TeeJet Technologies CENTERLINE User manual

OPERATORS MANUAL &

FITTING INSTRUCTIONS

FOR

CENTERLINE

No. 020-021-UK Version 1.11

Mølhavevej 2

9440 Aabybro

Denmark

Tlf. +45 9696 2500

Fax. +45 9696 2501

www.teejet.com

2

We have endeavoured to deliver a fault free product. To ensure optimal use of the

equipment we ask that great attention be paid when reading the manual. Please

contact your local dealer if further support is needed. Regarding responsibility for

use of the product, we refer to our sales and delivery terms especially paragraph

7, which follows:

7. Product usage.

7.1 Any use of the product is at the sole risk of the buyer. The buyer is

therefore not entitled to any form for compensation caused by, for example,

any of the following:

Disturbance to/from any electronic services or products that do not

confirm to the standards for CE marking,

Missing or poor signal coverage or a succession hereof from external

transmitters/receivers, used by the buyer,

Functional faults, which apply to or from a PC-program or PC-equipment,

not delivered by the seller,

Faults that may arise from the buyers negligence to react to warnings

and fault messages from the product, or which can be traced to

negligence and/or absent constant control of the work carried out in

comparison to the planned job.

7.2 When implementing any new equipment the buyer must take great care and pay

attention. Any doubts as to correct operation/use should result in

contacting the sellers service department.

This manual may not be altered, copied or manipulated in any way. Unoriginal

manuals can lead to operational faults damaging machines or crops as a

consequence thereof. TeeJet Technologies can therefore not be held responsible

for damages incurred, which can be traced to the use of unoriginal or manipulated

manuals. Original manuals can be requisitioned at any time from your dealer.

With regards

Mølhavevej 2

9440 Aabybro

Denmark

Tlf. +45 9696 2500

Fax. +45 9696 2501

www.teejet.com

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

C

ONTENTS

3

Contents

INTRODUCTION .................................................................................................................5

GENERAL OPERATION......................................................................................................6

THE WIRELESS REMOTE .........................................................................................6

ARROW UP & DOWN KEYS (POS. 1 & 3).............................................................7

RETURN TO POINT KEY (POS. 2) ........................................................................7

BRIGHTNESS + & - KEYS (POS. 4).......................................................................7

MENU/ESCAPE KEY (POS. 5) ...............................................................................7

ENTER KEY (POS. 6).............................................................................................7

THE CENTERLINE LIGHTBAR...................................................................................8

LIGHTBAR LIGHTS (POS. 1) .................................................................................8

MENU SCREEN (POS. 2).......................................................................................8

AN INTRODUCTION TO PARALLEL SWATHING......................................................8

STRAIGHT GUIDANCE ..........................................................................................9

CURVED GUIDANCE .............................................................................................9

HEADLAND GUIDANCE.........................................................................................9

A WORKING EXAMPLE .......................................................................................10

OPERATION......................................................................................................................13

OPERATING MENU OVERVIEW .............................................................................13

GENERAL .................................................................................................................13

NEW?....................................................................................................................13

RESUME?.............................................................................................................13

APPLY ON/OFF ....................................................................................................13

HEADLAND/STRAIGHT/CURVE AB ....................................................................13

NEW A – B............................................................................................................14

AREA ....................................................................................................................15

E-DIF.........................................................................................................................15

USING THE RETURN TO POINT FUNCTION..........................................................16

ENCODE ...........................................................................................................................17

SETUP MENU OVERVIEW.......................................................................................17

GENERAL .................................................................................................................18

GUIDANCE ...............................................................................................................18

WIDTH ..................................................................................................................18

AHEAD..................................................................................................................18

ANTENNA.............................................................................................................18

STATUS................................................................................................................19

ALARM..................................................................................................................19

GPS TYPE ............................................................................................................19

1HZ MESSAGE.....................................................................................................19

C

ONTENTS

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

4

LIGHTBAR ................................................................................................................19

SPACING..............................................................................................................19

MODE ...................................................................................................................20

TEXT 1 & TEXT 2 .................................................................................................20

STEER BAR?........................................................................................................20

SYSTEM....................................................................................................................20

UNITS ...................................................................................................................20

LANGUAGE ..........................................................................................................20

TOOLS...............................................................................................................................21

