Tecnosens NCL Series User manual

Assembly Instructions for Use

20TMN0001B (EN) 05/2021

Free and Total Chlorine Sensors

NCL and NCT model

PLEASE READ CAREFULLY THE FOLLOWING INSTRUCTIONS FOR USE.

DO NOT THROW THEM AWAY.

THE SYSTEM MANAGER WILL BE RESPONSIBLE FOR ANY DAMAGE CAUSED BY INSTALLATION

OR MANAGEMENT ERRORS.

I

INDEX

1INTRODUCTION .....................................................................................................1

1.1 MATERIALS CONTAINED IN THE SET...........................................................................3

1.2 STRUCTURE OF THE SENSOR.....................................................................................5

2INSTALLATION .......................................................................................................6

2.1 ASSEMBLY/DISASSEMBLY OF THE CAP........................................................................6

2.2 FILLING THE CAP WITH ELECTROLYTIC SOLUTION..........................................................6

2.3 INFORMATION ON THE ELECTROLYTE GEL ...................................................................8

2.4 MOUNTING ON THE PROBE HOLDER..........................................................................9

2.5 FLOW ADJUSTMENT..............................................................................................10

3ELECTRICAL CONNECTIONS ................................................................................ 12

3.1 ELECTRICAL INSTALLATION OF VOLTAGE OUTPUT .......................................................12

3.2 ELECTRICAL INSTALLATION OF CURRENT OUTPUT.......................................................14

4ACTIVATION AND MAINTENANCE OF THE SENSOR ............................................ 16

4.1 SENSOR COMMISSIONING .....................................................................................16

4.2 CALIBRATION.......................................................................................................16

4.3 ELECTRODE UNIT AND CAP MAINTENANCE..............................................................18

4.4 PUT THE PROBE OUT OF SERVICE............................................................................20

4.5 WORKING PARAMETERS AND SENSOR CHARACTERISTICS ...........................................21

5TROUBLESHOOTING AND SPARE PARTS ............................................................. 22

5.1 SPARE PARTS.......................................................................................................22

5.2 TROUBLESHOOTING..............................................................................................22

6DIRECTIVES AND STANDARDS OBSERVED........................................................... 26

7NOTES................................................................................................................. 27

1. Introduction

1

1INTRODUCTION

This assembly and use manual describes the technical data and functions of the

sensors of the NCL and NCT range, for the measurement of Free Chlorine and

Total Chlorine.

