Section 1—AM 502

OPERATING

INSTRUCTIONS

INTRODUCTION

Description

The AM 502 i$ adc-couple<j differential amplifier with

excellent common-mode rejection capabilities and high

gain for low voltage measurements. The dc offset capabili-

ty permits nulling up to 1volt dc, so that low level, low

frequency signals impressed on adc level can be

amplified without the degradation often introduced byac

Input coupling. High and low frequency -3d6 points can

be selected at the front panel to suit the application. Signal

inputs and outputs are available at the rear connector as

well as at the front panel. Afront panel lamp indicates

most overrange conditions of excessive input signal,

excessive gain, or excessive offset.

The input circuit can be represented by approximately

1megohm to ground paralleled by approximately 47

picofarads. The Input impedance can be raised to about

200 megohms with the removal of ajumper.

Overload protection is provided by fuses In series with

the input which open when largeamountsof current flow

due to overloading conditions.

ASTEP GAIN DC BALANCE control iS provided to

adjust for zero shift as the gain switch is changed from one

position to another.

The DC OFFSET COARSE and FINE controls give

offset up to ±1 volt dc potential difference at the input

connectors. The amplifier internal bias is changed to

accomplish the offset. The LF -3 dB switch must be In the

DC OFFSET position to actuate these controls.

The HF -3 dB switch is used to reduce the upper

bandwidth limit as necessary to improve the signal-to-

noise ratio when using the AM 502 in low-frequency

applications. The LF -3 dB control increases the lower

bandwidth frequency.

Use of the pre-charging feature prevents surge

currents, due to charging the ac coupling capacitor, from

damaging the circuit under test.

Installation and Removal

Turn lh» powermodule offbefore inserting the plug-

in: otherwise, damage may occur to the plug-in

circuitry. Because of the high current drawn by the

AM 502, it is also recommended that the power

module be forned off before removing the AM 502.

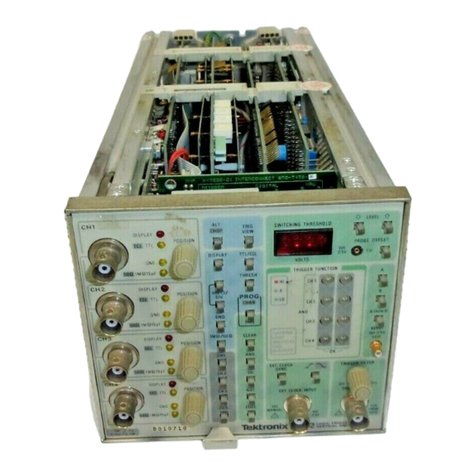

Refer to Fig. 1-1. Check to see that the plastic

barriers on the interconnecting jack of the selected

power module compartment match the cut-outs in

the AM 502 circuit board edge connector.

Align the AM 502 chassis with the upper and lower

guides of the selected compartment. Push the module in

and press firmly to seat the circuit board in the inter-

connecting jack.

To remove the AM 502. pull on the release latch located

in the lower left comer, until the interconnecting jack

disengages and the AM 502 will slide out.

Controls and Connectors

Refer to Fig. 1-2. Even though the AM 502 is fully

calibrated and ready to use. the functions and actions of

the controls and connectors should be reviewed before

attempting to use it. Pull the Power switch on the power

module to apply power to the AM 502. The POWER

indicator light indicates when power is applied to theAM

502

OPERATING CONSIDERATIONS

Overheating

The AM 502 is designed to operate at an ambient

temperature from 0” to -^-SO^C. However, when operating

several power supplies In amulti-plug-in power module,

especially at low output voltages, or when operating close

to other heat-producing equipment, internal temperature

may exceed safe limitsandactuatea thermal cutout in the

power module. Refer to the power module instruction

manual for more complete information.

REV DSEP 1980 M