Tecnomac T 93 E H2 User manual

AUT

MAX

AUT

MAX

Cod. 71503070/0 - 12/97

OUR SYSTEMS CONFORM TO EC STANDARD 73/23 CEE - 89/336

INSTRUCTION MANUAL

GB

STEAM HUMIDIFIERS

T 93 E H2

T 97 E H3

GB

8

1. ELECTRICAL CONNECTIONS

2. WATER MAINS CONNECTIONS

3. MACHINE INSTALLATION

4. MACHINE TEST RUN

5. REPAIRING MACHINE COMPONENTS AND PARTS

6. DISASSEMBLY OF MACHINE AND/OR COMPONENTS

7. ADJUSTMENT AND SETTING PROCEDURES

8. MACHINE CLEANING AND MAINTENANCE

RELATIVE TO THE FOLLOWING PARTS AND COMPONENTS:

– ELECTRICAL

– ELECTRONIC

– MECHANICAL

WW

WWAA

AARR

RRNN

NNII

IINN

NNGG

GG

!!

!!!!

!!!!

!!

MACHINE USER IS SVERELY PROHIBITED

FROM CARRYING OUT THE OPERATIONS

MARKED WITH THIS SYMBOL

GB

9

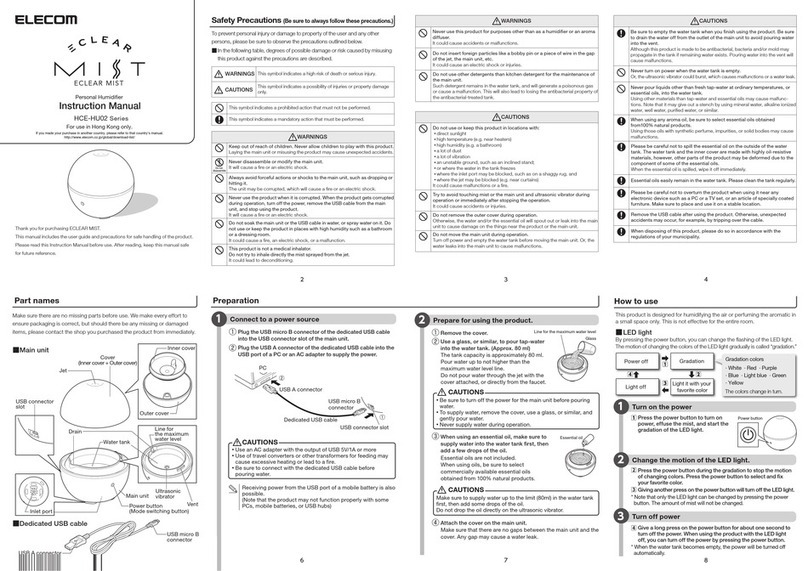

1. GENERAL FEATURES ON STEAM HUMIDIFIERS

FUNCTION LOGIC

It is possible to create a flow of electric current

by simply applying tension to two electrodes

immersed into a water container. This makes

the water boil. In fact, water containing just a

very small quantity of salts, behaves as if it

were an electric resistance and closes the cir-

cuit between the two electrodes.

MAIN PARTS

Any steam requirement is controlled by the

electronic controller (R). It energises thecon-

tactor to supply power to the immersed elec-

trodes. Steam production is indicated on the

control display and the absorbed energy is

controlled by the current transformer (TAM).

When steam production drops below the set

value following a decrease of water level, the

controller instructs the solenoid valve (C) to fill

the charge tank (V) so as to allow water to flow

into the boiler by gravity.

The fill tank has two electrodes which measure

the conductivity of the feed water.

The ensures the best operation of the humidifi-

er in relation to the chemical characteristics of

the feeding water. On the top of the cylinder

there are two small high level electrodes (E):

they measure the water level and if it exceeds

the maximum selected value, water is dis-

charged through the relative discharge pipe.

The controller will instruct the drain solenoid

valve (S) to open/close on the basis of the

feeding water chemical characteristics. This

serves to maintain the best concentration of

salts within the cylinder and ensures the cor-

rect functioning of the humidifier.

(fig. 1 e 2)

V - Feed tank with electrodes for conductivity

measurement

E - Top level electrodes

T - Overflow pipe

B - Cylinder boiler

C - Feed valve

S - Discharge valve

R - Electronic control panel

ELECTRONIC CONTROLLER

The compact OEM humidifier is equipped with

the new microprocessor-based controller CDA

303.

The controller has a current transformer as well

as the operative contacts for the single-phase

function mode.

TECHNICAL CHARACTERISTICS

T 93 e H2 T97 e H3

Production

Kg./h 3 3

Electrical absorption

amper 9,9 3,3

Power

kw 2,17

Feeding current

220/V/50 HZ

380/V/50 HZ

Monophase

xxxxxxx

GB

10

2. SETTING UP

WW

WWAA

AARR

RRNN

NNII

IINN

NNGG

GG!!

!!!!

!!!!

!!

THIS PROCEDURE MAY ONLY BE DONE

BY AN AUTHORISED TECNOMAC

INSTALLATION TECHNICIAN

Setting up the humidifier requires hydraulic

connections tho the fill and drain valve.

FEEDING PIPE

The feeding water will be conveyed from the

water-gate valve and pipework (min.) 6 mm.

internal diameter.

Please Note that pressure ranges between 1

and 10 bars. In case of higher pressure values

it will be necessary to use a pressure reducer

set at 3-4 bars. The feeding water temperature

must not go above 50°C.

IMPORTANT: Use water coming from the

city water mains. DO NOT USE TREATED

WATER (demineralized, soft, deionized

water).