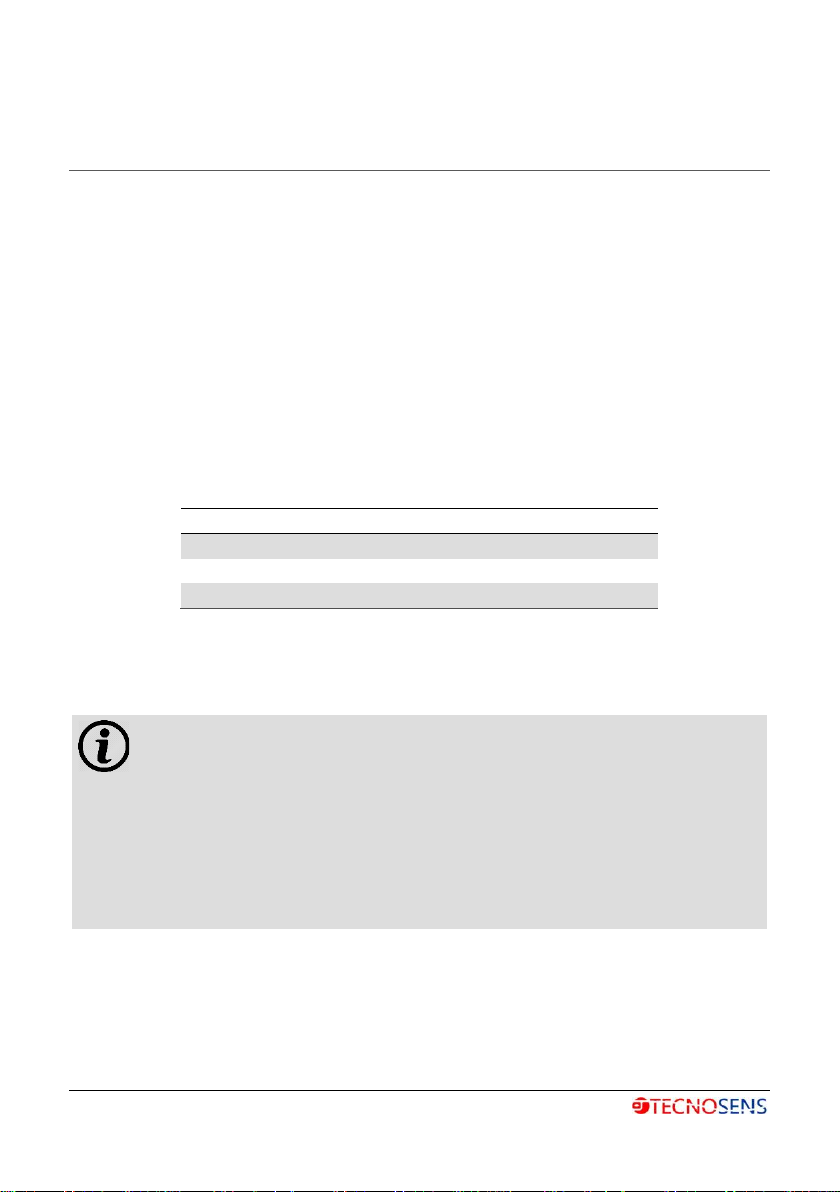

The characteristics of the different sensors are shown in Table 1 below, where

it is indicated which is the measured analyte, the measurement range, the

resolution and the type of electrical output, for the different sensors, to which

this manual can be applied.

The range of sensors for the measurement of free and total chlorine has a

structure of the type with three electrodes, two of which are covered by a

membrane cap and immersed in a gel electrolytic solution. The range allows to

measure the concentration of free/total chlorine in surfactant-free water.

These devices can be used in all those situations where the following operations

are required:

•Control and regulation of swimming pool chlorination.

•Control and regulation of the chlorination of drinking water.

1. Introduction

2

Tab 1: Characteristics of the different sensors to which this manual is applicable

Name

Analyte

Measurement

range [ppm]

Resolution[ppm]

