TECNOMAGNETE ST100 Series Instructions for use

Sistema elettronico di controllo per piani magnetici

Electronic control system for magnetic chucks

Système électronique de commande pour des plateaux magnétiques

Elektronisches Steuersystem für Magnetplatten

Sistema electrónico de control para planos magnéticos

Manuale uso e manutenzione

Instruction and maintenance manual

Manuel d’utilisation et d’entretien

Betriebs- und Wartungsanleitung

Manual de uso y mantenimiento

Nr. 50 100 7816

ITALIANO

ENGLISHFRANÇAISDEUTSCHESPAÑOL

ST100

ST200

31

Instruction and maintenance manual

ENGLISH

INDEX

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

1.13

2

2.1

2.2

2.3

2.4

3

3.1

3.2

3.3

3.4

4

4.1

4.2

4.3

5

5.1

5.2

6

6.1

6.2

6.3

7

Page

GENERAL NOTES .................................32

Overview of the company...........................32

Importance of the manual ..........................33

Storing the manual .....................................33

Conventions ...............................................33

Denition of symbols .................................33

Personnel responsible for operations ........33

Trained personal .........................................34

Individual protection means .......................34

General safety precautions.........................34

Behavior during emergency situations ......34

Limitations ..................................................34

Improper or non permitted use ..................35

Nameplate data ..........................................35

TRANSPORTATION AND

HANDLING ..............................................36

Receipt .......................................................36

Handling .....................................................36

Transportation ............................................36

Storage ......................................................36

DESCRIPTION OF THE SYSTEM ......37

Description of the controllers .....................37

Model ST100X ............................................37

Model ST200X ............................................38

Control push-buttons for ST controllers ....39

INSTALLATION ......................................43

General .......................................................43

Connecting ST100 controllers to the

power supply .............................................44

Connecting ST200 controllers to the

power supply ..............................................44

ENABLING ..............................................45

ST100 .........................................................45

ST200 .........................................................45

OPTIONAL COMPONENTS ...............46

Starting the ST100 controller .....................46

Push-button panels of models ST100

and ST200 ..................................................46

QE version ..................................................46

PLC ...........................................................46

8

8.1

8.2

8.3

8.4

9

9.1

9.2

10

11

11.1

11.2

11.3

11.4

11.5

11.6

11.7

12

13

13.1

13.2

14

14.1

14.2

15

Page

CONNECTION TO

TECNOMAGNETE MODULE .............48

Installation of miller ST100 .........................48

Installation of grinder ST100 ......................48

Installation of miller ST200 .........................49

Installation of grinder ST200 ......................50

ORDINARY USE .....................................51

ST100 .........................................................51

ST200 ........................................................51

ANALYSIS OF RESIDUAL RISKS ......52

MAINTENANCE .....................................52

Premise ......................................................52

Maintenance safety instructions.................52

Weekly maintenance ..................................53

Monthly maintenance ................................53

Maintenance to be carried out every

six months ..................................................53

Extraordinary maintenance.........................53

Information on extraordinary reparation

and maintenance ........................................53

TROUBLESHOOTING AND

CORRECTIVE ACTIONS ......................54

DECOMMISSIONING AND

DISPOSAL ...............................................54

Decommissioning ......................................54

Dismantling ................................................54

WARRANTY AND TECHNICAL

SUPPORT ................................................55

Warranty terms and conditions ..................55

Invalidity of warranty ..................................55

TECHNICAL SUPPORT SERVICE ....56

DELARATION OF

CONFORMITY .......................................57

Edition: 07-12

Replaces: 03-09

32 Instruction and maintenance manual

ENGLISH

1 GENERAL NOTES &

Thank you for purchasing one of the many products

manufactured by TECNOMAGNETE S.p.A.

This manual is designed to help you become familiar

with your new product and must therefore be care-

fully read and followed.

For further information on the system, you can con-

tact TECNOMAGNETE’s technical support at any

time.

The descriptions and illustrations provided in this

manual are for reference only.

While conrming the general characteristics

of the controllers described in the manual,

TECNOMAGNETE S.p.A. reserves the right, at its

discretion, to change at any time some of the char-

acteristics in order to improve the product or due to

manufacturing and commercial reasons. The neces-

sary updates, if required, shall be supplied as attach-

ments.

This manual is property of TECNOMAGNETE S.p.A.

and cannot be copied in whole or in part or made

available to third parties without the written authori-

zation of the manufacturer. Should the products be

amended and/or updated, upon authorization of

TECNOMAGNETE S.p.A., the manufacturer shall

integrate the existing manual by providing the text

explaining the use of the modied/integrated com-

ponent along with a description of potential residual

risks.

1.1 Overview of the company

TECNOMAGNETE started its activities in 1972 as

manufacturer of permanent-electro magnetic sys-

tems designed to ensure power, exibility and maxi-

mum safety. Its state-of-the-art technologies and the

patents developed over the years have enabled the

company to become a leading supplier in several

international markets.

