Tegam 710A User manual

710A

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ●

H

ANDHELD

B

OND

M

ETER

Models:

710A

Handheld Bond Meter

Operation

Manual

rev A

Manual Part Number: 710A-900, Rev. A

Published December 2019, Geneva, OH

Notices

ii

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ●

NOTICES

Copyright Notice

© TEGAM, Inc., 2019

No part of this manual may be reproduced in

any form or by any means (including electronic

storage and retrieval or translation into a

foreign language) without prior agreement and

written consent from TEGAM, Inc. as governed

by United States and international copyright

laws.

This Manual

Part Number:710-900

Revision A, December 2019

Supersedes: None

Published by:

TEGAM, Inc.

10 TEGAM Way

Geneva, OH 44041

Disclaimer and Manual Revisions:

THE MATERIAL CONTAINED IN THIS USER

MANUAL, AND ANY COMPUTER

SOFTWARE ASSOCIATED WITH THIS

USER MANUAL OR THE PRODUCTS

COVERED BY IT, ARE PROVIDED AS IS,

AND ARE SUBJECT TO CHANGE, WITHOUT

NOTICE, IN FUTURE REVISIONS.

This User Manual was current at the time of

publication. However, TEGAM is dedicated to a

process of continual product improvement, and

the products covered by this User Manual, and

any associated computer software, are subject

to periodic functional and design updates.

Please visit tegam.com for the most current

product documentation.

U.S. Government Rights

This computer software and/or technical data is

TEGAM proprietary information developed

exclusively at private expense. Computer

software and technical data rights granted to

the federal government include only those

rights customarily provided to the public,

pursuant to FAR 12.211 (Technical data) and

FAR 12.212 (Computer software) for the federal

government, and DFARS 252.227-7015

(Technical data – Commercial items) and

DFARS 227-7202-3 (Rights in commercial

computer software or commercial computer

software documentation) for the Department of

Defense. Except as explicitly permitted by the

foregoing, reproduction for non-governmental

use of the information or illustrations contained

in this computer software and technical data is

not permitted.

Compliance

FCC Notice: This equipment has been

tested and found to comply with the

limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are

designed to provide reasonable protection

against harmful interference when the

equipment is operated in a commercial

environment. This equipment generates, uses,

and can radiate radio frequency energy and, if

not installed and used in accordance with the

instruction manual, may cause harmful

interference to radio communications.

Operation of this equipment in a residential

area is likely to cause harmful interference in

which case the user will be required to correct

the interference at his own expense.

Safety Notice Symbols and Terms

Safety Notices denote hazards. They indicate an

operating procedure, instruction, or practice

that, if not correctly performed or followed,

could result in damage to equipment, or injury

or death to personnel. Do not proceed beyond a

Safety Notice until all conditions and

instructions are fully understood and complied

with.

Safety Notices Symbols:

WARNING

WARNING denotes an

imminent hazard that could

result in injury to personnel or

death.

CAUTION

CAUTION denotes a hazard

that could result in damage to

the unit or other equipment.

REMINDER denotes important

information about instrument

functions, menus, and

measurements.

Table of Contents

iii

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ●

TABLE OF CONTENTS

1. Instrument Description.........................................................................................1-1

Specifications ................................................................................................1-1

Optional Accessories and Ordering Information....................................1-3

TEGAM Family of Handheld Bond Meters ................................................1-4

2. Preparation for Use ..............................................................................................2-1

General Information.....................................................................................2-1

Feature Overview .........................................................................................2-1

Safety Notices and Information .................................................................2-2

Unpacking and Inspection .........................................................................2-4

Battery Installation and Replacement......................................................2-4

Making Your First Resistance Measurement.............................................2-5

3. Operating Instructions .........................................................................................3-1

Keypad Functions .........................................................................................3-1

LCD Display....................................................................................................3-1

Test Limit Menu ..............................................................................................3-3

Auto-Power Off .............................................................................................3-3

Backlight and Backlight Timeout ...............................................................3-3

Hold Function ................................................................................................3-3

Auto-Hold Function ......................................................................................3-4

Battery Indicator ...........................................................................................3-5

