE

Keep the surface of the track system clean, use a broom, compress air or vacuum. This

assure the welding carriage and pipe stands can move along the tracks smoothly.

2.1 Chain for motorization maintenance

Validation of the chain tension, we put the carriage at a certain distance of the end of the

track and we determine an amount play we suggest.

Chain tensioner localization

Chain tension

adjusting nut

10

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

3. WELDING CARRIAGE MAINTENANCE

3.1 Water cooler maintenance

3.1.1 Routine maintenance

1. Remove accumulated dust and dirt from the internal components of the cooler by

blowing it out with a low-pressure air hose or removing the dust and dirt with a

vacuum hose.

Validate if the fans are operating

3.1.2 Reservoir coolant level

The reservoir volume should be checked monthly.

1. Remove the reservoir fill cap and check the coolant level. The reservoir is full

when the coolant level is just below the reservoir fill opening. Keep the reservoir

full, especially after disconnecting the water lines or changing the accessory

being cooled.

3.1.3 Clean or replace the pump inlet strainer

Warning

The pump head has a "built in" strainer on the inlet side of the pump. It is

recommended to clean or replace the pump inlet strainer at least once a year.

1. Drain coolant from the reservoir and open the case of the water cooler.

Located the pump.

Fan location

11

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

2. Hold pump head to apply counter-torque when loosening strainerÕs 7/8

acorn nut. Do not confuse with 3/4 acorn nut. Remove nut and slide inlet

strainer down and out from pump head.

3. Inspect strainer for damage or excessive clogging: Replace or gently rinse

the strainer under running water to thoroughly clean it.

4. Use a mirror to inspect the inside of the pump for contamination. If hardened

debris is present and interferes with filter seating, carefully remove it with a

dental pick without scratching inside of the pump. Use care not to drop

debris into the pump.

5. Reinstall strainer and acorn nut, tightening with 75±15 in.-lbs. of torque.

6. Hold pump head to apply counter-torque when loosening strainers 7/8

acorn nut.

7. Add 2 gallons of coolant constituted of 1 gallon (4 liters) of water and 1

gallon (4 liters) of glycol.

12

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

3.1.4 Pump motor

The COOL ARC¨ 40 is rated for continuous operation.

It is recommended to re-oil the pump motor bearings once a year as follows:

1. Remove the plastic plugs located on the top of both the inboard and

outboard bearing endcaps.

2. Re-oil each bearing with 30-35 drops of SAE 20 oil then reinstall both

plugs.

3.1.5 Heat exchanger

13

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

To maintain maximum cooler efficiency, the heat exchanger should be kept free

of dust and dirt buildup.

1. Clean the heat exchanger periodically using a vacuum hose or a low-

pressure compressed air line. Avoid placing the unit near a flux hopper

or a flux waste container. A clean heat exchanger offers better cooling

performance and longer product life. In extremely dirty environments, it

may be necessary to remove the heat exchanger completely from the

cooler and clean the fins with soap and water. Use care to avoid

damaging the fins.

3.2 Gas flow meter maintenance

1. Verify for leaks at the flow meter connections with soap & water.

2. Verify for leaks at the shielding gas cylinder input connections at the pressure

regulators with soap & water.