Output

NCL T20

Free Chlorine

0.05 ÷ 20.00

0.01

0 ÷ -2000 mV

NCL T10

Free Chlorine

0.05 ÷ 10.00

0.01

0 ÷ -2000 mV

NCL T5

Free Chlorine

0.05 ÷ 5.00

0.01

0 ÷ -2000 mV

NCL T2

Free Chlorine

0.01 ÷ 2.00

0.005

0 ÷ -2000 mV

NCL C20

Free Chlorine

0.05 ÷ 20.00

0.01

4 ÷ 20 mA

NCL C10

Free Chlorine

0.05 ÷ 10.00

0.01

4 ÷ 20 mA

NCL C5

Free Chlorine

0.05 ÷ 5.00

0.01

4 ÷ 20 mA

NCL C2

Free Chlorine

0.01 ÷ 2.00

0.01

4 ÷ 20 mA

NCT T20

Total Chlorine

0.05 ÷ 20.00

0.01

0 ÷ -2000 mV

NCT T10

Total Chlorine

0.05 ÷ 10.00

0.01

0 ÷ -2000 mV

NCT T5

Total Chlorine

0.05 ÷ 5.00

0.01

0 ÷ -2000 mV

NCT T2

Total Chlorine

0.01 ÷ 2.00

0.005

0 ÷ -2000 mV

NCT C20

Total Chlorine

0.05 ÷ 20.00

0.01

4 ÷ 20 mA

NCT C10

Total Chlorine

0.05 ÷ 10.00

0.01

4 ÷ 20 mA

NCT C5

Total Chlorine

0.05 ÷ 5.00

0.01

4 ÷ 20 mA

NCT C2

Total Chlorine

0.01 ÷ 2.00

0.01

4 ÷ 20 mA

NCL T20 SW

Free Chlorine

0.05 ÷ 20.00

0.01

0 ÷ -2000 mV

NCL T10 SW

Free Chlorine

0.05 ÷ 10.00

0.01

0 ÷ -2000 mV

NCL T5 SW

Free Chlorine

0.05 ÷ 5.00

0.01

0 ÷ -2000 mV

NCL T2 SW

Free Chlorine

0.01 ÷ 2.00

0.005

0 ÷ -2000 mV

NCL C20 SW

Free Chlorine

0.05 ÷ 20.00