Invalid Measurement Indications...............................................................3-6

4. Service Information ..............................................................................................4-1

Inspection and Cleaning ............................................................................4-1

Calibration .....................................................................................................4-1

Troubleshooting.............................................................................................4-7

Diagnostic Routines and Error Codes........................................................4-8

Preparation for Calibration or Repair Service..........................................4-9

Expedite Repair & Calibration Form........................................................4-10

Warranty.......................................................................................................4-11

Warranty Limitations ...................................................................................4-11

Statement of Calibration...........................................................................4-12

A. Required Alignment and Verification Equipment ...........................................A-i

B. Instrument Verification Data Sheet.................................................................... B-i

Instrument Description

1-1

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ●

1. INSTRUMENT DESCRIPTION

Specifications

G

ENERAL

S

PECIFICATIONS

:

Uncertainty1

±(0.2% Reading + 0.02% Range) -10 to 55 °C

Resistance Ranges and Test Currents:

Full Scale

Resolution

Test Current

10.000 mΩ

1 μΩ

100 mA

100.00 mΩ

10 μΩ

10 mA

1.0000 Ω

100 μΩ

1 mA

10.000 Ω

1 mΩ

100 μA

100.00 Ω

10 mΩ

10 μA

Connector Type

M12

Display

Five (5) digit LCD, with Range, Units, Function, Battery, and

Decimal Indicators

Display Backlight

Four (4) LED Backlight with 30-second timeout

Reading Rate

3 / Second for Readings

Battery Type

3 AA (IEC LR6, ANSI 15) Alkaline

Battery Life

100 hours standby, 50 hours in 10 mΩ range

Battery Indicator

Four (4) Stage Battery Charge Indicator

Keypad Six (6) momentary switches with audible and tactile

feedback

Power Cycle

Configuration

Retention

Instrument retains:

-

Range -

Test Limit

Maximum Common

Mode Voltage 30 V

Compliance

CE (2014/30/EU) / RoHS (EU 2015/863) / EU REACH (EC)

No. 1907/2006

ESD

IEC 61000-4 2:2009, Class B

EMC

EN

55022:2010+A1:2015,

Class A; EN 61000-4

3:2006+A2:2010, 10

V/m (80 MHz to 1 GHz)

MIL-PRF-28800F, Class 2

195% confidence interval, approximately 2σ

Instrument Description

1-2

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ●

E

NVIRONMENT

:

Standards

MIL-PRF-28800F, Class

2

Operating Temp -10 to 55 °C -14 to 131 °F

Humidity

5 to 95%, 10 to 30 °C

5 to 95%, 50 to 86 °F

Altitude

0 to 4600 m

0 to 15,092 ft

Vibration

Random 10 – 500 Hz, 0.03 g2/Hz

Shock

30g Half Sine

Drop

4 drops from 1 m to concrete

Storage Temp

-51 to 71 °C

-60 to 160 °F

P

HYSICAL

C

HARACTERISTICS

:

Dimensions

193 x 84 x 28 mm

7.6 x 3.3 x 1.1 in

Weight (incl. batteries)

