TeeJet Technologies MATRIX PRO940gs User manual

MATRIX®PROGS

ASSISTED/AUTO STEERING

SETUP GUIDE

TeeJet Technologies

1801 Business Park Drive

Springeld, Illinois 62703 USA

www.teejet.com

For use with software version 3.0x

98-05242-ENUS R4 English-US

© TeeJet Technologies 2013

Copyrights

© 2013 TeeJet Technologies. All rights reserved. No part of this document or the computer programs described in it may be reproduced, copied,

photocopied, translated, or reduced in any form or by any means, electronic or machine readable, recording or otherwise, without prior written

consent from TeeJet Technologies.

Trademarks

Unless otherwise noted, all other brand or product names are trademarks or registered trademarks of their respective companies or organizations.

Limitation of Liability

TEEJET TECHNOLOGIES PROVIDES THIS MATERIAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR IMPLIED.

NO COPYRIGHT LIABILITY OR PATENT IS ASSUMED. IN NO EVENT SHALL TEEJET TECHNOLOGIES BE LIABLE FOR ANY LOSS OF

BUSINESS, LOSS OF PROFIT, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS, OR FOR INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES OF ANY KIND, EVEN IF TEEJET TECHNOLOGIES HAS BEEN ADVISED OF SUCH DAMAGES ARISING FROM

TEEJET TECHNOLOGIES SOFTWARE.

Safety Information

TeeJet Technologies is not responsible for damage or physical harm caused by failure to adhere to the following safety requirements.

As the operator of the vehicle, you are responsible for its safe operation.

Assisted/Auto Steering is not designed to replace the vehicle’s operator.

Do not leave a vehicle while the Assisted/Auto Steering is engaged.

Be sure that the area around the vehicle is clear of people and obstacles before and during engagement.

The Assisted/Auto Steering is designed to support and improve efciency while working in the eld. The driver has full responsibility for the quality

and work related results.

Disengage Assisted/Auto Steering before operating on public roads or when not in use to prevent loss of vehicle control.

WARNING: PINCH POINT HAZARD! To prevent serious injury or death, avoid unsafe practice while manually operating hydraulic

steering circuits. Keep others away and stay clear of mechanical steering linkages.

1

98-05242-ENUS R4

Matrix®Pro GS

Table of Contents

GENERAL MATRIX®PRO INFORMATION 2

Unavailable Options When Job is Active ....................................................................................................................2

Warnings and Information Pop-ups ............................................................................................................................2

Drop Down Menu Selections .....................................................................................................................................2

Scrolling Screens ......................................................................................................................................................2

Setup Option Information...........................................................................................................................................3

Keyboard Entry Screen .............................................................................................................................................3

Unit Setup Mode Availability ............................................................................................................................................3

GPS is Required .......................................................................................................................................................4

PRN Not Shown...............................................................................................................................................................4

ASSISTED/AUTO STEERING CONFIGURATION 5

AUTOSTEER 6

Assisted/Auto Steering Unavailable.................................................................................................................................6

Enable/Disable Assisted/Auto Steering..................................................................................................................................................6

Valve Setup .......................................................................................................................................................................................................7

Valve Type ...............................................................................................................................................................7

Valve Frequency .......................................................................................................................................................7

Minimum/Maximum Duty Cycle Tests ........................................................................................................................8

Minimum Duty Cycle Left Test .........................................................................................................................................8

Minimum Duty Cycle Right Test.......................................................................................................................................9

Maximum Duty Cycle Test ...............................................................................................................................................9

Steering Settings ......................................................................................................................................................................................... 10

Coarse Steering Adjustment ...................................................................................................................................11

Fine Steering Adjustment ........................................................................................................................................11

Deadband ...............................................................................................................................................................12

Lookahead ..............................................................................................................................................................12

Valve Test ....................................................................................................................................................................................................... 13

Valve Diagnostics......................................................................................................................................................................................... 13

Steering Valve – No Master Solenoid ............................................................................................................................14