0.01

4 ÷ 20 mA

NCL C10 SW

Free Chlorine

0.05 ÷ 10.00

0.01

4 ÷ 20 mA

NCL C5 SW

Free Chlorine

0.05 ÷ 5.00

0.01

4 ÷ 20 mA

NCL C2 SW

Free Chlorine

0.01 ÷ 2.00

0.01

4 ÷ 20 mA

1. Introduction

3

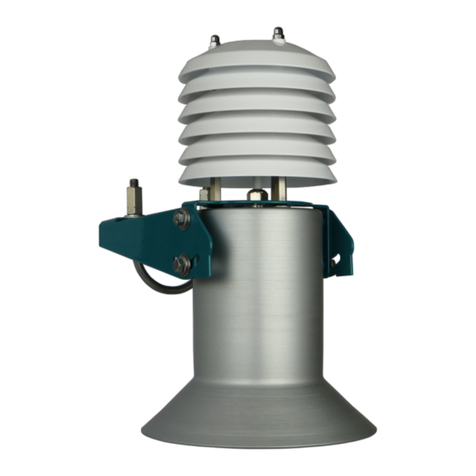

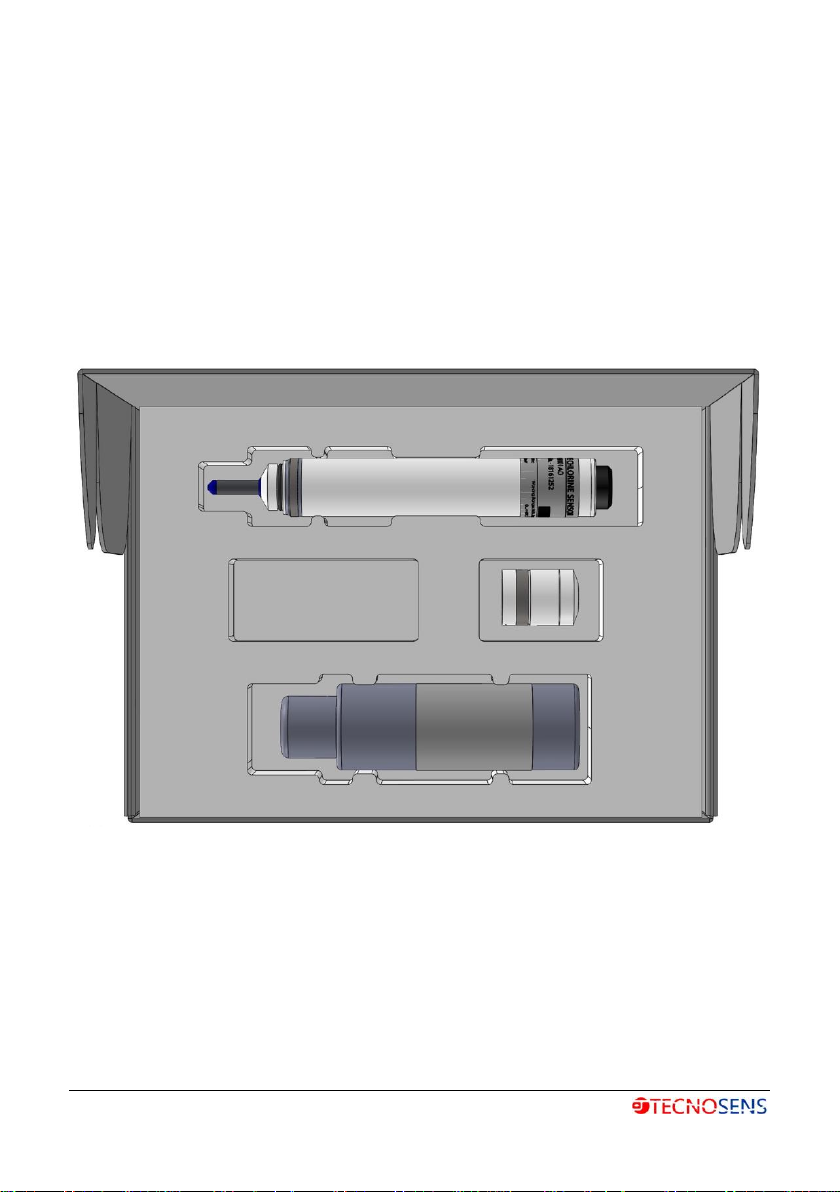

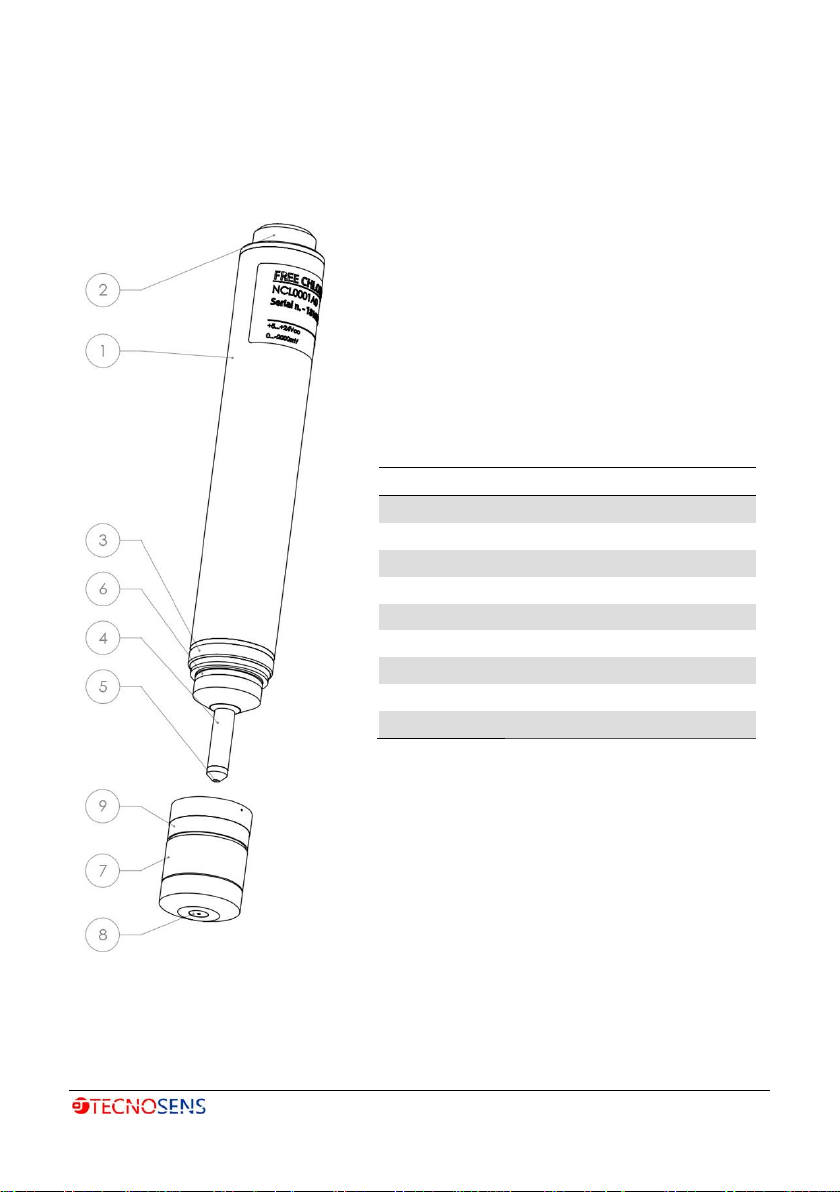

1.1 MATERIALS CONTAINED IN THE SET

The device is supplied in its packaging and is presented as shown in Figure 1 and

in Figure 2, in which the standard kit consists of:

I. sensor;

II. upper element (not present in

the version with voltage output);

III. membrane cap;

IV. bottle of gel electrolyte (100ml);

V. paper for polishing the gold

electrode;

VI. user manual

Figure 1: version with current output standard supply

1. Introduction

4

Figure 2: version with voltage output standard supply

1. Introduction

5

1.2 STRUCTURE OF THE SENSOR

The parts composing the sensor are shown in Figure 3.

Position

Description

1

Sensor body

2

Connector

3

Counter electrode

4

Reference Electrode

5

Working electrode

6

O-Ring

7

Cap

8

Membrane

9

Tubular gasket

Figure 3: Sensor structure and description of its components.