TOOLS MENU OVERVIEW ......................................................................................21

RECEIVER STATUS.............................................................................................21

LIGHTBAR ............................................................................................................22

DEMO ...................................................................................................................22

E-DIF.....................................................................................................................22

FITTING THE CENTERLINE .............................................................................................23

SYSTEM OVERVIEW ...............................................................................................23

FITTING ....................................................................................................................24

GENERAL.............................................................................................................24

FITTING THE LIGHTBAR (POS. 1) ......................................................................24

CENTERLINE POWER CABLE CONNECTION (POS. 2) ....................................24

BATTERY CABLE CONNECTION (POS. 3).........................................................24

CONNECTING THE DGPS RECEIVER....................................................................24

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

I

NTRODUCTION

5

INTRODUCTION

Congratulations on selecting the CenterLine

We – your supplier – feel certain that you will quickly learn to use it and within a

short time get the full benefit of this modern technology.

Please read this operator manual:

Sit in the tractor seat with the engine switched off!

Read the “Introduction to guidance” and look at the drawings on pages 10 & 11.

Get to know the 6 remote control buttons and their functions.

Learn to navigate through the menus.

Read the explanations for each menu item that you don’t understand carefully.

Only now, if you feel at home with the CenterLine, should you start the

tractor for the first test run.

Enjoy!

G

ENERAL

O

PERATION

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

6

GENERAL OPERATION

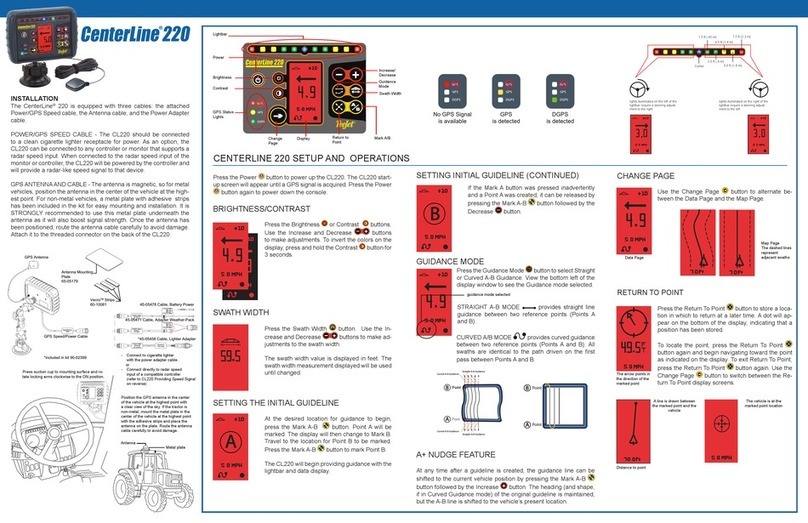

The CenterLine system consists of three main components; a DGPS receiver, the

lightbar and a wireless remote control. All of the menus for operation and encoding

the CenterLine are shown on the lightbar and are selected by using the wireless

remote control. Settings for the DGPS receiver depend on the type of receiver

used; please refer to the documentation supplied with the DGPS receiver.

A description of the wireless remote control and the lightbar follows:

THE WIRELESS REMOTE

As mentioned before CenterLine is operated via the wireless remote and a

description of the buttons can be seen in the following:

UP

DOWN

MENU

ESC

Pos.

Description Pos.

Description

1 Arrow up key 4 Brightness up and down keys

2 Return to point key 5 Menu/Escape key

3 Arrow down key 6 Enter key

1

2

3

5

6

4

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

G

ENERAL

O

PERATION

7

ARROW UP & DOWN KEYS (POS. 1 & 3)

Key Description

UP

DOWN

These keys are used to page through the menus, sub-menus

and the various settings that are available in the menus.

RETURN TO POINT KEY (POS. 2)

Key Description

This key is used to mark a position in the field and then to later

return to the marked position.

The return to point function is typically used if work in the field is

stopped and the point at which work stopped is to be found

when work commences again.

A description of this function can be seen on page 15.

BRIGHTNESS + & - KEYS (POS. 4)

Keys Description

Repeatedly pressing the brightness + key will increase the

brightness of the lightbar. Likewise repeatedly pressing the

brightness – key will decrease the brightness of the lightbar.

Different light conditions, i.e. bright sunlight or night work can be

compensated for with this function.

