Tecnospiro ROSCAMAT-500 Series User manual

OPERATOR’S

MANUAL

Range

ROSCAMAT-500

Serial no. Machine no.

Model

Year of

manufacture

Polígono Industrial Pla dels Vinyats, B – 08250 Sant Joan de Vilatorrada(Barcelona) Spain

+34 93 876.42.42 / +34 93 876.43.59 +34 93 876.77.38 / +34 93 876.40.44

E-mail :[email protected] – http://www.tecnospiromt.com

2

CONTENTS

Pagenr

Introduction

................................... 3

Description R-500 RH ....................... 4

Working areas R-500 RH .......... 5

Description R-500 ............................ 6

Working areas R-500

................ 7

Description R-500 (C-26 N) ................. 8

Working areas R-500 (C-26 N)....... 9

Description

.................................... 10

Installation

..................................... 12

Verification

............................ 13

Operation ......................................... 14

Anomalies

............................... 15

Technical data

................................. 16

Maintenance

................................ 18

Repairs

........................... 19

Operation R-500 RH .............................. 24

Spare parts list ............................ 27

Standard products range .................... 37

3

INTRODUCTION

Dear customer:

We wish to take this opportunity to thank you for choosing a

“ROSCAMAT” tapping machine to produce quality threads ans associated

operations.

This operation’s manual is given to you so that by careful reading of its

contents, it will be enable you to maintain its reliability and performance

for long-life.

