TEKELEK Ultrasonic LoRaWAN User manual

Ultrasonic LoRaWAN

Installation Guide (US 915mhz)

Thank you for purchasing the Tekelek Ultrasonic LoRaWAN sensor which

uses ultrasonic technology to measure the liquid level of your tank and

then communicates this data to a LoRaWAN network.

STEP 1: Activation

The Ultrasonic LoRaWAN sensor works in conjunction with a LoRaWAN

network and a connected platform and before activation must first be

registered with both. Access to the LoRaWAN backend server is required

to verify that the unit has correctly joined the network. See User Manual

for further details.

Ensure that the LoRaWAN™network is within communication range of the

sensor. This should occur before the sensor is physically fitted onto the

Tank. The sensor supports one factory configurable sub-band between 1

and 8.

Place the sensor as close as possible to the point of installation, press the

button for 1 second to connect to the LoRaWAN network and upload a

status message.

•The LED will stay illuminated as the sensor registers:

−Red LED flashing = The sensor is registering & connecting for the first

time. (Sensor is shipped in dormant state).

−Green LED flashing = The sensor is already registered. The

connection process will take between 20 & 40 seconds.

•After the connection has completed, the LED will

flash on & off (to indicate whether the connection

was a success or failure).

1

LED Patterns

•Press and hold the button for approximately 1 second, until the LED

turns green.

•Wait approximately 10-20 seconds and observe if the LED flashes

green or red.

See the following for description of Green/Red LED flash codes.

LED Radio Signal Strength Flash Codes:

LED Pattern

Function

Green X 3 Flashes

Excellent signal strength

Green X 2 Flashes

Good signal strength

Green X 1 Flash

Adequate signal strength

Alternate Green/Red Flash

Weak signal strength

Weak signal strength: Try 5 times and if this response is stable then

it’s deemed adequate. If the sensor shows some double red flashes

during this signal strength test - Sensor may need to be elevated for

best performance.

LED Error Flash Codes:

LED

Pattern

Function

Red X 1

Flash

Device registered with an incorrect AppKey.

Red X 2

Flashes

No response from LoRaWAN network

Red X 3

Flashes

General Error. Please try again. If the error

persists, contact the supplier for support.

2

STEP 2: Installation

The following outlines the Ultrasonic LoRaWAN sensor mounting options.

•The sensor must sit in a vertical position on top of the tank and be

fitted such that the sensor has a clear path to the tank contents.

Position it so that there are no internal obstructions that may

interfere with the ultrasonic signal.

•If obstacles cannot be avoided, then a waveguide may be required.

Please refer to Appendix 1 for further details.

•Locate a suitably positioned threaded opening on the top of the tank

to hold the sensor.

−The sensor will fit directly into threaded 2” BSP (British Standard

Pipe) existing tank connections.

−Ensure that the rubber seal is placed, and that the sensor is screwed

correctly into the tank. Do not over-tighten!

•For tanks that do not contain a suitably positioned threaded opening

on the top of the tank to hold the sensor, please refer to Appendix 2

& 5.