303.2 g

10.7 oz

Instrument Description

1-3

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ●

Optional Accessories and Ordering Information2

P

RODUCT

M

ODEL

D

ESCRIPTION

Probes

BKDP-M2

Big Kelvin Display Probe, 700 Series

BKP-M2

Big Kelvin Probe, 700 Series

BKDP-

M2S

Big Kelvin Display Probe, 700 Series, Intrinsically Safe

BKP-M2S

Big Kelvin Probe, 700 Series, Intrinsically Safe

BKP-B

Pin Kit, Spear Tip, 4 Pins per Pack

BKP-F

Pin Kit, Flat Tip, 4 Pins per Pack

BKP-H

Pin Kit, Serrated Tip, 4 Pins per Pack

BKP-J

Pin Kit, Round Tip, 4 Pins per Pack

MCDP-M2

Miniature Coaxial Display Probe, 700 Series

MCP-M2

Miniature Coaxial Probe, 700 Series

MCDP-

M2S

Miniature Coaxial Display Probe, 700 Series,

Intrinsically Safe

MCP-M2S

Miniature Coaxial Probe, 700 Series, Intrinsically Safe

MCP-A

Replacement Pins for the MCP Series Probe

MKDP-M2

Miniature Kelvin Display Probe, 700 Series

MKP-M2

Miniature Kelvin Probe, 700 Series

MKDP-

M2S

Miniature Kelvin Display Probe, 700 Series, Intrinsically

Safe

MKP-M2S

Miniature Kelvin Probe, 700 Series, Intrinsically Safe

MKP-F

Flat Tip Pin Kit, 4 Per Pack

MKP-H

Serrated Tip Pin Kit, 4 Per Pack

MKP-J

Round Tip Pin Kit, 4 Per Pack

MKP-LM

Serrated Rotating Tip Pin Kit, 4 Per Pack

KC-M2

Kelvin Clip, 700 Series, Regular Length

KC-M5

Kelvin Clip, 700 Series, Long Length

KC-M2S

Kelvin Clip, 700 Series, Regular Length, Intrinsically

Safe

KC-M5S

Kelvin Clip, 700 Series, Long Length, Intrinsically Safe

2Some accessories may not be available at time of printing

Instrument Description

1-4

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ●

Case

Accessories

700-910

Tilt Stand/Magnetic/Hanger (Factory Installed)

700-912

Tilt Stand/Magnetic/Hanger (User Installed)

700-911

Hard Carry Case

700-915

Sure Grip Cover

720-911

Hard Carry Case, Intrinsically Safe

Printed Manual

710A-900

Operation Manual

Manual

Translations

Chinese, Dutch, French, German, Japanese, Korean,

and Spanish (download at tegam.com)

Service Options

710-CAL

Standard Calibration

710-17025

17025 Calibration with Report

TEGAM Family of Handheld Bond Meters

Bond Meters

710A

Handheld Bond Meter

720A

Intrinsically Safe, Handheld Bond Meter

Preparation for Use

2-1

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ● [email protected]

2. PREPARATION FOR USE

General Information

The TEGAM 710A and 720A Handheld Bond Meters are high-accuracy micro-ohmmeters that

provide accurate resistance readings in a wide range of manufacturing and service

applications. These full-featured, durable, and versatile instruments simplify the process of

resistance measurement through the intuitive user-interface.

Feature Overview

•Battery life of 100 hours in standby, 50 hours in 10 mΩ range 3

•Five (5) digit LCD with LED Backlight

•Easy to clean

•Automatic and manual HOLD modes

•Programmable test limits with OK and FAIL annunciators

•OVER and UNDER annunciators

•Open lead and DUT detection

•Durable: Meets MIL-PRF-28800F, Class 2 requirements

•Optional Tilt Stand/Magnet/Hanger

3Typical battery life under normal use conditions in laboratory environment. Continuous or repeated use of

features such as the backlight or use or storage at high or low temperature extremes may reduce battery life.

Preparation for Use

2-2

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ● [email protected]

Safety Notices and Information

Read this Operation Manual thoroughly before using the instrument to become familiar with its

operations and capabilities.

Visually inspect instrument before using. Do not use if unit appears damaged or with any part of the

case removed.

WARNING

MAINTENANCE INSTRUCTIONS WITHIN THIS MANUAL ARE FOR USE BY QUALIFIED SERVICE

PERSONNEL ONLY. DO NOT ATTEMPT TO SERVICE THIS UNIT UNLESS YOU ARE QUALIFIED TO DO

SO.

SHOCK HAZARD

Disconnect probes from DUT and turn the unit off before removing the battery cover.

Always disconnect probes from DUT before opening the instrument housing. Internal circuits

can present a shock hazard if leads are connected to a source of elevated potential.

Do not use this instrument if the housing, probe wiring, probe, or probe handles are damaged

or distorted. Housings and wire insulation are part of the personnel protection system, and if damaged

could expose users to elevated potentials.

EXPLOSION HAZARD

Never use or store this product with batteries installed, or change batteries, in an

environment where explosive or flammable vapors or dust suspensions may exist.

Do not attempt to recharge alkaline batteries.

Do not put batteries into bags designed to protect parts from electrostatic discharge (ESD).