Steering Valve – With Master Solenoid..........................................................................................................................14

Options: Steering Wheel Sensor............................................................................................................................................................. 15

Steering Angle Sensor ............................................................................................................................................................................... 15

Enable/Disable Steering Angle Sensor ...................................................................................................................16

Sensor Calibration ...................................................................................................................................................16

On Line Calibration ................................................................................................................................................17

TILT CORRECTION 18

Field Level Unavailable..................................................................................................................................................18

Tilt Correction Unavailable.............................................................................................................................................18

Enable/Disable Tilt ...................................................................................................................................................................................... 18

Field Level ..............................................................................................................................................................19

AUTO/ASSISTED STEERING OPERATION 20

APPENDIX FACTORY SETTINGS & RANGES 21

2www.teejet.com

Assisted/Auto Steering

GENERAL MATRIX®PRO INFORMATION

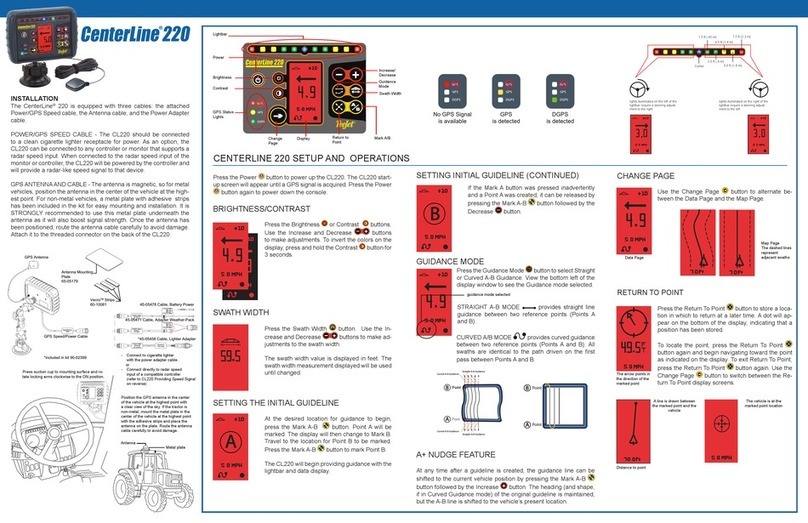

The Matrix Pro GS is used to congure the vehicle and its implements including assisted/auto steering and tilt correction.

Unavailable Options When Job is Active

When a job is active some setup options are unavailable. See the Unit

Setup Mode Availability Chart for indication of which options are not

accessible.

Figure GS-1: Example of Unavailable Options

Warnings and Information Pop-ups

A pop-up warning or information box will be displayed for approximately

ve (5) seconds. To remove the information box, tap anywhere on the

screen.

Figure GS-2: Information screens

Dimming backlight brightness to

reduce heat. Previous backlight

brightness will be restored when

unit reaches a safe temperature.

Overheat Protection

Drop Down Menu Selections

Press DOWN arrow to access the options. Use the UP/DOWN

arrows or slide bar if necessary to scroll through the extended

list. Select the appropriate option. To close the list without selecting an

option, tap anywhere on the screen outside the drop down menu.

Figure GS-3: Example of Drop Down Menu

Backward

Forward

Scrolling Screens

Some screens have more information or options that are visible beyond

the current screen. Use the UP/DOWN arrows or slide bar to

access additional options or information not currently visible on the

screen.

Figure GS-4: Example of Scrolling Screen

3

98-05242-ENUS R4

Matrix®Pro GS

Setup Option Information

Press the option’s icon or option’s name of any menu item to display a

denition and range values of that item. To remove the information box,

press anywhere on the screen.

Figure GS-5: Example of Information Text Box

Keyboard Entry Screen

Press the KEYPAD icon . Use the numeric keypad to enter a

value.

Press the ACCEPT icon to save the settings or the CANCEL

icon to leave the keypad without saving.