2. Installation

6

2INSTALLATION

2.1 ASSEMBLY/DISASSEMBLY OF THE CAP

Before proceeding with the assembly/disassembly operation of the cap from

the probe body, the tubular gasket must be moved from its position on the cap.

Pay attention that the vent hole, highlighted in Figure 4 and the other holes

present, remain uncovered throughout the assembly phase.

WARNING!

By leaving the tubular gasket in its place, during the operations of disassembly

and assembly of the cap from the probe, you risk damaging the membrane,

compromising the functioning of the probe. Also be careful not to cover the

upper holes with your fingers during the assembly or disassembly phase.

2.2 FILLING THE CAP WITH ELECTROLYTIC SOLUTION

Fill the cap with the gel electrolyte solution contained in the bottle present in

the package. The gel electrolyte must reach the edge of the cap, as reported in

Figure 4, leaving the tubular gasket displaced from its place.

Insert the probe vertically into the cap as shown in Figure 5 on the next page,

taking care during the assembly phase not to cover the excess gel outlet holes

with your fingers. This is in order not to damage the membrane and to avoid

the formation of air bubbles in the solution once the cap is tightened. By almost

completely screwing the cap to the probe, you will feel a slight resistance due

to the presence of the O-ring which guarantees the seal of the coupling.

Once the cap has reached the mechanic stop with the probe and the excess gel

has been expelled from the holes, the tubular gasket must be repositioned in

its place in order to avoid gel leaks during the normal use of the probe in flow.

2. Installation

7

Figure 4: Cap filling phase with gel electrolyte.

Figure 5: Assembly phase of the cap

on the probe.

SLOWLY SCREW THE PROBE CAP.

To ensure the correct functioning of the probe, it is necessary to avoid that

the air bubbles remain trapped inside the gel solution in the cap. For this

reason, it is useful to slowly screw the cap to the probe, and not to shake the

bottle before use.

After filling or restoring the electrolyte solution, the probe takes about an hour

to resume normal operation.

RESTORING THE ELECTROLYTIC SOLUTION

It is recommended to calibrate the instrument to which the probe is

connected after the operation has been restored. It is recommended to repeat

the calibration procedure after 24 h.

2. Installation

8

DO NOT TOUCH THE CAP AND ELECTRODES

Do not touch the membrane on the cap, nor the electrodes placed in the

lower part of the sensor; do not damage them and avoid that they come

into contact with greasy substances. Otherwise, the sensor will no longer

function accurately. In this case, replace the cap with a new one or send

the sensor to the manufacturer for cleaning the electrodes.

WARNING!

During all assembly, maintenance or other operations it is recommended not

to touch the membrane, in order to avoid damage that could lead to

malfunction of the probe.

2.3 INFORMATION ON THE ELECTROLYTE GEL

KEEP THE PRODUCT OUT OF REACH OF CHILDREN!

ELECTROLYTE GEL.

DO NOT SHAKE THE BOTTLE BEFORE USE!

✓The electrolyte is sensitive to oxidation: always keep the bottle of

electrolyte closed after use.

✓Do not transfer the electrolyte into other containers.

✓The electrolyte must not be stored beyond the permitted terms; for

the expiry date see the label on the electrolyte bottle.

✓Pour in the electrolyte avoiding, where possible, the formation of

bubbles. The small air bubbles are not a problem, while the larger

bubbles rise towards the upper edge of the cap and affect the

measurement.

✓Store the gel electrolyte bottle with the cap facing down, as indicated

on the bottle label.

2. Installation

9

WARNING!RISK DUE TO A DANGEROUS SUBSTANCE.

When using hazardous substances, please note that updated safety data

sheets of the manufacturers of these substances are available. Since the risk

potential of a substance can be re-evaluated at any time based on new

knowledge, the safety data sheet must be checked regularly and replaced if

necessary.

The system operator is responsible for the availability of the updated version

of the safety data sheet and for the preparation of the risk

assessment of the workplaces concerned connected to it.