MENU/ESCAPE KEY (POS. 5)

Key Description

MENU

ESC

This key is used to leave a menu item.

Each press of this key pages one step back in the menu

structure.

If the key is pressed when encoding, the specific setting will not

be saved.

ENTER KEY (POS. 6)

Key Description

The enter key is used to open a menu plus to select and accept

an encodement.

G

ENERAL

O

PERATION

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

8

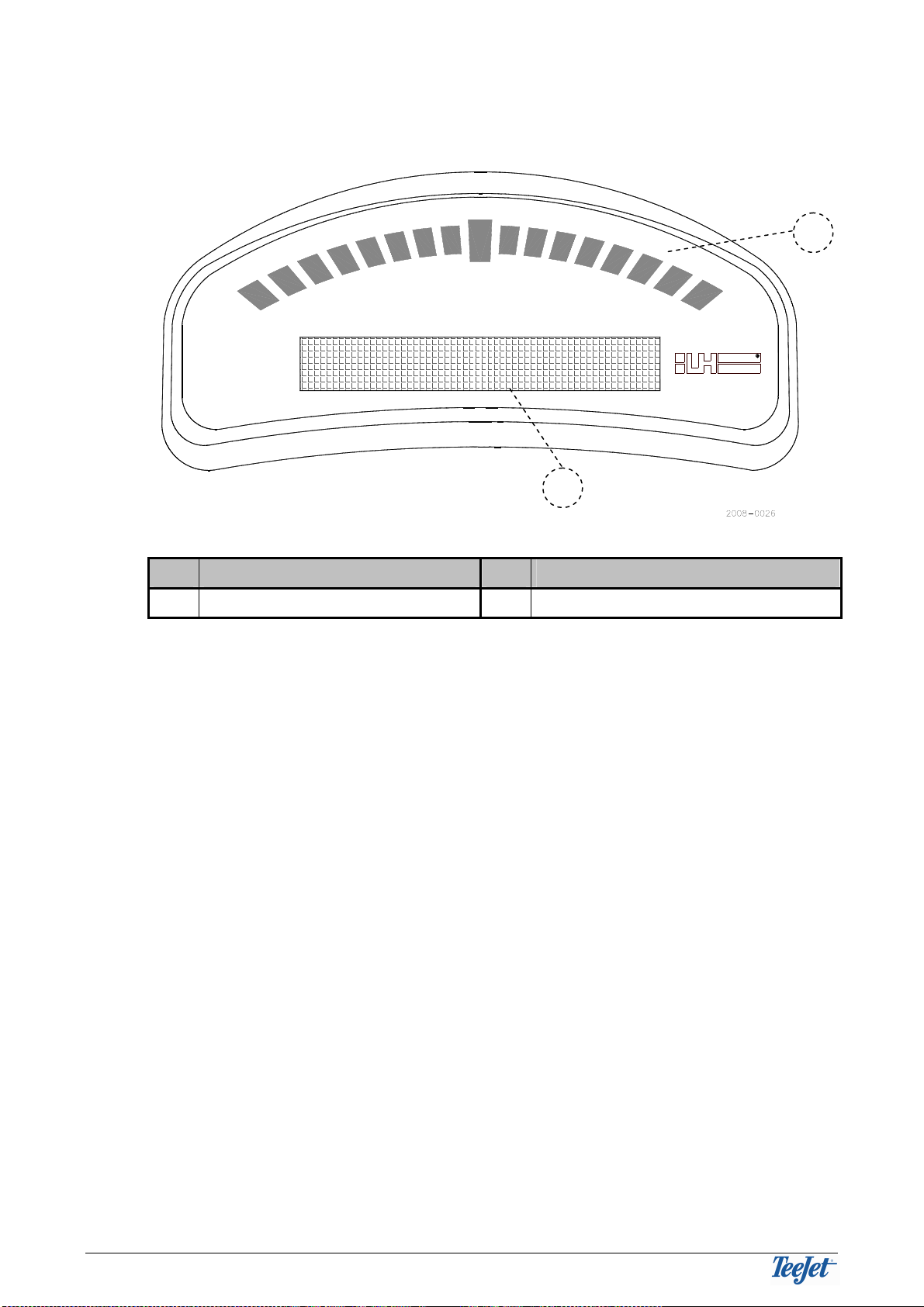

THE CENTERLINE LIGHTBAR

LH AGRO

Pos.

