TeeJet Technologies DynaJet Flex Series User manual

DYNAJET® FLEX

INSTALLATION, SETUP AND USER GUIDE

Software version 1.02

with optional high ow option

Copyrights

© 2016 TeeJet Technologies. All rights reserved. No part of this document or the computer programs described in it may be reproduced, copied, photocopied, translated, or

reduced in any form or by any means, electronic or machine readable, recording or otherwise, without prior written consent from TeeJet Technologies.

Trademarks

Unless otherwise noted, all other brand or product names are trademarks or registered trademarks of their respective companies or organizations.

Limitation of Liability

TEEJET TECHNOLOGIES PROVIDES THIS MATERIAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR IMPLIED. NO COPYRIGHT LIABILITY

OR PATENT IS ASSUMED. IN NO EVENT SHALL TEEJET TECHNOLOGIES BE LIABLE FOR ANY LOSS OF BUSINESS, LOSS OF PROFIT, LOSS OF USE OR DATA,

INTERRUPTION OF BUSINESS, OR FOR INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND, EVEN IF TEEJET TECHNOLOGIES HAS

BEEN ADVISED OF SUCH DAMAGES ARISING FROM TEEJET TECHNOLOGIES SOFTWARE.

Table of Contents

DYNAJET® FLEX OVERVIEW 1

INSTALLATION 1

CONSOLE 1

INSTALLATION – STANDARD MODE 3

DynaJet® drivers .............................................................................................................................................................................................3

Power ..................................................................................................................................................................................................................3

Nozzle harnesses ............................................................................................................................................................................................3

Pressure sensor interface kit.......................................................................................................................................................................4

Boom interface module (BIM)....................................................................................................................................................................4

DynaJet® interface..........................................................................................................................................................................................4

CAN cables and terminators.......................................................................................................................................................................4

INSTALLATION – HIGH FLOW MODE 5

DynaJet® interface and drivers ..................................................................................................................................................................5

Connect terminators .....................................................................................................................................................................................5

Nozzle harnesses ............................................................................................................................................................................................5

Connect can cables to drivers....................................................................................................................................................................5

Driver battery cables .....................................................................................................................................................................................5

Boom harnesses..............................................................................................................................................................................................5

Pressure sensor................................................................................................................................................................................................5

DynaJet® 7120 console.................................................................................................................................................................................5

Other battery cable........................................................................................................................................................................................5

INITIAL STARTUP 8

Favorites.............................................................................................................................................................................................................8

Setup...................................................................................................................................................................................................................8

Units.........................................................................................................................................................................................9

Number of sections..................................................................................................................................................................9

Maximum pressure sensor value.............................................................................................................................................9

Nozzle selection ..............................................................................................................................................................................................9

Select nozzle series.........................................................................................................................................................9

Select nozzle capacity .....................................................................................................................................................9

Ready to pressure test the system......................................................................................................................................................... 10

Work screen ................................................................................................................................................................................................... 10

On screen indicators..............................................................................................................................................................10

Droplet size chart...........................................................................................................................................................10

USER SETTINGS 11

OEM settings ................................................................................................................................................................................................. 13

Enable/disable options...........................................................................................................................................................13

TUNING DYNAJET® 13

DYNAJET® NOZZLE SELECTION 14

Nozzle selection example......................................................................................................................................................................... 15

55295 E-CHEMSAVER® MAINTENANCE INSTRUCTIONS 16

General disassembly and reassembly.................................................................................................................................................. 16

APPLICATION RATES AT GIVEN SPEED 17

1www.teejet.com

DynaJet®Flex

DYNAJET® FLEX OVERVIEW

The DynaJet Flex controller works in conjunction with an existing rate controller that regulates ow via a control valve or pump regulation to

achieve a target application rate while maintaining target droplet size(s) when a speed change occurs. This system only works with automatic

rate controllers that use ow based monitoring systems and not pressure based monitoring systems. Automatic rate controllers equipped for

both ow and pressure based control should have the pressure-based system disabled to work in conjunction with DynaJet Flex.

The independent automatic rate controller loop performs the same as it would if the DynaJet controller were not present. The DynaJet Flex

controller changes ow output to each individual nozzle based upon input provided from the operator about the optimum droplet size

(pressure) for the application.

INSTALLATION

CONSOLE

The DynaJet Flex console is designed to provide years of service under typical agricultural and turf operating conditions. A tight tting

enclosure means that typical dusty environments will not cause operational problems. While occasional splashing of water will not damage

the unit, the DynaJet Flex console is not designed for direct exposure to rain. Take care not to operate the DynaJet Flex console in wet

conditions.

Figure 1: DynaJet Flex 7120 console front and back

to DynaJet interface

harness connection

Power switch

USB port

Standard RAM bracket

Bright touch screen

Safety information

TeeJet Technologies is not responsible for damage or physical harm caused by failure to adhere to the following safety

requirements.

As the operator of the vehicle, you are responsible for its safe operation.

The DynaJet Flex is not designed to replace the vehicle’s operator.

Be sure that the area around the vehicle is clear of people and obstacles before and during engagement.

The DynaJet Flex is designed to support and improve efciency while working in the eld. The driver has full responsibility for the quality and

work related results.

2

98-05334-EN R2

DynaJet®Flex

Figure 3: System diagram - standard mode

90-02887 - DynaJet 7120 Console w/RAM Mount Kit

Kit includes: Console and Mount

45-10148 - Sentry Interface Harness

78-05091 - Boom Interface Module (BIM)

78-05106 - DynaJet Interface

45-05963 - CAN Bulkhead Cable

45-05965 - CAN to Bulkhead Cable

DynaJet Pressure Sensor Interface Kit

Kit includes: Interface, Sensor Cable, and Pressure Sensor

90-04007: 3 m

90-04008: 10 m

78-05122 - DynaJet Driver

45-05855 - CA

N Terminator, Female (Start)

35-50048 - DynaJet Solenoid

45-05943 - Battery 60 AMP Fuse Cable

78-05121-xx - Power Distribution Module

45-05971-xx - Driver to Power Extension Cable

45-05980-xx -

Driver to Power

“Y” Cable45-05942-xx - 6 Gauge Power Extension Cable

45-10142 - BIM Harness

401-0016 - Power Cable

45-05936-xx - Tip Harness Ext

ension

45-05948-xx - Solenoid Extension Cable

45-05935-20-xx -

Tip Harness

to 12V Power

Boom Sense Wires

Sensor Cable

Pressure Sensor

to Battery Power

45-05856 - CAN Terminator, Male (End)