The permanent-electro magnetic systems manufac-

tured by TECNOMAGNETE are able to produce all

the magnetic force required both to clamp and lift

work pieces, thus eliminating the need of using elec-

tric power during machining.

Its main elds of activity include:

CLAMPING SECTION FOR LIFTING

•

MTE permanent-electro lifters designed to ena-

ble the handling of ferrous loads of any shape and

dimension.

•

BAT-GRIP permanent-electro lifters with incor-

porated battery.

•

MaxX manual lifters.

WORK HOLDING LINE

•

QUADSYSTEM chucks for millers and machining

centers of all sizes.

•

TFP0 and TFP1 for high precision grinding.

•

RADIAL-POLE chucks for nishing or roughing

operations on boring mills.

•

QUAD-RAIL modules to clamp rails of varying

lengths.

•

MDS chucks for EDM machines.

STAMPING and MOLDING LINE

•

QUAD-PRESS systems to clamp molds.

TECNOMAGNETE has installed approximately

50,000 units in over twenty years, thanks mainly to

its wide-ranging offer, its exibility to meet custom-

ers’ requirements and its efcient post-sales serv-

ice.

33

Instruction and maintenance manual

ENGLISH

1.2 Importance of the manual

A copy of this manual must always be made availa-

ble to the operators responsible for the installation,

operation and maintenance of the controller in order

to allow them to carry out all the required operations

in compliance with the instructions provided in the

manual.

A full compliance with the instructions provided in

this manual is an essential requirement to be able to

correctly use the equipment and ensure the safety of

operators and other people.

The manual forms integral part of the controller.

Therefore, all reproduction and divulgation rights re-

lated to the manual or its exhibits are reserved.

The manual must always be transferred to the new

owner of the machine if the latter is sold.

1.3 Storing the manual

It is severely forbidden to remove parts, tear pages

or alter this manual.

The manual should always be carefully preserved so

that it is not damaged.

Always protect the manual from excessive humidity

and heat and store it in a location where it can be

easily accessed by operators in case of need.

1.4 Conventions

To simplify consultation, the manual has been divid-

ed into the following hierarchical order so that each

phase is described in detail:

1 Section 1 of the manual.

1.1 Chapter 1 of Section 1 of the manual.

1.1.1 Paragraph 1 of Chapter 1 of Section 1 of

the manual.

1.1.1.1 Subparagraph 1 of paragraph 1 of Chap-

ter 1 of Section 1 of the manual.

Some chapters and/or sections contain bulleted lists

to allow operators to follow the operation described

step by step.

Parts that require specic attention are highlighted

with symbols.

1.5 Definition of symbols

All information related to safety is highlighted in bold.

All warnings that draw the attention of operators on

operations that may be hazardous in terms of safety

or health or that may cause physical injuries, if the

applicable instructions are not followed, are high-

lighted in red and marked with the following sym-

bol:

All warnings related to operations that have to be

carried out by skilled and qualied personnel are

highlighted in bold and marked with the following

symbol:

1.6 Personnel responsible for operations

Some operations, as stated in this manual, can only

be performed by qualied and skilled personnel. The

qualication level is described by means of the fol-

lowing standard denitions:

•

Qualied personnel is personnel with specic

technical knowledge and/or the experience nec-

essary to avoid potential risks originating from

power supply (engineers and technicians).

•

Trained staff is personnel that operates following

the instructions and/or under the supervision of

qualied personnel, who is responsible for verify-

ing that they are not exposed to potential hazards

resulting from the contact with power (personnel

responsible for operation and maintenance). This

personnel must have the following qualications:

1. All personnel must be trained and authorized to

disconnect the machine from the power supply, to

connect it to the grounding system and to mark

circuits and equipment following standard safety

procedures.

2. All personnel must have been specically trained

to follow correct maintenance procedures and

use the protective equipment in accordance with

standard safety procedures.

•

Before using the unit, users shall always have to

verify with authorized personnel that:

1. All personnel has received a copy, has read and

understood the content of the instruction manu-

al.

2. All personnel has agreed to follow the instructions

provided.

34 Instruction and maintenance manual

ENGLISH

1.7 Trained personal

•

OPERATORS: workers who, after receiving the

necessary instructions, have been authorized by

the owner to operate the controller and the equip-

ment connected to it. Workers with this qualica-

tion must be thoroughly familiar with the content

of this manual.

•

ELECTRIC MAINTENANCE TECHNICIAN (ref.

EN60204 paragraph 3.45): this qualication is as-

signed to all personnel specically trained to per-

form operation on electric components, which in-

clude connections, adjustments, maintenance

and/or reparations, and to personnel who is qual-

ied to perform operations inside electric cubicles

and boards. This qualication implies having a

perfect knowledge and full familiarity with the

content of this manual.

1.8 Individual protection means

The personnel referred to in the paragraph above

must always wear suitable protective clothing

and use the protection means generally required

to operate the tool machine on which the Tec-

nomagnete module and controller are installed.

