Tegam 1830A Troubleshooting guide

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

TEGAM is a manufacturer of electronic test and measurement equipment for metrology,

calibration, and production test. We also provide repair, calibration, and other support services

for a wide variety of test and measurement equipment including RF power sensor calibration

systems, RF attenuation measurement systems, ratio transformers, arbitrary waveform

generators, micro-ohmmeters, LCR meters, handheld temperature calibrators, thermometers,

humidity and temperature control devices, and more.

TEGAM also repairs and calibrates test and measurement equipment formerly manufactured by

Electro-Scientific Industries (ESI), Gertsch, Keithley Instruments, Lucas Weinschel, and

Pragmatic Instruments. A complete list can be viewed on our Product Service Directory at

www.tegam.com

For more information about TEGAM and our products, please visit our website at

www.tegam.com: or contact one of our customer service representatives at sales@tegam.com

or 800-666-1010.

© Copyright TEGAM, Inc. 2010 - 2017

No part of this manual may be reproduced in any form or by any means (including electronic

storage and retrieval or translation into a foreign language) for any other purpose without the

prior written consent of TEGAM, Inc.

10 Tegam Way,

Geneva, Ohio 44041

Telephone: (440) 466-6100

Fax: (440) 466-6110

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Table of Contents

Section Page

I. Introduction

Purpose and Functions .............................................................. 1-1

Capabilities .............................................................................. 1-1

Specifications ........................................................................... 1-2

List of Items Furnished .............................................................. 1-4

List of Additional Items Required for Operation and Maintenance .... 1-4

Tools and Test Equipment.......................................................... 1-4

Preparation for Calibration or Repair Service ................................ 1-5

Warranty Information................................................................ 1-7

Contact Information .................................................................. 1-7

II. Preparation for Use and Installation

Unpacking and Inspection .......................................................... 2-1

Use in Proper Environment......................................................... 2-1

III. Principles of Operation

Understanding the 1830A Measurement Process ........................... 3-1

Theory of RF Power Measurements ............................................. 3-2

Principles of DC Substitution ............................................. 3-2

Power Measurements ....................................................... 3-2

Controlling Thermistor Temperature................................... 3-3

IV. Operating Instructions

Start-up Procedure ................................................................... 4-1

Standby Mode ................................................................. 4-1

Connecting the Proper Sensor ........................................... 4-2

1830A Front Panel Menus .......................................................... 4-3

1830A Menu Map .................................................................... 4-12

Normal Operation ................................................................... 4-13

RF Power Measurement Procedure ............................................ 4-13

Remote Operation................................................................... 4-15

Ethernet Interface Configuration…………………….……………….….4-17

1830A Commands .................................................................. 4-21

1830A Error/Status Reporting .................................................. 4-23

Sensor Calibration File Upload .................................................. 4-32

Heater Circuit Operation .......................................................... 4-34

Normal Shutdown Procedure .................................................... 4-35

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

V. Maintenance and Servicing

1830A System Calibration and Diagnostics................................... 5-1

Calibration and Verification Equipment ........................................ 5-1

Calibration Environment ............................................................ 5-2

Disassembly of 1830A ............................................................... 5-2

Calibration and Diagnostic Process .............................................. 5-2

Troubleshooting........................................................................ 5-9

VI. Reprogramming

Reprogramming the 1830A ........................................................ 6-1

Memory Sanitization Procedure................................................... 6-2

VII. Preparation for Shipment

Returning Power Meter for Service .............................................. 7-1

Package Power Meter for Shipment ............................................. 7-1

VIII. Storage

Storage Requirement ................................................................ 8-1

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Safety Information & Precautions:

The following safety information applies to both operation and service personnel. Safety

precautions and warnings may be found throughout this instruction manual and the equipment.

These warnings may be in the form of a symbol or a written statement. Below is a summary of

these precautions.

Terms in This Manual:

CAUTION statements identify conditions or practices that could result in damage to the

equipment or other property.

WARNING statements identify conditions or practices that could result in personal injury or loss

of life.

Terms as Marked on Equipment:

CAUTION indicates a personal injury hazard not immediately accessible as one reads the

marking, or a hazard to property including the equipment itself.

DANGER indicates a personal injury hazard immediately accessible as one reads the marking.

Symbols:

As Marked in This Manual:

!

This symbol denotes where precautionary information may be found.

As Marked on Equipment:

!

