Tegam 252 User manual

MODEL 252

Digital Impedance Meter

Instruction Manual

P/N 43158-CD

Rev F

This owner’s manual was as current as possible when this product was manufactured.

However, products are constantly being updated and improved. Because of this, some

differences may occur between the description in this manual and the product you

received.

TEGAM, INC.

TEN TEGAM WAY

GENEVA, OH 44041

TEL: (440) 466-6100

FAX: (440) 466-6110

www.tegam.com

Publication Date: June 2005

Ten Tegam Way, Geneva, Ohio 44041 (440) 466-6100 (440) 466-6110

TABLE OF CONTENTS

DANGEROUS VOLTAGE POTENTIALS EXIST INSIDE THIS INSTRUMENT. MAINTENANCE

INSTRUCTIONS WITHIN THIS MANUAL ARE FOR USE BY QUALIFIED SERVICE PERSONNEL ONLY.

TO AVOID ELECTRICAL SHOCK, DO NOT ATTEMPT ANY SERVICING OTHER THAN THAT

CONTAINED IN THE OPERATION INSTRUCTIONS UNLESS YOU ARE QUALIFIED TO DO SO.

1 DESCRIPTION

1.1 INTRODUCTION 1-1

1.2SPECIFICATIONS 1-2

2 OPERATION

2.1 CONTROLS AND CONNECTORS 2-1

2.1.1FrontPanel 2-1

2.1.2RearPanel 2-3

2.2OPERATINGPROCEDURE 2-4

2.2.1 Power Requirements 2-4

2.2.2ApplyingPower 2-5

2.2.3 Connection to Unknowns 2-6

2.2.3.1 Test Fixture Compensation 2-8

2.2.4 Function Selection 2-9

2.2.5RangeSelection 2-12

2.2.6SummaryofOperation 2-13

2.3 MEASUREMENT TECHNIQUES 2-15

2.3.1 Resistance Measurements at 1kHz 2-15

2.3.2 Capacitance Measurements 2-15

2.3.3 Inductance Measurements 2-18

2.3.4 Determining Quality Factor (Q) of Inductors 2-19

2.3.5 Determining Dissipation Factor (D) of

Capacitors using Nomograph 2-20

2.3.6 Using the Bias Feature 2-22

2.3.7 Signal Output Terminals 2-23

2.3.8 Measuring Grounded Unknowns 2-23

2.3.9 Measuring Battery Impedance 2-26

2.3.10ComponentSorting 2-28

3 CIRCUIT DESCRIPTIONS

3.1GENERALDESCRIPTION 3-1

i

TABLE OF CONTENTS (continued)

4 MAINTENANCE

4.1 CALIBRATION PROCEDURE 4-1

4.1.1PowerSupplyCheck 4-2

4.1.2 Oscillator Adjust 4-2

4.1.3L,C,R,GAlignment 4-2

4.1.4 Dissipation Factor (D) Alignment 4-3

4.2MAINTENANCE 4-5

4.2.1PreventiveMaintenance 4-5

4.2.1.1 Cleaning 4-5

4.2.1.2 Visual Inspection 4-5

4.3 PREPARATION FOR CALIBRATION OR REPAIR SERVICE 4-6

4.4 WARRANTY

ii

SECTION 1

DESCRIPTION

1.1 INTRODUCTION

Model 252 Digital Impedance Meter is a semi-automatic instrument which permits rapid

measurement of inductance (L), capacitance (C), resistance (R), conductance (G) and dissipation

factor (D) at a test frequency of 1kHz. Measurement accuracy and versatility satisfies most

demanding engineering or Scientific applications.

To operate, merely push the button for the desired function, manually turn the knob to the desired

range, and connect the unknown. KELVIN KLIPS® test leads are included, thus ensuring true four-

terminal connections. The position of the range switch, used in conjunction with the desired

function button and front panel range scale, indicate the unit of measurement being displayed by the

3-1/2 digit LED readout.

Excellent reliability of the Model 252 is assured through use of solid-state devices and etched circuit

board construction. Its small size is ideal for use on bench tops where work space may be at a

premium. The carrying handle tilts the unit to a convenient viewing angle. Rear panel brackets

provide line cord storage and enable it to be operated in a vertical position.