Console Extension Cable

45-05900: 1.5 m

45-05901: 3 m

45-05902: 6 m

45-05903: 12 m

45-058xx - CAN Extension Cable

Interface LED - Flashes until

CAN message is received,

then on steady

3www.teejet.com

DynaJet®Flex

CAN Start Terminator

(female)

at Boom Section 1

DynaJet Solenoids

to CAN connection

DynaJet Solenoids

Power Distribution Module

Nozzle Harness

DynaJet Driver

DynaJet Solenoids DynaJet Solenoids

Nozzle Harness

DynaJet Driver

DynaJet Solenoids DynaJet Solenoids

Nozzle Harness

DynaJet Driver

DynaJet Solenoids DynaJet Solenoids

Nozzle Harness

DynaJet Driver

INSTALLATION – STANDARD MODE

DynaJet® drivers

There will be one DynaJet driver 78-05122 per boom section with a

limit of 20 nozzles per section.

• Mount them so they are at the end of each section that is

closest to the middle of the boom.

Power

Power will be sourced from the battery using the 60 amp fused cable

45-05943.

Power from the battery will be routed to the boom using the 6 gauge

power cables 45-05942-xx

The power distribution modules 78-05121-xx will connect to the

45-05942-xx cables.

Power will then route from 78-05121-xx to each DynaJet driver

78-05122 using cables 45-05971-xx.

Figure 2: Installation diagram - standard mode

Nozzle harnesses

When installing nozzle harnesses 45-05935-xx-xx always start with

section 1 and continue to the last section.

Each section will require nozzle harnesses designed for your specic

nozzle spacing and number of nozzles.

• Nozzle harnesses are built with an even number of outputs.

• Some sections will use more than one harness to equal the

number of nozzles in that section.

The yellow and white solenoid cables on the nozzle harnesses must

alternate across the entire boom. When sections have odd numbers

of nozzles then accounting for the altering can be accomplished

one of two ways:

A. By crossing the two solenoid cables

B. By installing nozzle harness reversing adapters 45-05952

4

98-05334-EN R2

DynaJet®Flex

CAN Start Terminator

(female)

at Boom Section 1

DynaJet Solenoids

to CAN connection

DynaJet Solenoids

Power Distribution Module

Nozzle Harness

DynaJet Driver

DynaJet Solenoids DynaJet Solenoids

Nozzle Harness

DynaJet Driver

DynaJet Solenoids DynaJet Solenoids

Nozzle Harness

DynaJet Driver

DynaJet Solenoids DynaJet Solenoids

Nozzle Harness

DynaJet Driver

Pressure sensor interface kit

The DynaJet system requires pressure sensor interface kit 90-04007

or 98-04008 to be installed.

• The pressure sensor interface kit should be mounted close to

the boom manifold.

Boom interface module (BIM)

The boom interface module (BIM) 78-05091 is used by the DynaJet

system for boom sense.

The BIM harness connects between the BIM and the can.

On the BIM harness 45-10142, the boom sense wires (or ying

leads) are supplied to tie into existing machine boom section

12V on/0V off outputs.

If not using 45-10142, some machine specic harnesses are

available.

The BIM can be mounted in the cab or outside depending upon your

installation.

DynaJet® interface

The DynaJet interface 78-05106 connects to the Sentry interface

harness 45-10148:

The Sentry interface harness connects to

A. The console 75-30119 (extension cable may be used)

B. Power 12V for powering the CAN

C. CAN

The DynaJet interface can be mounted in the cab or outside

depending upon your installation.

CAN cables and terminators

The start terminator 45-05855 must be connected to the DynaJet

driver 78-05122 for section 1.

Can cables must be connected in series:

A. To each DynaJet driver 78-05122

B. To the boom interface module 78-05091 (via BIM harness

45-10142)

C. To the DynaJet interface 78-05106 (via sentry interface

harness 45-10148)

D. To the pressure sensor interface kit (via pressure interface

78-05110)

The end terminator 45-05856 must be connected to the driver

module 78-05122 for the last section.

5www.teejet.com

DynaJet®Flex

INSTALLATION – HIGH FLOW MODE

The following illustration and steps are only a guideline of an installation based on a specic vehicle conguration. Installations on

other vehicles may vary. If there are questions concerning the installation of the DynaJet Flex system on this vehicle, or due to the

changes in component specications the parts supplied in the kit are not exactly as presented in this document, please contact

your dealer or TeeJet customer service representative for clarication before installation. TeeJet technologies is not responsible for misuse or

incorrect installation of the system.

DynaJet® interface and drivers

Step 1a – mount the (F) DynaJet HF drivers 78-05124 onto brackets, one for each boom section.

Step 1b – mount the (D) DynaJet HF interface 78-05123, connecting to the (C) DynaJet interface harness 45-10177, and (H) boom harness

45-10178.

Connect terminators

Step 2a – connect the (I) start terminator 45-05855 to (K) 4 nozzle harness (1-4) 45-10174, rst section.

Step 2b – connect the (J) end terminator 45-05856 to (M) 4 nozzle harness (9-12) 45-10176, last section.

Nozzle harnesses

Step 3 – install nozzle harness (K) 4 nozzle harness (1-4) 45-10174, (L) 4 nozzle harness (5-8) 45-10175, and (M) 4 nozzle harness (9-12)

45-10176. Each harness features two solenoid connections per nozzle body, supporting (4) nozzle bodies in total.

Note: specific section breakdown may vary by installation

Connect can cables to drivers

Step 4 – using the (E) can extension cables, connect the (I) DynaJet HF drivers 45-05124 to the (D) DynaJet HF interface 78-05123.

Driver battery cables

Step 5 – connect the battery cable 45-05987 to the three (3) (F) DynaJet HF drivers 78-05124, and to the battery.

Boom harnesses

Step 6 – install the (H) boom harnesses 45-10178, 45-10179, or 45-10181 connecting to the (D) DynaJet HF interface 78-05123.