CAUTION –Risk of Danger

DANGER –Risk of Electric Shock

Earth Ground Terminal

l

On

O

Off

Frame or Chassis Terminal

Earth Ground Terminal

Alternating Current

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

1-1

Section I –Introduction

Purpose and Function

The 1830A power meter is designed for thermistor based RF power sensors which are universally

recognized as the most accurate means to measure and transfer RF power. The TEGAM Model

1830A is designed to replace the HP432 while further reducing uncertainties and accommodate a

wider variety of RF power sensors. It combines a modern DC substitution bridge with a 6.5 digit

measurement system to provide consistent normalized RF power readings manually or

automatically.

Key functions of the 1830A:

•Replaces the HP432 RF Power Meter

•Compatible with thermistor power sensors from: Agilent (HP), TEGAM,

Weinschel, Hughes, General Microwave, Millitech

•Supports 100 Ω and 200 Ω thermistors

•Integrates bridge balancer and power meter into one package

•Four digit calibration factor resolution

•Full remote programmability

•Heater control for ovenized sensors

Capabilities

There are many thermistor based RF power sensors available. The Model 1830A is designed to

bias either 100 Ω or 200 Ω mounts and has dual bridges for balancing both RF sense and

compensation thermistors such as contained in the Agilent 478A and 8478B. It also is works with

the Agilent 486A series of waveguide sensors and includes a heater circuit for all TEGAM and

Weinschel ovenized thermistor mounts.

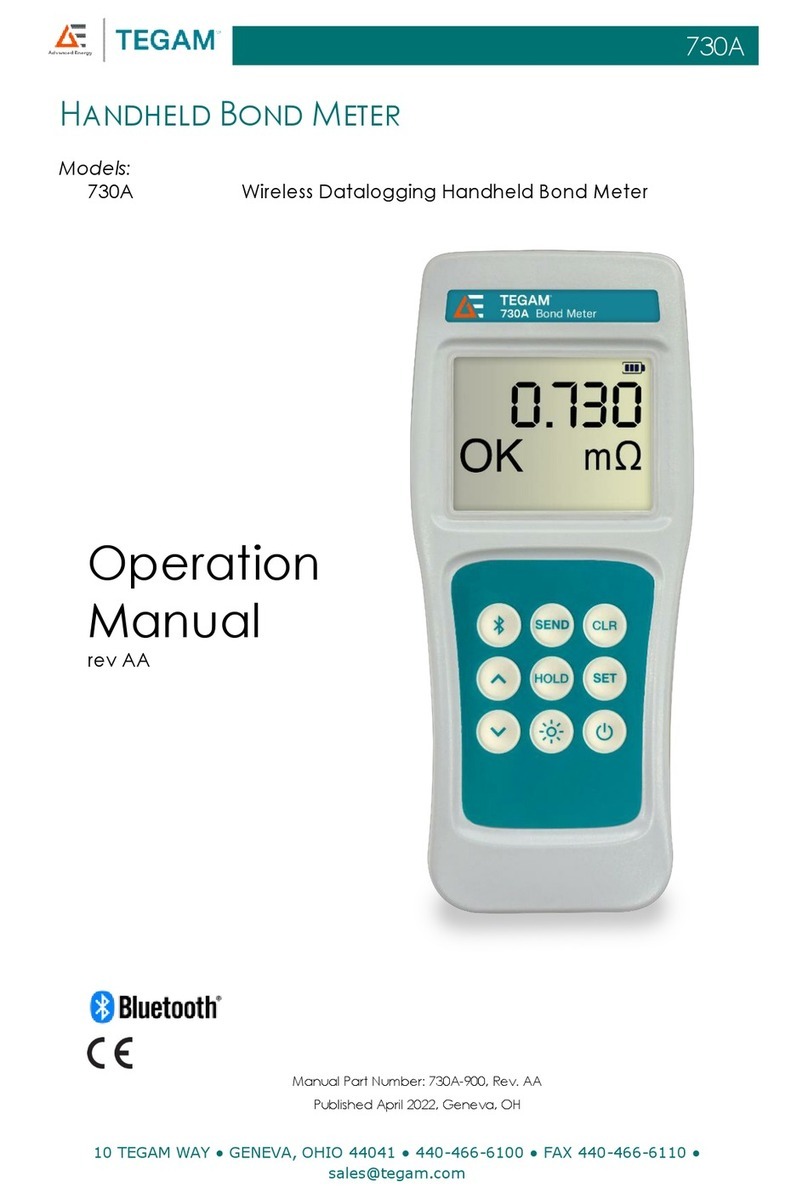

Figure 1.1 - Model 1830A RF Power Meter

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

1-2

Section I –Introduction

Specifications

(Includes performance characteristics, description, power and utility information

and environmental information)