4

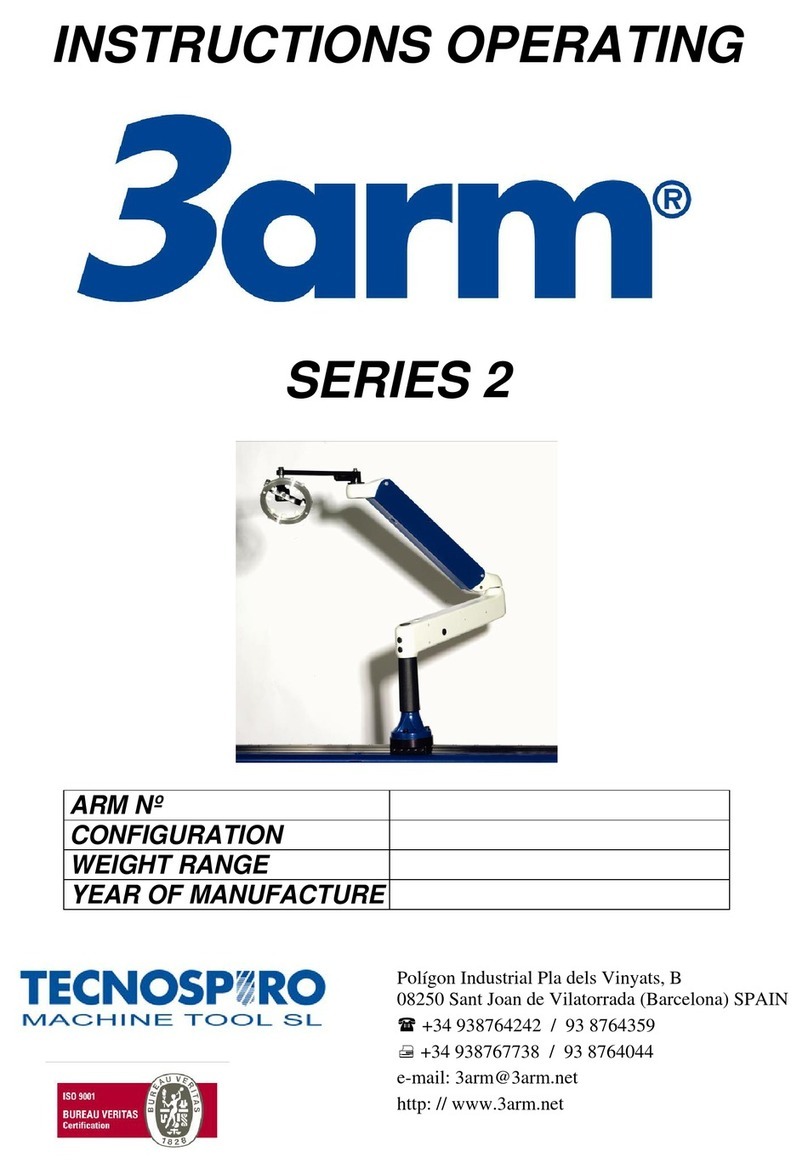

DESCRIPTION MACHINE ROSCAMAT-500 RH

1. MOTOR

2. FRONT BELLOW

3. TILTING ARMS

4. REAR BELLOW

5. ARM LOCKING KNOB

6. RADIAL ARM

7. AIR INLET SPIGOT

8. MACHINE BASE PLATE

9. BRAKE HANDLE

10. AIR & LUB PREPARATION UNIT

11. REAR DAMPER REGULATING

HANDWHEEL

12. CAPS

13. UPPER HAT

14. FRONT DAMPER REGULATING

HANDWHEEL

15. AIR PIPE

16. ARM LOCKING CONTROL

17. HEAD LOCKING HANDLE

18. MULTIPOSITION HEAD

19. TAPHOLDER

20. MODULE

The basic machine consists of a

radial parallelogram, plus two pendular

parallelograms which are balanced by

pneumatic springs and a two-rotation

axis head. This group fixes the motor

and keeps it perpendicular to the

working area.

El motor is equipped with a module

quick-change system, and rotates by

compressed air, that has previously

been filtered and lubricated by a unit

for that purpose.

Taps and shank tooling fit directly

to quick-change tapholders.

5

WORKING AREAS ROSCAMAT-500 RH

6

DESCRIPTION MACHINE ROSCAMAT-500

1. MOTOR

2. AIR PIPE

3. UPPER HAT

4. FRONT DAMPER REGULATION

HANDWHEEL

5. CAPS

6. REAR DAMPER REGULATION

HANDWHEEL

7. REAR BELLOW

8. AIR GROUP

9. AIR INLET SPIGOT

10. MACHINE BASE PLATE

11. RADIAL ARM

12. BRAKE HANDLE

13. TILTING ARMS

14. FRONT BELLOW

15. VERTICAL HEAD

16. TAPHOLDER

17. MODULE

The basic machine consists of a radial

arm, plus two pendular parallelograms

which are balanced by pneumatic

springs. This group fixes the motor head

and keeps it perpendicular to the

working area.

The motor is equipped with a module

quick-change system and rotates by

compressed air that has previously been

filtered and lubricated by a unit for that

purpose.

Tools and shank tooling fit directly

to the quick-change tapholders.

7

WORKING AREAS ROSCAMAT-500

8

DESCRIPCTION MACHINE ROSCAMAT-500 (C-26 N)

The ROSCAMAT-500 can be supplied with an articulated head (C-26

N). This bracket of easy handling can be set in four different positions 90º

apart.

Orientable head:

1.- Handle

2.- Milled nut

Vertical operations:

Place the motor in vertical position and lock the handle (1) and the milled

nut (2). The ROSCAMAT now is ready to work.

Horizontal operations:

Loose the milled nut (2) to unlock the joint of the motor.

Turn the head 90º till you reach the interlock, and then tighten the millet

nut (2) again.

Unlock the handle (1) located in the upper side of the head.

When moving the arm, the operator will have to manually maintain the

perpendicularity to the working plane.

Do not lock the handle (1) if you are working in horizontal operations.

9

WORKING AREAS ROSCAMAT-500 (C-26 N)

10

DESCRIPTION

PNEUMATIC MOTOR TS-VIII

REGULATING FILTER UNIT AIR LUBRICATION

1b.- Pressure regulator

2b.- Flow rate regulating valve

3b.- Pressure gauge

4b.- Reservoir (condensed water)

5b.- Drain pipe (WATER)

6b.- Oil reservoir (SAE-10)

7b.- Lubrication regulation knob

8b.- Lubrication inspection sight glass

1.- Starting lever

2.- Reversing button

3.- Motor Head

4.- Module change slide collar

5.- Module

6.- Quick change (module)

7.- Tapholder with clutch

11

DESCRIPTION

AUTOMATIC TAP LUBRICATOR EQUIPMENT (E)

The machines of the model ROSCAMAT 500 E / 500 (C26 N) E /500 RH E,

incorporate an automatic tap lubrication system.

The oil reservoir is arranged inside the radial arm and is connected to an

innerly arranged hydraulic cylinder. The desired cutting oil flow rate is

adjusted by means of ten control valve (3). When pressing the motor lever the

system pumps the flow rate in the pump being arranged the tilting arm.

After having filled the oil reservoir, immediately bleed the system by applying

pressurised air through the hole being provided in the filling cap (1) of the

reservoir.

*Caution: USE CUTTING OIL

Certain lubricant types containing trichlorines and alcohols can damage some

of the valve components.

1.- Filling cap

2.- Drain screw

3.- Regulation valve

4.- Articulated pipe

12

INSTALLATION

A : Mount the machine base plate on to the working table by means

of three M8 screws or the clamp.

B : Fill up the reservoir (6b, page 10) with lubricating oil SAE-10.