These bags are specially designed with metal shielding which can short circuit a battery.

Do not expose batteries to extreme heat or fire. Observe all regional laws and regulations when

disposing batteries.

BURN HAZARD

Do not touch a probe that has been exposed to toxic substances or extremely high or low

temperatures.

Safety Notices and Information continued on next page . . .

Preparation for Use

2-3

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ● [email protected]

CAUTION

RISK OF INCORRECT READING

Do not use when AC or DC voltages exist. Excessive voltage could result in an incorrect reading, or

in more extreme cases, a blown fuse that will result in incorrect readings and need for repair.

Do not use on reactive loads exceeding 2mH or 100uF. Measurements may also be impacted when

a large inductive load is measuredin the presence of high 50/60 Hz power. Polarized capacitors should

be avoided.

RISK OF INSTRUMENT DAMAGE

Only replace batteries with size AA (IEC LR6, ANSI 15). Observe proper polarity when installing

batteries. Do not mix old and new batteries.

Do not apply voltages across leads. Excessive input voltage could result in blown fuse, component

damage, or fire. Application of excessive voltage is not covered by the warranty.

Avoid making sharp bends in probe or sensor lead wires. Bending lead wires at sharp angles can

damage the wire and cause probe failure.

Static discharge through a connected probe may cause instrument damage. Use care to avoid

static discharge when handling the instrument or connected probes.

Preparation for Use

2-4

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ● [email protected]

Unpacking and Inspection

Each instrument is electrically and mechanically inspected before shipment. Upon receiving

your new TEGAM Handheld Bond Meter, unpack all items from the shipping container and

check for any obvious damage that may have occurred during transit. Use the original

packing materials if reshipment is necessary.

If any dents, broken, or loose parts are seen, do not use the equipment. Notify TEGAM

immediately.

Check that all items are present. If any items are missing, notify TEGAM immediately.

The following items are included with every new instrument:

•One (1) Handheld Bond Meter;

•One (1) Quick Start Guide;

•Statement of Traceability;

•Three (3) AA, 1.5 V batteries; and

•Optional accessories (if purchased).

Battery Installation and Replacement

Three (3) AA 1.5 V batteries are supplied with the instrument, but not installed. Read the

following battery replacement instructions before attempting to install or remove the

batteries.

CAUTION

Always turn the instrument off and disconnect any connections to DUT before

replacing the batteries. Re-install the battery compartment cover before resuming

use of the instrument.

CAUTION The battery compartment is sealed with a rubber gasket. Use care to not damage the

gasket when removing or installing the battery compartment cover.

CAUTION

Remove the batteries when storing the instrument for an extended period of time or

in a high temperature environment to prevent battery leakage and possible damage

to the instrument.

All measurement parameters may be reset to factory default if batteries are removed while

the instrument is powered on. Always turn the instrument off before changing batteries.

