Before you leave

• Install the wiring cover over the wiring chamber and secure it with the screw provided. • Place the front cover on the control to

coverthesettingdialsandsnapitintoplace. • Placethisbrochure,andallotherbrochuresrelatingtotheinstallation,intheprotective

plasticbagsuppliedwiththecontrol. • Placethebaginaconspicuouslocationnearthecontrolforfuturereference. • Itisimportant

to explain the operation of this control within the system to the end user, and anyone else who may be operating the system.

In North America: tekmar Control Systems Ltd., Canada

tekmar Control Systems, Inc., U.S.A.

Head office: 4611 - 23rd Street

Vernon, B.C. Canada V1T 4K7

Tel. (604) 545-7749 Fax. (604) 545-0650

All specifications are subject to change without notice.

Printed in Canada on recycled paper.

Product designs and literature are Copyright © 1993 by:

tekmar Control Systems Ltd. and tekmar Control Systems, Inc. 4

Limited Warranty: tekmar warrants to the original purchaser each tekmar product

againstdefectsin workmanship and materials when the product is installed and used

incompliancewithtekmar'sinstructions. Thislimitedwarrantycoversthecostofparts

and labour provided by tekmar to correct defects in materials and/or workmanship.

Returned products that are fully operational are not considered a warranty case.

tekmaralsodoesnotcoverpartsorlabourtoremove, transportor reinstalla defective

product. tekmar will not be liable for any damage other than repair or replacement of

the defective part or parts and such repair or replacement shall be deemed to be the

sole remedy from tekmar. This warranty shall not apply to any defects caused or

repairs required as a result of unreasonable or negligent use, neglect, accident,

improper installation, or unauthorized repair or alterations. In case of defect,

malfunction or failure to conform to warranty, tekmar will, for a warranty period of 24

months from the date of invoice to the original purchaser or 12 months from the date

ofinstallationofthe product,whichever occursfirst,repair,exchangeor givecredit for

thedefectiveproduct. Anyexpressorimpliedwarrantywhichthepurchasermayhave,

includingmerchantabilityand fitnessforaparticularpurpose,shallnotextendbeyond

24 months from the date of invoice or 12 months from the date of installation of the

product, whichever occurs first.

Replacements: tekmar can send replacement products if requested. All replace-

ments are invoiced. Any possible credit for the replacement will only be issued once

the replaced product has been returned to tekmar.

Product Return Procedure: Products that are believed to have failed must be

returnedtotekmarControl Systems Ltd. 4611-23rd Street, Vernon B.C. Canada V1T 4K7

whenagreedtoby tekmar. The installeror otherqualified servicepersonmust,atthe

owner's expense, determine which component has failed. The product must be

returned complete with all of its components (sensors, base, etc.). Products must be

returnedtogetherwiththeproof ofpurchase tothe originalpurchaser whothenreturns

theproducttotekmarafterreceivingaReturnGoodsAuthorization(RGA)numberfrom

tekmar.

Please include the following information with the product. The full address of the

original purchaser, the RGA number and a description of the problem.

Fromthe U.S.A.,inorder toavoid customs charges,products mustbereturned viaUS

Post with the package clearly marked with the RGA number, product type and the

statement "Canadian Product returned for repair". For shipping purposes the product

can be valued at one half list price.

1) If returned during the warranty period and the product is defective,

tekmar will issue full credit for the returned product less cost of missing parts.

2) If returned during the warranty period and the product is fully operational, tekmar

willreturntheproducttotheoriginalpurchaserforatestingcostof$30.00pluspostage.

3) If returned during the warranty period and the product is not damaged and is fully

operational, tekmar can take back the product for a return charge of 40% of the

product's net value. This request has to be specified otherwise the product will be

returned with a testing cost of $30.00 plus postage.

4) If returned after the warranty period and the product needs repair, tekmar will

repair and return the product. Repair and postage costs will be invoiced. tekmar's

repaircostsarecalculatedat$30.00/hourplusthecostofparts. Iftherepaircostswill

be more than $60.00 a repair estimate will be sent to the original purchaser.