Description Pos.

Description

1 Lightbar lights 2 Menu screen

LIGHTBAR LIGHTS (POS. 1)

An indication of the present position in comparison to the required position.

When driving “on track” the middle light will be lit.

MENU SCREEN (POS. 2)

Operating information and the various menus are displayed here.

AN INTRODUCTION TO PARALLEL SWATHING

Parallel swathing can be carried out in three different ways; driving around the

headland and parallel to a straight line or a curved line. Typically, work will start by

driving around the headland 2 or 3 times and thereafter “side to side” (as with

tramlines).

Whilst driving around the headland it is possible to create a reference line from

which the remainder of the field can be driven parallel to. This reference line is

created by marking 2 points, point A and point B. The shortest possible distance

between 2 points is a straight line and this straight line is the reference line that is

driven parallel to for straight guidance(not the headland).

The reference line can be created, as mentioned before, whilst working the

headland, but also at any other time whilst driving. Once the reference line is

marked, it is possible to drive parallel to this line anywhere in the field.

1

2

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

G

ENERAL

O

PERATION

9

STRAIGHT GUIDANCE

Straight guidance is simply driving in a straight line parallel to the reference line

created with points A & B. Once the reference line has been created it is possible

to drive parallel to the left and/or the right of the line and before and/or after the

initial reference points (A & B), the following diagram illustrates this:

The solid line represents the reference line

created with points A & B.

The dashed line shows that parallel lines are

automatically created on the left- and right-

hand side plus in front of and behind the

reference line.

This means that parallel guidance is possible

outside the points A and B

CURVED GUIDANCE

Curved guidance is driving parallel to a curved line in a similar fashion to straight

guidance. Parallel guidance is possible to the left and/or right of the reference line

but not before or after the initial reference points. The following diagram illustrates

this:

The solid line represents the initial

reference line created with points A & B.

The dashed lines show that parallel lines

are automatically created in front of the

initial reference line.

The dashed lines also show that parallel

lines are not created in to the side of the

initial reference points

This means that curved guidance is not

possible outside of the points A and B

HEADLAND GUIDANCE

Headland guidance is driving parallel around the headland of the field. Once the

headland has been completed it is possible to drive to the left and/or to the right of

the initial bout. A reference line (A & B) for straight or curved guidance can be

created whilst in headland mode.

A detailed example of headland guidance can be seen on page 11.

