Step Six

Before you leave

• Install the wiring cover over the wiring chamber and secure it to the base with the screw provided. Place the front cover over the

control and snap it into place.

• Placethisbrochure,andallotherbrochuresrelatingtotheinstallation,intheprotectiveplasticbagsuppliedwiththecontrol. Place

the bag in a conspicuous location near the control for future reference.

• It is important to explain the operation of the control and melting system to all users who may be operating it.

Technical Data

Theinstallermustensurethatthiscontrolanditswiringareisolatedand/orshieldedfromstrongsourcesofelectromagneticnoise.Conversely,

thiscontroldoesnotexceedtheClassBlimitsforradionoiseemissionsfromdigitalapparatusassetoutintheRadioInterferenceRegulations

of the Canadian Department of Communications. If this equipment does cause interference, the user is encouraged to try and correct the

interference by reorienting the receiving antenna and/or relocating the receiver with respect to this equipment.

Le présent numérique n’émete pas de bruits radioeléctriques dépassant les limites applicables aux appareils numériques de Classe B

prescrites dans le réglement sur le brouillace radioeléctrique édicté par le Ministére des Communications du Canada.

Limited Warranty and Product Return Procedure

Limited Warranty: tekmar warrants to the original purchaser each tekmar

product against defects in workmanship and materials when the product is

installed and used in compliance with tekmar's instructions. This limited

warranty covers the cost of parts and labour provided by tekmar to correct

defects in materials and/or workmanship. Returned products that are fully

operational are not considered a warranty case. tekmar also does not cover

parts or labour to remove, transport or reinstall a defective product. tekmar will

not be liable for any damage other than repair or replacement of the defective

part or parts and such repair or replacement shall be deemed to be the sole

remedy from tekmar. This warranty shall not apply to any defects caused or

repairsrequired asa result ofunreasonable ornegligentuse, neglect,accident,

improper installation, or unauthorized repair or alterations. In case of defect,

malfunction or failure to conform to warranty, tekmar will, for a warranty period

of24monthsfromthedateofinvoicetotheoriginalpurchaseror12monthsfrom

the date of installation of the product, whichever occurs first, repair, exchange

or give credit for the defective product. Any express or implied warranty which

the purchaser may have, including merchantability and fitness for a particular

purpose, shall not extend beyond 24 months from the date of invoice or 12

months from the date of installation of the product, whichever occurs first.

Replacements: tekmar can send replacement products if requested. All

replacements are invoiced. Any possible credit for the replacement will only be

issued once the replaced product has been returned to tekmar.

Product Return Procedure: Productsthat are believed to have failed must be

returnedtotekmarControlSystemsLtd.4611-23rdStreet,VernonB.C.Canada

V1T 4K7 when agreed to by tekmar. The installer or other qualified service

person must, at the owner's expense, determine which component has failed. The

product must be returned complete with all of its components (sensors, base, etc.).

Products must be returned together with the proof of purchase to the original

purchaser who then returns the product to tekmar after receiving a Return Goods

Authorization (RGA) number from tekmar.

Please include the following information with the product. The full address of the

original purchaser, the RGA number and a description of the problem.

From the U.S.A., in order to avoid customs charges, products must be returned via

USPostwiththepackageclearlymarkedwiththeRGAnumber,producttypeandthe

statement "Canadian Product returned for repair". For shipping purposes the

product can be valued at one half list price.

1) If returned during the warranty period and the product is defective, tekmar will

issue full credit for the returned product less cost of missing parts.

2) Ifreturnedduringthewarrantyperiodandtheproductisfullyoperational,tekmar

will return the product to the original purchaser for a testing cost of $30.00 plus

postage.

3) Ifreturnedduringthewarrantyperiodandtheproductisnotdamagedandisfully

operational, tekmar can take back the product for a return charge of 40% of the

product's net value. This request has to be specified otherwise the product will

be returned with a testing cost of $30.00 plus postage.

4) If returned after the warranty period and the product needs repair, tekmar will

repair and return the product. Repair and postage costs will be invoiced.

tekmar's repair costs are calculated at $30.00 / hour plus the cost of parts. If

the repair costs will be more than $60.00 a repair estimate will be sent to the

original purchaser.

4

All specifications are subject to change without notice.

Printed in Canada on recycled paper.

Product designs, software and literature are Copyright © 1994 by:

tekmar Control Systems Ltd. and tekmar Control Systems, Inc.

In North America: tekmar Control Systems Ltd., Canada

tekmar Control Systems, Inc., U.S.A.