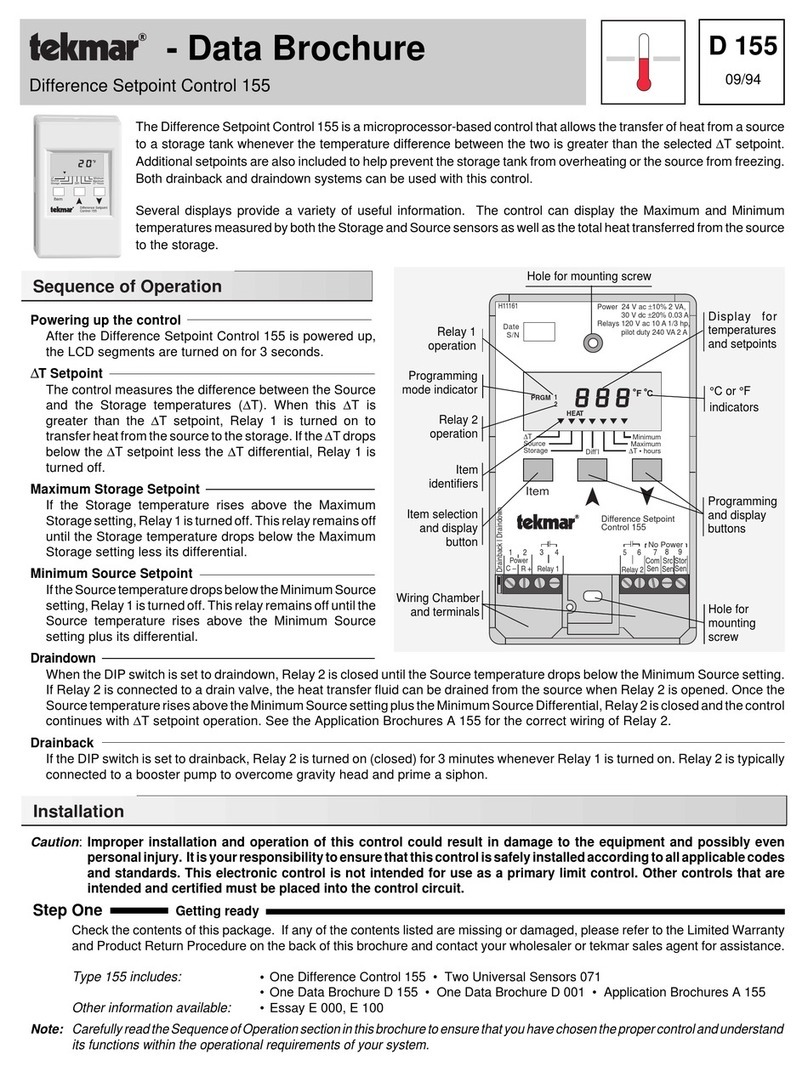

Testing and Troubleshooting

IftroubleshootingbecomesnecessarywiththeMixingSetpointControl153,followthetestingprocedureinstepfouroftheinstallation

procedure on page 2 of this brochure.

Ifthedisplaywindowshows"Err1",theSupply(1)sensoriseitheropencircuited,shortcircuited,orthesensortemperatureisoutside

the temperature range of the control. If this type of fault occurs, the control will run the mixing valve fully closed.

Ifthedisplaywindowshows“Err2”theBoilerReturn(2)sensorisshortcircuited,thecontroloperatesasifnoreturnsensorisinstalled.

Ifthe Boiler Return (2) sensorisconnected,butprogramming or Return (2)temperaturedisplaysdonot function, the sensoriseither

open circuited or colder than -85 °F (-65 °C).

If you do not think the control is operating properly, check to see that the settings have been made correctly and that the problem is

not a result of external causes. Make sure that all wiring connections are solid and the sensor(s) is located in the correct location.

Throttling Range

Setting the Throttling range on any control depends entirely on the actual operating characteristics of the mixing device and the load

in each specific application. Experience plus trial and error during actual operating conditions is usually the way most installers

determinethecorrectsetting. ForatekmarActuatingmotor,atypicalsettingis28°F(15°C). Fastermotorsrequirealargerthrottling

range.

Return (2)

The Return (2) setting provides a method to constrain the temperature of water returning to a boiler from a 4-way mixing valve. This

setting should be adjusted to the lowest return temperature that the boiler is rated for. When the boiler return water temperature

becomes too cold, the mixing valve is closed until the temperature is hotter than the Return (2) setting.

Limited Warranty and Product Return Procedure