Power Range (typical, sensor dependent)

0.001 to 30 mW (-30 to +14 dBm)

Frequency Range

100 kHz to 110 GHz (sensor

dependent)

Accuracy

±0.05% of reading, ±0.5 μW

(0.1% at 1 mW)

Measurement Scale

mW dB

Cal Factor Resolution

4 digits, linear decimal

Bridge Resistance

Variable from 50 Ω to 300 Ω (RF

termination 12.5 Ω to 75 Ω)

Connectors

Bias Voltage

Temp

14-pin Quick Connect

4-pin mini-microphone

Heater Controller

8 VDC @ 200 mA (compatible with

all TEGAM and Weinschel

thermistor mounts)

Environmental Specified Temperature Range

Operating Temperature

Storage Temperature

Calibration Temperature

Humidity

+17°C to +29°C (+63°F to +84°F)1

0 °C to +55 °C (+32 °F to +131 °F)

-40 °C to +75 °C (-40 °F to +167 °F)

+17°C to +29°C (+63°F to +84°F)

0% to 95%, non-condensing

Power Requirements

100 to 240 Vac, 48 to 62 Hz, 75

VA max

Input Power Fuse

250 V, 1.5 Amp (slow blow)

Weight

2 kg (4.4 lb)

Physical Dimensions

Height

Width

Depth

8.89 cm (3.5 in)

21.59 cm (8.5 in)

36.5 cm (14.5 in)

Table 1.1 Physical and Electrical Specifications

1

Please note that the Celsius scale specifications are controlling, the Fahrenheit conversions are

approximations for information only.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

1-3

Section I –Introduction

Power Source

This product is intended to connect to a power source that the voltage between the supply

conductors or between either supply conductor and ground will not apply more than the

voltage rating for the particular power supply. A protective ground connection by way of

the grounding conductor in the power cord is essential for safe operation.

Line Voltage Selection

The power supply in a Model 1830A operates with a line voltage of 100 to 240 VAC at

48 to 62 Hz.

CAUTION DO NOT APPLY POWER TO THE INSTRUMENT BEFORE READING THIS SECTION.

Check the Power Cord

Make sure the power cord supplied with the Model 1830A is not frayed, broken, or

cracked. A damaged power cord is a fire and electrical hazard. If the power cord is

damaged, it should be replaced.

Use the Proper Fuse

To avoid fire hazard, use only the correct fuse type as specified for the AC power supply in

the unit. The correct fuse for the 1830A is a 250 V 1.5 Amp slow blow fuse.

The fuse is located just below the power cord socket. Before replacing the fuse, place the

Model 1830A front panel power switch to the OFF position and remove power cord on the

back of the Model 1830A. To replace the fuse, gently slide out the fuse drawer. Remove

the old fuse and snap a new one into the fuse holder. Reinstall the fuse by simply pushing

the fuse drawer back into its original position. The fuse drawer should snap into place.

Grounding the Equipment

This product is grounded through the grounding conductor of the power cord.

WARNING To avoid electrical shock or other potential safety hazards, plug the power cord

into a properly wired receptacle before using this instrument. The proper grounding of this

instrument is essential for safety and optimizing instrument operation.

Danger Arising from Loss of Ground

WARNING If the connection to ground is lost or compromised, a floating potential could

develop in the instrument. Under these conditions all accessible parts, including insulating

parts such as keypads and buttons could develop a hazardous voltage and put the user at

risk.

!

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

1-4

Section I –Introduction

List of Items Furnished

Item

Power Cord

User/Maintenance Manual

Statement of Calibration

Table 1.2 - 1830A Packing List

List of Additional Items Required For Operation and Maintenance

Accessory

Part Number

Heater Cable (4 pin mini, 48” or 15”)

Heater Cable (4 pin large, 48”)

Sensor Cable (478A & 8478B, 48”)

Sensor Cable (1830A/Legacy Mounts. 48” or 15”)

Sensor Cable (1830A/PM Series Mounts, 48” or 15”)

Universal Cable (Un-terminated, 48”)

Calibration Cable (Lug-terminated, 48”)

USB Cable 2 meter (USB A –USB A)

Rack Mount Kit (Single Unit)

Rack Mount Kit (Dual Unit)

CA-11-48/CA-11-15

CA-10-48

CA-6-48

CA-7-48/CA-7-15

CA-21-48/CA-21-15

CA-9-48

CA-20-48

CA-14-2M

1830-910

1830-911

Table 1.3 - 1830A Accessory List

Tools and Test Equipment

No special tools and test equipment are needed to operate the 1830A. The follow is a list of

thermistor mounts that will operate with the 1830A RF Power Meter.