In particular, personnel shall always have to wear

industrial shoes along with ear protection, hel-

mets and goggles, if required.

All personnel should refrain from wearing loose

clothing that could get tangled with moving com-

ponents.

1.9 General safety precautions

The instructions and recommendations provided

below comply with current safety regulations and

imply the obligation of complying with applicable

provisions.

TECNOMAGNETE S.p.A. shall not be responsible

for damages caused to people or equipment

originating from the failure to follow applicable

safety provisions and to comply with the instruc-

tions given below.

All operators are therefore expected to follow the

instructions below and to thoroughly comply with

the safety procedures concerning the installation

and use of the equipment applicable in the coun-

try in which the unit is used.

All ordinary and extraordinary maintenance op-

erations shall have to be carried only after the

unit has been disconnected from the power sup-

ply.

Before connecting the power cable, it is essential

to verify that the line voltage complies with the

one shown on the nameplate of the controller.

All transportation, installation, ordinary and ex-

traordinary maintenance operations performed

on the controller must be carried out only by per-

sonnel with the qualifications stated in Chapter

1.6 and 1.7.

1.10 Behavior during emergency

situations

In the event of emergency, it is always advisable

to follow the procedures outlined in the operation

and maintenance manual of the machine on

which the controller is installed.

In the event of fire, always use the extinguishing

means provided being careful not to use water to

extinguish fires on electric parts.

1.11 Limitations

The unit can be used only for the applications

specified in operating instructions and only in

combination with the equipment and compo-

nents recommended by TECNOMAGNETE S.p.A.

35

Instruction and maintenance manual

ENGLISH

1.12 Improper or non permitted use

The controller is not designed and has not been

manufactured to be used in explosive environ-

ments.

An improper use may:

•

Cause injuries to personnel.

•

Damage the controller or any other equipment

connected to it.

•

Affect the reliability and performance of the

controller.

In particular, it is essential to adhere to the fol-

lowing instructions:

•

Always use suitable working parameters.

•

Carry out the required maintenance in accord-

ance with the instructions provided.

•

Use suitable equipment.

•

Comply with all the instructions provided.

•

Fix the unit onto a stable surface.

•

Contact TECNOMAGNETE S.p.A. in case of

doubt to determine whether a specific opera-

tion is permitted.

1.13 Nameplate data

The controller is tted with an identication label in

compliance with current laws.

ATTENTION

The nameplate should never be removed even if

the unit is resold.

If the nameplate is damaged or has been

removed, it is necessary to contact

TECNOMAGNETE S.p.A. to order a duplicate.

Always quote the model printed on the

nameplate in all communications with

TECNOMAGNETE S.p.A.

Failure to comply with the above instructions

shall entitle TECNOMAGNETE S.p.A. to disclaim

any responsibility for injuries to personnel and

damage to equipment, making the user fully re-

sponsible before competent authorities.

36 Instruction and maintenance manual

ENGLISH

2 TRANSPORTATION AND

HANDLING

The unit is shipped in a cardboard box, covered with

a plastic sheet and enveloped by polyurethane foam

to protect it from damage in the event of impacts or

accidents.

2.1 Receipt

All units are carefully inspected before shipping.

Upon receipt, customers should verify that the

packaging and the material inside it has not

been damaged (unless otherwise instructed by

TECNOMAGNETE S.p.A.) in order to ensure that the

unit has not been damaged during transport and that

the material supplied complies with order specica-

tions. Visible transport damages should be immedi-

ately reported to TECNOMAGNETE S.p.A. and the

forwarding agent.

ATTENTION

All damages and anomalies must be reported within

ten days from receiving the goods.

2.2 Handling

Weight of model ST100: 0,4 kg.

Weight of model ST200: 2,0 kg.

Always keep the original packaging so that it can

be used to transport the unit if needed.

2.3 Transportation

The unit should always be transported within the fol-

lowing environmental limits: temperature ranging

from –10°C to +55°C, with temperature increase up

to 70°C for a maximum of 24 hours.

If the unit requires the use of specic transportation

means (by sea or air), special provisions shall have to

be adopted in order to protect it from damages

caused by potential impacts. The box should also

contain hygroscopic salts to protect the unit from

atmospheric agents.

2.4 Storage

The unit should always be throughly cleaned and

adequately protected when stored for long periods

of time.

Disconnect the controller from the magnetic chuck

and from the power supply.

It is generally advisable to cover the unit with a wa-

terproof bag and store it in dry and safe place.

The temperature of the storage area should range

between 0°C (32°F) and 55°C (131°F).

Relativy humidity should be between 30% and 90%,

non condensing.

The atmosphere should be clean, free from acids,

corrosive gases, salts, etc

When restarting the machine, always follow the in-

structions provided in Chapter 4.

37

Instruction and maintenance manual

ENGLISH

3 DESCRIPTION

OF THE SYSTEM

3.1 Description of the controllers

ST is an innovative electronic controller for

networked chucks designed for milling and grin-

ding operations.