A

B

No guidance

No guidance

A B

G

ENERAL

O

PERATION

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

10

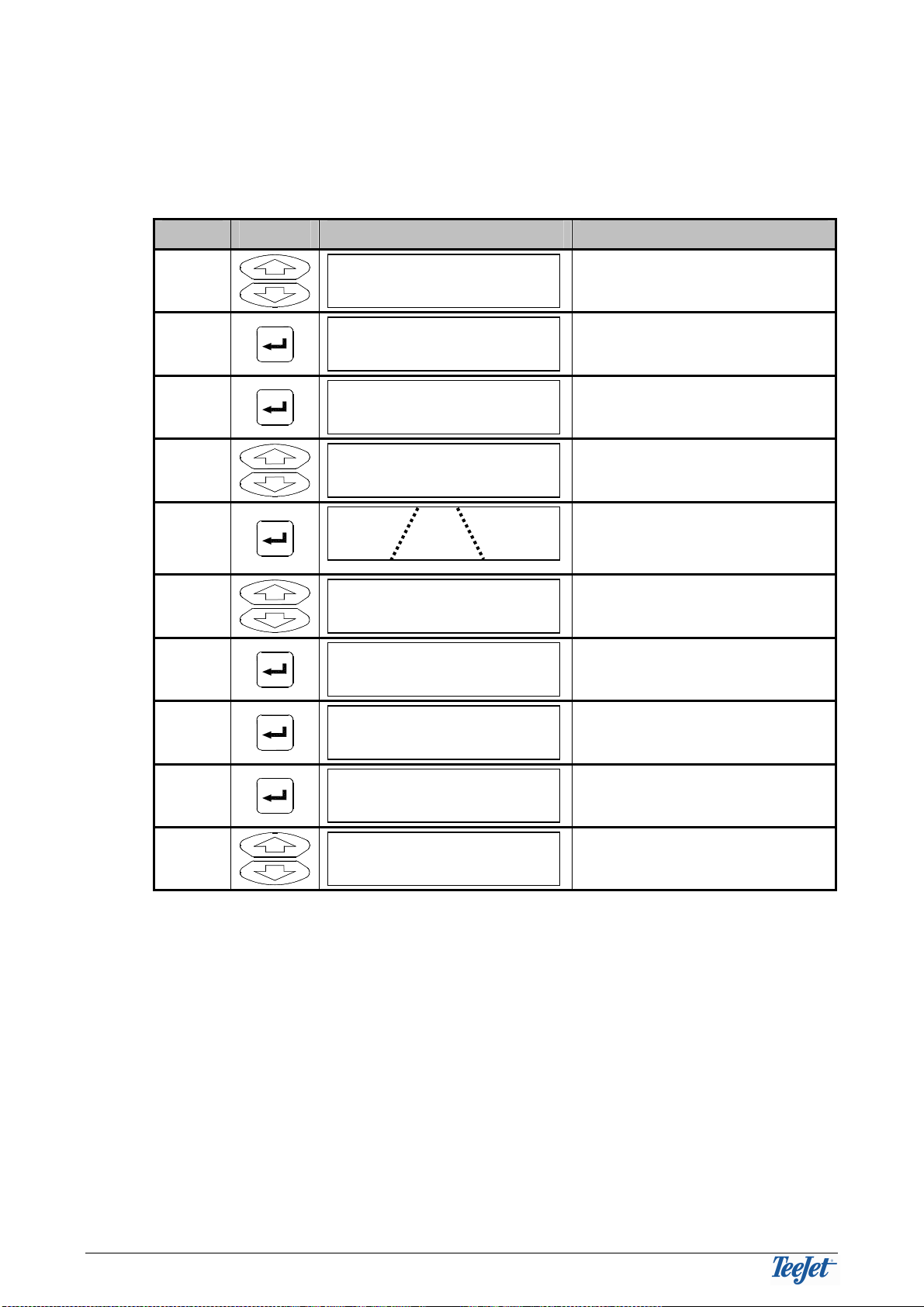

A WORKING EXAMPLE

The following example shows that the headland is driven twice. Two reference

marks are made to create the straight reference line that the rest of the field is to

be driven parallel to:

Step Key Display Description

1

UP

DOWN

Select "Start” to begin real-

time guidance.

2

Start a new field

3

Only displayed if "STATUS” =

OFF under setup.

4

UP

DOWN

Select for headland work.

5

Start working the headland. 2

lines are shown in the

display.

6

UP

DOWN

Prepare for a new reference

line.

7

Start the reference line.

8

Drive the straight line.

9

Stop marking the reference

line.

10

UP

DOWN

Change to straight work.

Straight?

Mark B

Mark A

New A - B

Headland?

Spray On

New?

Start

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

G

ENERAL

O

PERATION

11

The first pass is almost finished and the marks for the reference line have been

created (mark A & B) for which the rest of the field will be driven parallel to. See

steps 7, 8, & 9 in the above for marking the reference line).

The second pass of the headland has just been started. Marks A & B were created

in the first pass around the headland.

When changing from the first to the second pass around the headland the

following is displayed:

This shows that a left turn is approaching.

First pass

Mark A Mark B

First pass

Mark A Mark B

Start of the second

pass

G

ENERAL

O

PERATION

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

12

The second pass around the headland is finished and work has started parallel to

the straight reference line, which was created with marks A & B during the first

pass around the headland.

The field is finished.

Mark A Mark B

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

O

PERATION

13

OPERATION

OPERATING MENU OVERVIEW

GENERAL

Each menu item is described in the following:

Encoding all settings is necessary for correct operation, see ENCODE on

page 17.

NEW?

Select this if starting a new field. Previous fieldwork will be erased (not

encodements).

RESUME?

Select this to continue work in a previously worked field.

APPLY ON/OFF

This function is only displayed if “STATUS” = OFF under encode – see page 19.

If the system is not fitted with an “implement sensor” (see “FITTING THE

CENTERLINE” on page 24) then this function is used to, manually, tell the system

whether the implement is in work or not.

If the system is fitted with an “implement sensor” and “STATUS” = ON under

encode the system will automatically detect if the implement is in work or not.

HEADLAND/STRAIGHT/CURVE AB

Select whether the machine is driving around the headland or driving straight

(parallel to a reference line) – see “AN INTRODUCTION TO PARALLEL

SWATHING”) on page 8.