Pressure sensor

Step 7 – connect the boom pressure sensor 0-10 bar to the (C) DynaJet HF interface harness 45-10177. The pressure sensor interface kit

should be mounted close to the boom manifold

DynaJet® 7120 console

Step 8 – connect the (A) DynaJet 7120 console 90-02887 to the (C) DynaJet HF interface harness 45-10177 via console extension cables.

Other battery cable

Step 9 – connect 401-0012 to the battery and route leads as needed.

6

98-05334-EN R2

DynaJet®Flex

Figure 4: System diagram - high flow mode

(H) Boom Harness

45-10178 to IC18

45-10179 to Raven 440

45-10181 to Raven Envizio

(F)

78-05124

DynaJet HF Driver

(D) 78-05123

DynaJet HF Interface

(C) 45-10177

DynaJet Interface Harness

(M) 45-10176

4 Nozzle Harness 9-12

(L) 45-10175

4 Nozzle Harness 5-8

(K) 45-10174

4 Nozzle Harness 1-4

(A) 90-02887 - DynaJet 7120 Console w/RAM Mount Kit

Kit includes: Console and Mount

Sensor Cable

Pressure Sensor

(I)

45-05855

CAN Terminator,

Female (Start)

to Battery Power

to Battery Power

to Battery Power to Battery

(J) 45-05856

CAN Term

inator,

Male (End)

(B) Console Extension Cables

45-05900: 1.5 m

45-05901: 3 m

45-05902: 6 m

45-05903: 12 m

(E) 45-058xx

CAN Extension Cable

(G) DynaJet Pressure Sensor Interface Kit

Kit includes: Sensor Cable and Pressure Sensor

90-04007: 3 m

90-04008: 10 m

7www.teejet.com

DynaJet®Flex

Item Part # Description Illustration

A90-02887 DynaJet 7120 console

B45-05900: 1.5 m

45-05901: 3 m

45-05902: 6 m

45-05903: 12 m

Console extension cable

C45-10177 DynaJet interface harness

D78-05123 DynaJet HF interface

E45-05857: 1 m

45-05858: 2 m

45-05859: 4 m

45-05864: 10.5 m

CAN extension cable

F78-05124 DynaJet HF driver

G90-04007: 3 m

90-04008: 10 m

DynaJet pressure sensor interface kit

H45-10178 to IC18

45-10179 to Raven 440

45-10181 to Raven Envizio

Boom harness

I45-05855 CAN terminator, female (start)

J45-05856 CAN terminator, male (end)

K45-10174 4 Nozzle harness 1-4

L45-10175 4 Nozzle harness 5-8

M45-10176 4 Nozzle harness 9-12

8

98-05334-EN R2

DynaJet®Flex

INITIAL STARTUP

This section will explain basic setup of the values required for rst-time setup of a DynaJet Flex system.

When these settings are completed, initial operation and ne-tuning should be possible.

To access setup menu from the work screen, touch center of the screen.

1. Select from:

►Favorites – the FAVORITE icon represents favorite spray

nozzles. This function automatically stores the most recent

ve (5) nozzles chosen. Use this to quickly access your most

frequently used spray nozzles.

►Setup – the SETUP icon is used to access settings. This

will enter the conguration menu.

►Nozzle selection – the SPRAY NOZZLE icon is used to

select the spray nozzle style and capacity. Once chosen here,

the spray nozzle style and capacity is automatically added to

the favorites list.

2. Press HOME icon to return to the main work screen.

Figure 5: Options menu

Favorites

The favorite icon represents favorite spray nozzles. This

function automatically stores the most recent ve (5) nozzles

chosen. Use this to quickly access your most frequently used spray

nozzles.

Figure 6: Favorites

Work

screen

Setup

The setup icon is used to access settings. This will enter the

conguration menu. Selections are automatically saved when

adjusted.

Note: Not all settings are listed below. See “User settings” section

of this guide for additional settings and details.

Figure 7: Setup

Previous

page

Next

page

Change value

Work

screen

9www.teejet.com

DynaJet®Flex

Units

Sets the units to us (PSI) or metric (bar)

Figure 8: Units

Number of sections

Set the number of boom sections. This should match the number of

sections used on the spray controller. Range is 1 to 15.

Figure 9: Number of sections

Maximum pressure sensor value

Verify this value by looking at the pressure sensor description.

Values will be either 10 bar or 25 bar.

If pressure value displayed on the DynaJet Flex console are not

accurate compared to a mechanical gauge, adjust this value until

there is a match.

►Increasing the value will reduce the pressure value displayed

during operation

►Decreasing this value will increase the pressure value

displayed during operation

Figure 10: Maximum pressure sensor value

Nozzle selection

Accesses the nozzle selection process to select which nozzle

is to be used. At this time only TeeJet nozzles are supported.

Figure 11: Nozzle selection

Select nozzle series

Use the green up and down arrows to highlight the correct spray

nozzle series/family.

Figure 12: Select nozzle series

Select nozzle capacity

With the correct nozzle capacity highlighted, select the

HOME icon to return to operating mode. The selected nozzle will

be active and will automatically be added to the favorites list.

Figure 13: Select nozzle capacity

10

98-05334-EN R2

DynaJet®Flex

Ready to pressure test the system

1. Ensure that current rate control system is operating at the

optimum level. Set DynaJet operating mode to manual and set

PWM duty cycle at 100%. This will make the system operate as if

DynaJet was not present. Use this conguration to verify the rate

control system is operating normally.

2. Keep DynaJet operating mode on manual and change PWM

duty cycle to 50%. Use this conguration to verify the rate control

system is operating normally.

3. Conrm boom section functionality by observing the row of

rectangles below the on the operating display.

4. Switch the master switch ON (on rate control or other boom

section control switches) and individual sections one at a time

Make sure each section appropriately changes colour to blue.

With the master switch off, all active sections will be grey again.

5. Start pump and ensure no leaks.

6. Verify pressure on mechanical gauge matches the digital

pressure display within reason. If not, adjust maximum pressure

sensor value as previously described.

7. Congure in PWM mode DynaJet at duty cycle of 50%. Conrm

each e-ChemSaver (ECS) is pulsating.

At this point the system is functioning. Further details for ne-tuning

the system are available in the user settings section of this guide.

Work screen

On screen indicators

Current droplet size – displays the current droplet size using both the

appropriate colour droplet icon and size letter code.