Figure GS-6: Example of Keyboard

Antenna to Boom (ft)

1 2 3

14.50

Clear

4 5 6 <--

7 8 9

0 . +/-

Unit Setup Mode Availability

Conguration

Implement

–

Machine Type

GPS Antenna Height

Implement Type

Symmetric Implement Layout

Implement Offset Distance

Implement Offset Direction

Number of Implement Sections

Guidance Width

Application/Working Width

Applied Area Alarm

–

Straight

Mode

Boom Offset Direction

Antenna to Boom Distance

Overlap

Delay On/Off Times

Spreader

Mode

Setup Type: TeeJet

• Antenna to Disks Distance

• Overlap

• Delay On/Off Times

• Spread Offset Distance

• Section Offsets

• Section Lengths

Setup Type: OEM

• Antenna to Disks Distance

• Start/Stop Distance

• Section Start/Stop Offsets

Staggered

Mode

Section 1 Offset Direction

Antenna to Section 1

Overlap

Delay On/Off Times

Section Offsets

AutoSteer

–Enabled/Disabled

–Valve

Setup

Valve Type

Valve Frequency

Minimum Duty Cycle Left/ Right

Maximum Duty Cycle

–Steering

Settings

Coarse Steering Adjustment

Fine Steering Adjustment

Deadband

Lookahead

–Valve Test

–Valve Diagnostics

–Options Steering Wheel Sensor

–

Steering

Angle

Sensor

Enable

Sensor Calibration

On Line Calibration

Tilt

Correction –Enabled/Disabled

Field Level

GPS –

GPS Type

GPS Port

GPS Status Information

Program Receiver

PRN

Available during an active job

Not Available during an active job

4www.teejet.com

Assisted/Auto Steering

GPS is Required

GPS is used to congure GPS Type, GPS Port and PRN as well as to

view GPS status information. For detailed setup instructions, refer to

the GPS chapter in the Matrix Pro GS user manual.

NOTE: These settings are required for assisted/auto steering and tilt

sensor operation, as well as proper implement operation.

1. Press CONFIGURATION side tab .

2. Press GPS .

3. Select from:

►GPS Type – select GPS source transmissions

►GPS Port – sets (D)GPS communication port

►GPS Status – displays information regarding GGA/VTG (Data

Rates), Number of Satellites, HDOP, PRN, GGA Quality, GPS

Receiver, Receiver Version and UTM Zone

►Program – allows direct programming of the GPS receiver

through a command line interface

►PRN – selects the SBAS PRN that will provide GNSS differential

correction data. Set to Automatic for automatic PRN selection.

►Alternate PRN – when PRN is not automatic, a second alternate

SBAS PRN will provide a second set of GNSS differential

correction data.

4. Press RETURN arrow or CONFIGURATION side tab to

return to the main Conguration screen.

Figure GS-7: GPS

PRN Not Shown

When GPS Type is set to “GPS+GLONASS”, PRN options are not

available, nor shown on screen.

5

98-05242-ENUS R4

Matrix®Pro GS

ASSISTED/AUTO STEERING CONFIGURATION

The Matrix Pro GS is used to congure the vehicle and its implements

including assisted/auto steering and tilt. For recommendations and

factory settings for the FieldPilot or UniPilot setup values, see chart on

page 21.

To access Matrix Pro GS AutoSteer and Tilt conguration options:

1. Press UNIT SETUP bottom tab .

2. Press CONFIGURATION side tab .

3. Select from:

►AutoSteer – used to enable/disable assisted/auto steering as

well as establish valve setup settings, steering settings and

steering angle sensor settings; and perform valve tests, or valve

diagnostics

►Tilt Correction – used to enable/disable and calibrate the tilt

gyro module, allowing for tilt correction for application on hilly or

sloped terrain

Figure GS-8: Configuration Options - AutoSteer

Figure GS-9: Configuration Options - Tilt Correction

6www.teejet.com

Assisted/Auto Steering

AUTOSTEER

When a Steering Control Module (SCM) is present, Assisted/Auto

Steering options will be available

NOTE: An update of your SCM software may be required when

upgrading to a Matrix Pro GS from previous Matrix

systems. To view version of software information, see the

Console->About screen.

