© 2009 W 423 - 03/09 10 of 12

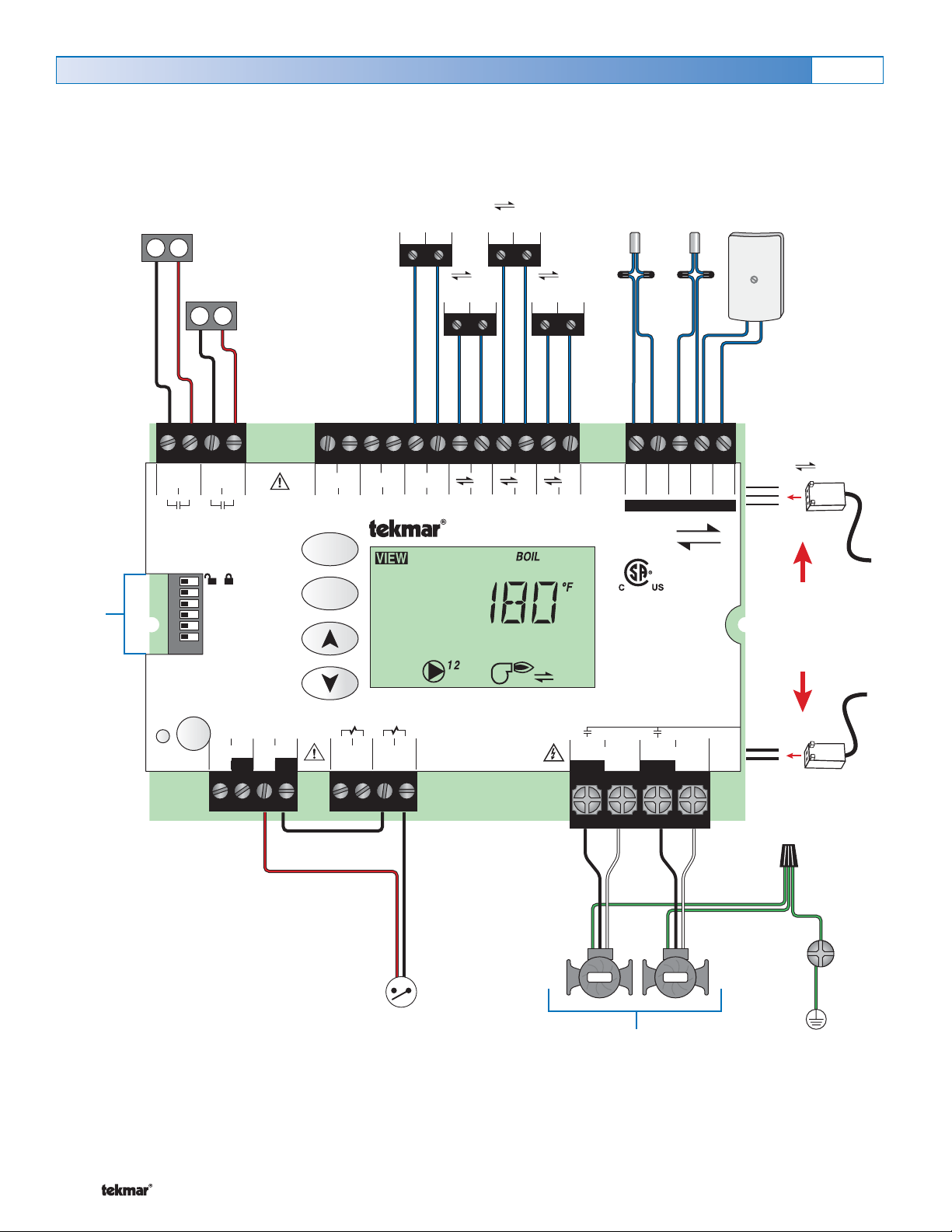

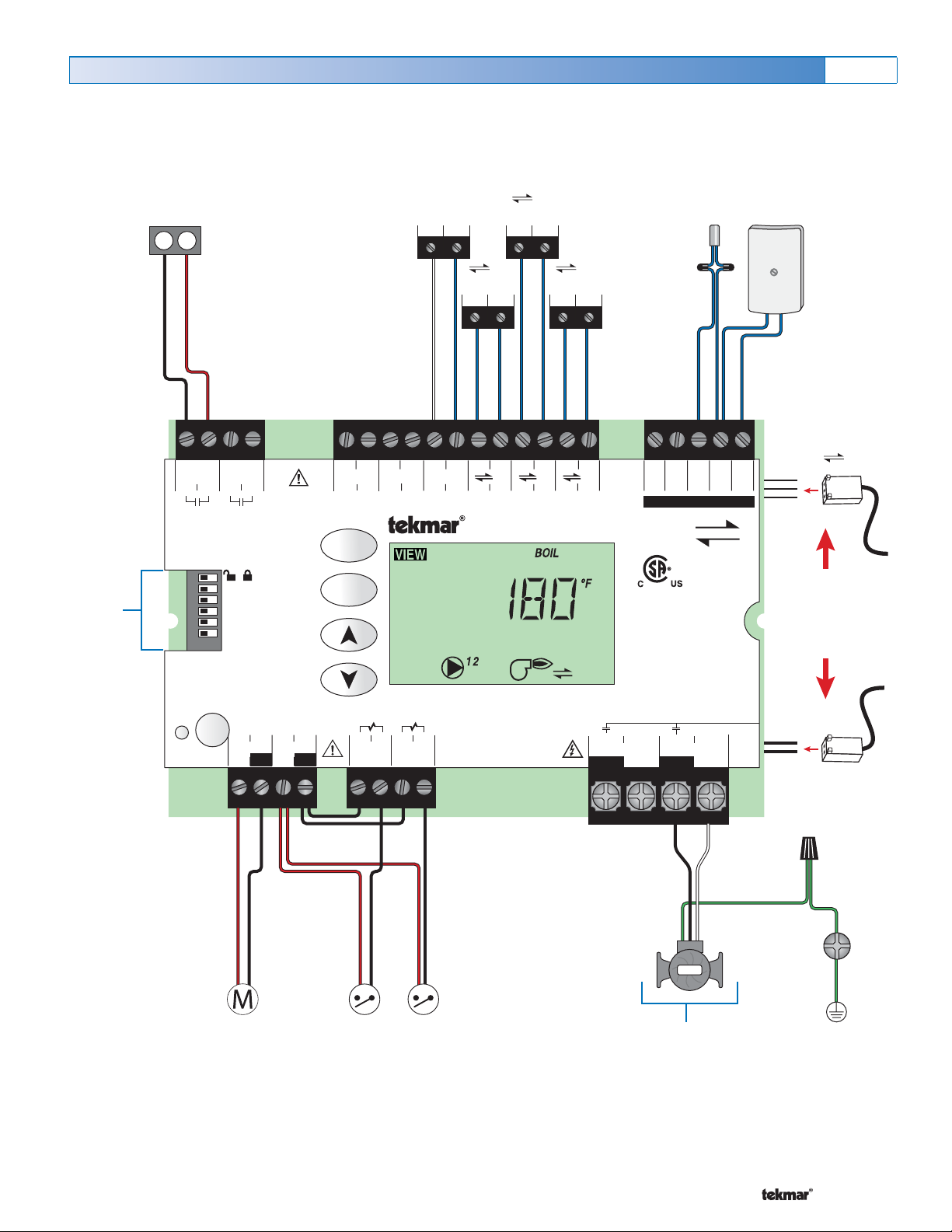

Wiring the DHW and Primary Pump Terminals 79 - 80, 81 - 82

The control operates a Primary Pump, and a DHW

Pump.

• If a Primary Pump is used, the pump is wired directly to

terminals 81 and 82.

• If a DHW Pump is used, the pump is wired directly to

terminals 79 and 80.

• The pumps’ ground wires are connected to the ground

screw provided in the wiring chamber.

Note: For pumps larger than the control’s rated capacity,

an external isolation relay must be used.