3

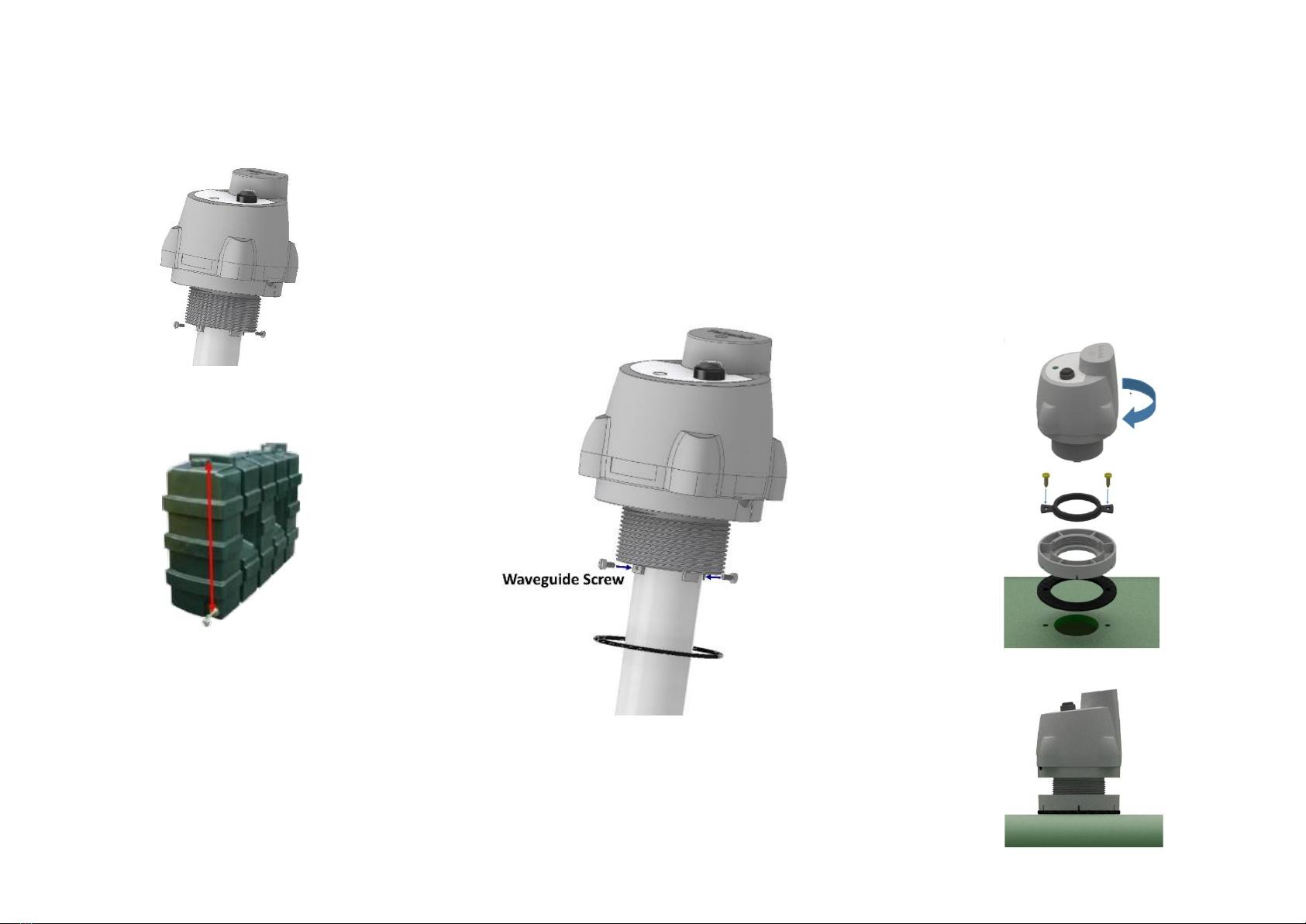

Appendix 1: Standard Waveguide

•For the waveguide option, source a suitable pipe to act as the

waveguide. This pipe should have an outer diameter of 40mm. The

recommended pipe material is PVC (domestic waste pipe is often

used). Other materials are possible but should be checked for

chemical resistance to fuel oil.

•The pipe should be cleanly cut to length. The length required should

be measured from the top of the tank (where the sensor is to be

mounted) to that of the fuel outlet point (as shown).

Note: The bottom of the pipe should be a minimum of 5cm from the base

(floor) of the tank to prevent it from touching in the case of tank

dimensional changes due to temperature etc.

•The waveguide pipe should be securely attached via the two screws

provided and hand tightened (Note: over-tightening the screws can

damage the plastic). Drill a 1.5mm pilot hole in 2 opposite tabs of the

adaptor to guide the screws.

•Care should be taken to keep the sensor and pipe vertically aligned

and supported, while fitting during the installation.

•Insert the rubber seal ring (supplied) and position it on the

face of the adaptor that is screwed onto the top of the tank.

4

•Insert the whole assembly carefully into the tank, taking care not

to loosen the pipe, and fit into position. Hand tighten the

assembly until the rubber seal locks into position.