C : The air connection is carried out by means of a notched

connections (17, page 4 y 14, page 6 ) located on the machine

base.

IMPORTANT:

Table showing the ratio length to inside diameter of the feeding pipe:

Length (mts.) Minimum inside diameter. (mm.)

< 8 12

> 8 14

13

INSTALLATION VERIFICATION

Once the machine has been connected to the main, have to be checked:

1. Supply pressure:

6-8 bar for full power

2. The pressure gauge reading can drop 0,5 maximum 1,5 bar when the

motor is started (if a drop greater than 2 bar is noticed, this means that

the supply flow rate is not sufficient).

3. Make sure, by checking the sight glass (8b, page 10) that when the

machine is in operation two to three drops per minute are fed. The

regulation is carried out by means of the control knob. (7b, page 10).

4. Arm balance:

By turning the regulation handwheel (11 and 14, page.4) and (4 and 6,

page.6) to the right (-) or to the left (+) different weight at the arm end

are balanced.

14

OPERATION

1. Turn the slide collar (4, page 10) to the left, insert the module and turn

the slide collar to the right.

2. Regulate the arm balance for the 90 and 170 modules.

3. Insert the tapholder in the quick change of the module.

4. Clockwise rotation: push lever (1, page 10)

5. Counterclockwise rotation: push simultaneously lever (1, page 10) and

button (2, page 10).

6. Pulling up the tool quick change (6, page 10) the tapholder will come

out automatically.

SPEED CONTROL - CONSUMPTION CONTROL

By means of the flowrate regulating valves (2b, page 10) and the pressure

regulator (1b, page 10).

RATIO VALVE POSITION

(Consumption-Pressure-Rotation speed)

Module Maximum

Speed

(rpm)

Maximum

Torque

(Nm)

Coupling

diameter

(mm.)

Max. Thread.

Aluminium

Cast Iron

Max. Thread

Steel < 80 Kg.. Max. Thread

Steel >80Kg.

90 90 150 31 M27 M24 M22

170 170 79 31 M22 M18 M16

300 300 44 19 M16 M16 M14

550 550 24 19 M14 M12 M10

750 750 17 19 M12 M10 M8

1.050 1.050 12,5 19 M8 M8 M6

2.100 2.100 6 Cone B-16

To drill up to 8 Aluminium, Brass, Cast Iron,..

15

OPERATION ANOMALIES

Slipping clutch type tapholders. The clutch slips and the tap cannot be

turned.

1. Clutch slackness. Clutch adjustment (page 15)

2. No tools lubrication. Use cutting oil.

3. Inappropriate tap for the material to machine. Use the correct tap. (page

16).

4. Tap spoiled “worn”.

5. Misaligned hole.

6. Drilled hole diameter too small.

When neither the tap or the motor turns, this could be attributed to one of

the previous items 2 to 6, or to insufficient motor power.

1. Check items 1 to 3 (page 13).

2. MINIMUM pressure 6 bar (for high power and rotation speed).

3. Clogged exhaust filter (page 19).

4. Worn motor plates (pages 20 y 21).

If the pivoted arm drops:

1. Arm not balanced. Check item 4 (page 13).

2. Faulty damper. Substitution (page 22, 23).

If the lubrication system don’t work:

1. The oil tank is empty. Fill the reservoir ( page 11)

2. The oil-hole is clogged. Introduce a un a 0,3-0,4 mm wire through the

oil-hole.

Upon having filled the oil reservoir immediately bleed the system

(page 11)

CLUTCH ADJUSTMENT

Remove small spring clip around perimeter and turn the notched nut

clockwise or counter clockwise to increase or decrease the clutch tension and

put the small ring back on the new notch.

16

TECHNICAL DATA

TURNING TORQUE (Nm) FOR THREADING

Metric thread Steel > 100 Kg. Steel 80-100 Kg. Steel < 80Kg. Aluminium

Cast Iron

2

3

4 2 1.3 1.2 0.8

5 3 2 2 1.3

6 5 4 4 2.4

8 11 8 8 5

10 20 15 14 9

12 33 24 23 14

14 50 36 35 22

16 57 42 40 26

18 101 73 70 45

20 112 81 78 50

22 123 90 86 55

24 194 140 135 86

27 218 158 152 97

MACHINE TAPS

Blind hole Helical-flute tap.

Lubrication

Through hole Straight-flute tap with helical

feed-in

Steel > 80 Kg. Rake angle 8-10. Cutting oil with additive.

Steel < 80 Kg. Rake angle 12-14.

Cutting oil.

Steel < 50 Kg. Stainless Rake angle 14-16.

Surface treatment.

Cast Iron Straight-flute tap. Surface

treatment. Nitrated.

