© 2015 680_B - 10/15

3 of 8

A Watts Water Technologies Company

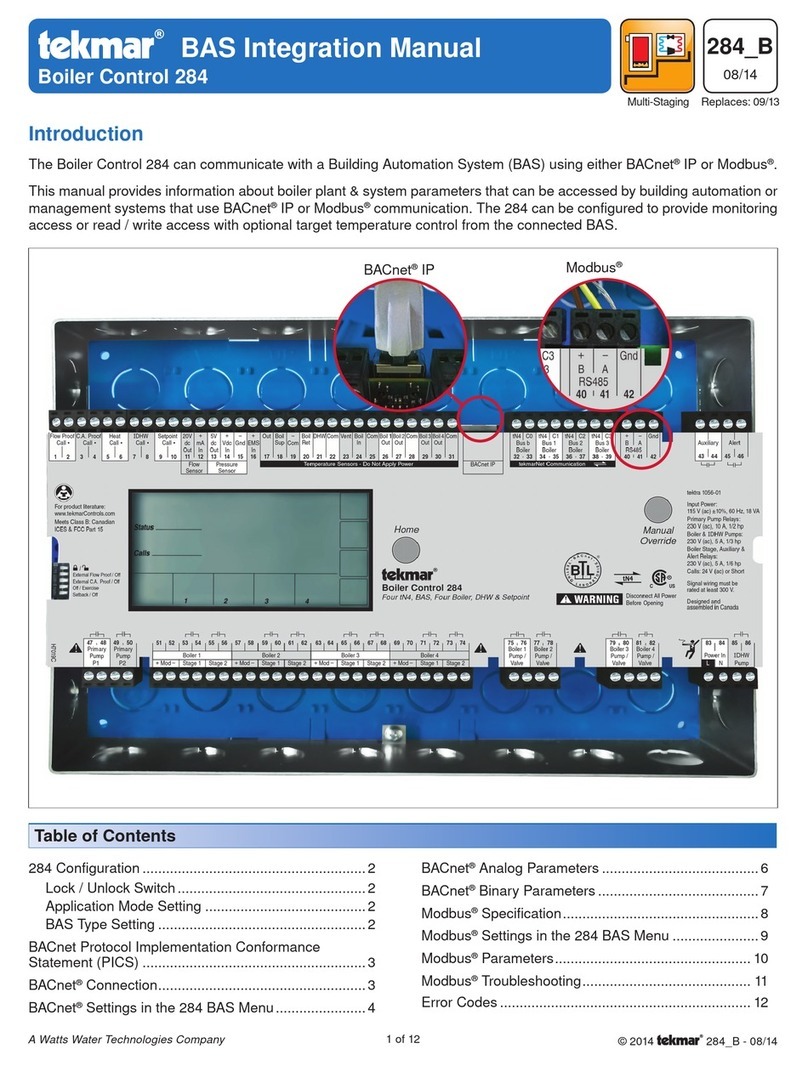

Object

ID

Name Data

Type

Read/

Write

Units Range/Value

Analog Input Objects

0 Operation AI R No Units (95)

0 = Off, 1 = Idle,

2 = Storm, 3 = Melt,

4 = Manual Override

1 Operation Status AI R No Units (95)

0 = Normal, 1 = WWSD,

2 = CWSD, 3 = Timed Melting,

4 = Warming Up, 5 = Pending

2 Melt Time Remaining AI R Hours (71) 0 to 24:00 hours

3 Additional Melt Time Remaining AI R Hours (71) 0 to 6:00 hours

4 Outdoor Air Temperature AI R °F (64) -67 to 149°F

5 Slab 1 Temperature AI R °F (64) -58 to 167°F

6 Slab 2 Temperature AI R °F (64) -58 to 167°F

7 Coldest Slab Temperature AI R °F (64) -58 to 167°F

8 Slab Target Temperature AI R °F (64) 20 to 120°F

9 Boiler Supply Temperature AI R °F (64) -31 to 266°F

10 Boiler Return Temperature AI R °F (64) -31 to 266°F

11 Boiler Target Temperature AI R °F (64) 50 to 230°F

12 Boiler Output AI R % (98) 0 to 100%

13 System Supply Temperature AI R °F (64) -31 to 266°F

14 System Return Temperature AI R °F (64) -31 to 266°F

15 Mix System Target Temperature AI R °F (64) 50 to 230°F

16 Mix System Output AI R % (98) 0 to 100%

17 PWM and Electric Heat Output AI R % (98) 0 to 100%

18 System Flow Rate AI R US GPM (89) 0 to 1000 GPM

19 System Pressure AI R PSI (56) 0 to 300 psi

19 Melting Energy AI R Therms (21) 0 to 65535 Therms

21 Melting Hours AI R Hours (71) 0 to 65535 Hours

22 Heat Cycles AI R No Units (95) 0 to 65535 Cycles

23 System Pump Run Time AI R Hours (71) 0 to 65535 Hours

24 Primary Pump Run Time AI R Hours (71) 0 to 65535 Hours

25 Boiler Pump Run Time AI R Hours (71) 0 to 65535 Hours

26 Error Code AI R No Units (95) See Error Codes list

Analog Value Objects

0BAS Outdoor Air Temperature AV R/W °F (64) -67 to 149°F

1Melt Setpoint AV R/W °F (64) 32 to 95°F

2Idle Setpoint AV R/W °F (64) 20 to 95°F, 0 = off

3Storm Setpoint AV R/W °F (64) 20 to 95°F, 0 = off

4Manual Melt Time AV R/W Hours (71) 0:30 to 24:00 Hours

5Add Melt Time AV R/W Hours (71) 0:00 to 6:00 Hours

6Storm Run Time AV R/W Hours (71) 0:30 to 24:00 Hours

7Snow/Ice Sensitivity 1 AV R/W No Units (95) 0 = Auto, 1 = Min, 2 = -2, 3 = -1,

4 = Mid, 5 = +1, 6 = +2, 7 = Max

8Snow/Ice Sensitivity 2 AV R/W No Units (95) 0 = Auto, 1 = Min, 2 = -2, 3 = -1,

4 = Mid, 5 = +1, 6 = +2, 7 = Max

9Warm Weather Shut Down AV R/W °F (64) 32 to 95°F

10 Cold Weather Cut Out AV R/W °F (64) -30 to 50°F

BACnet Analog Parameters

Analog Input Object = AI Analog Value Object = AV Read = R Read/Write = R/W