14

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

3.3 Wire feeder maintenance

Disconnect main power before maintenance

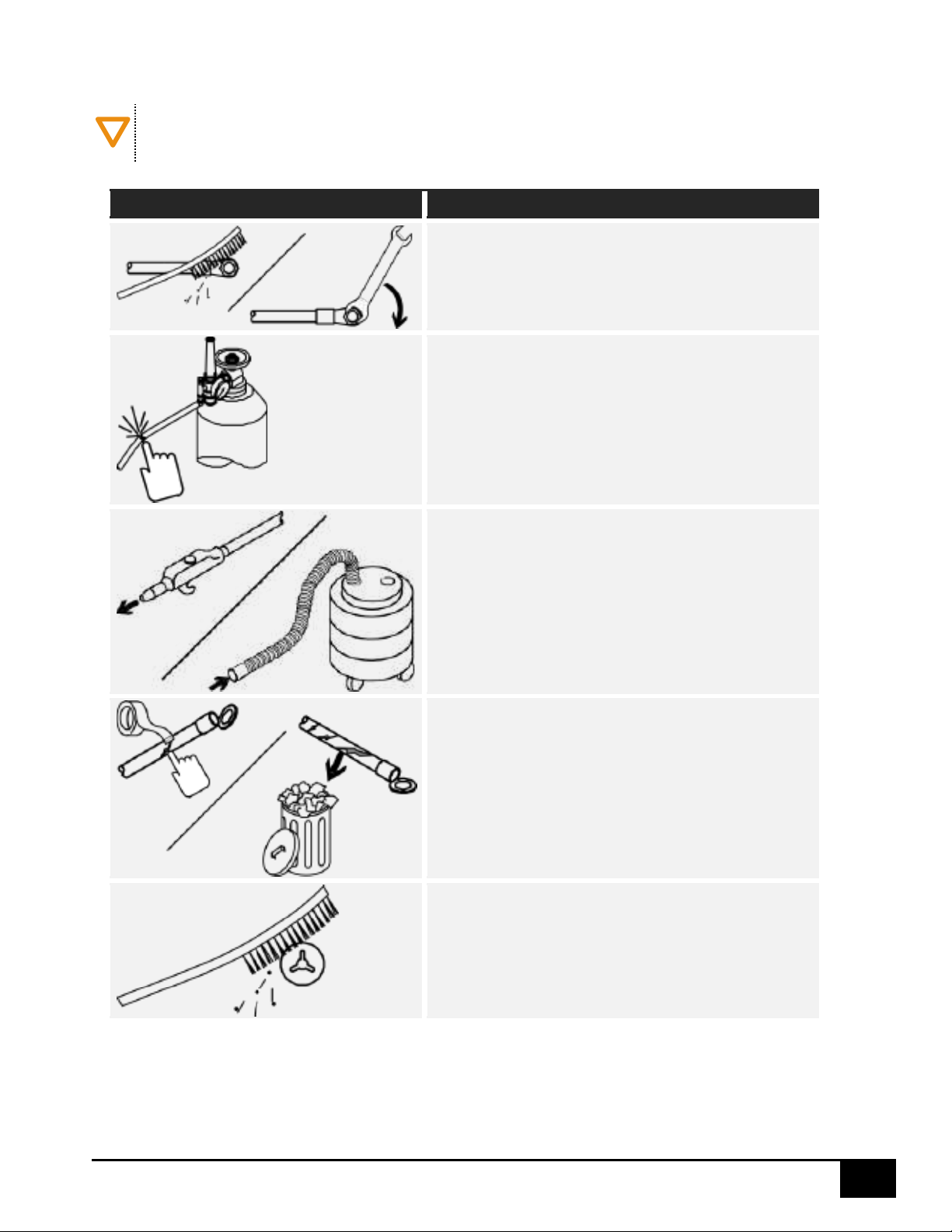

Section

Maintenance

1. Clean and tighten wire feeder weld

terminals.