CLOSE

START

SETUP

TOOLS

NEW?

RESUME?

RIGHT

APPLY OFF

HEADLAND

NEW A-B

AREA

EXIT

APPLY ON

STRAIGHT

MARK A

LEFT

MARK B

PATTERN

CURVE AB

O

PERATION

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

14

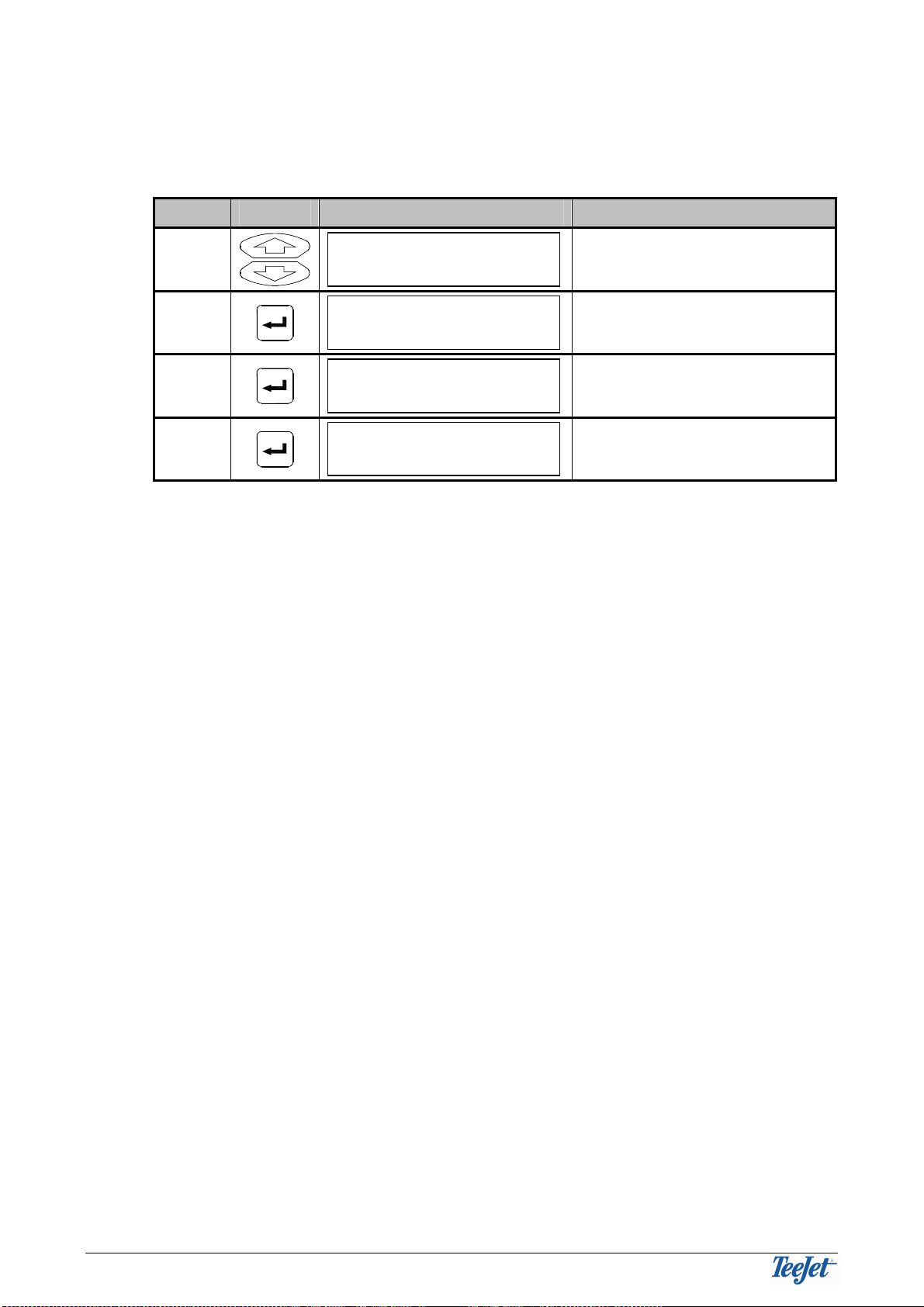

NEW A – B

Selecting this function allows a new reference line to be created. The procedure

for creating a new reference line follows:

Step Key Display Description

1

UP

DOWN

Prepare for a new reference

line.