AutoSteer setup is used to Enable/Disable Assisted/Auto Steering and

congure Valve Setup, Steering Settings, Valve Test, Valve Diagnostics

and Steering Angle Sensor. For recommendations and factory settings

for the FieldPilot or UniPilot setup values, see chart on page 21.

1. Press CONFIGURATION side tab .

2. Press AutoSteer .

3. Select if assisted/auto steering is enabled or disabled.

4. When enabled, select from:

►Valve Setup – used to congure Valve Type, Valve Frequency,

Minimum Duty Cycle Left/Right and Maximum Duty Cycle

►Steering Settings – used to establish Coarse Steering

Adjustment, Fine Steering Adjustment, Deadband and

Lookahead

►Valve Test – used to verify if steering is directed correctly

►Valve Diagnostics – used to test the valves to see if they are

connected properly

►Options: Steering Wheel Sensor – used to select whether the

steering disengage sensor is magnetic or pressure sensor based

►Steering Angle Sensor – used to establish and calibrate the

Steering Angle Sensor (SAS) as the primary feedback sensor for

auto steering.

5. Press RETURN arrow or CONFIGURATION side tab to

return to the main Conguration screen.

Figure GS-10: AutoSteer

Assisted/Auto Steering Unavailable

If a assisted/auto steering system is not installed, setup options will not

be available.

Figure GS-11: Assisted/Auto Steering Not Detected

Enable/Disable Assisted/Auto Steering

Set assisted/auto steering to Enable or Disable.

1. Press DOWN arrow to access the list of options.

2. Select:

►Enable

►Disabled

If disabled, all Assisted/Auto Steering capabilities and setup functions

will be unavailable (options will be grayed out).

Figure GS-12: Enabled and Disabled Assisted/Auto Steering Options

7

98-05242-ENUS R4

Matrix®Pro GS

Valve Setup

Valve Setup is used to congure Valve Type, Valve Frequency,

Minimum Duty Cycle Left, Minimum Duty Cycle Right and Maximum

Duty Cycle. For recommendations and factory settings for the FieldPilot

or UniPilot setup values, see chart on page 21.

1. Select Valve Setup .

2. Select from:

►Valve Type– used to select the type of steering valve

►Frequency – used to select the valve frequency used to drive the

steering valve

►Minimum Duty Cycle Left and Right – used to set the minimum

amount of drive required to begin steering the vehicle left or right

►Maximum Duty Cycle – used to select the maximum speed that

the wheels will steer from lock to lock

Figure GS-13: Valve Setup

Valve Type

Valve type is used to set the type of steering valve. For

recommendations and factory settings for the FieldPilot or UniPilot

setup values, see chart on page 21.

1. Press DOWN arrow to access the list of options.

2. Select type.

Figure GS-14: Valve Type

Standard/PWM

Standard Voltage

Reverse Voltage

One-Wire PWM

UniPilot

Valve Frequency

Valve frequency is used to drive the steering valve. The type of valve

being used determines the frequency. Range is 0.9 - 15000.1. For

recommendations and factory settings for the FieldPilot or UniPilot

setup values, see chart on page 21.

1. Press the KEYPAD icon .

2. Use the entry screen to establish the valve frequency.

Figure GS-15: Valve Frequency

Valve Frequency

1 2 3

175

Clear

4 5 6 <--

7 8 9

0 . +/-

8www.teejet.com

Assisted/Auto Steering

Minimum/Maximum Duty Cycle Tests

Minimum Duty Cycle (Minimum DC Left + Right) sets the minimum

amount of drive required to begin steering the vehicle left or right.

Range is 0.0 - 50.0. Default is 20%.

Maximum Duty Cycle sets the maximum speed that the wheels will

steer from left to right / right to left (lock to lock). Range is 25 - 100.

Default is 50%.