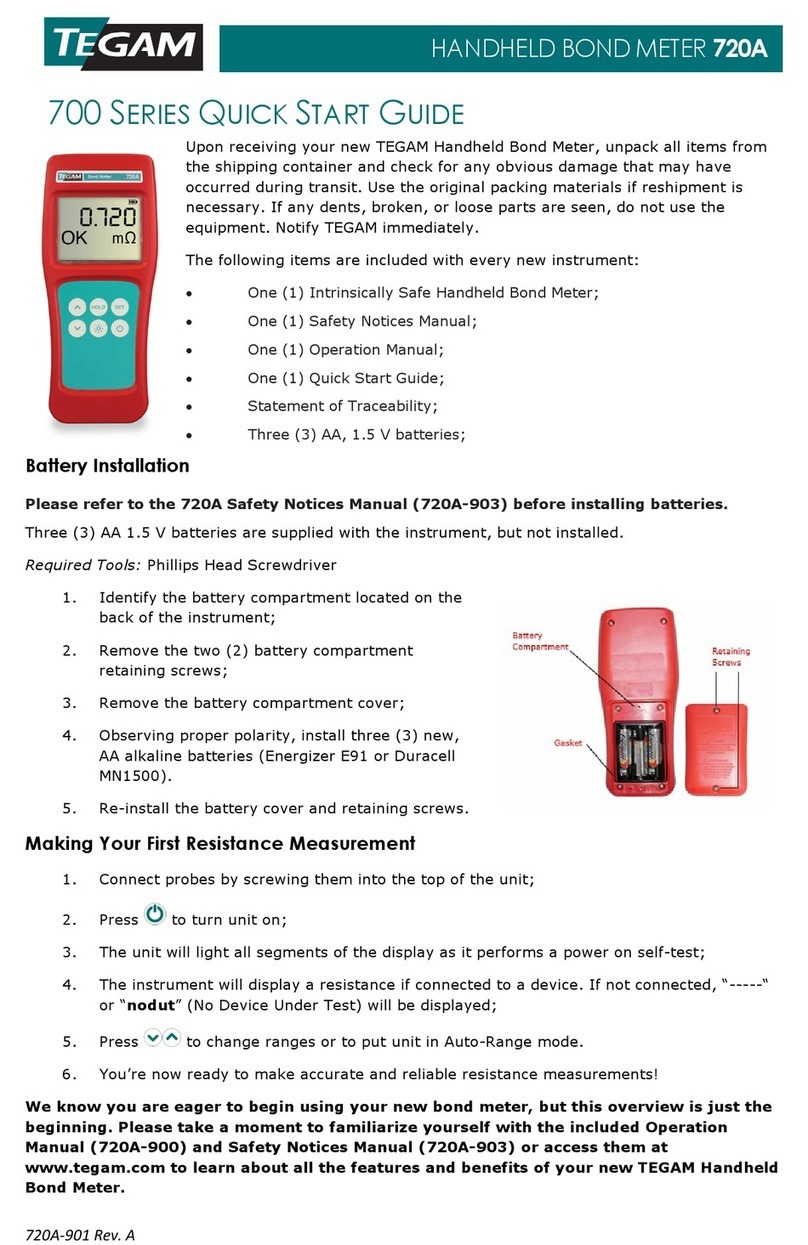

To install or replace batteries:

Required Tools: Phillips Head Screwdriver

1. Identify the battery compartment located on the back of the instrument (see

Figure 1: Battery Installation);

2. Remove the two (2) battery compartment retaining screws;

3. Remove the battery compartment cover;

4. If present, carefully remove old batteries being careful to not damage the battery

contacts;

Preparation for Use

2-5

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ● [email protected]

5. Observing proper polarity, install three (3) new, AA alkaline (IEC LR6, ANSI 15)

batteries;

6. Re-install the battery cover and two (2) retaining screws;

7. At initial power on after battery replacement, allow approximately 30 seconds for

instrument to stabilize.

Figure 1: Battery Installation

Making Your First Resistance Measurement

TEGAM’s 700 Series Handheld Bond Meters are designed for easy operation, while still

providing a feature-rich experience via the intuitive user interface.

To get started making resistance measurements right away, follow these steps:

1. Perform Section 2.5, Battery Installation and Replacement;

2. Connect probes to unit;

3. Press to turn unit on;

4. The unit will light all segments of the display as it performs a power on self-test;

5. The instrument will display a resistance if connected to a device or “nodut” if not

connected;

6. Press to change ranges or to put unit in Auto-Range mode.

Congratulations! You’re now ready to make accurate and reliable resistance measurements,

wherever and whenever you may need to.

We know you are eager to begin using your new bond meter, but this overview is just the

beginning. Please take a moment to familiarize yourself with this Operation Manual to learn

about all the features and benefits of your new TEGAM Handheld Bond Meter.

Retaining

Screws

Battery

Compartment

Gasket

Operating Instructions

3-1

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ● [email protected]

3. OPERATING INSTRUCTIONS

Keypad Functions

The instrument keypad is a six (6)key, sealed membrane keypad. Each key provides audible

and tactile user feedback when pressed. Key functions are described in Figure 2below.

Power instrument ON or OFF

(1.5s)

Disable auto-power OFF while instrument is

on.