If the feeding water contains dirt or impurities,

it is advisable to use a filter to improve the

quality of water. There is a series of water filters

available, forfiltering particles from 1 to 5 µm.

For further information please contact

Tecnomac Service.

3. START-UP PROCEDURES

HUMIDIFIER START-UP

The humidifier can be started after having car-

ried out the necessary connections (hydraulic

and electric) and after having connected it to a

humidistat, regulator or probe.

The humidifiers are started by pressing the

switch.

Wait just a few seconds for the initial test to

take place.

After that:

THE CONTROLLER WITH LEDSs AND

PUSHBUTTONs will:

turn ON the capacity led indicators.

Tecnomac garantees the working of its own

humidifiers only if they are connected to the

water network (not softned, not be, ineralised,

not treated with any kind of thing) with conduc-

tivity between 125 and 1250 µS/cm.

There are two different starting procedures,

depending on the water conductivity:

FEEDING WATER WITH CONDUCTIBILITY

HIGHER THAN 750 µS/cm.

The humidifier reaches full efficiency immedi-

ately, adjusting water flow to the cylinder to

provide the value of current necessary to pro-

duce the required steam quantity.

FEEDING WATER WITH CONDUCTIBILITY

FEEDING PIPE

Min. internal dia. feeding pipe (mm)

Mains pressure (bar)

Max. capacity feeding water (I/min)

Feeding water temperature

Feeding water connection

DISCHARGE

Discharge water connection (mm)

Min. dia. discharge pipe (mm)

STEAM CONVEYANCE

Pipe diameter (mm)

6

1-10

0,6

50°C

3/4” G(M)

30

3/4” G(F)

25

T 93 E H2 - T 97 E H3

GB

11

LOWER THAN 750 µS/cm.

The humidifier gets to the real working level

slowly, as it takes some hours (sometimes

some days) to make the water evaporate as to

concentrate the salts inside of the cylinder, so

the water can get to a conductivity higher than

750 µS/cm.

SWITCH > AUTOMATIC POSITION (AUT)

SWITCH > AUTOMATIC POSITION (MAX)

IMPORTANT

(fig. 8)

SWITCH TO CHOOSE HUMIDIFICATION

POWER.

In “AUT” position the system supplies 30% of

max. water vapour delivery which is preset in

phases Iª and IIª of LevControl 1; Iª, IIª, IIIª of

LevControl 2. It supplies the max. water vapour

delivery in phase IIIª of LevControl 1 and in

phase IVª of Lev Control 2.

In “MAX” position it always supplied the maw.

water vapour delivery.

Note: The “MAX” position must be used

only during the manual leavening phase.

WW

WWAA

AARR

RRNN

NNII

IINN

NNGG

GG!!

!!!!

!!!!

!!

THE USER MUST NOT INTERVENE SHOULD ANY OF THE FOLLOWING MACHINE MAL-

FUNCTIONS OCCUR.

IT IS OBLIGATORY TO CONTACT AN AUTHORIZED TECNOMAC TECHNICIAN.

1. THE CONTROL PANEL IS NOT WORKING

2. THE HEATING SYSTEM IS NOT WORKING

3. IN ANY OTHER CASE OF IRREGULAR FUNCTIONING

4. PERIODIC MAINTENANCE

WW

WWAA

AARR

RRNN

NNII

IINN

NNGG

GG!!

!!!!

!!!!

!!

THIS PROCEDURE MAY ONLY BE DONE

BY AN AUTHORISED TECNOMAC

INSTALLATION TECHNICIAN

STEAM BOILER UNIT

Maintenance is advisable any time you the

humidifier after a long period of inaction or

when the “worn-out cylinder” alarm appears. In

such a case it is necessary to remove and

replace the cylinder, the only component sub-

ject to deterioration. If the humidifier operates

particularly with hard or aggressive water, it

should be necessary to substitute the cylinder

more frequently. Don't use decalcifiers or any

type of acids to wash the cylinder, as to avoid

the corrosion of the internal parts.

Remove the cylinder as follows:

– Empty the cylinder, draining water through

the “DR” key;

– Power supply OFF;

– Disconnect the steam pipe from the cylinder;

– Disconnect the electric connections to the

GB

12

main electrodes;

– Remove the plugs from the high level elec-

trodes;

– Remove the fixing bracket to free the cylin-

der;

– Lift the cylinder and remove it.

Before replacing it:

– Check that the gasket between cylinder and

drain section is in good conditions;

– Replace the cylinder and follow the indication

above, starting from the last point.

IT IS RECOMMENDED TO COMPLETELY

EMPTY THE CYLINDER ANY TIME THE

HUMIDIFIER WILL REMAIN INACTIVE FOR

LONG PERIODS.

FILL AND DRAIN SOLENOID VALVES

– Disconnect the power supply leads;

– Remove the fill/drain solenoid valve;

– Remove any possible salt deposits under a

jet of water;

– Check the conditions of the flow sensor with-

in the fill solenoid valve: don’t use com-

pressed air as to avoid damages to the flow

regulator;

– Refit the valves and power the humidifier.

DRAINAGE AND STEAM

CONVEYANCE PIPINGS

These pipes may get damaged because of the

high temperatures they undergo during normal

function of the humidifier. Please check period-

ically their conditions and - if necessary -

replace them.

NOTE: ALL THE MAINTENANCE HAS TO BE

DONE AFTER DISCONNECTING THE HUMIDI-

FIER.

This manual suits for next models

1

Table of contents

Other Tecnomac Humidifier manuals