HP/Agilent

478A, 8478B, S486A, G486A, J486A, H486A,

X486A, M486A, P486A, K486A, R486A

TEGAM/Weinschel

1107-7, 1107-8, 1807A, M1110, M1111,

M1118, M1120, M1125, M1130, M1135,

F1109, F1116, F1117, F1119, F1125, F1130,

F1135

Table 1.4 - 1830A Compatible Thermistor Mounts

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

1-5

Section I –Introduction

Preparation for Calibration or Repair Service

Once you have verified that the cause for 1830A malfunction cannot be solved in the field and

the need for repair and calibration service arises, contact TEGAM customer service to obtain an

RMA, (Returned Material Authorization), number. You can contact TEGAM customer service via

the TEGAM website, www.tegam.com or by calling 440.466.6100 (All Locations) OR

800.666.1010 (United States Only).

The RMA number is unique to your instrument and will help us identify you instrument and to

address the particular service request by you which is assigned to that RMA number.

Of even importance, a detailed written description of the problem should be attached to the

instrument. Many times repair turnaround is unnecessarily delayed due to a lack of repair

instructions or of a detailed description of the problem.

This description should include information such as measurement range, and other instrument

settings, type of components being tested, are the symptoms intermittent, conditions that may

cause the symptoms, has anything changed since the last time the instrument was used, etc.

Any detailed information provided to our technicians will assist them in identifying and correcting

the problem in the quickest possible manner. Use a copy of the Repair and Calibration Service

form provided on the next page.

Once this information is prepared and sent with the instrument to our service department, we

will do our part in making sure that you receive the best possible customer service and

turnaround time possible.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

1-6

Section I –Introduction

Expedite Repair & Calibration Form

Use this form to provide additional repair information and service instructions. The Completion of

this form and including it with your instrument will expedite the processing and repair process.

RMA#:

Instrument Model

#:

Serial

Number:

Company:

Technical

Contact:

Phone

Number:

Additional

Contact

Info:

Repair Instructions:

Evaluation Calibration Only Repair Only Repair & Calibration Z540 (Extra Charge)

Detailed Symptoms:

Include information such as measurement range, instrument settings, type of components being

tested, is the problem intermittent? When is the problem most frequent? Has anything changed

with the application since the last time the instrument was used?, etc.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

1-7

Section I –Introduction

Warranty Information

TEGAM, Inc. warrants this product to be free from defects in material and workmanship for a

period of three years from the date of shipment. During this warranty period, if a product proves

to be defective, TEGAM Inc., at its option, will either repair the defective product without charge

for parts and labor, or exchange any product that proves to be defective.

TEGAM, Inc. warrants the calibration of this product for a period of one year from date of

shipment. During this period, TEGAM, Inc. will recalibrate any product, which does not conform

to the published accuracy specifications.

In order to exercise this warranty, TEGAM, Inc., must be notified of the defective product before

the expiration of the warranty period. The customer shall be responsible for packaging and

shipping the product to the designated TEGAM service center with shipping charges prepaid.

TEGAM Inc. shall pay for the return of the product to the customer if the shipment is to a

location within the country in which the TEGAM service center is located. The customer shall be

responsible for paying all shipping, duties, taxes, and additional costs if the product is

transported to any other locations. Repaired products are warranted for the remaining balance of

the original warranty, or 90 days, whichever period is longer.

Warranty Limitations

The TEGAM, Inc. warranty does not apply to defects resulting from unauthorized

modification or misuse of the product or any part. This warranty does not apply to fuses,

batteries, or damage to the instrument caused by battery leakage.

Statement of Calibration

This instrument has been inspected and tested in accordance with specifications published

by TEGAM Inc. The accuracy and calibration of this instrument are traceable to the

National Institute of Standards and Technology through equipment, which is calibrated at

planned intervals by comparison to certified standards maintained in the laboratories of

TEGAM Inc.

Contact Information:

TEGAM Inc.