PWM duty cycle – displays the current PWM duty cycle as a

percentage.

Active solenoid (high ow mode only) – displays if one or both sets of

solenoid are active.

Actual pressure – displays the actual pressure.

Current nozzle selection – displays the current selected nozzle.

Boom status

►Blue – turned on (standard mode or high ow mode single

solenoid active)

►Green – turned on (high ow mode both solenoids active)

►Empty – turned off

Pressure gauge

►Red diamond – actual pressure

►Colors – droplet size,

Operation modes

►Nozzle mode (pressure) – when the user changes the desired

drop sizes choices (via the droplet size selectors checkboxes)

the system will recalculate the desired pressure. It will then

adjust the PWM duty cycle to attempt to attain the desired

pressure in the system.

►Manual mode (PWM) – the user can manually adjust the

PWM duty cycle to attempt to attain the desired pressure in

the system.

Droplet size selectors

►Red X and greyed out – not selected

High ow mode

►Single – one set of solenoids active

►Dual – both sets of solenoids active

Droplet size chart

When choosing a spray nozzle that produces droplet sizes in one

of the eight droplet size classication categories, it is important to

remember that a single nozzle can produce different droplet size

classications at different pressures. A nozzle might produce medium

droplets at low pressures, while producing ne droplets as pressure

is increased.

Category Symbol Color code

Extremely ne XF Violet

Very ne VF Red

Fine F Orange

Medium M Yellow

Coarse C Blue

Very coarse VC Green

Extremely coarse XC White

Ultra coarse UC Black

11 www.teejet.com

DynaJet®Flex

Figure 14: Work screen - standard mode

Droplet size selectors

(nozzle mode)

Current nozzle

selection

Pressure gauge

Boom status

Manual mode

(PWM)

PWM duty cycle Actual pressure

Nozzle mode

(Pressure)

Current droplet size

Figure 15: Work screen - high flow mode single

Manual adjustment

(manual mode)

High fow mode

single solenoid

Active solenoid

Figure 16: Work screen - high flow mode dual

Manual adjustment

(manual mode)

High ow mode

dual solenoid

Active solenoids

USER SETTINGS

If there are questions concerning the setup of the

DynaJet Flex, please contact your dealer or TeeJet customer

service representative for clarication before operation. TeeJet

technologies is not responsible for misuse or incorrect operation of

the system.

Setup is used to congure units, display brightness, key beep,

number of sections, boom section on/off beep, maximum pressure

sensor value, minimum duty cycle, control hold delay, ne gain,

coarse gain, and coarse gain on/off.

Display brightness

Sets the brightness level of the display. Range is 5% to 100% in 5%

increments.

Units

Sets the units to us (PSI) or metric (bar).

Key beep

Enable/disable all beeping from console.

Number of sections

Set the number of boom sections. Range is 1 to 15.

12

98-05334-EN R2

DynaJet®Flex

Number of nozzles (high ow mode only)

Set the number of nozzle locations for each boom section.

Range is 1 to 120.

Section number

Number of nozzle locations

Boom section on/off beep

Enable/disable beep when a boom section is turned on or off.

Maximum pressure sensor

Sets the value from the pressure sensor description. Either 10 bar or

25 bar.

Minimum duty cycle

Sets the minimum duty cycle to which the DynaJet will control.

Default is 30%, minimum is 20%.

Higher values reduce the overall control range of the system.

Control hold delay

When any boom switch changes state, DynaJet Flex will not make

control adjustments for the specied time period. Range is 0.0 to

10.0 seconds. Default is 1.0 second.

Fine gain

Allows the control system to make minor adjustments when close to

the target, with the goal of stable pressures and minimal overshoot of

target. Range is 0 to 100. Default is 30.

Fine gain settings are 1/10 as powerful gain as coarse gain settings.

Coarse gain

This is the more aggressive gain setting and will have the largest

impact on the stability and function of the DynaJet Flex system.

Coarse gain makes major adjustments to duty cycle to attempt to

bring actual pressure back to the target. A coarse gain setting that is

too high will result in pressure oscillation. Range is 1 to 100. Default

is 5.

Coarse gain on

This setting determines the threshold at which coarse gain becomes

active. Value is shown in the pressure units previously chosen.

Range is 0.07 To 1.38 bar.

For example, if operating in bar units with a setting of 0.48; coarse

gain becomes active when actual pressure is 0.48 or more bar

away from the target value. Increasing this value makes the coarse

setting in effect less of the time (higher value means higher tolerance

between actual pressure and target pressure). Decreasing this value

means coarse regulation is active more frequently. Setting coarse

gain on too high would disable the feature. Decreasing this value too

much will result in pressure oscillations.

13 www.teejet.com

DynaJet®Flex

Coarse gain off

This setting determines the threshold at which coarse regulation is

switched off and ne regulation takes over. Value is shown in the

pressure units previously chosen. Range is 0.07 to 1.38 bar.

This value must be lower than coarse gain on. For example, if

operating in bar units and with a setting of 0.28; coarse regulation will

be switched off (and ne gain becomes active) when the difference

between target and actual pressure is 0.28 bar or less. Regulation

will remain in ne until the error reaches the coarse gain on value

described above.

OEM settings

The settings described below are engineering and development

values used in development of the DynaJet Flex system. Do not

alter these settings unless directed by TeeJet Technologies support

personnel.

Setting Description Default Value

PWM frequency 10 Hz

On pulse duration 38

Hold current frequency 10 counts

Hold current duty cycle 5 counts

Phase offset 128 counts

Jump point 0.35 bar.

Maximum duty cycle 80% (all ON above this value)

PWM off time 0 counts

Enable/disable options

To enter the OEM setup:

1. Press the TeeJet logo 3 times within the rst three seconds of

the splash screen being displayed. The console will beep to

acknowledge the OEM option has been activated.

Figure 17: OEM setup

TUNING DYNAJET®

1. Identify the speed range, rate range and system pressures for

the application. Ensure the operating conditions are compatible

with the nozzle capacity, speeds and duty cycles shown in the

TeeJet PWM nozzle selection guide.

2. Using the identied speed range based on nozzle selection use

the rate controllers test speed or simulated speed to target a

desired application rate and droplet size.