2. Repair or replace cracked weld cable

3. Blow out or vacuum inside.

4. Repair or replace cracked weld cable

5. Clean drive roll

15

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

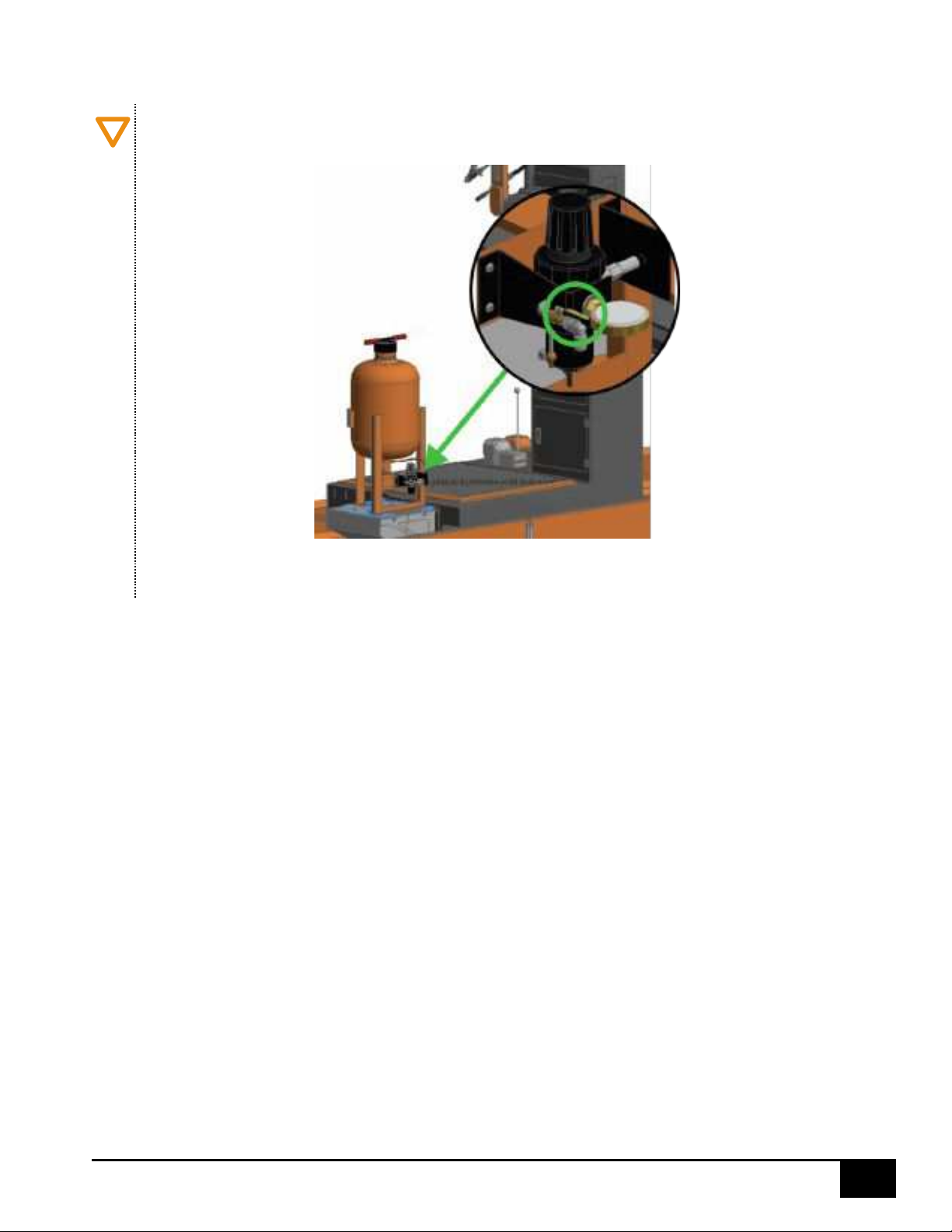

3.4 Pressurized flux feed tank maintenance

Shut down the air pressure valve before attempting any services

16

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

Localization

Maintenance