10 Tegam Way

Geneva, OH 44041

PH: 440.466.6100

FX: 440.466.6110

EMAIL: sales@tegam.com

WEB: http://www.tegam.com

Document publishing dates may lag product changes.

Visit www.tegam.com to download the latest version of this manual.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

2-1

Section II –Preparation for Use and Installation

Unpacking and Inspection

Each 1830A is put through a series of electrical and mechanical inspections before shipment to

the customer. Upon receipt of your instrument unpack all of the items from the shipping carton

and inspect for any damage that may have occurred during transit. Report any damaged items

to the shipping agent. Retain and use the original packing material for reshipment if necessary.

Upon Receipt, inspect the carton for the following items:

Model 1830A RF Power Meter

Model 1830A Operating and Service Manual (CD) P/N 1830A-901-01

Calibration Certificate

Power Cord

Mounting

The Model 1830A is shipped with four feet mounted to the bottom cover. When the Model

1830A is placed on a bench or table, these feet support the instrument. The Model 1830A

can also be rack mounted in a standard 19” rack using the optional rack adapter kit 1830-

910 for a single 1830A and kit 1830-911 to rack two 1830A’s side-by-side.

NOTE It is recommended to remove all 4 feet prior to rack mounting.

Use in Proper Environment

Normal calibration laboratory practice dictates that the environment should be closely controlled.

This will minimize errors introduced by temperature and humidity changes. A nominal

temperature as specified in Table 1.1 provides a good working condition. Controlled

temperatures also stabilize the aging process of the standards.

Do Not Use in Explosive Environments

CAUTION The 1830A is not designed for operation in explosive environments.

Do Not Block Air Vents on Rear Panel

CAUTION The Model 1830A has an air intake and exhaust on the back panel of the instrument.

When installing the Model 1830A, ensure there is at least two inches of space behind the

instrument for airflow. DO NOT set the instrument on its rear panel as its airflow will be

restricted and may result in damage to the internal circuitry.

Ensure Power Switch is Accessible

CAUTION Ensure that the POWER switch is easily accessible at all times and nothing is in place

that would impede proper use.

Do Not Operate Without Covers

WARNING This device should be operated with all panels and covers in place. Operation with

missing panels or covers could result in personal injury.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

3-1

Section III –Principles of Operation

Understanding the 1830A Measurement Process

The Model 1830A RF Power Meter combines a DC substitution balancer with a digital voltmeter

system. The use of a A/D converter converts our analog measurement to a digital output on the

1830A front panel. This eliminates the need for any type of analog output that an instrument like

the Agilent 432A may require.

Because of the circuit construction, a “four-wire” circuit is used to sense bolometer resistance”,

allowing the user to use nearly any practical cable length without recalibrating the 1830A.

NOTE Limited by the resistive drop in the source leads. The small currents involved make

circuits of 100 meters or more possible, although electromagnetic coupling issues could

compromise measurements in some cases.

The balancer is composed of a controllable source that allows current to flow through Rref and

the bolometer. Identical precision instrument amplifiers feed the bolometer voltage and the

voltage across a reference resistor to a servo-amplifier that has been adjusted for low offset.

The servo amplifier controls the main supply transistor and therefore regulates power to the

combined reference/bolometer circuit. The 1830A is connected to support NTC devices. When

the bolometer voltage is higher than the reference resistor voltage, indicating that the

bolometer’s resistance is higher than desired, power is increased to heat the bolometer and

decrease resistance. When the bolometer voltage is lower than the reference resistor voltage,

power is decreased. At balance, the reference resistor voltage and the bolometer voltage match

closely. Since their currents are the same, the resistances also match closely.

NOTE The reference resistor is either 100 or 200 Ohms. Additionally, in some modes, the

reference resistor voltage is multiplied by a variable to produce the variable resistance feature.

At resistances other than 100 or 200 Ohms, the multiplication adds some uncertainty.

The 1830A computes power from changes in the voltage across the reference resistor as follows:

When ZERO is pressed, the voltage across the Reference resistor is stored in a combination of

DAC settings and software variables. This is done on both the “RF” channel and the

“Compensating” channel. For any subsequent readings, the actual values of the voltages are

used.

When an uncompensated mode is selected, change in substituted DC power is computed as

R

VV

POnOff 22 −

=

Equation 1 - Substituted Power Calculation

When a compensated mode is used, change in DC substituted power is computed using the

complicated methodology described in the H-P 432 Manual. This gives the identical answer to

the uncompensated equation in the case that the compensating thermistors do not have a

change in voltage (caused by a change in environment).

