Rev. 863-av1_12_en

ASTRA-863

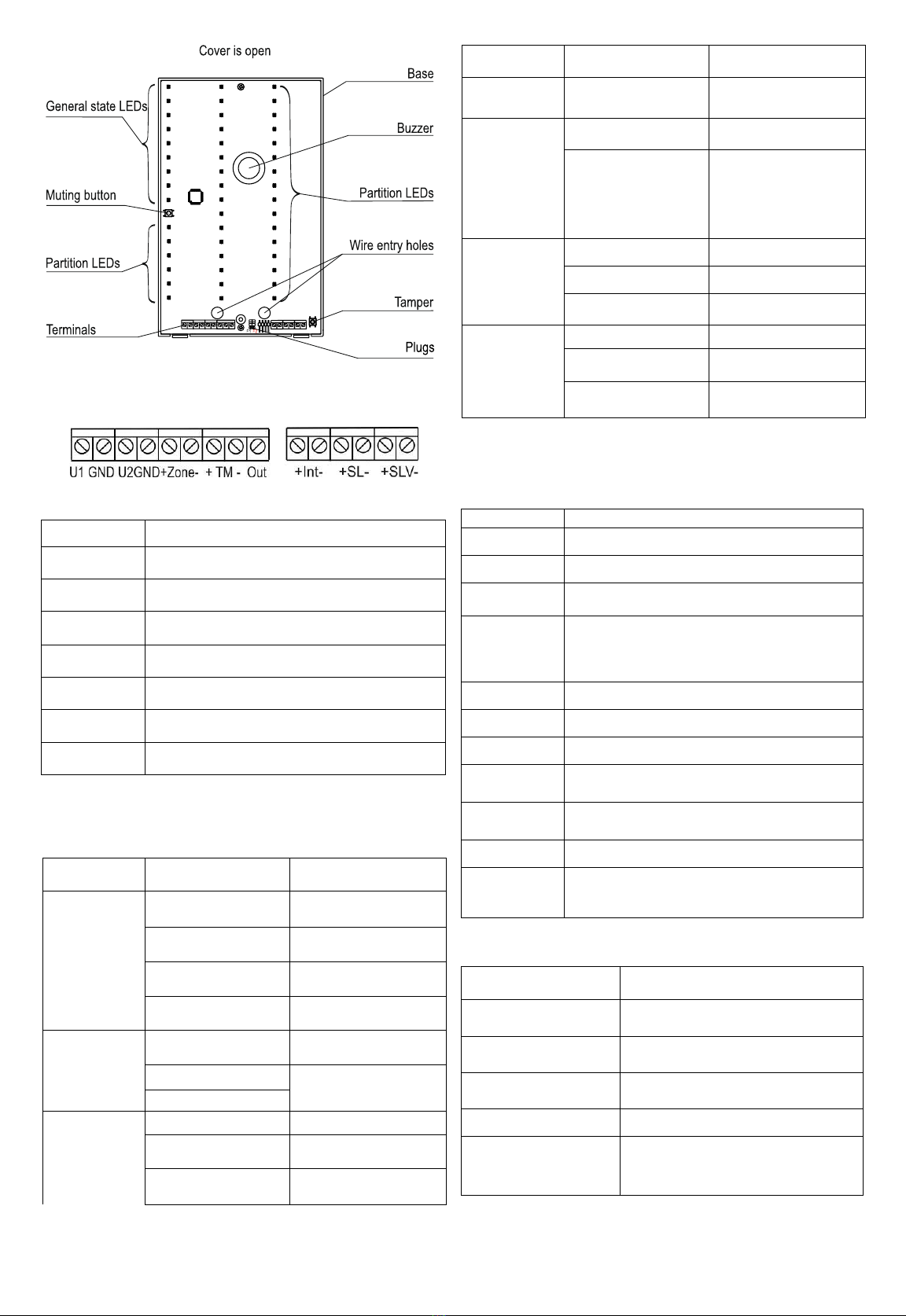

Indication unit

User guide

This operating manual is intended to

study the principle of operation, proper

use, storage and maintenance of the

indication unit "Astra-863" version A

(hereinafter referred to as BI) (Pic. 1).