2

Start the reference line.

3

Drive the straight stretch.

4

Stop marking the reference

line.

All straight guidance work hereafter will be parallel to the reference line. A new

reference line can be created at any time during work in the field by following this

(the above) procedure.

The reference line remains in the memory until either:

1. A new real-time guidance is started (using the "Continue?” function keeps

the reference line).

Or

2. A new reference line is created (only one reference line can be stored at a

time).

Mark B

Mark A

New A - B

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

O

PERATION

15

AREA

It is possible to measure and thereafter see, e.g. the size of the field, with this

function.

The field area is automatically calculated from the driven circumference (of, i.e. the

field).

If the field area has not been measured with the CenterLine before then select

whether the actual field boundary is on the RIGHT- or LEFT- hand side of the

implement after selecting the AREA function. The display shows that area is being

measured whilst driving.

The area measurement will automatically stop and close the boundary when the

implement is within 4.5 metres of the start position. The boundary can also be

closed manually by selecting “CLOSE”. When the boundary is closed, the field

size is calculated and the area is saved. The calculated area is displayed for 3

minutes and can be seen again by selecting the “SHOW” function under the AREA

menu.

The calculated area remains in the memory until either:

1. A new real-time guidance is started (using the “Continue?” function keeps

the calculated area).

Or

2. A new area measurement is started.

E-DIF

Using e-Dif is normally not necessary in area where correctional signals

from Egnos are available.

Only displayed if the system is fitted with a RX350P Egnos DGPS receiver

(no. 78-50108).

Calibration for the e-Dif receiver. Please see the description on page 22.

O

PERATION

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

16

USING THE RETURN TO POINT FUNCTION

The “Return to point” function is used when a marked position in the field is to be

found again. This function is typically used when work in the field is stopped and

the point at which worked stopped is to be returned to.

The “Return to point” function is operated with the “Return to point” key (pos. 2,

see page 7).

When a certain position is to be marked simply press this key. The marked

position will remain in the memory until either:

1. A new real-time guidance is started (using the “Continue?” function keeps

the marked position).

Or

2. A previously marked position is returned to and the key is pressed again

(3rd.time).

When the marked position is to be found again simply press the key again. The

lightbar guidance lights will show the way to drive and the display will show the

distance (in metres) between the present position and the marked position.

Press the “Menu/Esc” key to exit the “Return to point” function when the previously

marked position has been found.

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

E

NCODE

17

ENCODE

SETUP MENU OVERVIEW

START

SETUP

TOOLS

GUIDANCE

WIDTH

ANTENNA

STATUS

ALARM

TO START

NEXT

GPS TYPE

1 Hz MSG

DISTANCE

DIRECTION

FORWARD

BACK

HEIGHT

OFF

ON

ON

OFF

DGPS

GPS

YES

NO

LIGHTBAR SPACING

MODE

TEXT 1

TEXT 2

NEXT

TO START

VEHICLE

SWATH

X-TRACK

SWATH #

SPEED

AREA

COURSE

OFF

SYSTEM UNITS

US

METRIC

LANGUAGE

NEXT

STEER BAR

YES

NO

TO START

S

NEXT

XT

TO START

AHEAD

NEXT

E

NCODE

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

18

GENERAL

There are two shortcuts in the setup menus, NEXT and TO START.

Selecting the NEXT function will automatically page back to the main menu for the

sub menu. Therefore, if, i.e. the SYSTEM menu is active and the NEXT function

was selected then the menu will automatically “jump” back to SETUP.

If the TO START function is selected, regardless of what menu is active, then the

system will automatically “jump” to the real-time guidance menu (operation). This

function can, e.g. be used if a setting needs to be altered during operation and

then the guidance task is to be continued.

We recommend encoding the system settings first as these decide, amongst

other things, the units used for operation and the other settings (see page

20).

GUIDANCE

All vehicle and implement related settings are encoded here.

The following settings presuppose that UNITS (in the SYSTEM menu) has been

set to METRIC and that the LANGUAGE is set to ENGLISH:

WIDTH

Encode the distance between the tracks in steps of 10 cm (min = 1m, max =

100m).