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

3-2

Section III –Principles of Operation

Theory of RF Power Measurements

Principles of DC Substitution

Power sensors are not ideal devices, so in order to make good measurements they must be

characterized and corrected for. DC substitution is the key for precise RF power

measurements. The Model 1830A uses the principle of DC substitution to measure RF power.

DC substitution refers to the measurement of RF power according to the amount of DC

power that must be substituted for the RF power in a bolometer in order to cause equivalent

thermal effects. This is done by monitoring voltage changes of the 1830A’s self-balancing

bridge circuits.

Power Measurements

The Model 1830A RF Power Meter makes measurements based on a 4-wire technique. The

reference resistor RRef is used to monitor a constant current source that heats the RF

sense thermistors in the sensor. Separate sense leads monitor the voltage drop across

the thermistors. An error amplifier compares the difference between the voltage drop of

RRef and the voltage drop of the sense thermistors to regulate the constant current source

and acts to keep the resistances equal. Once RRef and the resistance of the sensor are

equivalent, the change in the value of VRRef is proportional to the RF energy incident on

the sensor.

As RF enters the sensor the constant current source keeps the sensor resistance = RRef by

reducing amount of DC current applied. The Voltage output VRRef is then fed into a

programmatic gain amplifier where there is an offset adjustment as shown in Figure 3.1.

The ZERO function is also utilized in this section, when the RF power is off (no power at

sensor) the offset adjustment creates a voltage that maintains a constant zero reference

point (0mW). Once a RF signal is applied the A/D calculates power based on the reference

ZERO level.

Figure 3.1 - Basic 1830A RF Power Measurement Diagram

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

3-3

Section III –Principles of Operation

Controlling Thermistor Temperature

A thermistor is a temperature-sensitive device. In order to provide precise measurements,

the effects of changes in the ambient temperature upon the thermistor must be

eliminated or minimized. The Model 1830A temperature controller accomplishes this by

raising the TEGAM or Weinschel power standard’s internal temperature to a level higher

than the ambient temperature (approximately 60° C) and maintaining that level by

controlling the current applied to the power standard’s heater element. This prevents any

thermistor imbalance due to ambient temperature change. Therefore, all temperature

changes are due to the application of RF and DC power.

Refer to Figure 3.2 for the following discussions concerning the temperature control

circuit. The Model 1830A “bridge” balancer is composed of a controllable source that

allows current to flow through Rref and the bolometer. Identical precision instrument

amplifiers feed the bolometer voltage and the voltage across a reference resistor to a

servo-amplifier that has been adjusted for low offset.

Figure 3.2 - Simplified Schematic of the Model 1830A Heater Circuit

NOTE The reference resistor is either 100 Ω or 200 Ω. Additionally, in some modes, the

reference resistance voltage is multiplied by a variable to produce a variable resistance feature.

At resistance other the 100 Ω or 200 Ω, the multiplication adds some uncertainty.

The servo amplifier controls the main supply transistor and therefore regulates power to the

combined reference/bolometer circuit.

The Model 1830A is designed to support NTC devices. When the bolometer voltage is higher than

desired, power is increased to heat the bolometer to decrease resistance. When the bolometer

voltage is lower than the reference resistor voltage, power is decreased. At balance, the

reference resistor voltage and the bolometer voltage match closely. Since the currents are the

same, the resistances also match closely.

The computation of power is determined by the change in voltage across the reference resistor.

When ZERO is pressed, the voltage across the reference resistor is stored in a combination of

DAC settings and software variables. This is done on both the “RF” channel and the

“Compensating” channel. For any subsequent reading, the actual values of the voltages are

used.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-1

Section IV–Operating Instructions

Start-up Procedure

After unpacking the 1830A and setting up in the proper operating environment, plug in the

AC power cord. Do not connect any cables at this point. Press the POWER button located on

the lower left side of the 1830A. When the 1830A finishes the power on cycle, it will power

into Standby Mode.

Figure 4.1 1830A Start-up Screen

Standby Mode

The 1830A Standby Mode shuts down measurement capability; minimal current will flow

through the sensor. This capability is needed to change sensors and is needed upon initial

power up. Because of the 1830A’s unique capability to connect to any thermistor mount it

is necessary to have different connections. This makes it very important that the 1830A be

placed in Standby prior to changing sensors.