3. Fine tune the regulation performance of the rate control system

and the DynaJet system.

a. Typical settings used for DynaJet ne-tuning include ne gain,

coarse gain, coarse gain on and coarse gain off.

b. Coarse gain on must be a higher value than coarse gain off. A

good starting point for coarse gain on is a pressure value that

is about 35-40% of the target pressure.

c. Coarse gain off value is typically is about 25% of the target

pressure, or 0.3 - 0.6 bar lower than coarse gain on.

d. Coarse gain on and coarse gain % are used to make major

adjustments to pressure regulation. Once coarse gain has

brought pressure near target; coarse gain off and ne gain will

inuence the smaller adjustments.

e. Coarse gain should be increased if large pressure

adjustments need to be made more quickly.

f. Fine gain should be decreased if actual pressure constantly

moves across the target pressure.

DynaJet and the existing rate controller are two control systems

that must coexist. Because DynaJet is a second control device that

is installed on the same liquid system, users should be prepared to

adjust the rate controller regulation settings to harmonize the two

system. For example, if subtle changes in duty cycle on DynaJet

induce noticeable rate or pressure oscillations, the rate control

regulation gain settings may need to be reduced. Placing the rate

control system in manual regulation mode during the tuning process

will help determine if oscillations are being caused by the DynaJet or

by the rate controller.

TeeJet control systems like 844E, 854 or Radion will typically perform

better with DynaJet when their coarse and ne regulating speeds are

reduced by 2-3 units.

General rule of thumb under normal operating conditions for ow rate

changes; DynaJet in combination with the rate controller should have

rate/pressure stabilized in ~ 2-3 seconds.

14

98-05334-EN R2

DynaJet®Flex

DYNAJET® NOZZLE SELECTION

Selection of the proper spray nozzle for use with the DynaJet system is much like selecting the spray nozzle for a traditional spraying operation.

Along with the extra application exibility, DynaJet brings a few other nozzle-related considerations that will be summarized below.

1. Duty cycle

a. DynaJet Flex controls nozzle ow rate by varying the portion of time that each nozzle is ‘on’ vs. ‘off’. The on time is referred to as duty

cycle. The range of duty cycle available is typically 30% to 100%, meaning that the nozzles on the machine will have approximately 30% to

100% of their rated ow capacity.

b. With the DynaJet system:

• Standard mode Spray Nozzle Flow Capacity = Spray Nozzle Size x Duty Cycle

• High ow mode Spray Nozzle Flow Capacity = Spray Nozzle Size x Duty Cycle x 2

c. By varying the duty cycle, the DynaJet Flex is essentially varying spray nozzle capacity on the y. When more pressure is required, the

nozzle capacity (duty cycle) is reduced. When higher nozzle capacity is required, the duty cycle is increased.

d. Although the operator has a much more exible and forgiving application system with DynaJet, care should be taken to select spray

nozzles that give the best possible results.

e. When selecting a spray nozzle, review the DynaJet nozzle selection charts and select a spray nozzle capacity that produces the

target application rate at a duty cycle of about 70% when running at expected travel speeds. In other words, choose nozzle capacity

and desired pressure/droplet size closer to the high end of the speed (or rate) range than to the lower end. This will provide plenty of

adjustment range for DynaJet to reduce duty cycle when travel speed slows, while also providing additional capacity if travel speed

increases above the planned speed.

• The default setting for minimum duty cycle is 30%. This means the system will not adjust the duty cycle below 30% ‘on’. While this

setting can be set as low as 20% by the operator, the higher default value provides a more uniform application at lower speeds.

2. Spray nozzle selection

a. The DynaJet system is not compatible with air inducted spray nozzles. Be sure to select a conventional spray nozzle for use with the

system. The recommended options are XR TeeJet, DG TeeJet, Turbo TwinJet and Turbo TeeJet.

b. Different nozzle styles have different droplet size characteristics across the range of operating pressures. The spray nozzle style

should be selected based on the desired droplet size at the pressures expected to be in use for your application.

c. Always use spray nozzles with 110° (or wider) spray pattern. These spray nozzle part numbers will typically include the 110 in their

name – for example TT11006vp or XR11006-VS. 80° spray nozzles are not recommended with DynaJet.

3. Spray height

a. In order to achieve the best possible spray coverage, make sure to keep spray height at or above 20″ from the nozzle to the target.

15 www.teejet.com

DynaJet®Flex

Nozzle selection example

These columns show ow rates at various

pressures. The Delta P represents pressure loss

through the DynaJet solenoid valve, and the

resulting Nozzle bar and Flow show actual values

at the spray nozzle.

These columns show droplet sizes

for different styles of spray nozzle at

given pressures. Use these columns

to choose the best nozzle style for

your application.

Just like a normal nozzle chart, these columns show rates

available at given speeds. The only difference is the range of

values that corresponds to the range of ows available with

DynaJet Flex.

1.51.680.2 1.31.54 VC XC 92 to 308 69 to 231 55 to 185 46 to 154

21.940.3 1.71.80 VC XC 108 to 360 81 to 270 65 to 216 54 to 180

32.370.4 2.62.21 VC C 133 to 442 99 to 332 80 to 265 66 to 221

42.740.5 3.52.57 CC

154 to 514 116 to 386 93 to 30877 to 257

53.060.6 4.42.88 CC

173 to 576 130 to 432 104 to 34686 to 288

63.350.7 5.33.16M C190 to 632 142 to 474 114 to 37995 to 316

73.620.8 6.23.42M C205 to 684 154 to 513 123 to 410 103 to 342

Nozzle spacing 50 cm

Minimum duty cycle 30%

Nozzle

number

Nozzle

11006

TT TJ60 TTJ60

XR XRC (50)

Rated

l/min Pressure

(bar)

Flow

(l/min) l/ha l/ha

TTJ60TT

ΔP

l/ha l/ha

Gauge

pressure

(bar)

6 km/h 8 km/h 10 km/h12 km/h

If the operator wants to apply 120 l/ha at 10 km/h, he would look in the 10 km/h column, and nd the row that shows 120 l/ha with room above and below to compensate for

higher and lower speeds that may be experienced in the eld. In this case a TT11006 at 3-4 bar will work very well.