The information relating to the gel electrolyte and the safety

data sheet are available on the manufacturer's website at

http://www.aedes.info/prodotto.asp

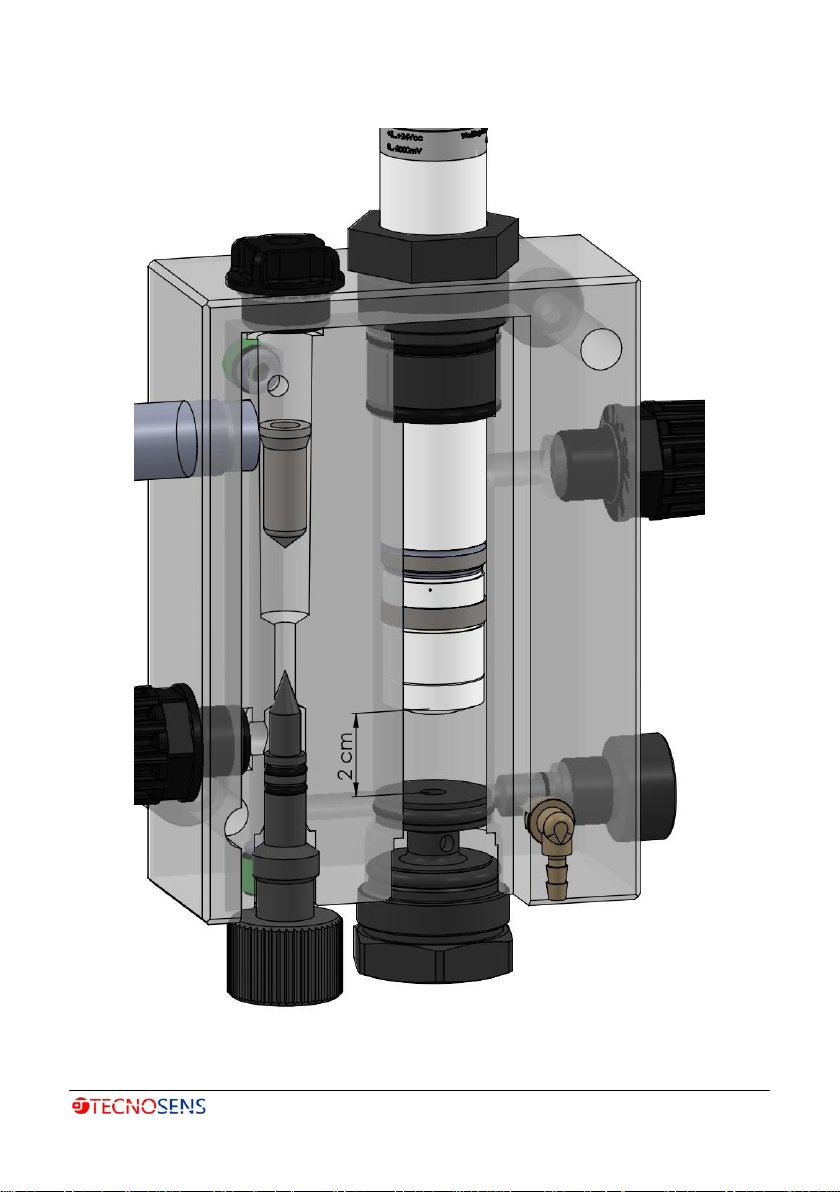

2.4 MOUNTING ON THE PROBE HOLDER

Insert the probe into a dedicated probe holder in the appropriate housing. A

distance of about 2 cm must be ensured between the membrane and the

bottom of the probe holder as indicated in Figure 6 on the next page, in order

to ensure optimal operation of the probe.

The phase of installing the probe in the probe holder must be carried out

delicately; do not push too hard to avoid the risk of damaging the membrane

due to excessive pressure. In order to avoid the occurrence of an overpressure

it is recommended to open at least one drain valve or sampling cock. Once the

probe is blocked in the probe holder at the desired height, it is possible to close

the drain valve or sampling cock, and gradually open the delivery cock.

2. Installation

10

INSTALLATION INSTRUCTION

✓

Make sure that the membrane does not come into contact with

other objects to avoid damage and obstruction of the membrane.

✓

Once the probe has been positioned on the probe holder, it is

recommended to slowly open the delivery cock to protect the

membrane from the pressure front produced by the water flow.

✓

After installation, the sensor must always be kept wet, e.g. the

probe holder must never run dry.

2.5 FLOW ADJUSTMENT

To ensure correct operation of the probe, the flow rate of fluid passing through

the probe holder must be between 30 l/h and 60 l/h and with a pressure

between 0 bar and 1 bar (the recommended working range for probe is 0.3 -

0.5 bar).