There are two suggested ways to place the 1830A in Standby Mode:

•Unit power cycle

•Through the instrument menus

NOTE There is a third way that the instrument will enter Standby Mode. If a sensor is

removed the instrument will attempt to refresh the measurement at the normal interval.

The instrument will then detect an unbalanced voltage and will prompt the user to place

unit in standby. This is not a recommended procedure and should not be the normal way

of removing a sensor.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-2

Section IV–Operating Instructions

Connecting the Proper Sensor

There are many thermistor based RF power sensors available. The Model 1830A is

designed to bias either 100 Ω or 200 Ω mounts and has dual bridges for balancing both RF

sense and compensation thermistors such as contained in the Agilent 478A and 8478B. It

also is works with the Agilent 486A series of waveguide sensors and includes a heater

circuit for all TEGAM and Weinschel ovenized thermistor mounts.

To connect a TEGAM temperature compensated thermistor mount (F1130A, F1130B,

F1135A, etc.) the following cables will be needed.

Figure 4.2 - CA-7-48

Sensor Cable (15XX/25XX, 48” or 15”) CA-21-48/CA-21-15

Heater Cable (F113X, 48” or 15”) CA-11-48/CA-11-15

Sensor Cable (F/M113X 48” or 15”) CA-7-48/CA-7-15

Heater Cable (M113X, 48”) CA-10-48

To connect an Agilent model thermistor mount (8478B, S486A, G486A, J486A,

H486A, X486A, M486A, P486A, K486A, and R486A) the following cables will be

needed.

Figure 4.3 –CA-6-48

Agilent Thermistor:

Sensor Cable (Agilent Mounts, 48”) CA-6-48

These sensors are not ovenized so no heater cable is needed.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-3

Section IV–Operating Instructions

1830A Front Panel Menus

SETUP menu

Once all necessary cables are connected enter the SETUP menu. The SETUP menu

contains four selections.

1. Standby mode

2. Instrument

3. Cal Factor Tables

4. Maintenance

Figure 4.4 SETUP Menu

Standby Mode (Write Only)

Standby is explained above, it is available in the SETUP menu, also the 1830A will power

up in standby mode every time.

Instrument Menu

Located in the SETUP menus where all measurement related parameters are set. The

Instrument menu contains 11 selections.

1. Range

2. Comp Mode

3. ReZero Unit

4. Network Options

5. Ref Resistor

6. Comp Resistor

7. Read Avgs

8. Display

9. System Temperature

10.Serial Number

11.Firmware Version

12.Analog Brd FW Ver

13.Cal Factor Limit

14.Auto Scale Reading

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-4

Section IV–Operating Instructions

Range (Read/Write)

Located SETUP—Instrument menu. Select the proper measurement range. There are two

possible measurement ranges available on the 1830A:

•10 mW

•100 mW

10 mW –This range assumes that power below 10 mW will be measured. Similar to a DMM

range selection, the more accurate your range the more accurate the reading. A user could

select 100 mW range to measure 1 mW but the reading would be much more accurate in

the 10 mW range.

100 mW –This range assumes that power greater than 10 mW will be measured. Similar

to a DMM range selection, the user cannot select a range below the desired power

measured. 100 mW must be selected for any power above 10 mW.

Comp Mode (Read/Write)

Located SETUP—Instrument menu. Select the proper compensation mode. There are three

possible ambient temperature compensation modes available on the 1830A:

•No Compensation

•432 Compatible

•432 Bias Comp

No Compensation –To be used with TEGAM thermistor mounts such as the F1130A.

The TEGAM thermistor mount is a type of bolometer whose resistance decreases as a

function of increasing heat associated with ambient temperature or applied power. This

system also features the Model 1830A temperature control circuitry that temperature

stabilizes TEGAM and Weinschel thermistor mounts. This eliminates changes in the

thermistor element's resistance due to ambient temperature changes and thus isolates the

causes of thermistor variation to the application of RF and DC power only. Therefore

compensation for ambient temperature is not needed.

432 Compatible and 432 Bias Comp –To be used with Agilent (HP) temperature

compensated thermistor mounts such as the 478A and 8478B.

432 Compatible –This mode assumes that a temperature-compensated mount is

attached. The diagnostic and error checking routines monitor both channels for errors, and

the voltmeter readings from both channels are combined using the same equation that

appears in the HP432 manual for making compensated power measurements using external

voltmeters. This mode introduces the uncertainty and noise of two channels, but can

compensate for significant environmental swings.