NOTE: A GPS signal is required for these tests.

RECOMMENDATION: Have a large area of clear space available to

perform test cycles. Vehicle speed must be between 1.0 mph

and 8.0 mph / 1.5 - 13.0 km/h (0.4 - 3.6 m/s).

WARNING: Pinch Point Hazard!

To prevent serious injury or death, avoid unsafe practice while

manually operating hydraulic steering circuits. Keep others

away and stay clear of mechanical linkage.

Figure GS-16: Duty Cycle Tests

Minimum Duty Cycle Left Test

Minimum Duty Cycle Left sets the minimum amount of drive required to

begin steering the vehicle to the left.

NOTE: If the valve frequency is set below 15 Hz (non proportional), set

the amount of drive to “25.0”. Cycle test is not necessary.

1. Press the KEYPAD icon .

2. While the vehicle is moving in a slow forward straight line motion

between 1.0 mph and 8.0 mph / 1.5 - 13.0 km/h (0.4 - 3.6 m/s),

press Test Left .

3. Press the engage/disengage switch or foot switch to activate the

test.

4. Slowly increase the duty cycle number using the UP arrow until

the vehicle begins to turn left.

5. Turn the steering wheel or press the engage/disengage switch or

foot switch to complete the test.

Figure GS-17: Minimum Duty Cycle Test

9

98-05242-ENUS R4

Matrix®Pro GS

Minimum Duty Cycle Right Test

Minimum Duty Cycle Right sets the minimum amount of drive required

to begin steering the vehicle to the right.

NOTE: If the valve frequency is set below 15 Hz (non proportional), set

the amount of drive to “25.0”. Cycle test is not necessary.

1. Press the KEYPAD icon .

2. While the vehicle is moving in a slow forward straight line motion

between 1.0 mph and 8.0 mph / 1.5 - 13.0 km/h (0.4 - 3.6 m/s),

press Test Right .

3. Press the engage/disengage switch or foot switch to activate the

test.

4. Slowly increase the duty cycle number using the UP arrow until

the vehicle begins to turn right.

5. Turn the steering wheel or press the engage/disengage switch or

foot switch to complete the test.

Figure GS-18: Minimum Duty Cycle Test

Maximum Duty Cycle Test

Maximum Duty Cycle sets the maximum speed that the wheels will

steer from lock to lock. For recommendations and factory settings for

the FieldPilot or UniPilot setup values, see chart on page 21.

NOTE: If the valve frequency is below 15 Hz (non proportional), set the

value to 100. Speed will be established during the Valve Test.

1. Press the KEYPAD icon .

2. While the vehicle is moving in a slow forward motion between 1.0

mph and 8.0 mph / 1.5 - 13.0 km/h (0.4 - 3.6 m/s), turn the wheels

all the way to the left (or right).

3. Press the RIGHT arrow (or LEFT arrow ).

4. Press the engage/disengage switch or foot switch to activate the

test. This will start a timer as well as turn the vehicle to the right (or

left).

WARNING! When using a UniPilot, the UniPilot will move the

steering wheel very quickly. Keep loose clothing, hair and

hands away from the steering wheel while preforming this test.

5. When the wheels are all the way to the right (or left), stop the test

by pressing the engage/disengage switch or foot switch. The time

displayed is the lock to lock time.

6. Repeat to perform procedure to the opposite side.

7. Compare the lock-to-lock time with the recommended time.

8. Press the UP/DOWN arrows to adjust the value.

►Lock-to-lock time is too low (turning too fast) – decrease the

value

►Lock to lock time is higher (turning too slow) – increase the value

9. Repeat until recommended lock time is achieved.

10 www.teejet.com

Assisted/Auto Steering

Figure GS-19: Maximum Duty Cycle Steering Settings

Steering Settings is used to congure Coarse Steering Adjustment,

Fine Steering Adjustment, Deadband and Lookahead settings.

