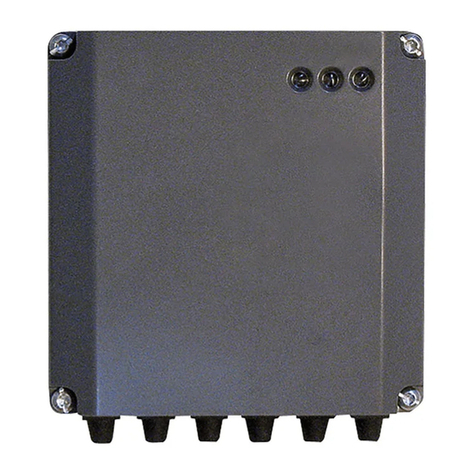

Norac UC7 User manual

Other manuals for UC7

4

Table of contents

Other Norac Control System manuals

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac John Deere 4720 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac SPRA-COUPE 7000 Series User manual

Norac

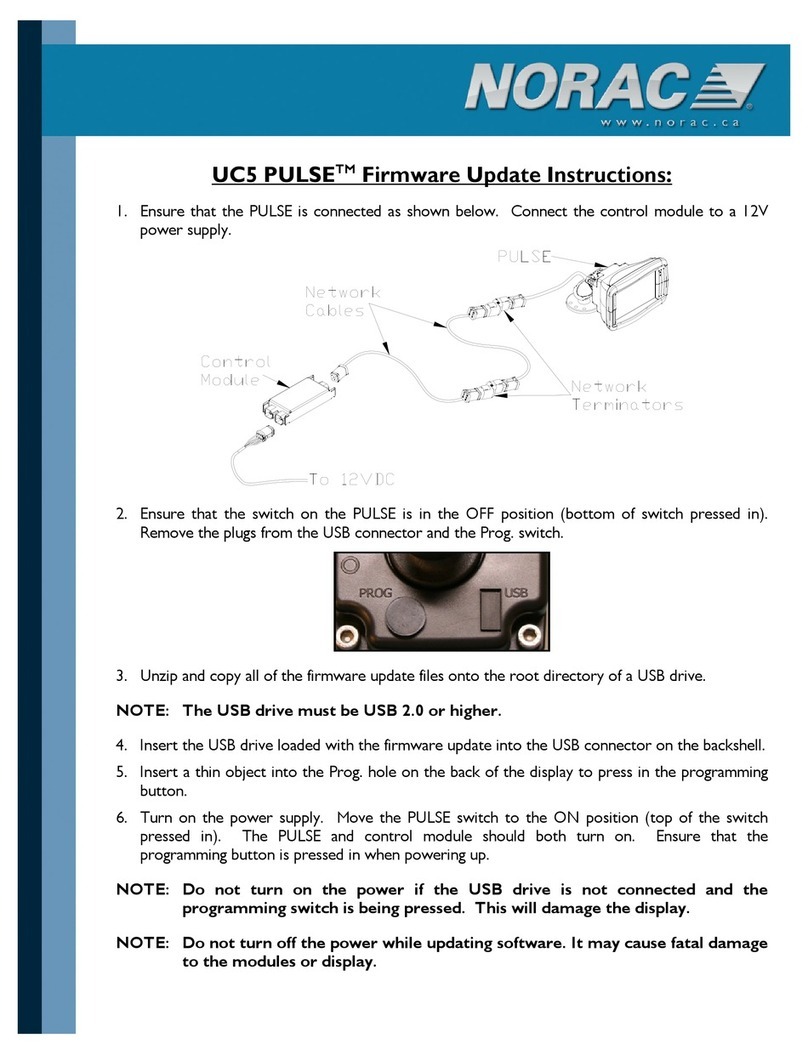

Norac PULSE UC5 Use and care manual

Norac

Norac UC4 Total Control User manual

Norac

Norac UC4 Total Control User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Rogator 600 User manual

Norac

Norac UC4+ User manual

Norac

Norac U5 User manual

Norac

Norac UC5-CAB-HG06-HG07 User manual

Norac

Norac RG11 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4 Total Control User manual

Norac

Norac UC4+ User manual

Popular Control System manuals by other brands

Seav

Seav LRX 2035 NEW manual

auer

auer Thorix EVOLUTION 2C Installation and operating instructions

Crestron

Crestron 4 Series quick start guide

Cardin Elettronica

Cardin Elettronica CDR Series manual

Rockwell Automation

Rockwell Automation MSR300 instruction manual

MachMotion

MachMotion 2000 Series General installation manual

Ariston

Ariston Chafforeaux elco 3319130 Assembly and operation instructions

GDC

GDC SR-1000 STANDALONE INTEGRATED MEDIA BLOCK installation manual

dbx

dbx DriveRack 260 manual

DITEC

DITEC NOVOTECNICA Lan60 manual

Invacare

Invacare LiNX REM110 user manual

Mitsubishi Electric

Mitsubishi Electric PAC-YT32PTA installation manual