(1.5s)

Enter Test Limit Menu (See Section 3.3)

While in Test Limit Menu, save current value

and advance to next parameter

Toggle display backlight

(1.5s)

Disable backlight 30-second timeout

Hold currently displayed measurement and

OK/FAIL result

(1.5s)

Enter/Exit Auto Hold mode (See Section 3.7)

Increment/Decrement through ranges, including AUTO

While in Test Limit Menu, advance or reverse selected parameter

Figure 2: Keypad Button Functional Description

The , , ,and keys have multiple functions which can be accessed by

momentarily pressing the key, or alternatively, by pressing and holding the key for

approximately 1.5 seconds. Throughout this Operation Manual, the press and hold sequence

is indicated by the key designator followed by the subscript (1.5s). For instance, (1.5s)

indicates that the key should be pressed and held for 1.5 seconds, then released to

access the desired function.

LCD Display

The display is a large, easy to read, LCD display, with an LED backlight for clear viewing in

low-light conditions. It can simultaneously display the resistance reading, range, PASS/FAIL

status, open lead detection,over/under indication and the battery level.

Operating Instructions

3-2

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ● [email protected]

See Figure 3below for further description of each display indicator.

1 Measurement is overrange

2 Measurement is 10% or less

of range

3

Solid: Hold function is active

Flashing: Auto Hold function

is active

4

One or both probes are not

electrically connected (See

Section 3.8, Broken Lead

Detection)

5

If a probe is not electrically

connected, the open channel

is indicated (See Section 3.8,

Broken Lead Detection)

6Remaining battery life

7 Resistance measurement

8AUTO range is active

9 Currently selected range

10 The measurement is less than the test limit

11 The measurement is greater than the test limit

12 Reserved for future use

13 Reserved for future use

Figure 3: LCD Display Description

Operating Instructions

3-3

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ● [email protected]

Test Limit Menu

Key designators followed by (1.5s), e.g.

(1.5s)

, indicate that the key should be

pressed and held for 1.5 seconds, then released to access the desired function.

Test limits are available for the customer to easily identify if a measurement is above or

below a resistance value. Press (1.5s) to access the Test Limit Menu. From within the Test

Limit Menu, press to step through the digits, decimal point, and resistance range. Press

the keys to advance or reverse the selected value for the active parameter. The active

parameter value will flash on the display.

To enter the Test Limit Menu, press (1.5s).The active parameter value will flash on the

display.

Press to save a setting and step to the next parameter. If no key is pressed for 10

seconds, the current configuration is saved and the instrument will exit the Test Limit Menu.

Auto-Power Off

Key designators followed by (1.5s), e.g.

(1.5s)

, indicate that the key should be

pressed and held for 1.5 seconds, then released to access the desired function.

To conserve battery life, the instrument automatically turns off if no key is pressed for 20

minutes. To disable this feature, press (1.5s). The remaining battery life indicator will flash

once, indicating auto-power off is disabled.

Auto-power off will remain disabled until instrument power is cycled. At next power on,

auto-power off returns to the default enabled condition.

Backlight and Backlight Timeout

The instrument includes an LED backlight feature to ensure measurement data can be easily

read in low-light conditions. To activate the backlight, press .

Once the backlight is activated, it will automatically turn off to preserve battery life if no key

is pressed within 30 seconds. To disable the backlight timeout feature, press (1.5s). The

backlight will flash to indicate the timeout feature has been disabled. To re-enable the

backlight timeout feature, turn the backlight off then on by pressing twice.

Hold Function

Press to hold the current reading. HOLD is displayed at the top-center of the LCD

display. New measurements are not displayed while the hold function is active. If test limits

are active, the OK or FAIL annunciators will also be held. To disable the hold function and

resume normal operation, press again.

Operating Instructions

3-4

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ● [email protected]

Auto-Hold Function

The Auto Hold function allows the user to take a measurement,have the unit determine a

stable reading,and hold that value. Once the user is ready to make the next measurement,

is pressed momentarily to clear the last reading from the display and re-initiate Auto-

Hold mode.

To use the Auto-Hold Function:

1. Press (1.5s) to initiate Auto-Hold mode.

The unit will not initiate Auto-Hold mode if it is already in Hold mode. If the HOLD

indicator is solid, simply press to exit Hold mode and try initiating Auto-Hold

mode again.