The manufacturer reserves the right to

make changes to the design, firmware,

circuit solutions and product packaging that

do not worsen its technical characteristics,

do not violate mandatory regulatory

requirements, without prior notice to the

consumer.Abbreviations:

IU –indication unit ASTRA-863version A;

Instruction –Instructions built into the

PKM program Astra Pro, Pconf-Pro or

Pconf-RR, or Astra-812 Pro setup instruc-

tions from the keyboard or User instruc-

tions on Wireless extender (available on

the website www.teko.biz);

Buzzer –built-in sound signaling device;;

Control panel –control panel and fire control device "Astra-

8945 Pro" or "Astra-812 Pro";

Wireless extender –radio expander "Astra-RI-M RR" in au-

tonomous mode;

Control device –Control device (Control panel; Wireless ex-

tender);

RS-485 –wired interface Astra-RS-485»;

PKM ASTRA Pro –monitoring firmware package "Astra

Pro" for configuring and monitoring the Control Panel (see on

the website www.teko.biz);

Pconf-Pro - program for configuring Control panel (located on

the website www.teko.biz);

Pconf-RR –computer program "Pconf-RR" for configuring and

monitoring RR (see on the website www.teko.biz);PC –per-

sonal computer;

PO –firmware;

Wireless device –radio channel devices (detectors, relay

blocks, annunciators, etc.) of the Astra-RI-M system

1 FUNCTION

1.1 IU is for:

- receiving notifications from the control device via the wired inter-

face RS-485CONTROL DEVICE,

- displaying the generalized state of the system based on the

CONTROL PANEL or WIRELESS EXTENDER on 8 system

indicators,- displaying the states of CONTROL PANEL logical

partitions or Wireless devices registered in WIRELESS EXTEND-

ER on 38 indicators,

- sound signaling of incoming notifications,

- accepting Touch Memory identifiers from the TM input and trans-

ferring them to the CONTROL PANEL.

1.2 Binding of indicators to partitions or Wireless device is

done from a PC through the program Pconf-Pro, ZL Astra Pro

or Pconf-RR in accordance with the Instructions for CONTROL

DEVICE.

1.3 IU has two independent power inputs (main and backup)

in accordance with GOST R 53325.

1.4 The IU has an input for monitoring the health of external

power sources (terminals ZONE).).

1.5 IU has the ability to connect to the RS-485 CONTROL

PANEL ring interface using Astra-A ILS short circuit isolators.

The IU is powered by external redundant DC sources with a

nominal voltage of 12 V or 24 V.