1.51.680.2 1.31.54 VC XC 92 to 308 69 to 231 55 to 185 46 to 154

21.940.3 1.71.80 VC XC 108 to 360 81 to 270 65 to 216 54 to 180

32.370.4 2.62.21 VC C 133 to 442 99 to 332 80 to 265 66 to 221

42.740.5 3.52.57 CC

154 to 514 116 to 386 93 to 30877 to 257

53.060.6 4.42.88 CC

173 to 576 130 to 432 104 to 34686 to 288

63.350.7 5.33.16M C190 to 632 142 to 474 114 to 37995 to 316

73.620.8 6.23.42M C205 to 684 154 to 513 123 to 410 103 to 342

Nozzle spacing 50 cm

Minimum duty cycle 30%

Nozzle

number

Nozzle

11006

TT TJ60 TTJ60

XR XRC (50)

Rated

l/min Pressure

(bar)

Flow

(l/min) l/ha l/ha

TTJ60TT

ΔP

l/ha l/ha

Gauge

pressure

(bar)

6 km/h 8 km/h 10 km/h12 km/h

The next consideration is droplet size. The chart shows that a Turbo TeeJet (TT) nozzle will give Very Coarse (VC) droplets in this pressure range, and a Turbo TwinJet

(TTJ60) will give Coarse (C) droplets. The benet of the TT is that the operator could select droplets from VC to M all at the same rate and speed.

1.51.680.2 1.31.54 VC XC 92 to 308 69 to 231 55 to 185 46 to 154

21.940.3 1.71.80 VC XC 108 to 360 81 to 270 65 to 216 54 to 180

32.370.4 2.62.21 VC C 133 to 442 99 to 332 80 to 265 66 to 221

42.740.5 3.52.57 CC

154 to 514 116 to 386 93 to 30877 to 257

53.060.6 4.42.88 CC

173 to 576 130 to 432 104 to 34686 to 288

63.350.7 5.33.16M C190 to 632 142 to 474 114 to 37995 to 316

73.620.8 6.23.42M C205 to 684 154 to 513 123 to 410 103 to 342

Nozzle spacing 50 cm

Minimum duty cycle 30%

Nozzle

number

Nozzle

11006

TT TJ60 TTJ60

XR XRC (50)

Rated

l/min Pressure

(bar)

Flow

(l/min) l/ha l/ha

TTJ60TT

ΔP

l/ha l/ha

Gauge

pressure

(bar)

6 km/h 8 km/h 10 km/h12 km/h

16

98-05334-EN R2

DynaJet®Flex

55295 E-CHEMSAVER® MAINTENANCE INSTRUCTIONS

The 55295 e-ChemSaver is a solenoid-actuated shutoff compatible with a wide range of TeeJet nozzle bodies equipped with a diaphragm

check valve. It can be used for end-of-boom nozzles as well as individual nozzle shutoff and PWM controls.

The valve is normally closed and opens when the solenoid is energized. The 55295 has a 2-pin MetriPack connector molded into the body for

a clean, weather-tight electrical connection.

General disassembly and reassembly

Note: O-rings (8, 9, 10) should be handled with care as they can be damaged/deformed

1. Loosen and remove the nylon nut (4) and stainless steel washer (5)

2. Separate the coil assembly (1) from the rest of the tube/plunger assembly (2, 3, 6-11)

3. Remove the locking ring (11)

4. Using pliers to grip the stainless steel interface cap (7), loosen the tube sub-assembly (2) using a 14 mm or adjustable wrench. Note a

low-prole 14 mm wrench is available from TeeJet using part number 97-00067.

All repairable parts should be accessible

at this point. The plunger sub-assembly

(3), stainless steel spring (6), and O-rings

(8, 9, 10) can be replaced without further

disassembly

5. During reassembly, place the plunger

sub-assembly (3) and stainless steel

spring (6) in the tube sub-assembly (2)

NOTE: the plunger sub-assembly

(3) should be oriented with the black

insert facing outward (visible) when

placed in the tube sub-assembly (2)

6. While compressing the spring (6), thread

the tube/plunger assembly (2, 3, 6-11) to

the stainless steel interface cap (7) and

tighten using a wrench and pliers

Optional: apply 1 drop of

Loctite Blue 243 to the threads of

the interface cap (7) and tube sub-

assembly (2)

Torque specifications: tighten

interface cap (7) and tube sub-

assembly (2) to 12 in-lbs (1.36 N-m)

7. Return the locking ring (11) to its original

position and slide the tube/plunger

assembly (2, 3, 6-11) through the coil

assembly (1)

NOTE: the coil assembly (1) should

be oriented with the MetriPack

connectors facing away from the

interface cap (7)

8. Place the stainless steel washer (5)

above the coil assembly (1) and tighten

the nylon nut (4) to the tube/plunger

assembly (2, 3, 6-11)

17 www.teejet.com

DynaJet®Flex

APPLICATION RATES AT GIVEN SPEED

Figure 18: Metric - standard mode

30%

1.51.120.1 1.41.07M VC -VC -77 to 257 64 to 214 48 to 16139 to 128 32 to 107 28 to 92 24 to 80 21 to 71 19 to 64

21.290.2 1.81.24M CFCC89 to 29874 to 248 56 to 186 45 to 14937 to 12432 to 106 28 to 93 25 to 83 22 to 74

31.580.2 2.81.52F CFCM109 to 365 91 to 304 68 to 22855 to 182 46 to 152 39 to 130 34 to 11430 to 10127 to 91

41.820.3 3.71.76F MFCM127 to 422106 to 352 79 to 264 63 to 211 53 to 176 45 to 15140 to 13235 to 11732 to 106

52.040.3 4.71.98- M-C- 143 to 475 119 to 39689 to 29771 to 238 59 to 198 51 to 170 45 to 149 40 to 13236 to 119

62.230.3 5.72.16- M-C- 156 to 518 130 to 43297 to 32478 to 259 65 to 216 56 to 185 49 to 162 43 to 14439 to 130

72.410.4 6.62.34 -----168 to 562 140 to 468105 to 351 84 to 281 70 to 234 60 to 201 53 to 176 47 to 15642 to 140

1.51.390.2 1.31.30M VC -VC -94 to 312 78 to 260 59 to 195 47 to 156 39 to 130 33 to 111 29 to 98 26 to 87 23 to 78