The sections that follow provide information on the

size and the basic characteristics of the available

models:

•

ST100F (milling)

•

ST100R (grinding)

•

ST200F (milling)

•

ST200R (grinding)

3.2 Model ST100X

The rated operating voltage is 230V.

The control push-button panel is integrated in to the

controller.

The control electronics are situated under the control

push-button panel and enclosed in a plastic hou-

sing.

To simplify installation and facilitate the reading of

the push-button panel, it is also possible to install

the controller on a workbench or mount it on the wall

by simply rotating the control panel.

The plastic material of the housing ensures a high

level of insulation and the utmost safety during use.

The rear part of the controller has a block with a male

pin (designed to be connected to the power cable),

an ON–OFF (0-1) switch and a fuse-holder with two

12.5A protection fuses (type 5x20 mm). Two or more

cable ties for the output of the discharge cables of

the chucks to be magnetized may be present next to

these components.

The maximum useful current that ows into the

ST100X controller is approximately 12.5A; the cur-

rent supplied to the module is impulsive with a cycle

time around a few hundreds of milliseconds (app. 1

second per discharge).

ST100X controllers are suitable to control small

chucks with a single phase voltage of 230V and a

maximum absorption of rated current of 3kW.

For different rated voltages, use a transformer with a

suitable transformation ratio and a rating suitable to

handle the maximum power of the chuck or at any

rate a maximum power of 4kVA. For example, if the

available voltage is 400V, a transformer with a

400/230 transformation ratio is required.

ATTENTION! Control units can be moved only

when controls are not powered.

135

135

40

50

75

135

40

MAIN PARTS

A ➜ Main switch

B ➜ Push-button panel

C ➜ Discharge cable output

D ➜ Start contact

E ➜ Power supply input

Fuse-holder Main Power supply

switch input

Rear

38 Instruction and maintenance manual

ENGLISH

3.3 Model ST200X

The rated operating voltage of this controller varies

according to the type of magnetic chuck to which it

is connected.

The control push-button is external, but can also be

integrated into the controller.

The control electronics are enclosed in a metal hous-

ing. The metal material of the housing is grounded in

order to guarantee maximum safety during the ena-

bling cycles.

It is important to verify that the grounding system is

always in good working order.

The controller does not have a socket for the con-

nection to the power supply. The controller has an

ON–OFF (0-1) switch, thus to adequately protect it

against short circuits, it is necessary to install a suit-

able protection system upstream from the controller.

It is generally advisable to use a magneto thermal

switch (curve C) with an In value compliant with the

rating specied on the magnetic chuck nameplate

that will be connected to the controller.

The maximum power of controller ST200X is ap-

proximately 25kW per discharge if the single phase

power supply is 400V, 15kW for power supplies of

230V and 30kW for power supplies of 480V. The ab-

sorbed current is impulsive with a cycle time around

a few hundreds of milliseconds (approximately 1

second per discharge).

ST200X controllers are suitable to power single

chucks or chucks that are part of large magnetic

banks

When using chucks with a different rated voltage,

install a transformer with a suitable transformation

ratio and a rated power that matches the maximum

power of the chuck.

It is also possible to order a compact version for

ST200-QE electric cabinets with supporting terminal

board, to power the controller and magnetic chuck,

with interface connector and push-button panel.

275

331

85

39

Instruction and maintenance manual

ENGLISH

3.4 Control push-buttons for ST

controllers

ST controllers can be connected to the push-button

panels described below.

3.4.1 ST100 (basic version),

ST200 (basic version)

This push-button panel is the base model used to

control milling chucks.

It is tted with the following three-buttons:

•

Magnetization FULL-MAG,

•

Demagnetization DEMAG,

•

Enabling ENABLE.

The ENABLE button is used together with the mag-

netization and demagnetization button, depending

on the cycle that needs to be performed.

There are also 4 indicator lights placed next to the

FULL-MAG and DEMAG buttons and the CYCLE

and ALARM symbols.

These indicator lights provide information on the sta-

tus of the controller. When the controller is started,

the corresponding LED indicator switches on.

If a cycle is active, the only LED that is on is the one

related to the cycle, while all the others are off.

At the end of the cycle, the only visual indication that

is on is the one related to the new system status.

G

DEF

A C

B

PUSH-BUTTON PANEL

A

➜ FULL-MAG button

B

➜ ENABLE button

C

➜ DEMAG button

D

➜ MAG led

E

➜ Cycle led

F

➜ DEMAG led

G

➜ Alarm status led

System status MAG Led DEMAG Led Cycle Led Alarm Led

Full-Mag Permanently on Off Off Off

Demag Off Permanently on Off Off

Cycle Off Off Permanently on Off

Current alarm Off Off Off Permanently on

Communication

alarm

*

Off Off Off On ashing

*

For version ST200 only

40 Instruction and maintenance manual

ENGLISH

3.4.2 ST100 (version with 2 levels),

ST200 (version with 2 levels)

To be able to use different levels of magnetization, it

is possible to replace the push-button panel de-

scribed above with a 2-level model that enables to

control milling and grinding chucks.