1. Select Steering Settings .

2. Select from:

►Coarse Adjustment – used to select how aggressively the

vehicle maintains a guideline in Straight AB Guidance

►Fine Adjustment – used to select how aggressively the vehicle

maintains a guideline in Curved AB Guidance

►Deadband – used to set if steering is too choppy/responsive or

remains consistently off the guideline

►Lookahead – used to select the vehicle’s approach to the

guideline in Straight AB Guidance mode

Figure GS-20: Steering Settings

11

98-05242-ENUS R4

Matrix®Pro GS

Coarse Steering Adjustment

Coarse Steering Adjustment adjusts how aggressively the

vehicle maintains a guideline in Straight AB Guidance mode.

Range is 0.0 - 100.0. Default is 25.0.

1. Press:

►UP arrow if the vehicle is drifting away from the guideline or

not approaching it fast enough.

►DOWN arrow if the vehicle is oscillating rapidly or

overshooting the guideline.

Figure GS-21: Coarse Steering Adjustment

Fine Steering Adjustment

Fine Steering Adjustment adjusts how aggressively the vehicle

maintains a guideline in Curved AB Guidance mode. Range is 0.0 -

100.0. Default is 25.0.

1. Press:

►UP arrow if the vehicle drives outside of corners.

►DOWN arrow if the vehicle cuts corners.

Figure GS-22: Fine Steering Adjustment

12 www.teejet.com

Assisted/Auto Steering

Deadband

Deadband adjusts if steering is too choppy/responsive or remains

consistently off the guideline. As the value is increased, stability will

increase but so will steady state error. Range is 1 - 10. Default is 1.

1. Press:

►UP arrow if steering is too choppy or too responsive.

►DOWN arrow if the vehicle remains consistently off the

guideline.

Figure GS-23: Deadband

Lookahead

Lookahead used during Straight AB Guidance mode to

adjust the vehicle’s approach to the guideline. Fine tune the

Lookahead by conducting several approaches to the guideline.

Range is 0.0 - 10.0 seconds. Default is 4.0 seconds.

1. Press:

►UP arrow if the vehicle is overshooting the guideline when

approaching.

►DOWN arrow if the vehicle takes too long to get to the

guideline.

Figure GS-24: Lookahead

13

98-05242-ENUS R4

Matrix®Pro GS

Valve Test

The Valve Test veries if steering is directed correctly. It can also be

used to test the amount of time to steer the wheels from full left to full

right (lock to lock) for non-proportional valves.

For non-proportional valves, the amount of time for left-to-right or right-

to-left (lock to lock) will be established by mechanically adjusting oil

ow through the valve.

For a UniPilot ESM, the amount of time for left-to-right or right-to-left

(lock to lock) will be established by adjusting the Max Duty Cycle value.

For recommendations and factory settings for the FieldPilot or UniPilot

setup values, see chart on page 21.

1. Select Valve Test .

2. While the vehicle is moving in a slow forward motion, turn

the wheels all the way to the left.

3. Press RIGHT arrow .

4. Press the engage/disengage switch or foot switch to activate the

test. This will start a timer as well as turn the vehicle to the right.

WARNING! When using a UniPilot, the UniPilot will move the

steering wheel very quickly. Keep loose clothing, hair and

hands away from the steering wheel while preforming this test.

5. Press the engage/disengage switch or foot switch when the wheels

are all the way to the right. The time displayed is the lock to lock

time.

6. While the vehicle is moving in a slow forward motion, turn

the wheels all the way to the right.

7. Press LEFT arrow .

8. Press the engage/disengage switch or foot switch to activate the

test. This will start a timer as well as turn the vehicle to the left.

WARNING! When using a UniPilot, the UniPilot will move the

steering wheel very quickly. Keep loose clothing, hair and

hands away from the steering wheel while preforming this test.

9. Press the engage/disengage switch or foot switch when the wheels

are all the way to the right. The time displayed is the lock to lock

time.