•The use of a waveguide requires that the Ultrasonic LoRaWAN

sensor be configured with a waveguide ultrasonic profile from the

LoRaWAN server.

Note: the default sensor configuration is non-waveguide mode and the

measurements will be inaccurate unless a waveguide configuration mode

is used.

Note: The use of this Waveguide option is limited to a range of 3m and

not 4m as per standard operation.

5

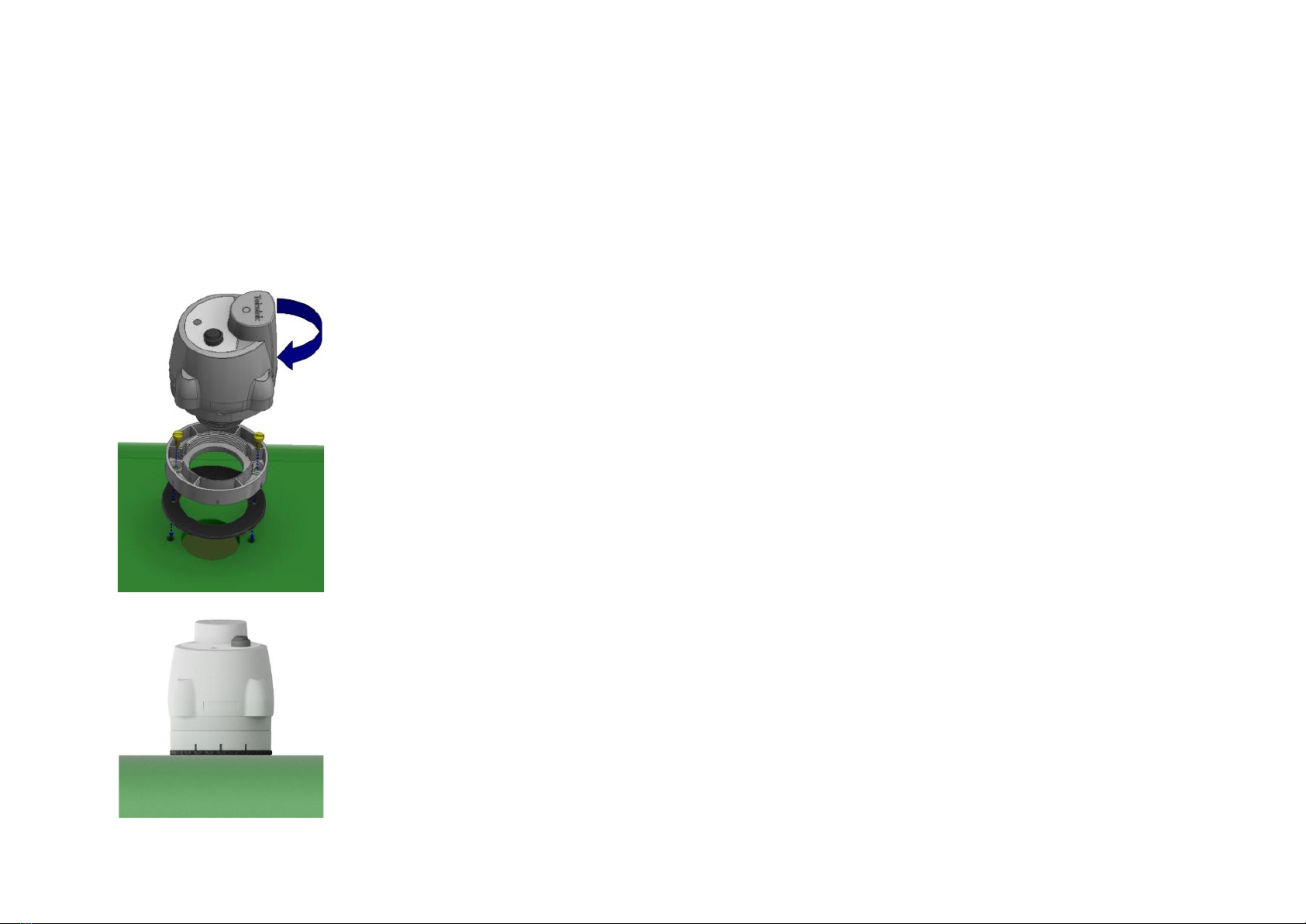

Appendix 2: Drilling procedure for Mounting adaptor.