21.610.2 1.81.52M VC MCC109 to 365 91 to 304 68 to 228 55 to 182 46 to 152 39 to 13034 to 11430 to 10127 to 91

31.970.3 2.71.87M CMCC135 to 449 112 to 374 84 to 281 67 to 224 56 to 187 48 to 16042 to 14037 to 12534 to 112

42.270.4 3.62.17F CFCM156 to 521130 to 434 98 to 326 78 to 260 65 to 217 56 to 18649 to 16343 to 14539 to 130

52.540.4 4.62.43- M-C- 175 to 583 146 to 486 109 to 365 87 to 292 73 to 243 62 to 20855 to 182 49 to 162 44 to 146

62.790.5 5.52.67- M-C- 192 to 641 160 to 534 120 to 401 96 to 320 80 to 267 69 to 22960 to 200 53 to 178 48 to 160

73.010.6 6.42.89- M-C- 208 to 694 173 to 578 130 to 434 104 to 34787 to 28974 to 24865 to 21758 to 19352 to 173

1.51.680.2 1.31.54M VC -XC-111 to 370 92 to 308 69 to 231 55 to 185 46 to 154 40 to 132 35 to 11631 to 10328 to 92

21.940.3 1.71.80M VC MXC-130 to 432 108 to 360 81 to 270 65 to 21654 to 18046 to 15441 to 13536 to 12032 to 108

32.370.4 2.62.21M VC MC- 159 to 530 133 to 44299 to 33280 to 265 66 to 221 57 to 189 50 to 166 44 to 14740 to 133

42.740.5 3.52.57M CFC- 185 to 617 154 to 514 116 to 386 93 to 308 77 to 257 66 to 22058 to 193 51 to 171 46 to 154

53.060.6 4.42.88F CFC- 207 to 691 173 to 576 130 to 432 104 to 34686 to 28874 to 24765 to 21658 to 19252 to 173

63.350.7 5.33.16- M-C- 228 to 758 190 to 632 142 to 474 114 to 37995 to 31681 to 27171 to 237 63 to 21157 to 190

73.620.8 6.23.42- M-C- 246 to 821 205 to 684 154 to 513 123 to 410 103 to 34288 to 293 77 to 257 68 to 22862 to 205

1.51.820.3 1.21.66 CXC ---120 to 398 100 to 33275 to 249 60 to 199 50 to 166 43 to 142 37 to 125 33 to 11130 to 100

22.580.4 1.62.28 CVCMXC-164 to 547137 to 456 103 to 342 82 to 274 68 to 22859 to 195 51 to 171 46 to 15241 to 137

33.160.6 2.42.82M VC MVC - 203 to 677 169 to 564 127 to 423 102 to 33885 to 28273 to 24263 to 21256 to 18851 to 169

43.650.8 3.23.27M CMVC - 235 to 785 196 to 654 147 to 491 118 to 39298 to 32784 to 28074 to 24565 to 21859 to 196

54.081.0 4.03.67M CMC- 264 to 881 220 to 734 165 to 551 132 to 440 110 to 367 94 to 315 83 to 275 73 to 24566 to 220

64.471.2 4.84.02- M-C- 289 to 965 241 to 804 181 to 603 145 to 482 121 to 402 103 to 34590 to 30280 to 26872 to 241

74.831.3 5.74.34- M-C- 312 to 1042 260 to 868 195 to 651 156 to 521 130 to 434 112 to 37298 to 32687 to 28978 to 260

1.52.790.5 1.02.29 VC ---- 165 to 550 137 to 458103 to 344 82 to 275 69 to 229 59 to 196 52 to 172 46 to 15341 to 137

23.230.6 1.42.67 C--XC -192 to 641 160 to 534 120 to 401 96 to 320 80 to 267 69 to 22960 to 20053 to 17848 to 160

33.950.9 2.13.30 C-MXC -238 to 792 198 to 660 149 to 495 119 to 396 99 to 330 85 to 28374 to 24866 to 22059 to 198

44.561.2 2.83.82M -MVC - 275 to 917 229 to 764 172 to 573 138 to 458 115 to 382 98 to 327 86 to 28776 to 25569 to 229

55.101.5 3.54.26M -MC- 307 to 1022 256 to 852 192 to 639 153 to 511 128 to 426 110 to 36596 to 32085 to 28477 to 256

65.591.8 4.24.66M -MC- 336 to 1118 280 to 932 210 to 699 168 to 559 140 to 466 120 to 399 105 to 35093 to 31184 to 280

76.032.2 4.85.01 ---C- 361 to 1202 301 to 1002 225 to 752 180 to 601 150 to 501 129 to 429 113 to 376 100 to 33490 to 301

Nozzle

number

Nozzle

11008

TT TJ60

TTJ60 XR

XRC (50)

11010

TJ60 TTJ60

XR XRC (50)

11005

DG TT TJ60

TTJ60 XR

XRC (50)

11006

TT TJ60

TTJ60 XR

XRC (50)

Rated

l/min Pressure

(bar)

Flow

(l/min) l/ha l/ha

11004

DG TT TJ60

TTJ60 XR

XRC (50)

16 km/h 18 km/h 20 km/h

l/ha l/hal/ha

TTJ60DGTT TJ60

ΔP

l/ha l/hal/ha l/ha

Gauge

pressure

(bar)