2. The HOLD indicator will begin to flash.

3. If the unit is not connected to a Device Under Test (DUT):

a. “nodut” will appear on the display.

b. Connect leads to DUT.

4. When the unit detects a connection, the display of the unit will blank and begin to

cycle, indicating that the unit is taking a measurement.

5. Once a stable value has been determined and the measurement is completed, the

unit will display the reading of the DUT along with PASS/FAIL status (if enabled).

6. The determined reading and status are temporarily saved and will stay displayed

unless is pressed or the unit is power-cycled.

7. Press to re-arm Auto-Hold mode.

8. The HOLD indicator will begin to flash.

9. If the unit has been disconnected from the DUT, “nodut” will appear on the

display.

10. The unit is ready to take another measurement.

To exit Auto-Hold mode, press (1.5s). The HOLD annunciator will turn off. The unit

is now in normal operating mode.

For best results, put unit in Auto-Range when using Auto-Hold.

Operating Instructions

3-5

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ● [email protected]

Broken Lead Detection

The 700 Series Handheld Bond Meters feature broken lead detection for all ranges. This

feature monitors the test current across the leads on each channel. A small current is

sourced between the Kelvin connection of each channel’s test leads. This detection is

independent of whether a DUT is or is not connected.

If the unit detects anopen circuit in either channel it will illuminate the OPEN annunciator

along with the channel(s) the unit has detected anopen circuit in.

When using the unit with MKP, BKP, and MCP probes, the OPEN and channel

annunciators will be illuminated when not connected to a DUT.

Battery Indicator

Battery depletion or battery replacement will reset all measurement parameters to

their default values. After battery replacement, set measurement parameters as

required.

The battery voltage indicator provides a visual representation of approximate remaining

battery life. It is located at the top-right of the

display.

The battery voltage indicator uses three bars

to represent remaining battery life. Figure 4

shows the approximate battery life for each

bar.

At zero (0) bars, the instrument will

momentarily display bATT and initiate a

shutdown sequence. To prevent disruption of

the measurement process and statistics and

data collection, the batteries should be

replaced before the battery voltage indicator reaches zero (0) bars. See Section 2.5, Battery

Installation and Replacement.

BARS APPROX.BATTERY LIFE

3 100% - 50%

2 50% - 20%

1 20% - 5%

0 0% - Shutdown Initiated

Figure 4: Battery Voltage Indicator

Operating Instructions

3-6

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ● [email protected]

Invalid Measurement Indications

The LCD display indicates when a measurement is invalid, as shown in Figure 5 below.

INDICATION DESCRIPTION

————— The device is auto ranging.

OVER and ----- Reading is 110% of full scale or higher. If possible, switch to a higher

range.

UNDER Reading is 10% of full scale or less. If possible, switch to a lower

range.

OPEN, 1, 2

If the leads become electrically disconnected, the OPEN segment will

illuminate along with segment 1, 2, or both to indicate the

disconnected channel.

“nodut”

The device does not detect a DUT. (no device under test) This

message will appear when Kelvin Clips are connected and closed or in

Auto-Hold Mode between measurements.

Figure 5: Invalid Measurement Indications

Service Information

4-1

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ● [email protected]

4. SERVICE INFORMATION

Inspection and Cleaning

To extend the life of the instrument, inspect and clean the instrument regularly. Inspect the

instrument for any significant abrasions, cuts, cracks, dents, or other signs of damage on

the case, keypad, and display lens. Inspect the connectors for breaks, dirt, or corrosion.

Ensure all screws are securely fastened, and if equipped, that the tilt stand/magnet/hanger

is in good condition and locks into position properly.

With all screws securely fastened and the battery compartment cover in place, use a damp

cloth or towel to wipe down the instrument. Use care to avoid scratching the display lens.

Mild, non-abrasive detergents may be used providing the instrument is then wiped down

with a clean damp cloth or towel.

Calibration

4.2.1 Verification Procedure

1. This procedure shall be performed within environmental conditions of 23 ±1.5 °C

and 5% to 95% RH.

2. The unit under test (“UUT”) shall be acclimated to the controlled environment for a

minimum of four (4) hours.