Table of contents

Other Tegam Measuring Instrument manuals

Tegam

Tegam AVM-2000 Troubleshooting guide

Tegam

Tegam R1L-BR1 User manual

Tegam

Tegam Advanced Energy GEMINI 5540A User manual

Tegam

Tegam 710A User manual

Tegam

Tegam 253 User manual

Tegam

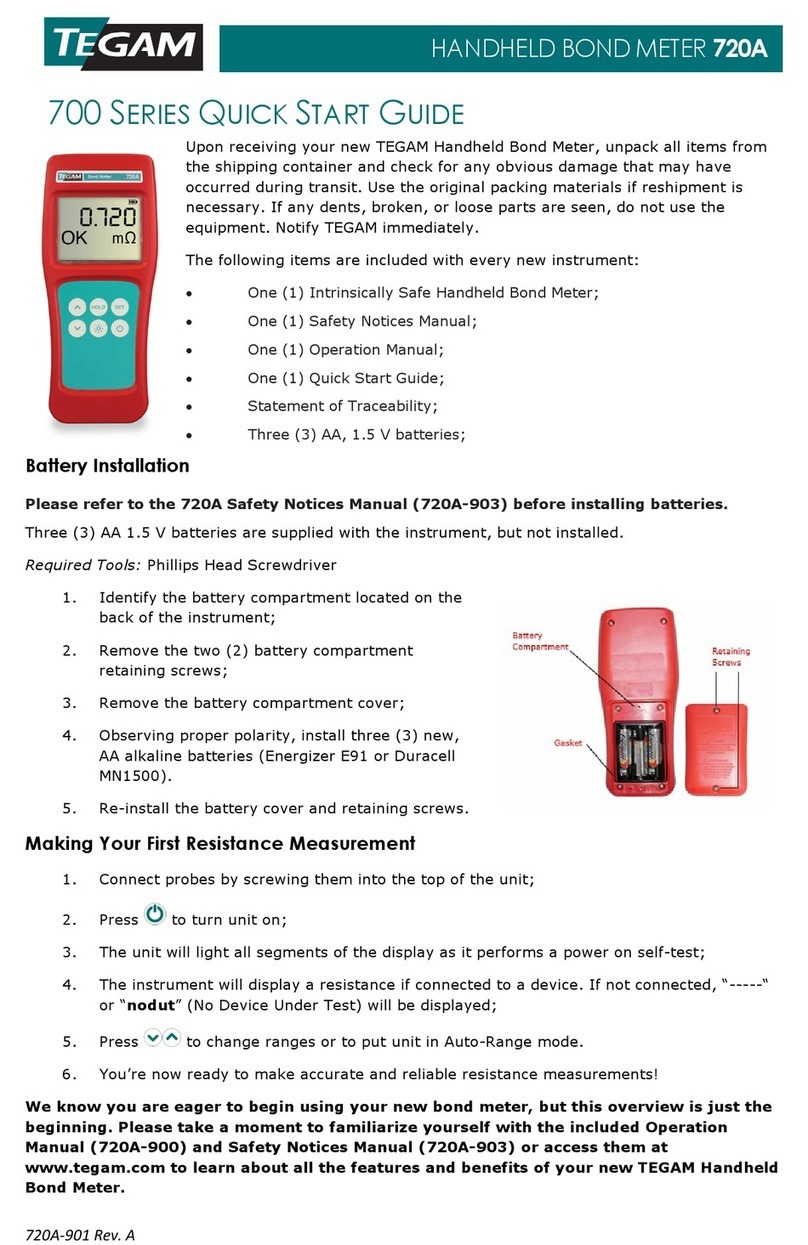

Tegam 720A User manual

Tegam

Tegam 1750 User manual

Tegam

Tegam R1L-BI User manual

Tegam

Tegam R1L-BIR1 User manual

Tegam

Tegam R1M-A User manual

Popular Measuring Instrument manuals by other brands

Dostmann Electronic

Dostmann Electronic P700-EX Operation manual

Greenlee

Greenlee 5883 user guide

Fluke

Fluke ASM-990 Series Operating guidelines

Pfeiffer Vacuum

Pfeiffer Vacuum HPT 200 operating instructions

Mirion Technologies

Mirion Technologies RDS-31 S user manual

Swan Analytical Instruments

Swan Analytical Instruments AMU Inducon Operator's manual