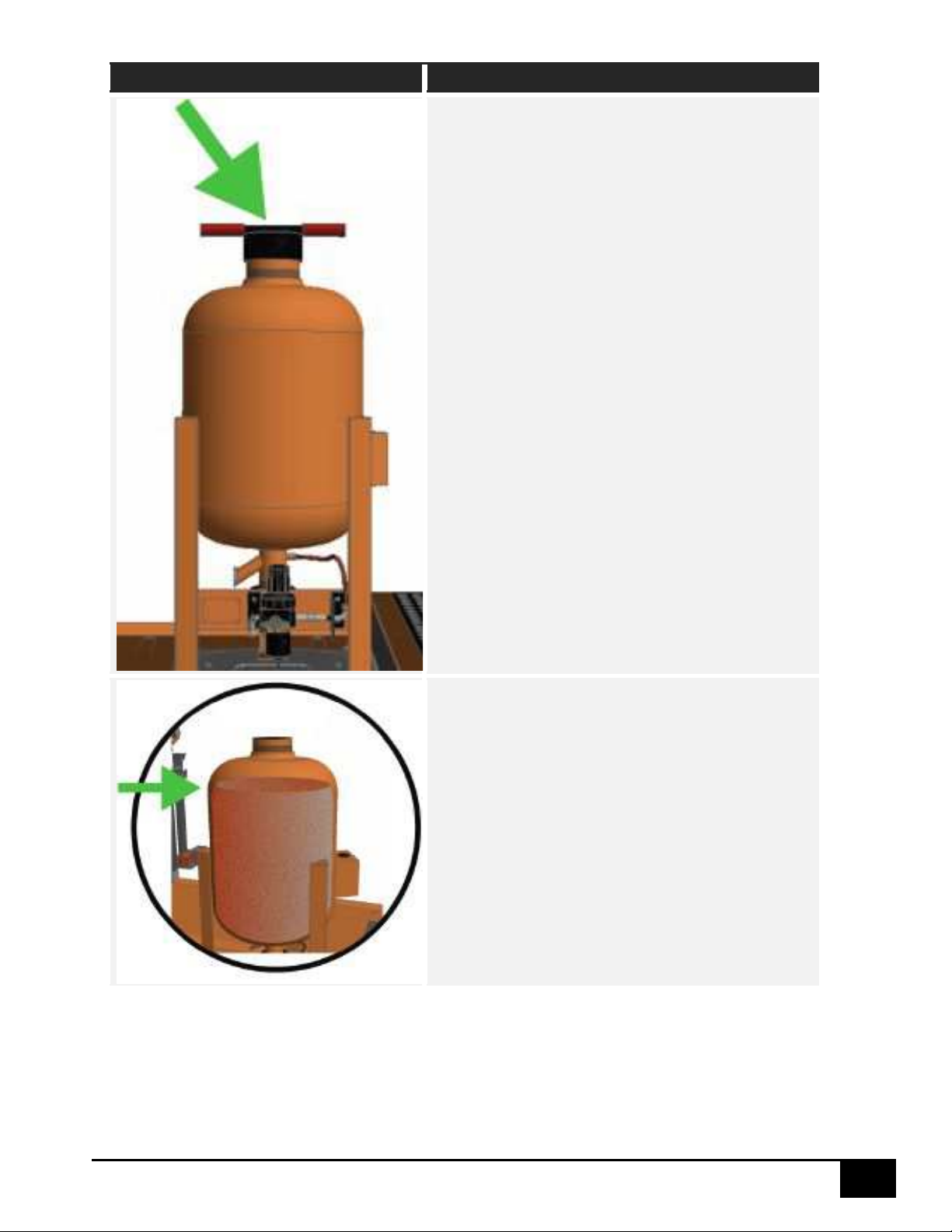

1. Carefully unscrew the cover of the flux

tank. Do not unscrew completely.

Allow the remaining air to escape

completely from the reservoir. When

the air is completely removed from the

reservoir you can unscrew the cap

completely.

2. Do services if needed

17

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

3. Install the tank cover and make sure it

is properly tightened so that air does

not escape.