Pump

Pump

L & N

81 82

Primary

Pump N

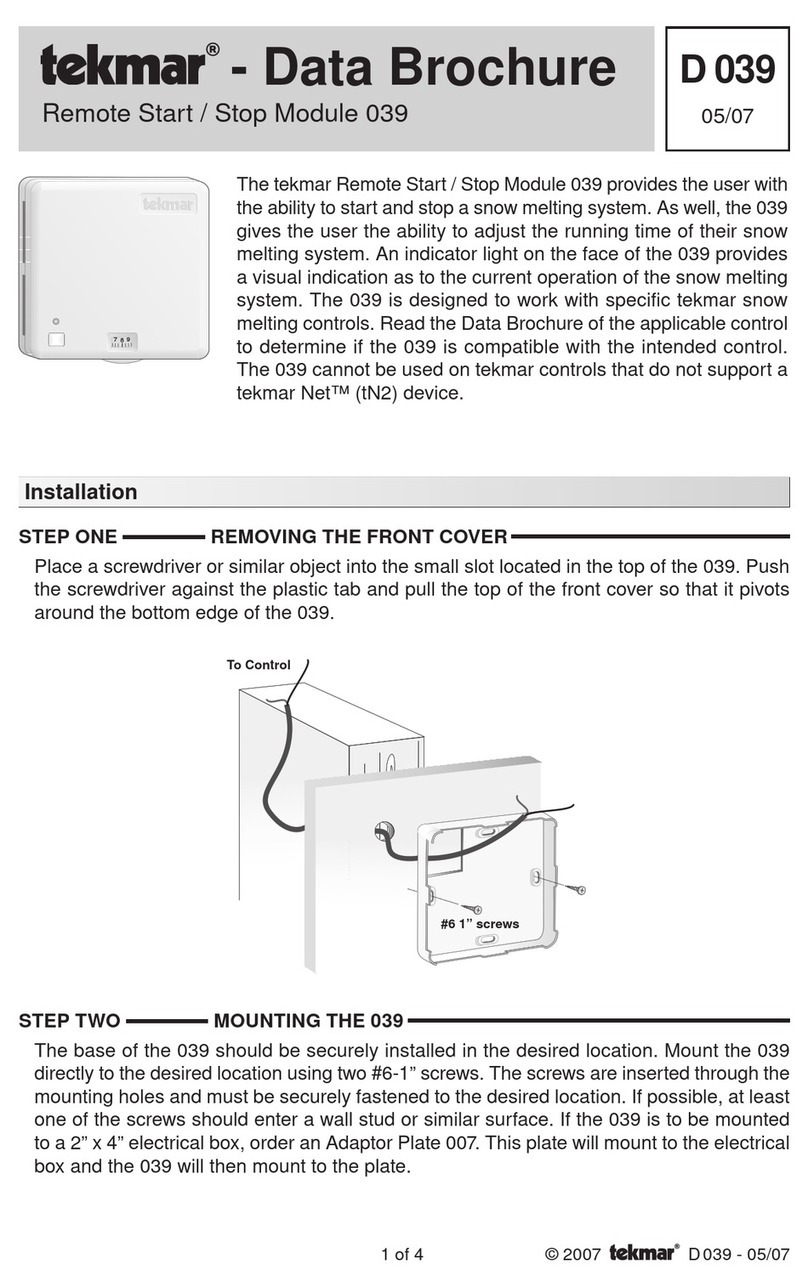

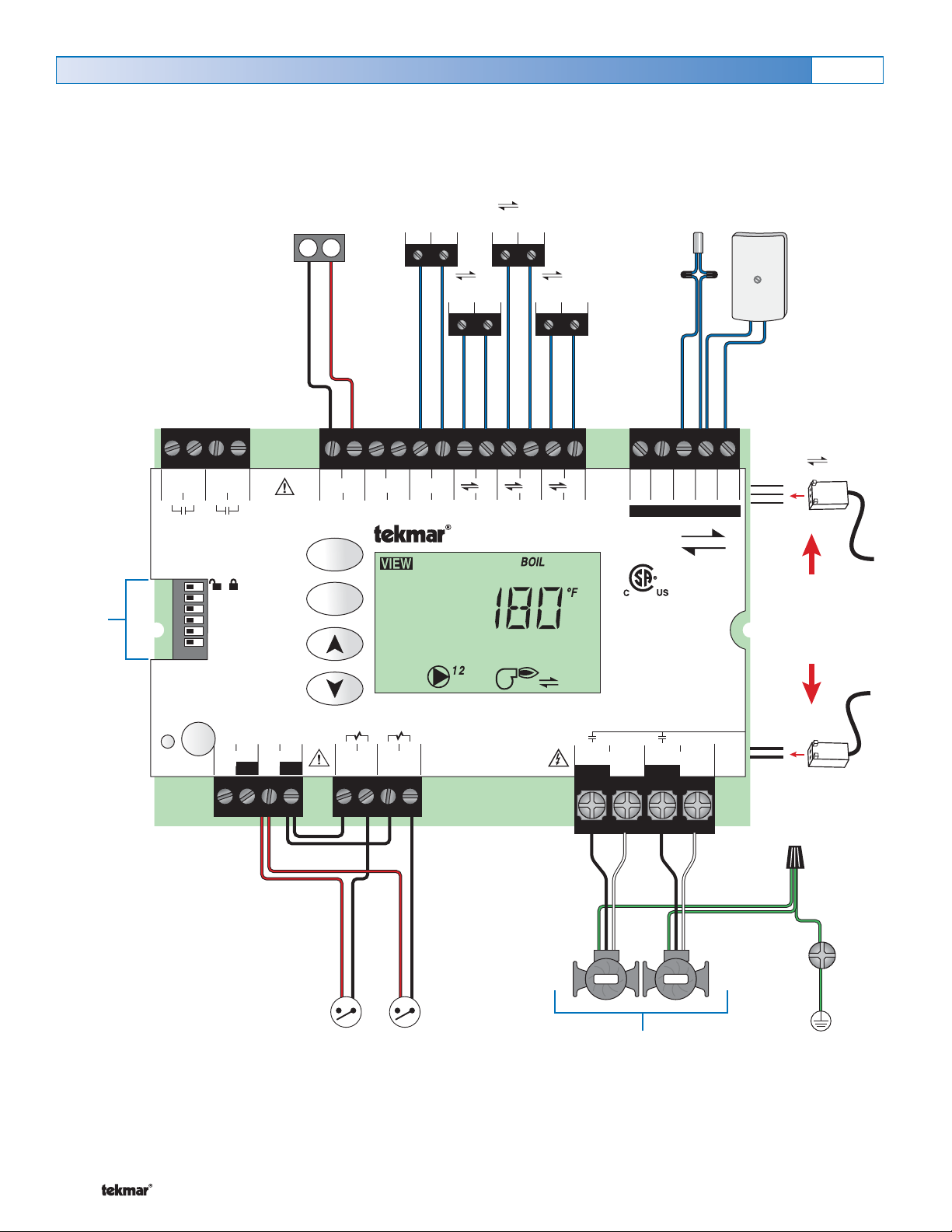

Testing the Control Terminals 50 - 82

Test the Stage 1 and Stage 2 Contacts Terminals 50-53

1. Shut off power to the control and the boiler circuit.

2. Remove the front cover from the control. Disconnect the

wires from the Stage 1 and Stage 2 contacts (terminals

50-51, 52-53).

3. Apply power to the control and press the Test Button.

4. Use an electrical test meter and check for continuity

between terminals 50-51 and 52-53.

• When each stage symbol is displayed in the LCD, there

should be continuity.

• When the stage symbol is not displayed in the LCD,

there should be no continuity.

5. Reconnect the wires to the Stage 1 and Stage 2 contacts

(50-51 and 52-53), install the front cover on the control

and apply power to the boiler circuit.