1-1

Table 1-1. Model 252 Specifications

Test Frequency: 1kHz ±1%.

Unknown Excitation: The 1kHz voltage (Vx) and current (Ix) levels listed in Table 1-1 are held

constant by an internal amplitude control circuit.

Measurement Rate: Four per second; one second is required for first reading after connecting

unknown to terminals.

Measurement Display: 3-1/2 digit LED with decimal point. Blanked for overload conditions.

Unit Display: Unit of mesurement being displayed by the LED readout is indicated by position

of the range switch, used in conjunction with the desired function button and the

front panel range scale.

External Bias: Rear panel terminals are provided for connection of external supply. 0V to 50VDC,

0.1A maximum. (Read Section 2.2.6 before using external bias.)

Static Charge Protection: Diode and resistor discharge network.

1-2

1.2 SPECIFICATIONS

Connection to Unknown: Four-terminal, shielded, connections are provided by the KELVIN KLIPS®

cable assembly (Tegam Part Number 43072) supplied with the Model

252.

Outputs: Analog signals of 1V per 1,000 counts, 1kΩsource resistance is available at rear panel.

L, C, R, or G, with simultaneous output of D for L or C.

Power Consumption: 4 watts typical.

Power Requirements: 100 to 125V or 200to250V,50/60Hz.

Fuse: 110V: 1/16A 250VAC Slow-Blow

220V:1/20A 250VAC Slow-Blow

Size: Height (with feet) - 100mm (3.9 in.)

Width - 260mm (10.2 in.)

Depth (overall) - 370mm (14.6 in.)

Weight: 3.2kg (7 lb.)

Accessories supplied with Model 252: Part No.

KELVIN KLIPS® Four-Terminal Clips 43072

Instruction Manual 43158

Options Available: Part No.

Model 1412B Universal Limits Comparator 31412B

Sorting Fixture Model 2001 (low frequency) 32001

Cable Assembly (for Model 2001 connection) 43586

Front Panel Dust Cover 43374

AdditionalAccessories PartNo.

Chip Tweezers 2005B/SP5132

Kelvin Klip Rebuild Kit KK100

Chip Tweezer Rebuild Kit 47422

1-3

SECTION 2

OPERATION

2.1 CONTROLS AND CONNECTORS

2.1.1 Front Panel

Figure 2-1. Model 252 Front Panel

1. ON/OFF Switch – A push-on, push-off switch for applying and

removing power from the instrument.

2. UNKNOWN Connector – Terminals designed to be used with KELVIN

KLIPS® test leads (Tegam Part No. 43072),

Provided with Model 252, to provide a true

Four-terminal connection to the unknown or

Testfixture.

3. L, R, C, and G Pushbuttons – Function pushbuttons select the type

of meter circuit that will measure

series inductance (L) and resistance

(R) or parallel capacitance (C) and

conductance (G).

2-1

4. D Pushbutton -- The push-to-read D (dissipation factor) pushbutton displays the D of a capacitor or

inductor when the C or L function is selected.

5. Range Switch -- Selects the decimal multiplier and units of measurement for the meter circuit being

used. The basic multipliers and units are: H (henrys), mH (millihenrys), µH

(microhenrys), pF (microfarads), nF (nanofarads), pF (picofarads), k Ω(kilohms),

Ω(ohms), mS (millisiemens), and µS(microsiemens).

6. Display — A 3-1/2-digit readout for all functions.

7. Tiltstand Handle -- Aids portability; tilts instrument for easier viewing of the LED display.

2-2

2.1.2 Rear Panel

Figure 2-2. Model 252 Rear Panel

1. Bias Terminals – Allows application of a 2V to 50VDC, 0.1A maximum bias to the

capacitor being measured. (The shorting bar must be in place

when not using bias feature.) See Section 2.3.6 before

using external bias.

2. Output Terminals – Provides two analog signals proporational to the function

selected (L, R, C, or G) and D (for L and C). These terminals

can be used with external DVM’s (for increased full scale

readings or resolution capability), with chart recorders, or with

limits comparators, such as the Tegam Model 1412B.