WATER FLOW

Do not exceed the recommended working range:

✓do not use the sensor with a lower or higher range than the indicated

limits;

✓before commissioning the probe, the flow rate must be measured

using suitable measurement methods.

INSTALLATION INSTRUCTIONS

Avoid installations that create air bubbles in the sample water. The air bubbles

adhering to the sensor membrane can cause an insufficient measurement

value. An insufficient measured value can lead to incorrect dosing in a control

circuit.

2. Installation

11

Figure 6: installation of the probe in a probe holder, where the optimal

operating distance is shown

3. Electrical Connections

12

3ELECTRICAL CONNECTIONS

3.1 ELECTRICAL INSTALLATION OF VOLTAGE OUTPUT

The probe equipped with the electric voltage output (0 ÷ −2000 mV) is provided

with a circular connector. It is essential, to connect the probe to the measuring

instrument, to use the dedicated electric cable (see paragraph 5.1 page 21 to

identify the code) to be purchased separately. The cable is made up on one side

of the connector and on the other of the wires as in Figure 7, to be connected

as shown in Table 2. For the electrical installation of the probe, it is necessary

to connect the cable to the measuring instrument and then couple the

connector on the cable to the connector on the probe.

3. Electrical Connections

13

Figure 7: Electrical connection of cables to the measuring instrument

Table 2: Characteristics of electrical connections

Terminal

Color

Function

Value

1

Green

Signal (Vout)

0 ÷ -2000 mVdc

2

Yellow

Signal (GND)

0

3

Brown

Power supply (+Vin)

+10 ÷ +30 Vdc

4

White

Power supply (GND)

0

Single Power Supply

Terminal

Color

Function

Value

1

Green

Signal (Vout)

0 ÷ -2000 mVdc

2

Yellow

Signal (GND)

0

3

Brown

Power supply (+Vin)

+5 ÷ +15 Vdc

4

White

Power supply (-Vin)

-5 ÷ -15 Vdc

Single Power Supply

3. Electrical Connections

14

3.2 ELECTRICAL INSTALLATION OF CURRENT OUTPUT

Below is reported the procedure for the electrical installation of the probes

equipped with the current output with two-wire connection, as shown in Figure

8

1. Rotate the upper element (3) of the sensor counterclockwise and

extract the upper element.

2. Loosen the locking nut (2) of the threaded connector and pass the

measuring cable (1) through it.

3. Uncover the ends of the cable by 0.5 cm, apply the cable lugs (ϕmax

=0.5 mm2) and connect them to the 2-conductor connection

respecting the polarity indicated on the terminal (4).

4. Fully insert the upper element of the sensor (3) on the probe body (5)

and tighten it by turning clockwise until it stops.

5. Insert the measurement cable as far as possible into the upper element

of the strain relief sensor.

6. Tighten the lock nut (2) on the threaded connector.

Terminal

Function

Value

+

Power supply (+Vin)

+12 ÷ 30 Vdc

-

Power supply (GND)

0

4. Activation and Maintenance of the Sensor

15

Figure 8: Electrical installation for probes with two-wire current output

4. Activation and Maintenance of the Sensor

16

4ACTIVATION AND MAINTENANCE OF THE SENSOR

4.1 SENSOR COMMISSIONING

Once the sensor has been mounted on the probe holder and checked the

correct working conditions, such as the probe insertion height, the control

water flow rate and the pressure, and the connection to the electrical

measuring system has been made, the activation times of the probe are those

shown in Table 3. In any case, the activation times depend on the working

conditions of the system where the sensor is placed.

Table 3: Activation times required for the probe to provide a stable signal

Phase

Time [h]

First Installation

1 ÷ 24

Subsequent installations

1 ÷ 24

Gel and/or Cap replacement

1 ÷ 3

4.2 CALIBRATION

The probe calibration must be carried out once the probe signal is stable,

therefore not before the activation times indicated in Table 3.

The calibration of the measuring instrument connected to the probe must be

carried out and checked periodically using the DPD-1 method ("Free Chlorine").

PROBE CALIBRATION

Depending on the accuracy required of the probe, it may be necessary to

calibrate once a week. It may be necessary to carry out calibration whenever

the working conditions of the water are changed (analyte concentration,

temperature or pressure), or after replacing the gel electrolyte and/or

membrane.

This manual suits for next models

25

Table of contents