This push-button panel has the following ve but-

tons:

•

Magnetization FULL-MAG,

•

Partial magnetization MAG-1L

•

Partial magnetization MAG-2L

•

Demagnetization DEMAG,

•

Enabling ENABLE.

The magnetization buttons MAG-1L, MAG-2L and

FULL-MAG enable to select three different levels of

magnetization.

The ENABLE button is used together with the mag-

netization and demagnetization buttons, depending

on the cycle that needs to be performed.

There are also 4 indicator lights placed next to the

FULL-MAG and DEMAG buttons and the CYCLE

and ALARM symbols.

These indicator lights provide information on the sta-

tus of the controller. When the controller is started,

the corresponding LED indicator switches on.

If a cycle is active, the only LED that is on is the one

related to the cycle, while all the others are off.

At the end of the cycle, the only visual indication that

is on is the one related to the new system status.

FULL-MAG and DEMAG indicator lights are always

on; MAG-1L and MAG-2L ash only during partial

magnetization cycles.

GH

DEF

AC

B

PUSH-BUTTON PANEL

A

➜ FULL-MAG button

B

➜ ENABLE button

C

➜ DEMAG button

D

➜ FULL-MAG led (xed) of MAG led for partial

magnetization (ashing)

E

➜ Cycle Led

F

➜ DEMAG Led

G

➜ 2nd level MAG button

H

➜ Alarm status Led

I

➜ 2nd level MAG button

System status MAG Led DEMAG Led Cycle Led Alarm Led

Full-Mag Permanently on Off Off Off

Demag Off Permanently on Off Off

Mag Level 1 On ashing Off Off Off

Mag Level 2 On ashing Off Off Off

Cycle Off Off Permanently on Off

Current alarm Off Off Off Permanently on

Communication

alarm

*

Off Off Off On ashing

*

For version ST200 only

41

Instruction and maintenance manual

ENGLISH

3.4.3 ST200 (model with 7 levels)

To be able to use several levels of magnetization, it is

possible to replace the basic push-button panel with

a 7-level model that enables to control milling and

grinding chucks.

This push-button panel has the following ve but-

tons:

•

Magnetization MAG,

•

Increase of magnetization

level +

•

Reduction of magnetization

level –

•

Demagnetization DEMAG,

•

Enabling ENABLE.

The ENABLE button is used together with the mag-

netization and demagnetization buttons, depending

on the cycle that needs to be performed.

There are also ve indicator lights placed next to the

full FULL-MAG, DEMAG, + and – buttons and the

CYCLE and ALARM buttons.

These indicator lights are used to provide informa-

tion on the status of the system, which is automati-

cally reset to the last operating cycle.

Once the start sequence has been successfully

completed, the indicator light corresponding to the

total/partial magnetization or demagnetization

switches on, depending on the option selected. A

failure in the start sequence switches on the central

alarm indicator light.

If a cycle is active, the only LED that is on is the one

related to the cycle, while all the others are off.

The FULL-MAG and DEMAG indicator lights are al-

ways on and ash during partial magnetization cy-

cles only.

J

G

I

H

D

E

F

A

C

B

PUSH-BUTTON PANEL

A

➜ MAG button

B

➜ ENABLE button

C

➜ DEMAG button

D

➜ Button +

E

➜ Button -

6

➜ FULL-MAG Led (xed) of MAG Led for

partial magnetization (ashing)

G

➜ Cycle Led

H

➜ DEMAG Led

I

➜ Alarm status Led

J

➜ Level selection LED (levels from 1 to 7) and

FULL-MAG 8

System status MAG Led DEMAG Led Cycle Led Alarm Led

Full magnetization

Level 8 Permanently on Off Off Off

Demag Off Permanently on Off Off

Partial magnetization

Levels 1-7 On ashing Off Off Off

Cycle Off Off Permanently on Off

Current alarm Off Off Off Permanently on

Communication

alarm

*

Off Off Off On ashing

*

For version ST200 only

42 Instruction and maintenance manual

ENGLISH

3.4.4 ST200 CH-ENABLE

This push-button panel can be used when you need

to select different discharge levels for the magnetic

chucks, i.e. enable or disable the desired discharge.

The push-button panel can be used in combination

with a push-button and LED to manage selections.

It has four buttons that enable to select/deselect the

desired discharge channel. The status of the channel

is shown by the corresponding LED.

After you have selected the discharge sequence,

you can also specify which discharges have to be

carried out with a full or partial magnetization and/or

select them with the appropriate buttons (CH1, CH2,

CH3 and CH4).

The status LEDs are off when the corresponding

magnetic chuck is in DEMAG mode, are on (though

not ashing) in FULL-MAG mode and ashing when

the partial magnetization mode is selected.

The cycle LEDs shall be on (though not ashing)

when a cycle is in progress and off when no cycle is

in progress.

Alarm LEDs are on (though not ashing) during all

alarm conditions, except for communication alarms.