3. Fuse – A 1/16A, 250V, type MDL Slow Blow for 110V line voltage, or a 1/20A, 250V

type MDL Slow Blow for 220V line voltage.

2-3

2.2 OPERATING PROCEDURE

2.2.1 Power Requirements

Before turning the power ON, make sure the instrument is set to the proper line voltage.

The Model 252 contains an internal slide switch to select the nominal line voltage

(see Figure 2-3). In its up position, the switch selects 100 to 125VAC, 50/60Hz operation. In

the down position it selects 200 to 250VAC, 50/60Hz operation.

WHEN CHANGING FROM 110VAC OPERATION TO 220VAC OPERATION (OR

IN OPPOSITE ORDER), BE SURE TO REPLACE THE REAR PANEL AC FUSE

WITH THE PROPER VALUE FOR THE LINE VOLTAGE SELECTED.

Figure 2-3. Line Voltage Switch

2-4

Because of differing power requirements, all instruments shipped outside the United States are without a

power cord connector. When placing a connector on the power cord, care must be taken to assure

the wires are connected properly. The green or green with yellow stripe wire is always connected to

earth ground. The white or light blue wire is connected to the neutral side of the power line. And,

the black or brown wire is connected to the high side of the power line.

2.2.2 Applying Power

The push-on, push-off, ON/OFF button in its depressed position applies power to the measurement

circuitry. When power is applied, the LED display lights and reads zero when in C and G modes or the

display is blank with the decimal point lit in the L and R modes.

2-5

2.2.3 Connection to Unknowns

The KELVIN KLIP® test lead set (Tegam Part No. 43072) is plugged into the 252’s front panel

UNKNOWN connector. The test leads connector cover is spring-locking and should be squeezed together

before inserting or removing.

The test leads provide a shielded, four-terminal connection to the unknown (see Figure 2-5a). The clip

with the red hinge-spool provides the HI DRIVE and HI SENSE connections to the unknown and the clip

with the black hinge-spool make the LO DRIVE and LO SENSE connections.

Figure 2-5a.

2-6

Figure 2-5a.

Figure 2-5b.

For connection to three terminal unknowns (the third connection is to ground), a ground wire must be

added to the test lead set. This wire is connected as in Figure 2-5b.

2-7

2.2.3.1 Test Fixture Compensation

The Model 252 uses a 3.3pF capacitor (C6 in Figure 2-6) to compensate for the capacitance of

the test leads. If the 252 is used with a test fixture, the larger capacitance of the fixture must

also be compensated for. There are two methods for compensating this larger capacitance. The

first method is to make a zero capacitance measurement with the test fixture connected. This

reading is mentally subtracted from all other measurements.

The second method for compensating the larger capacitance is to change the value of C6 from 3.3 pF

to 10 pF and to add an external trim capacitor. The external trim capacitor is connected in parallel with

the unknown and should be of such a value that the test fixture capacitance can be trimmed to zero.

Typically, the maximum value of this trim capacitor is 15pF. The trim capacitor can either be added

to the test cable, between Terminals 1 and 3 of the connector as shown in Figure 2-6, or it can be

added to the test fixture.

Figure 2-6. Test Fixture Compensation

2-8

2.2.4 Function Selection

Model 252 is designed to measure series inductance (L), parallel capacitance (C), series resistance (R),

parallel conductance (G), and dissipation factor (D) of inductance and capacitance. One of these

measurement modes is selected by depressing the proper front panel button. (If all buttons are in their

out position, the instrument reverts to the inductance measurement mode.)

Example: Select the capacitance measurement function. (Depress the C pushbutton.)

2-9

Example: Select the conductance measurement function. (Depress the G Pushbutton.)

If a negative sign appears on the display when measuring an unknown, possible causes are:

“C” button has been pushed when measuring an inductor.

“L” button has been pushed when measuring a capacitor.

The unknown is more capacitive (or inductive) than suspected. For example, an

inductor that resonates below 1kHz will measure as though it were a capacitor.

A diode requires bias voltage (a negative reading may appear if bias voltage is not applied).