5 km/h 6 km/h8km/h 10 km/h 12 km/h 14 km/h

XR/XRC

Nozzle spacing 50 cm

Minimum duty cycle

This manual suits for next models

1

Table of contents

Other TeeJet Technologies Control System manuals

Popular Control System manuals by other brands

Bouyer

Bouyer PC 1106 quick start guide

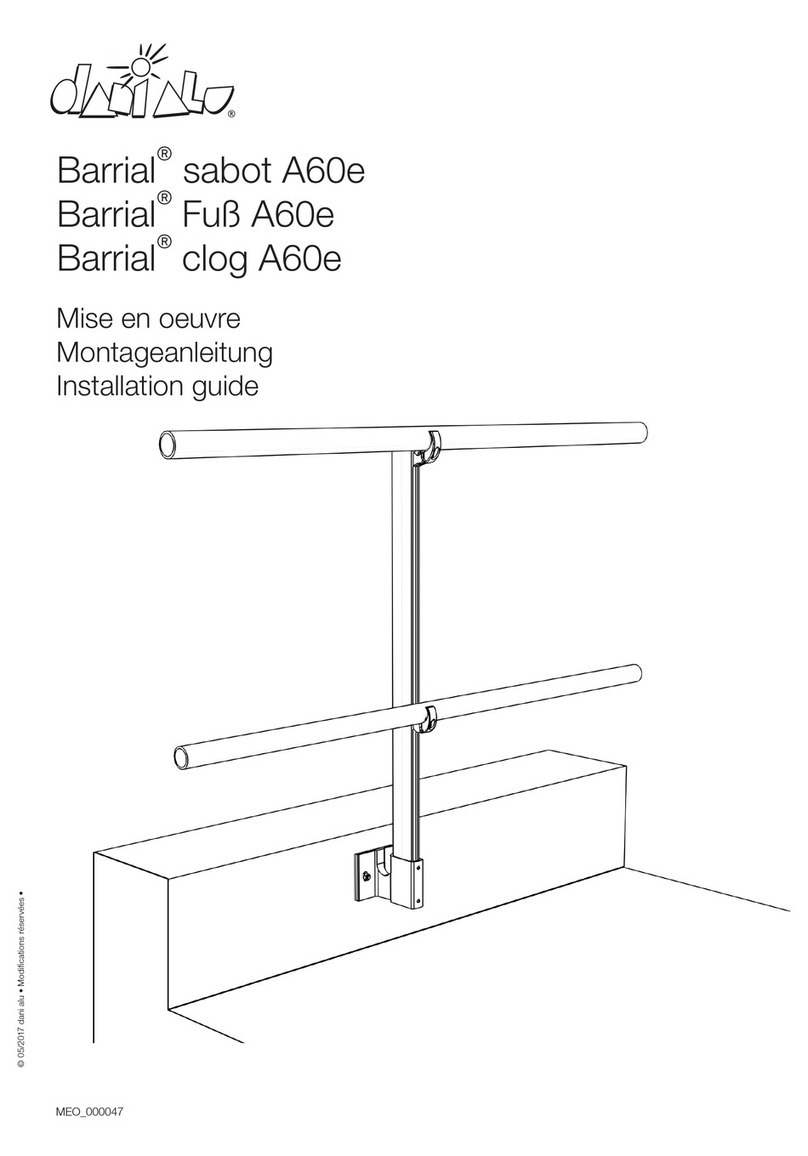

dani alu

dani alu Barrial A60e installation guide

BFT

BFT GIOTTO BT A ULTRA 36 Installation and user manual

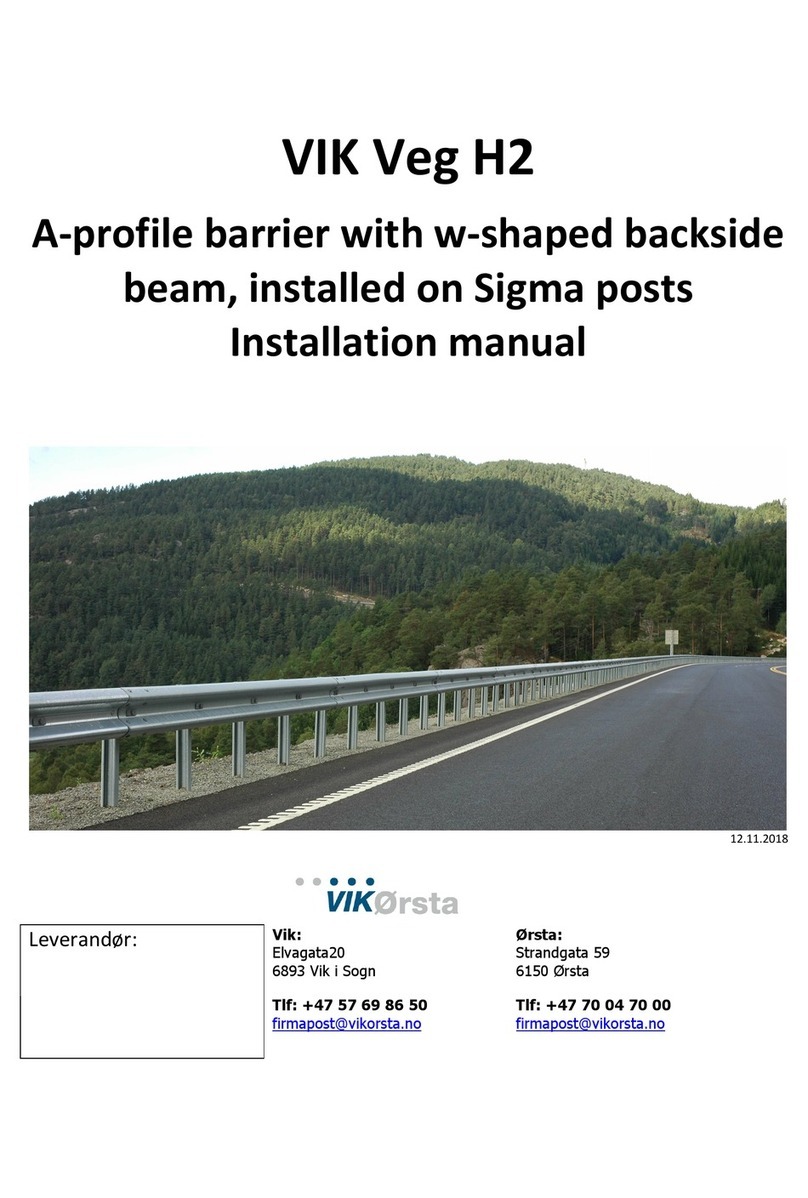

Saferoad

Saferoad VikOrsta VIK Veg H2 installation manual

Vertiv

Vertiv WSN Gateway Installer and user guide

Chamberlain

Chamberlain GAROG TST-2 Operational description

Mitsubishi Electric

Mitsubishi Electric MELDAS FCU6-DX561 Maintenance manual

Kugelmann

Kugelmann K-BASIC 2 Original operating instructions

btsr

btsr IS3 operating manual

Norac

Norac UC7 installation manual

Pulse Instruments

Pulse Instruments System 2 user manual

Micatrone

Micatrone MicaFlex FHC Programming manual