Rake angle 5.

Petroleum, Coolant, dry

machining.

Duraluminium Rake angle 12-15. Coolant, dry machining

Aluminium

Rake angle 17-25. Cutting oil with additive.

Plastics Coolant, dry machining.

17

TECHNICAL DATA

R-500 RH R-500

Pneumatic motor:

Power 730 W. 730 W.

Consumption 300-900 l/m 300-900 l/m

Machine weight 39 Kg. 27 Kg.

Intake filter 5 U.m. 5 U.m.

Noise level 78 db. 78 db.

Machine colours Blue to RAL 5002

Fog grey to RAL 7035

(Pneumatic motor TS-VIII)

18

MAINTENANCE

Practically the only machine’s part that we can wear is the motor.

Therefore its maintenance should be carried out very carefully, which means

that the air supply must be in dry & clean condition. For this purpose, the

following three points must be taken into account:

1. Drain periodically the water collected in the left air treatment

unit cup by pressing the relief knob (5b, page 10).

2. Fill up the right air treatment unit cup with SAE-10 (light duty

oil).

3. Check through the sight glass (8b, page 10) that when the

machine is in operation, two or three drops per minute are

supplied. The regulation is made by means of the control knob

(7b, page 10).

WARRANTY

The warranty period for the motor and for the rest of the machine is one

year. The warranty does not cover any damage caused by overloads or

improper handling of the machine.

19

MAINTENANCE REPAIRS

EXHAUST FILTER (REPLACEMENT) Ref. 40202304

1. Close the flow rate regulating valve situated on

the left-hand side of the filtering unit (2b, page

10) and actuate the motor starting lever.

2. Take out the intake tube and the reversing

button (1, 4).

3. Unscrew the raccord (2) situated on the upper

side of the motor. Remove the external casing

(3) and take out the exhaust filter.

4. Replace the exhaust filter.

Reverse the process for the reassembling.

INTAKE FILTER (REPLACEMENT) Ref. NH120856

Remove the left air treatment unit cup (4b, page 10), unscrew the filter

and replace it with a new one. The installation is carried out in the reverse

order.

MOTOR REPLACEMENT Ref. 40201105

1. Close the air inlet valve (2b,page 10) being arranged to the left of the

FRL air servicing unit and actuate the motor air lever to expel the air

compressed.

2. Disconnect the air intake pipe being connected upper the motor

3. Remove the motor slide change collar (4, page 10). First, you must

remove the “seeger ring” situated under the lower part of the slide

collar.

WATCH THE Ø9 mm. BALLS OF THE INSIDE OF THE SLIDE CHANGE COLLAR

4. Loosen the two ALLEN screws of the head

5. To extract the motor (upwards), you must align the bolt ø2,5 mm of the

motor gearbox with the front milled gap of the machine motorhead

Carry out the whole process in reverse order for the assembly.

20

MAINTENANCE REPAIRS

PRESSURE GAUGE (REPLACEMENT) Ref. NH40516

1. Close the flow control valve (2b, page 10), and actuate the motor lever

in order to expel the compressed air from the inside of the motor

2. Turn the manometer "sight" to the right, and unscrew the two screws

securing the manometer to the FRL air servicing unit.

Replace the manometer with a new one, and carry out the whole process in

reverse order

MOTOR PLATES (REPLACEMENT) Ref. NH120846

1. Close the air inlet valve (2b, page 10) located on the left side of the

filtering unit and operate the motor to expel the air.

2. Remove the intake pipe entering the top of the motor.

3. With a “belt key”, unscrew (LEFT HAND THREAD) the motor casing.

4. Remove the whole rotor assembly from inside the casing.

5. Pull out the “seeger ring” (nr.6) of the upper part of the motor and

remove the upper head (nr. 4), the stator (nr.2) and the MOTOR

PLATES (nr.3).

ATTENTION:

Notice the direction and positions of the motor

stator and top head.

1. Rotor

2. Stator

3. Motor plates

4. Top head

5. Ball bearing 607-Z THB

6. “Seeger” O-ring

7. Bottom head

8. Ball bearing 6000-Z THB

9. Joint

10. Rod

This manual suits for next models

1

Table of contents

Other Tecnospiro Robotics manuals

Popular Robotics manuals by other brands

rozum robotics

rozum robotics Pulse Operator's manual

ROKAE

ROKAE xMate CR18 Hardware installation manual

Robokits

Robokits TrackBot RKI-1247 Assembly guide and user manual

killerspin

killerspin THUNDER Assembly and operating instructions

Omron

Omron Medium Series Hardware installation manual

Kinova

Kinova JACO Driver installation guide