4. Open the air valve

18

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

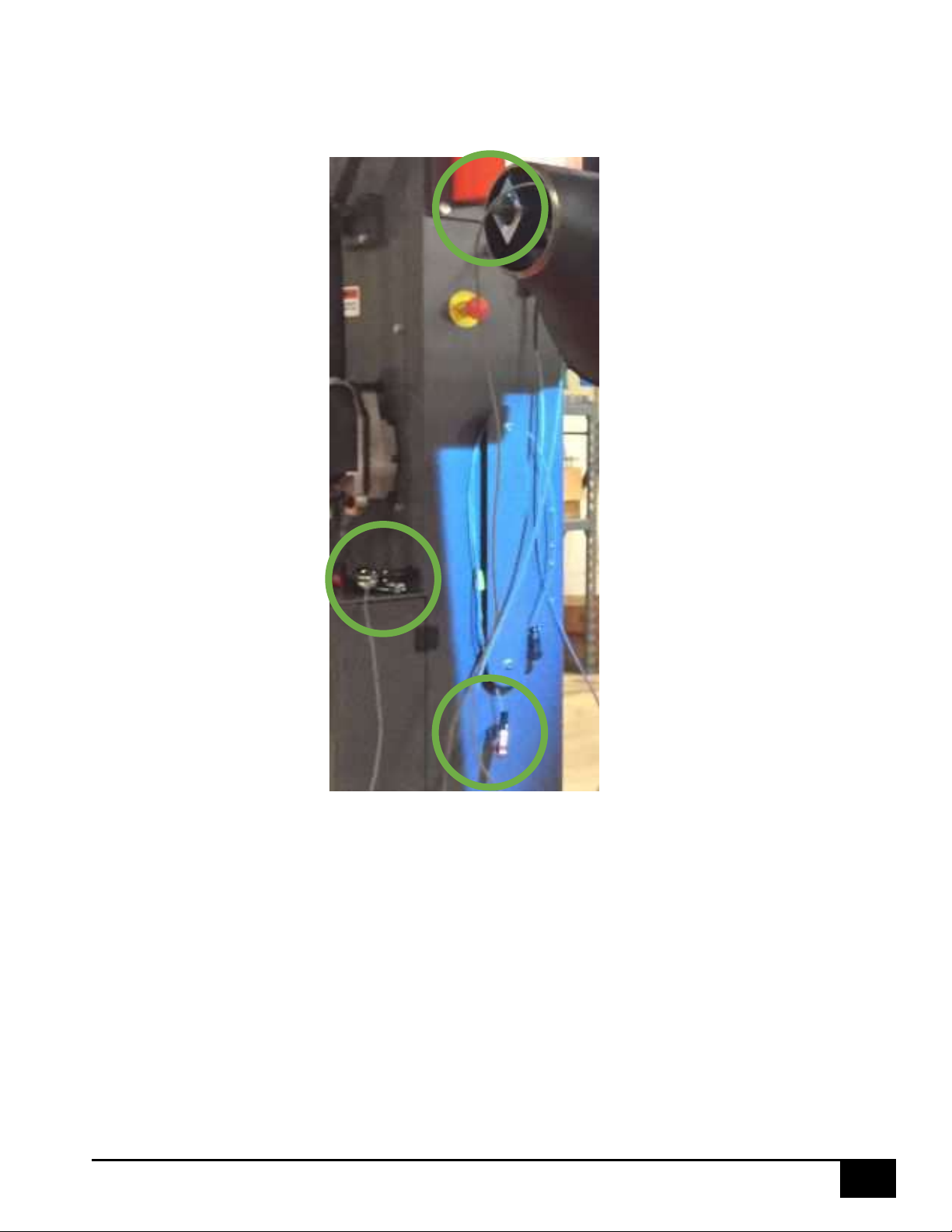

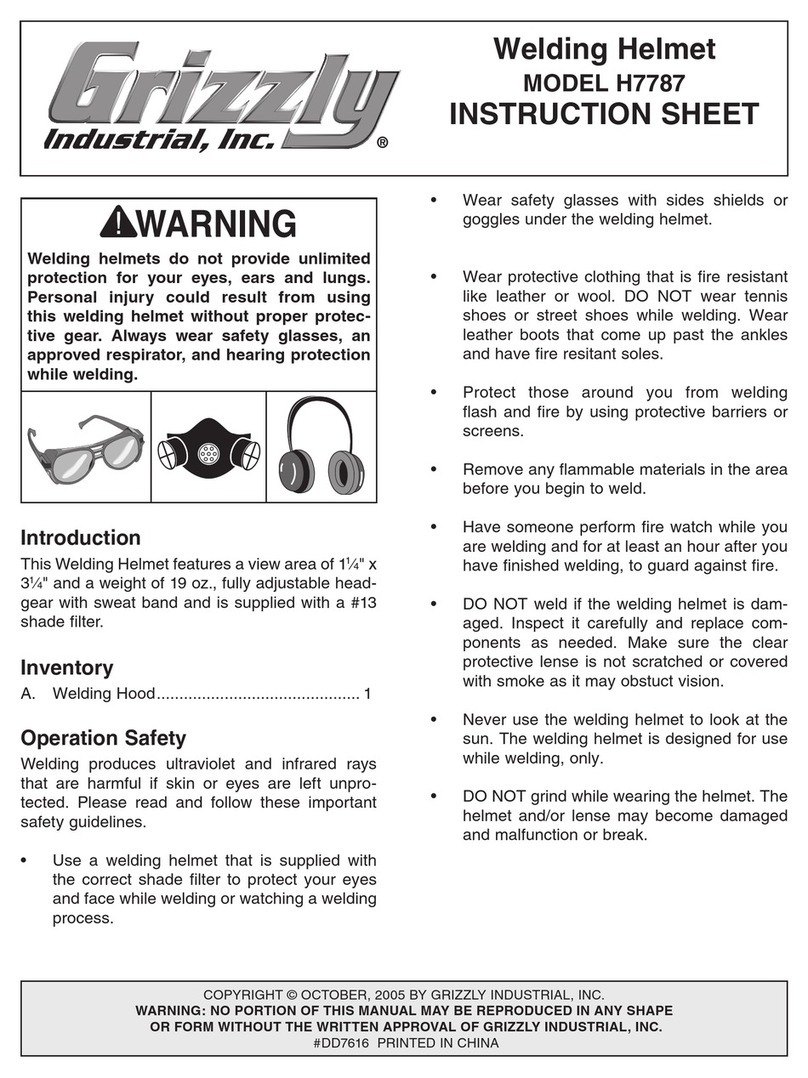

3.5 STT arc sensor maintenance

1. Verify the wire, clamp and magnet for damages, repair or replace if required.

19

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

3.6 Pyrometer maintenance

1. Verify the wire, clean the sensor input reader.

2. Point the carriage with the pyrometer, the temperature reading should be close

to the ambient temperature. If not, service is required. Refer to the manual of the

pyrometer.