2-10

Table of contents

Other Tegam Measuring Instrument manuals

Tegam

Tegam 1316A User manual

Tegam

Tegam 1806 User manual

Tegam

Tegam R1L-BI User manual

Tegam

Tegam R1L-D1 User manual

Tegam

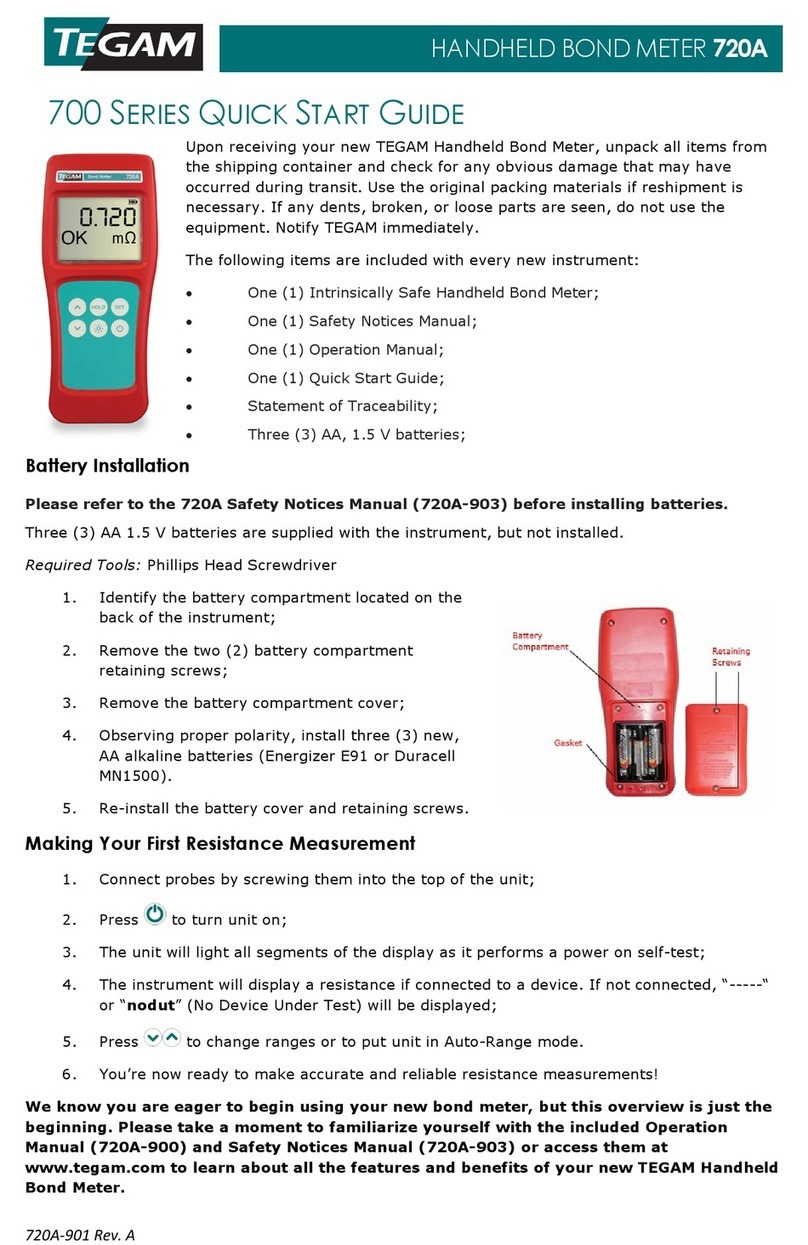

Tegam 720A User manual

Tegam

Tegam 110A User manual

Tegam

Tegam 1830A Troubleshooting guide

Tegam

Tegam AVM-2000 Troubleshooting guide

Tegam

Tegam 710A User manual

Tegam

Tegam R1L-BR1 User manual

Popular Measuring Instrument manuals by other brands

LaserLiner

LaserLiner AutoCross-Laser 360 PowerBright operating instructions

KERN

KERN MSF 200 operating instructions

Keysight Technologies

Keysight Technologies N8262A P Series user guide

Montana Instruments

Montana Instruments CryoCore quick start

Rae

Rae VRAE PGM-7800 Operation and maintenance manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS 645B01 Installation and operating manual