M

I

JN

D

H

EF

AB

C

L

G

K

PUSH-BUTTON PANEL

A

➜ CH1 selection button

B

➜ CH2 selection button

C

➜ CH3 selection button

D

➜ CH4 selection button

E

➜ FULL-MAG Led (xed) of MAG Led for partial

magnetization (ashing), discharge 1

F

➜ FULL-MAG Led (xed) of MAG Led for partial

magnetization (ashing), discharge 2

G

➜ FULL-MAG Led (xed) of MAG Led for partial

magnetization (ashing), discharge 3

H

➜ FULL-MAG Led (xed) of MAG Led for partial

magnetization (ashing), discharge 4

I

➜ Cycle Led

J

➜ Alarm status Led

K

➜ CH1 selection Led

L

➜ CH2 selection Led

M

➜ CH3 selection Led

N

➜ CH4 selection Led

43

Instruction and maintenance manual

ENGLISH

4 INSTALLATION

4.1 General

Electric safety can be guaranteed only if the electric

system is correctly connected to a grounding sys-

tem in good working order, as foreseen by current

laws concerning electric safety. Therefore, it is es-

sential to always verify this safety requirements be-

fore starting the unit and have the distribution sys-

tem carefully inspected by qualied personnel in

case of doubt. TECNOMAGNETE S.p.A. shall not be

responsible for damages originating from the failure

to connect the unit to an appropriate grounding sys-

tem.

Users shall have to make sure that the unit is pro-

tected with a differential magnetothermal switch

suitable to withstand the rated current used by the

system. It is therefore necessary to install a suitable

protection with magnetothermal switch (curve C)

with a In value compliant with nameplate data.

TECNOMAGNETE systems are permanent-electro

systems, which means that they need to be powered

only during the short cycle phases. This congura-

tion is designed to ensure maximum safety in the

event of power failure.

TECNOMAGNETE controllers use the power supply

by means of a sophisticated partializing process,

which means that they can be operated only when

the machine is idle and that they require a rated cur-

rent that is normally lower than the one required to

operate the machine on which the magnetic system

being controlled is installed.

ATTENTION

Do not perform repeated MAGNETIZATION/DE-

MAGNETIZATION CYCLES

TECNOMAGNETE systems are constituted by per-

manent magnets and use electric power only to en-

able/disable the area being machined. Therefore,

they can be regarded “COLD” magnetic clamping

systems.

The repetition of MAGNETIZATION/DEMAGNETI-

ZAZION cycles at very close intervals may increase

the temperature of the magnetic chuck, especially

when using controllers with DEMAG NUFLUX cycle.

It is therefore advisable to run cycles only when nec-

essary.

The connection of the magnetic chuck to the power

supply must be carried out by qualied personnel

only.

Check the supply voltage and frequency.

The electrical supply to the controller must be sin-

gle-phase 230V/400V/480V (phase + neutral) or two-

phase (phase + phase).

ATTENTION

ST100 controllers are designed to operate with sup-

ply voltages of 230V 50/60 Hz and cannot therefore

be used for Tecnomagnete modules with lower or

higher ratings. To use different voltages, install a

transformer with a suitable rating (not above 4 kVA)

or contact TECNOMAGNETE S.p.A. for assistance.

ATTENTION

ST200 controllers are designed to operate with

supply voltages of 200V - 480V at 50/60 Hz and

can therefore be used, after validation, to enable

TECNOMAGNETE modules with different voltage

specications. To use different voltages, install a

transformer with a rating compliant to that of the

magnetic chuck or contact TECNOMAGNETE S.p.A.

for assistance.

ATTENTION

All cables supplied must have a bending radius with

a diameter <10mm and a tension of >15N/mm2. In-

stallation must always be performed by qualied

technicians in accordance with current law require-

ments.

44 Instruction and maintenance manual

ENGLISH

4.2 Connecting ST100 controllers to the

power supply

4.2.1 Connecting the controller to the power

supply

The controller must be supplied with a single-phase

voltage. The multi-pole cable supplied with the con-

troller has three leads suitable for the purpose.

The controller cannot be powered from the three-

phase + neutral distribution network that supplies

the tool machine used. If the voltage required for the

controller is not available, install a power transformer

with a rating suited for the magnetic chuck.

F

N

PE

BLACK

BROWN

YELLOW/GREEN

Single-phase power supply

4.2.2 Power cable

TECNOMAGNETE supplies a suitable multi-pole

power cable with a standard length of two meters,

which prevents overheating problems and a voltage

drop within the rating of the TECNOMAGNETE mod-

ule, if used in ordinary operating conditions.

Before using longer cables, always make sure that

the cable section used guarantees a voltage drop

below 1%.

Ordinary operating conditions are intended as inter-

mittent working cycles, with intervals of at least one

minute between two enabling cycles.

4.2.3 Selecting the correct dimensions for dis

charge cables

The discharge cable tted on ST100 comprises suit-

able leads, has a standard length of three meters

and is dimensioned to prevent overheating and the

loss of power on the chuck in ordinary operating

conditions.