3.7 Foot pedal maintenance

3.7.1 Main & Secondary positioner:

1. Test the foot pedal functionality, forward reverse and the estop.

2. Visual inspection of the electrical cables for damages.

3. Repair or replace damaged wiring.

20

ROTOWELD 3.0 Ð MAINTENANCE SCHEDULE MANUAL (40101-00058--00)

3.7.2 Carriage:

1. Test the foot pedal functionality, forward reverse.

2. Visual inspection of the electrical cables for damages.

3. Repair or replace damaged wiring.

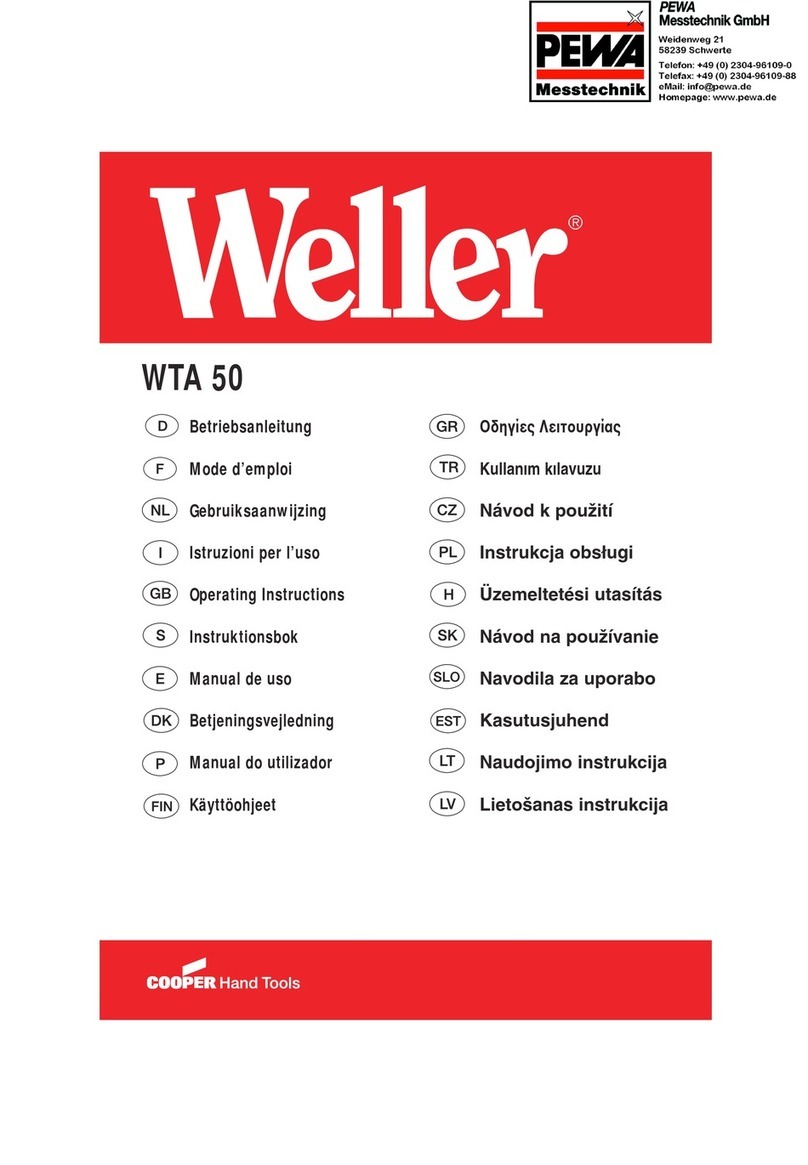

3.8 Carriage wheels maintenance

Lubrification of the wheel.

1. Use the zerk grease fitting to lubricate each wheel.

Other manuals for Rotoweld 3.0

1

Table of contents

Popular Welding Accessories manuals by other brands

Chicago Electric

Chicago Electric 46092 Owner's manual & safety instructions

Grizzly

Grizzly H7787 instruction sheet

Miller Electric

Miller Electric Millermatic 185 owner's manual

Sundstrom

Sundstrom SR 591 Instructions for use

3M

3M Versaflo M-153SG User instructions

Weller

Weller WTA 50 operating instructions

BorMann

BorMann BIW1500 manual

Lincoln Electric

Lincoln Electric VIKING 1740 Series Operator's manual

Lincoln Electric

Lincoln Electric Activ8X Operator's manual

Miller

Miller Swingarc DS-74DX owner's manual

Abicor Binzel

Abicor Binzel xFUME TIG 150/260W Translation of the original operating instructions

Walter

Walter Surfox Mini user guide