10. Compare the lock-to-lock time with the recommended time.

11. Adjust the valve oil ow as needed and repeat test as needed.

Figure GS-25: Valve Test

Valve Diagnostics

The valve diagnostic test veries if the valve is operating correctly.

This test is not necessary for UniPilot.

NOTE: The diagnostic tests do not require that the vehicle is in motion.

A valid GPS signal is not required.

Figure GS-26: Valve Diagnostics

14 www.teejet.com

Assisted/Auto Steering

Steering Valve – No Master Solenoid

1. Select Valve Diagnostics .

2. Activate the Left or Right check boxes associated with the valve direction to be tested.

3. Press and hold the engage/disengage switch or foot switch for one second.

NOTE: Do not activate the Master check box.

Test Reactions

Selected

Reaction Issue

Left Master Right

None Valve is operating correctly

Wheels turn Either the left valve or right valve is stuck open

● Vehicle turns left Valve is operating correctly

● None SCM, harness or valve malfunction

● Vehicle turns right Left and right connections to valve are reversed

● Vehicle turns right Valve is operating correctly

● None SCM, harness or valve malfunction

● Vehicle turns left Left and right connections to valve are reversed

Steering Valve – With Master Solenoid

1. Select Valve Diagnostics .

2. Activate the Master check box.

3. Activate the Left or Right check boxes associated with the valve direction to be tested.

4. Press and hold the engage/disengage switch or foot switch for one second.

Test Reactions

Selected

Reaction Issue

Left Master Right

● None Valve is operating correctly

● Wheels turn Either the left valve or right valve is stuck open

● None Valve is operating correctly

● Wheels turn Master valve is stuck open

● None Valve is operating correctly

● Wheels turn Master valve is stuck open

● ● Vehicle turns left Valve is operating correctly

● ● Vehicle turns right Left and right connections to valve are reversed

● ● None SCM, harness or valve malfunction

● ● Vehicle turns right Valve is operating correctly

● ● Vehicle turns left Left and right connections to valve are reversed

● ● None SCM, harness or valve malfunction

15

98-05242-ENUS R4

Matrix®Pro GS

Options: Steering Wheel Sensor

Steering wheel sensor selects whether the sensor used to automatically

disengage FieldPilot when the steering wheel is turned is magnetic or

pressure based. Check your specic conguration to determine if a

Steering Wheel Switch Kit or a Pressure Swich is being used.

The UniPilot is not affected by this setting.

1. Select Options .

2. Press DOWN arrow to access the list of options.

3. Select:

►Magnetic

►Pressure

Figure GS-27: Options: Steering Wheel Sensor

Magnetic

Pressure

Steering Angle Sensor

Steering Angle Sensor is used establish the Steering Angle Sensor

(SAS) as the primary feedback sensor for auto steering.

1. Select Steering Angle Sensor .

2. Select if the steering angle sensor is

►Enabled

►Disabled.

3. Select from:

►Sensor Calibration – sets the turn rate when steering the vehicle

left and right

►On Line Calibration – adjusts the path of travel to the established

guideline when auto steering is tuned well and the vehicle

maintains a straight line, but the vehicle hangs off the guideline

to one side or another

Figure GS-28: Steering Angle Sensor

16 www.teejet.com

Assisted/Auto Steering

Enable/Disable Steering Angle Sensor

Set the use of a steering angle sensor to enabled or disabled.

1. Press DOWN arrow to access the list of options.

2. Select:

►Enabled

►Disabled

If Steering Angle Sensor is set to “Disabled”, all Steering Angle

Sensor capabilities and setup functions will be disabled (options

will be grayed out).

Figure GS-29: Enabled and Disabled Assisted/Auto Steering Options

Sensor Calibration

Sensor Calibration sets the turn rate when steering the

vehicle left and right. Calibration is required after the SAS is

installed.

NOTE: A GPS signal is required for this test.

RECOMMENDATION: Have a large area of clear space available to

perform test cycles. Vehicle speed must be between 1.0 mph

and 8.0 mph / 1.5 - 13.0 km/h (0.4 - 3.6 m/s).