Ordinary operating conditions are intended as ena-

bling/disabling cycles occurring at an interval above

1 minute.

Before using longer cables, always make sure that

the cable section used guarantees a voltage drop

below 1%.

4.2.4 Electric specifications

The fuses of model ST100 model are 12.5A lagged

fuses with a length of 20 mm and a diameter of 5 mm

(20 x 5 mm).

4.3 Connecting ST200 controllers to the

power supply

4.3.1 Connecting the controller to the power

supply

The controller must be supplied with a single-phase

voltage. The supplied multi-pole cable has three

leads suitable for the purpose, two for the phase and

neutral terminals (or phase) and one for the earth

(yellow/green).

The controller cannot be powered from the three-

phase + neutral distribution network that supplies

the tool machine used. If the voltage required for the

controller is not available, install a power transformer

with a rating suited for the magnetic chuck.

F

N

PE

BLACK

BROWN

YELLOW/GREEN

R

S

T

PE

BLACK

BROWN

YELLOW/GREEN

Single-phase power supply

Three-phase power supply

45

Instruction and maintenance manual

ENGLISH

4.3.2 Power cable

TECNOMAGNETE supplies a suitable multi-pole

power cable with a standard length of four meters,

which prevents overheating problems and a voltage

drop within the rating of the TECNOMAGNETE mod-

ule, if used in ordinary operating conditions.

Before using longer cables, always make sure that

the cable section used guarantees a voltage drop

below 1%.

Ordinary operating conditions are intended as inter-

mittent working cycles, with intervals of at least one

minute between two enabling cycles.

4.3.3 Selecting the correct dimensions for dis-

charge cables

The discharge cable tted on ST200 comprises four

leads suitable for the purpose, has a standard length

of six meters and is dimensioned to prevent over-

heating and the loss of power on the chuck in ordi-

nary operating conditions.

Ordinary operating conditions are intended as ena-

bling/disabling cycles occurring at an interval above

1 minute.

Before using longer cables, always make sure that

the cable section used guarantees a voltage drop

below 1%.

4.3.4 Electric specifications

All ST200 controllers are available as single and two-

phase models; the maximum installed power for

each cycle is 25 kVA (cosϕ=0.9) for two-phase 400V

plants, 15kVA for 230V plants and 32 kVA for 480V

plants.

To optimally protect the installation, it is necessary to

install a suitable magnetothermal switch (curve C)

with an In value compliant with the rating specied

on the nameplate.

5 ENABLING

5.1 ST100

ST100 controllers are not tted with a specic ena-

bling device, which may however be ordered as op-

tional (see Chapter 6.1).

5.2 ST200

The ST200 controller has an enabling device tted

on connector DB9 situated on the rear of the control-

ler (PINS 8 and 9).

The technical specications for the contact are:

•

Voltage 30V, current 1A

•

Voltage 110V, current 0.3A

It is always advisable to use an auxiliary relay.

Before using other models of start systems, contact

TECNOMAGNETE S.p.A. for assistance.

When at least one of the magnetic chucks controlled

by ST200 is in magnetization mode, the enabling

contact is closed. PINS 6 and 7 can be connected to

the power of the tool machine and used to run the

enabling cycles through the controller: the controller

can only run the cycles when PINS 6 and 7 are clo-

sed. Connect the safety catch to the operating ma-

chine on which the TECNOMAGNETE module is in-

stalled.

DB9 PIN connector

5 4 3 2 1

9 8 7 6

ENABLE ENABLE

MACHINE CONTROLLER

pin n° 1 ➜ B1

pin n° 2 ➜ A2

pin n° 3 ➜ Vdc

pin n° 4 ➜ Gnd

pin n° 5 ➜ Alarm

pin n° 6 ➜ COM ENABLE Controller

pin n° 7 ➜ ENABLE Controller

pin n° 8 ➜ COM ENABLE machine

pin n° 9 ➜ ENABLE machine

When possible, it is advisable to use both types of

contacts.

46 Instruction and maintenance manual

ENGLISH

6 OPTIONALS

6.1 Starting the ST100 controller

ST100 models can be tted with an optional external

start button, connected with means of a male/female

connector.

When the magnetic chuck is controlled by the ST100

controller, it is magnetized, which means that the

controller enabling contact is closed

The technical specications for the contact are:

•

30V voltage, 1A current

•

110V voltage, 0.3A current

It is generally advisable to use an auxiliary relay.

Before using other models of start systems, contact

TECNOMAGNETE S.p.A. for assistance.

6.2 Push-button panels of models ST100

and ST200

ST100 controllers can be tted with an optional two-

level push-button panel for milling and grinding

chucks.

Model ST200 can instead be tted with an optional

2-level push-button panel for milling and grinding

operations and with a 7-level push-button panel.

It is also possible to remotely connect all models of

push-button panels (basic, 2-level, 7-level).