Head office: 4611 - 23rd Street

Vernon, B.C. Canada V1T 4K7

Tel. (604) 545-7749 Fax. (604) 545-0650

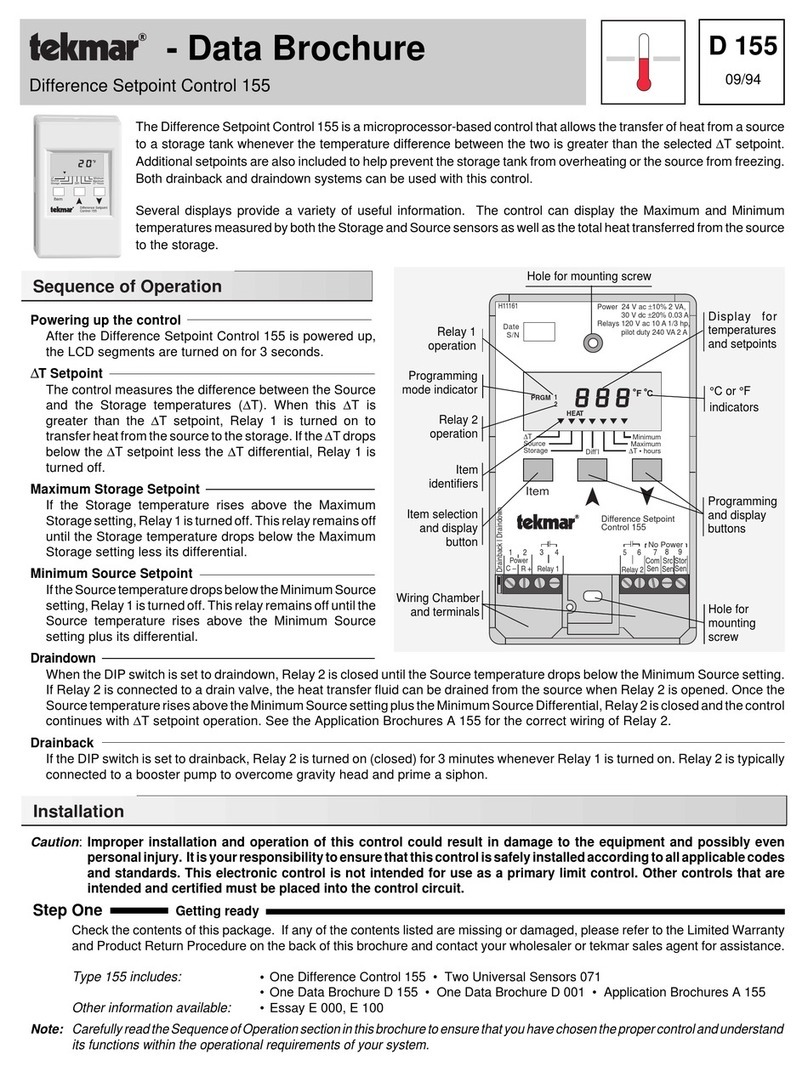

Snow Melting Control 650

Literature — D 650, A650, D 001, E 000, E 600

Control — Microprocessor PI control; This is not a safety (limit) control.

Packaged weight — 1.3 lb. (600 g), Enclosure C, PVC plastic

Dimensions — 4-3/4” H x 2-7/8” W x 7/8” D (120 x 74 x 22 mm)

Approvals — Meets DOC regulations for EMI/RFI.

Ambient conditions — Indoor use only, -20 to 120°F (-30 to 50°C), < 90% RH non-

condensing.

Power supply — Class 2, 24 V ac ±10% 50/60 Hz 3 VA

Relays — 120 V ac 10 A1/3 hp, pilot duty 240 VA 2 A

Sensors — NTC thermistor, 10 kΩ@ 25°C ±0.2°C ß=3892

included: Outdoor Sensor 070 and Slab Sensor 072.

Control accuracy — ±0.5°F (±0.25°C) with up to 1000 feet (300m) of 18AWG wire

to sensors.

On Time

— 0:30 to 19:50 hours to ‘Infinite’

Melting

— 34 to 45°F (1 to 7°C)

Idling

— Off, 23 to 34°F (-5 to 1°C)

CWCO

— Off, -22 to 23°F (-30 to -5°C)

Snow Melting

Control 650

Pulse Width Modulation

On

Time

PRGM

FC

Item

Date

S/N

Power Supply:

24V 60Hz 3VA

Relay Capacities:

120V 10A 1/3hp

5

System

Melt at power up

On

Off

6

34

Heat

No Power

789

Com

Sen

Slab

Sen

Out

Sen

24 V Only

21

CR

Power

Outdoor

Slab Sensor

Target Slab

Start Stop

CWCO

Idling

Melting

H11131