3. The equipment listed in Appendix A is required to fully verify the UUT.

4. Refer to Appendix B for standard measurement points and tolerances for each

710A resistance range.

5. Record standard resistance values on the Instrument Verification Data Sheet in

Appendix B.

6. Calculate high and low limits using tolerances noted in Appendix B.

7. If not already, connect the M12 connectors of the bond meter probes.

8. Press until UUT is in 100 Ω range. If UUT is in AUTORANGE, press once.

9. Connect the UUT leads to the 100 Ω resistance standard.

10. Note value in “Reading” column of Appendix B.

11. Indicate if the value exceeds the high limit or low limit calculated in Step 6 using

“Pass/Fail” column of Appendix B.

12. Staying in the 100 Ω range, connect UUT leads to 10 Ω standard and record value.

13. Indicate if the value exceeds the high limit or low limit calculated in Step 6 using

“Pass/Fail” column of Appendix B.

14. Press the to put UUT into 10 Ω range and record value.

15. Indicate if the value exceeds the high limit or low limit calculated in Step 6 using

“Pass/Fail” column of Appendix B.

16. Staying in the 10 Ω range, connect UUT leads to 1 Ω standard and record value.

Service Information

4-2

10 TEGAM WAY ● GENEVA, OHIO 44041 ● 440-466-6100 ● FAX 440-466-6110 ● [email protected]

17. Indicate if the value exceeds the high limit or low limit calculated in Step 6 using

“Pass/Fail” column of Appendix B.

18. Press to put UUT into 1 Ω range and record value.

19. Indicate if the value exceeds the high limit or low limit calculated in Step 6 using

“Pass/Fail” column of Appendix B.

20. Staying in the 1 Ω range, connect UUT leads to 100 mΩstandard and record

value.

21. Indicate if the value exceeds the high limit or low limit calculated in Step 6 using

“Pass/Fail” column of Appendix B.

22. Press to put UUT into 100 mΩ range and record value.

23. Indicate if the value exceeds the high limit or low limit calculated in Step 6 using

“Pass/Fail” column of Appendix B.

24. Staying in the 100 mΩ range, connect UUT leads to 10 mΩ standard and record

value.

25. Indicate if the value exceeds the high limit or low limit calculated in Step 6 using

“Pass/Fail” column of Appendix B.

26. Press to put UUT into 10 mΩ range and record value.

27. Indicate if the value exceeds the high limit or low limit calculated in Step 6 using

“Pass/Fail” column of Appendix B.

28. Staying in the 10 mΩ range, connect UUT leads to 1 mΩ standard and record

value.

29. Indicate if the value exceeds the high limit or low limit calculated in Step 6 using

“Pass/Fail” column of Appendix B.

30. Connect UUT leads to 100 µΩ standard and record value.

31. Indicate if the value exceeds the high limit or low limit calculated in Step 6 using

“Pass/Fail” column of Appendix B.

32. Short the leads of the unit in the following order: +I to -I, -I to +E, and +E to -E.

The unit should display 0.000 (±0.002)

33. Indicate if the value exceeds the high limit or low limit calculated in Step 6 using

“Pass/Fail” column of Appendix B.

Other manuals for 710A

2

Table of contents

Other Tegam Measuring Instrument manuals

Tegam

Tegam 710A User manual

Tegam

Tegam 1316A User manual

Tegam

Tegam R1L-D1 User manual

Tegam

Tegam AVM-2000 Troubleshooting guide

Tegam

Tegam 253 User manual

Tegam

Tegam 3525 User manual

Tegam

Tegam GEMINI 5541A User manual

Tegam

Tegam R1L-BIR1 User manual

Tegam

Tegam GEMINI 5540A User manual

Tegam

Tegam 730A User manual

Popular Measuring Instrument manuals by other brands

SEW

SEW PT-30 instruction manual

Emerson

Emerson Micro Motion installation manual

GLI International

GLI International GLI-93711 operating manual

Keysight

Keysight EXA X-Series N9010A Configuration guide

Endress+Hauser

Endress+Hauser Levelflex M FMP40 Brief operating instructions

Tempo Communications

Tempo Communications TV220E Quick reference card