6.3 QE version

On models QE it is possible to use an optional exter-

nal teleruptor with a power rating compliant to the

one printed on the nameplate of the connected mag-

netic chuck. Said teleruptor must be installed in ac-

cordance with the instructions provided on the elec-

tric wiring diagram supplied with the equipment.

This device ensures a more efcient control of the

electric commands through the machine.

7 PLC

Model ST100 is not tted with a PLC interface that

can be used for control purposes.

Model ST200 has a PLC interface that is constituted

by an external housing that has to be connected to

the controller by means of the DB9 connector. The

interface is constituted by a DB37 pin connector de-

signed to be interfaced with the control system and

used to receive the magnetization/demagnetization

enabling controls, to increase and reduce the mag-

netization levels and to provide indications on the

machine status.

The function of available contacts is described be-

low.

47

Instruction and maintenance manual

ENGLISH

19 1

37 20

Pin Name Direction Description

1 SW Mag Magnetization button

2 SW Demag Demagnetization button

3 SW Level + Button that increases the magnetization level

4 SW Level - Button that decreases the magnetization level

5 Abilit PLC Enabling input for PLC management

6 Input Enable Input-Enable input

7 nc Not connected

8 nc Not connected

9 nc Not connected

10 Level 1 1st level magnetization output

11 Level 2 2nd level magnetization output

12 Level 3 3rd level magnetization output

12 Level 4 4th level magnetization output

14 Level 5 5th level magnetization output

15 Level 6 6th level magnetization output

16 Level 7 7th level magnetization output

17 Level 8 8th level magnetization output

18 COM Normally open common contact Out-Abilit

19 NO2 Normally open contact Out-Abilit

20 Wait Output, cycle in progress

21 Alarm Alarm output

22 Ld3 Not used

23 Ld5 Not used

24 Out2 Not used

25 Out1 Not used

26 nc Not connected

27 nc Not connected

28 Vext Common contact for buttons Mag, Demag, Level+, Level-

29 Vext Insulated 24Vdc (power supply provided by customer)

30 Vext Insulated 24Vdc (power supply provided by customer)

31 Rif Common contact for output statuses

32 Rif Insulated 0V (reference to customer power supply)

33 Rif Insulated 0V (reference to customer power supply)

34 Mag Magnetization status output

35 Demag Demagnetization status output

36 COM Normally open common contact Out-Abilit

37 NO2 Normally open contact Out-Abilit

48 Instruction and maintenance manual

ENGLISH

8 CONNECTION TO THE

TECNOMAGNETE MODULE

8.1 Installation of miller ST100

8.2 Installation of grinder ST100

Magnetic

module

Connector

Discharge cable

Controller

Power supply

Cable tie

Power supply

Controller

Discharge cable

Magnetic

module

49

Instruction and maintenance manual

ENGLISH

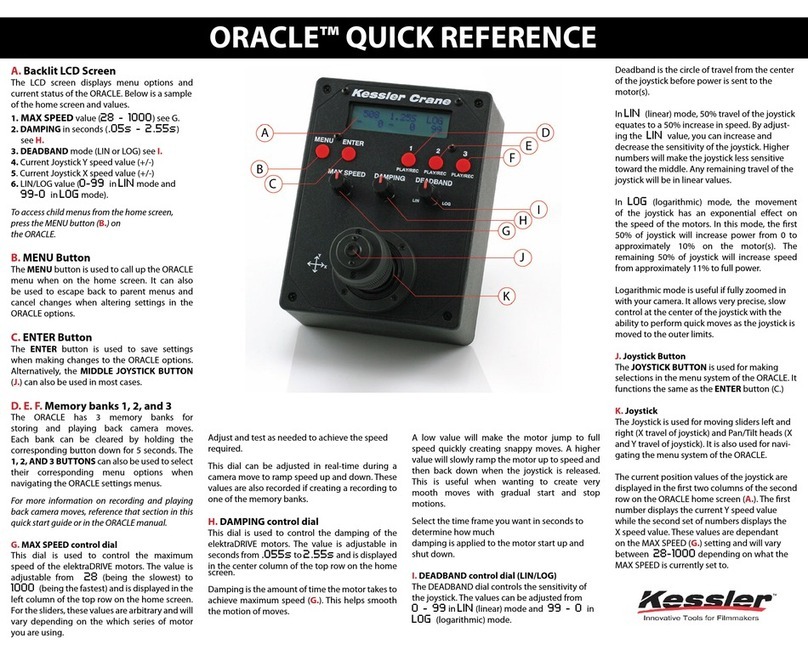

8.3 Installation of miller ST200

Power supply

Push-button panel

CH ENABLE push-button panel

Enabling

Discharge

Discharge

PLC interface

ON/OFF

4 PIN connector

7 PIN connector

Junction box

Controller

ST200

Controller

ST200

Controller

ST200

Controller

ST200

Installation of Installation of

1 chuck 3 chucks

Magnetic chucks

Magnetic chuck

Installation of Installation of

2 chucks 4 chucks

Magnetic chucks

Magnetic chucks

This manual suits for next models

4

Table of contents