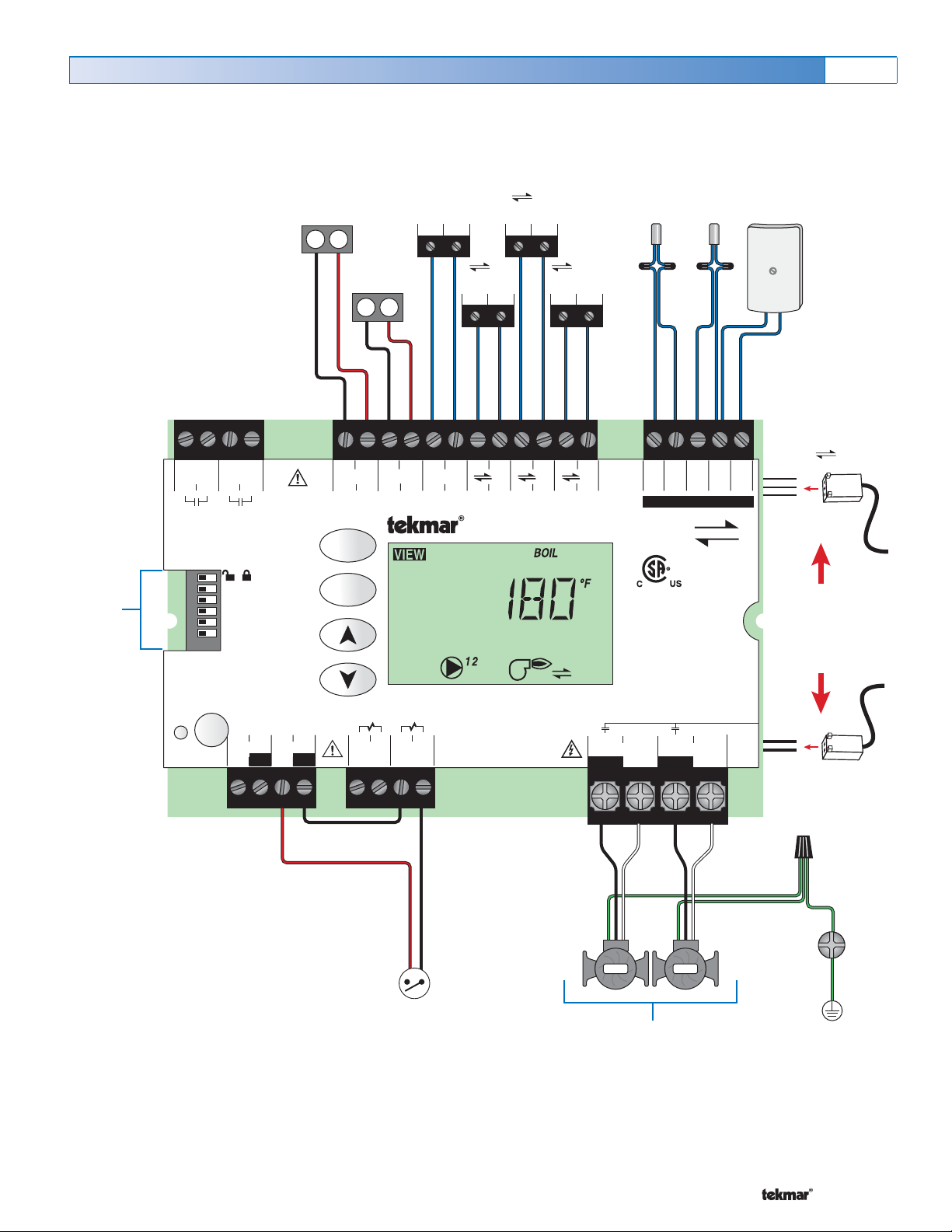

Testing Modulating Action (0 - 10 V dc) Terminals 54 - 57

1. Ensure that the control is set to operate the modulating

output.

2. Remove the front cover from the control.

3. Press the Test Button.

4. When the % output graph and the burner symbol are

displayed in the LCD, use an electrical test meter to

measure the (dc) voltage between the Mod (dc) + and

the Mod (dc) - terminals (54-55, 56-57). The reading

should vary between 0 V (dc) and 10 V (dc).

5. If power is not present:

• Check the power supply to the Zone Manager and the

field replaceable fuse for the transformer on the Zone

Manager.

• If the fuse is blown, determine the cause of the failure

before replacing the fuse.

• Also check the Plug in connections on the underside of

the control.

Troubleshooting the Wiring

Test Meter

Control Terminals

The following tests are to be performed using standard

testing practices and procedures and should only be carried

out by properly trained and experienced persons.

A good quality electrical test meter, capable of reading from

at least 0-300 V (ac), 0-30 V (dc), 0-2,000,000 Ohms, and

testing for continuity is essential to properly test the wiring

and sensors.

General

For an explanation on the use of the Test Button, the ‘Test’ sequence or any error messages, refer to the Data Brochure.