This width is typically the working width of the implement. If the encoded width is

set slightly smaller than the actual working width of the implement then chances

for “misses” in the field is reduced. If the encoded width is slightly larger than the

actual width of the implement, then overlapping will be reduced.

AHEAD

Encode, in seconds, how far ahead the Centerline should look ahead (typically set

to 1.5 or 2 seconds).

The look ahead function takes the current speed, direction plus this look ahead

value and calculates where the vehicle will be in relation to the current track. The

value to be encoded depends greatly on the machine operator.

When set to 0 the system does not use this function.

ANTENNA

The DGPS antenna is typically fitted either in front or behind the implement (front

mounted implements). Encode whether the DGPS antenna is in front or behind the

implement plus the distance between the antenna and the implement.

DIRECTION: Select “BACK” if the implement is behind the DGPS antenna.

Select “FORWARD” if the implement is in front of the DGPS

antenna.

DISTANCE: The distance between the DGPS antenna and the implement is

encoded in steps of 10 centimetres (min. = 0m, max. = 300m).

Consider the “drop point” of the implement. If the implement used

is i.e. a fertiliser spreader then the product will hit the ground up to

40 metres behind the DGPS antenna.

HEIGHT: The height from the ground to the DGPS antenna is encoded in

steps of 10 cm (min. = 0m, max. = 10m).

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

E

NCODE

19

STATUS

If this setting is encoded to “ON”, then the CenterLine will receive a signal from the

implement telling whether the implement is in work or out of work (see page 24).

This is used for, amongst other things, area measurement and warnings for

previously worked area (see the following alarm description).

If “OFF” is selected (standard setting) then the CenterLine will not give a warning

for previously worked area regardless of whether the implement is in work or out of

work.

ALARM

If “ON” is selected under ALARM then the CenterLine will give a visual warning

when a previously worked area is approached or driven into. APPLIED is shown in

the display when previously worked area is driven in, e.g. the headland.

If “OFF” is selected then no warning will be given when driving in previously

worked areas.

GPS TYPE

If differential corrections are not available, setting this menu item to GPS will allow

work to continue without reference signals.

When the standard setting (DGPS) is used a warning will appear on the

CenterLine and work can not continue should the differential signal be lost.

Accuracy will be greatly reduced if work is carried out without DGPS signals.

We do not recommend changing this setting.

1HZ MESSAGE

If the DGPS receiver being used is not able to send data to the CenterLine at an

acceptable rate it is possible to allow the system to accept DGPS signals from

such a receiver.

When the standard setting (NO) is used a warning will appear on the CenterLine if

the DGPS signals are not being received fast enough.

Accuracy will be greatly reduced if work is carried out with slow DGPS

signals. We do not recommend changing this setting.

LIGHTBAR

Settings related to the lightbar are encoded in the LIGHTBAR menus. A

description of these settings follows:

SPACING

This distance expresses the distance each LED on the lightbar represents. The

spacing can be set from 10 cm to 300 cm in steps of 10 cm.

E

NCODE

C

ENTER

L

INE

O

PERATOR

&

FITTING INSTRUCTIONS

20

MODE

If MODE is set to “VEHICLE” then the middle line on the lightbar represents the

position of the implement. Steer the machine so that the middle line of the lightbar

is moved to the moving light.

If MODE is set to “TRACK” then the middle line of the lightbar represents the track.

Steer the machine so that the moving light is moved to the middle of the lightbar.

TEXT 1 & TEXT 2

Select one of the following text messages (one for TEXT 1 plus one for TEXT 2) to

be displayed whilst working:

X-TRACK: Shows the distance between the required track and the actual

position of the machine.

SWATH #: Shows the actual track number.

SPEED: Shows the present forward speed as kilometres per hour.

AREA: Shows the measured area that has been worked (not to be

confused with the calculated area from the AREA function as

described on page 15).

COURSE: Displays the machine heading in degrees.

OFF: No information is displayed.

STEER BAR?

When the STEER BAR option = “Yes” then all lights will be lit from the centre to

the left or right indicator light, whereas if the STEER BAR option = “No” (standard

setting) then only the left or right indicator light will be lit.

SYSTEM

UNITS

The units used for operation and encoding. Select between US (feet & inches) and

METRIC (metres & centimetres).

LANGUAGE

Select the operating language of the CenterLine.

Table of contents

Other TeeJet Technologies Car Navigation System manuals