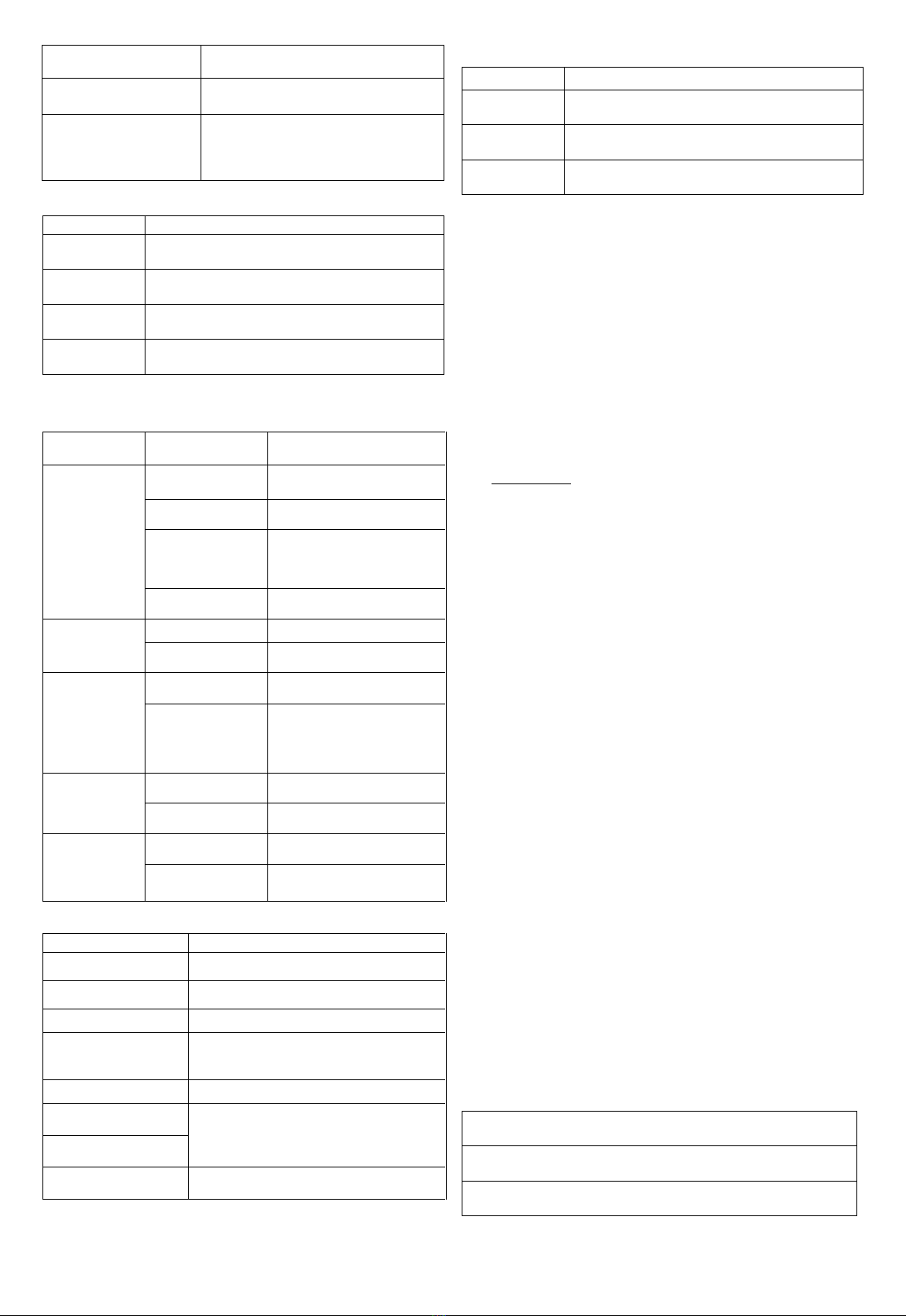

2 SPECIFICATION

Vltage, V..............................................................from 10 to 27

Average current consumption* at 12 (24) V, mA, .........62 (55)

Increase in current consumption at voltage

power supply 12 (24) V:

- with each additional indicator, not more, mA...................4 (2)

- when the buzzer is turned on, not more, mA ..................2 (3)

Maximum current consumption at 12 (24) V, mA............236(144)

Input ZONE parameters:

Zone terminal voltage in standby mode, V5Short circuit current

at ZONE terminals, mA,

not more ....... 20 Resistanceofwires connected totheZONEinput

(excludingexternalelement), Ohm,nomore220Leakage resistance

between ZONEinput wires

or each wire and"Earth", kOhm, notless than...........................20

ZONE input resistance, kOhm:

- in "Normal" state....................................................from 3 to 5

- in "Violation" state..........................from 0 to 3 or more than 5

ZONE input integration time, ms...................................300±30

OUT parameters:

Maximum load current, mA, not more.................................100

Output voltage, V, not more................................................. 27

RS-485 interface range, m, not more................................1000

TM interface range, m, not more ..........................................25

Overall dimensions, mm, not more....................... 22514523

Weight, kg, not more............................................................0,3

Operating conditions

Temperature range, °С....................................from -10 to + 55

Relative humidity, %....................................до 93 при + 40 °С

without moisture condensation

_______________________

* When using only one partition/Wireless device/valve status indicator

3 DELIVERY SET

IU ASTRA-863version A......................................................1 pc.

Screw...................................................................................3 pc.

Dowel...................................................................................3 pc.

Resistor C1-4-0.25 W 3.9 kOhm ± 5%.................................1 pc.

Manual.............................................................................1 copy.

Sticker..................................................................................2 pc.

4 DESIGN

4.1 Structurally, the IU is made in the form of a block consist-

ing of a base and a removable cover. A printed circuit board

with radio elements is mounted inside the block (Pic. 2).

4.2 The board has three-color (red-green-yellow) indicators:

-POWER indicator to show IU power status,- 8 indicators for

displaying the generalized current status of all partitions

or Wireless device of the system bound to the IU,

- 38 indicators to display the status of a section/valve or

group of sections when working with the CONTROL PAN-

EL or to show the status of the Wireless device when

working with the WIRELESS EXTENDER.

4.3 Installed on the board: a buzzer for sound notifications

and a mute button.

4.4 The board has an opening button, which, when the cover

is removed, generates a “Tamper” notification, and is also used

to restore factory settings.