•Choose a flat spot on the top of the tank.

•Use a 45.5mm tapping drill to drill a 1 ½” BSP hole on the surface of

the tank.

•Place the foam gasket over the hole followed by the mounting

adaptor.

•Place mounting plate seal in the required groove of the mounting

adaptor.

•Tighten on to tank with 2 stainless steel self-tapping, counter sunk

screws, supplied. Do not over tighten!

•Screw the sensor into the adaptor. Ensure that the sensor is vertical

on the tank and screwed correctly into the base and that the threads

have not crossed, to give a secure seal.

Note: Some threading will still be visible after the sensor has been

secured.

6

Appendix 3: Multi-Thread Adaptor

•For tanks that do not contain a suitably positioned threaded opening

on the top of the tank to hold the sensor, the pre-existing 2” adaptor

will need to be removed from the sensor and replaced with a multi-

thread adaptor, shown below.

•Remove the 2” adaptor by unscrewing the M3.5x10 Pozi screws x

4 that attach it to the base of the ultrasonic sensor.

•The Multi-Thread adaptor should be attached to the pairing

adaptor using No.8x13mm Pozi screws x 2.

•The pairing adaptor should then be attached to the ultrasonic

sensor base using the M3.5x10 Pozi screws x 4 that previously

held the 2” adaptor in place.

Note: This adaptor can also be used with the waveguide option but will

require a 36mm pipe. The waveguide pipe should be securely attached via

the two grub screws provided and hand tightened with an M1.5 Allen key

(Note: over-tightening the grub screws can damage the plastic).

7

Appendix 4: Multi-Thread Adaptor Waveguide

•For the waveguide option when using the Multi-Thread adaptor,

source a suitable pipe to act as the waveguide. This pipe should

conform the dimensions in the figure below in order to fit the

sensor. The recommended pipe material is PVC (domestic waste

pipe is often used). Other materials are possible but should be

checked for chemical resistance to fuel oil.

•Cross-section of waveguide pipe assembly:

•The pipe should be cleanly cut to length. The length required should

be measured from the top of the tank (where the sensor is to be

mounted) to that of the fuel outlet point (as shown).

Note: The bottom of the pipe should be a minimum of 5cm from the

base (floor) of the tank to prevent it from touching in the case of

tank dimensional changes due to temperature etc.

•The waveguide pipe should be securely attached via the two grub

screws and hand tightened with an M1.5 Allen key (Note: over-

tightening the grub screws can damage the plastic). Care should be

taken to keep the sensor and pipe vertically aligned and supported,

while fitting during the installation.

8

Note: Depending on the weight, length and surface finish of the

pipe, it may be necessary to glue it into position. In this case a hole

should be drilled near the top of the waveguide pipe, just below the

adapter, to ensure that any trapped air can exit.

•Insert the correctly sized rubber seal ring, as required for the

tank opening (supplied), and position it on the face of the

adapter that is screwed onto the top of the tank.

•Insert the whole assembly carefully into the tank, taking care not

to loosen the pipe, and fit into position. Hand tighten the

assembly until the rubber seal locks into position.

9

Appendix 5: Drilling procedure for Multi-Thread adaptor.

•Set up Multi-Thread adaptor as indicated in Appendix 3.

•Choose a flat spot on the top of the tank.

•Use a 45.5mm tapping drill to drill a 1 ½” BSP hole on the surface of

the tank.

•Place the foam gasket over the hole followed by the mounting

adaptor.

•Tighten on to tank with 2 stainless steel self-tapping, counter sunk

screws, supplied. Do not over tighten!

•Screw the sensor into the adaptor. Ensure that the sensor is vertical

on the tank and screwed correctly into the base and that the threads

have not crossed, to give a secure seal.

10

9-6133-02

Other TEKELEK Accessories manuals