1. Select Sensor Calibration .

2. Slowly move the vehicle in a slow forward motion so the

center two calibration boxes ll to 100%.

3. While still moving, slowly turn to the right or left until the appropriate

right or left calibration boxes are lled to 100%.

4. While still moving, slowly turn in the opposite direction until the

appropriate left or right calibration boxes are lled to 100%

5. “Calibration Successful” will appear when both left and right

calibrations have been completed.

Press Stop to cancel the calibration.

Figure GS-30: Calibrate Sensor

17

98-05242-ENUS R4

Matrix®Pro GS

On Line Calibration

On Line Calibration adjusts the path of travel to the established

guideline when auto steering is tuned well and the vehicle maintains

a straight line, but the vehicle hangs off the guideline to one side or

another.

NOTE: A GPS signal is required for this test.

RECOMMENDATION: Have a large area of clear space available

to perform a test cycle. Typical operating speed must be

maintained for at least 30 seconds.

1. Establish and/or activate a Straight AB guideline.

2. Select On Line Calibration .

3. Engage assisted/auto steering guidance on established straight AB

guideline.

4. While the vehicle is moving in a forward straight line motion at

typlical operating speed on the established guideline, press Start .

5. Allow the vehicle to drive using the Assisted/Auto Steering for

30 seconds

6. “Calibration Successful” will appear when calibration has been

completed.

Press Stop to cancel the calibration.

Figure GS-31: On Line Calibration

18 www.teejet.com

Assisted/Auto Steering

TILT CORRECTION

When a Steering Control Module (SCM) or Tilt Gyro Module (TGM)

is present, Tilt Correction options will be available. The Tilt function

corrects the GPS signal to compensate for errors in the GPS position

while operating on sloped terrain.

NOTE: A mistake in the calibration process that results in a 1 degree

error in the Tilt reading from the SCM/TGM will result in a

2.0 in. / 5.1 cm error in guidance [on a machine that has

9.5 ft. / 2.9 m antenna height]. This potential error necessitates

that all reasonable care is taken to ensure that the system is

installed and calibrated correctly in order to produce accurate

Tilt measurement and machine guidance.

1. Press CONFIGURATION side tab .

2. Press Tilt Correction .

3. Select if Tilt Correction is enabled or disabled.

4. When enabled, select Field Level to calibrate tilt correction

5. Press RETURN arrow or CONFIGURATION side tab to

return to the main Conguration screen.

NOTE: If FieldPilot or UniPilot is being used, a Tilt Gyro Module is built

into the system.

NOTE: Antenna Height must be entered prior to Field Level procedure.

Figure GS-32: Tilt Correction

Field Level Unavailable

If the vehicle is in motion, the eld level option will not be available.

Vehicle must be stopped for at least 10 seconds to begin to calibrate tilt

correction.

Tilt Correction Unavailable

If a TGM or SCM is not connected, setup options will not be available.

Figure GS-33: Tilt Correction Not Detected

Enable/Disable Tilt

Set Tilt option to enable or disable.

1. Press DOWN arrow to access the list of options.

2. Select:

►Enable

►Disable

NOTE: When tilt is enabled and the vehicle is in motion, Field Level

will not be available. Vehicle must be stopped for at least

10 seconds to begin to calibrate tilt correction.

Figure GS-34: Tilt Enable/Disable

If tilt correction is set to “Disable”, eld leveling capabilities will be

disabled (option will be grayed out).

This manual suits for next models

1

Table of contents

Other TeeJet Technologies Car Navigation System manuals

Popular Car Navigation System manuals by other brands

Garmin

Garmin nuvi 205W Series Quick start manual

Kenwood

Kenwood DNX570TR quick start guide

Volkswagen

Volkswagen 1999 Radio Navigation System operating instructions

Magellan

Magellan Magellan eXplorist 300 Manual de referencia

Hyundai

Hyundai Elantra 2018 Getting started

Toyota

Toyota RAV4 2009 Quick reference guide