TEL AFA1000/E MK2 Use and care manual

Startup

The AFA1000/E must be eld-calibrated once the

room air supply and exhaust is proportionally

balanced. When the unit is powered up, the

following sequence of events occurs:

1. The alarm performs a self-test of its

functions, LEDs and audible alarm

(approximately 3 seconds).

2. At the end of the delay, the unit will do

one of two things:

a. If the controller has been calibrated, the

unit enters normal operating mode (displays

airow velocity, LED’s and audible alarm

enabled).

b. If the controller has not been calibrated,

the unit will display “ Requires set up, press

Enter to continue”.

Installation &

Calibration Guide

Airow Controls

AFA1000/E MK2

Calibration

1. Press Enter from the “Requires set up” screen or if the controller

is in the Run screen Press and Hold the Enter button for 5 seconds

until the Main Menu is displayed.

2. Using the + / - buttons select SET UP, then select CONFIGURE, then

enter the password (the factory default password is 0-0-0-0), press

Enter to continue.

3. Using the + / - buttons select ECON CONFIGURE, then select

MANUAL / AUTO and press Enter, select MANUAL and press

Enter to continue.

4. Open the sash to the normal operating height and measure the

face velocity using a calibrated instrument. Using the + / - buttons

adjust the Manual output so that the face velocity is equal to the

design velocity, e.g. 0.50m/sec (100fpm) , then press Enter, then

select DONE and press Enter again.

5. Using the + / - buttons select SET UP, then select CALIBRATION,

then enter the password (the factory default password is 0-0-0-0),

press Enter to continue.

6. With the sash open to the normal operating height again measure

the face velocity using a calibrated instrument. Using the + /

-buttons enter the measured face velocity then press Enter, the

controller will then sample the airow for 5 seconds.

7. If the airow sample is unstable the controller will display

“Deviations too High”, follow the instructions to repeat the

sample or quit the calibration.

Temperature Electronics Ltd. Unit 2, Wren Nest Road, Glossop SK13 8HB UK

Installation &

Calibration Guide

Temperature Electronics Ltd. Unit 2, Wren Nest Road, Glossop SK13 8HB UK

8. If the sample is accepted, lower the sash by half and

measure the face velocity using a calibrated instrument.

Using the + / - buttons enter the measured face velocity

and press Enter, the monitor will then sample the airow

for 5 seconds.

9. If the calibration is successful the controller will return the

Main Menu, select RUN to go to normal operating mode

and check the velocity reading is accurate and stable.

10. If the airow sample is unstable the controller will

display “Deviations too High”, follow the instructions to

repeat the sample or quit the calibration.

11. The controller will display “Increase higher airow

sample” if the second sample value is too close to the

rst value entered, close the sash a little and repeat

the higher sample. The minimum dierence between

the samples that the controller will accept is 0.3m/

sec (60fpm).

12. The controller will display “Sensor di too low” if the

controller doesn’t detect any dierence in the sensor

output between the 2 airow samples, check that the

sensor hose is connected and repeat the calibration.

13. If the calibration is stable and accurate Press and

Hold the Enter button for 5 seconds until the Main

Menu is displayed.

14. Using the + / - buttons select SET UP, then select

CONFIGURE, then enter the password (the factory

default password is 0-0-0-0), press Enter to continue.

15. Using the + / - buttons select ECON CONFIGURE, then

select MANUAL / AUTO and press Enter, then select

AUTO and press Enter to continue, then select DONE

and press Enter.

16. The controller will return to the MAIN MENU, select

RUN to go to normal operating mode.

Calibration Tips

1. Ensure that the sensor hose is connected correctly at the

side wall and rear of the sensor.

2. Ensure that the extract fan is running and the Fume

Cupboard is balanced before calibrating the monitor.

3. Take extra time (at least 15 to 20 seconds) to wait for the

airow to settle before capturing the airow samples.

This will minimize the chance of a calibration error due

to turbulence or uctuations.

4. Avoid movement in front of the Fume Cupboard whilst

calibrating the monitor.

5. The Low and High air samples must be at least 0.3m/sec

(60 fpm) apart to calibrate the monitor. This is to avoid

inaccuracy in the calibration sue to insucient dierence

between the samples. The minimum dierence can be

changed in the “Low High di” parameter in the

Cal Cong menu.

6. Do not use fully open and fully closed sash positions for

the calibration points, the recommended positions are

normal operating height (e.g. 500mm 20”) for the rst

sample and approximately half the sash opening (e.g.

250mm 10”) for the second sample.

Installation &

Calibration Guide

Temperature Electronics Ltd. Unit 2, Wren Nest Road, Glossop SK13 8HB UK

Control Settings

The ECON CONFIG menu includes the following control

parameters:-

1. MANUAL / AUTO -- Allows the control output to be set

to Auto or Manual control, manual control is shown

as 0-100% and can be adjusted using the + / - buttons.

In Auto control the output will automatically adjust to

maintain the velocity set point.

2. HIGH SET POINT -- This is used to enter the required face

velocity set point for standard VAV control or the High

set point for dual set point occupancy control.

3. LOW SET POINT -- This is used to enter the required

reduced face velocity set point for dual set point

occupancy control.

4. DAMPER / INVERTER -- This is used to set the output

to 0-10v (direct - for damper) or 10 to 0v (reverse - for

Inverter)

5. MIN OUTPUT -- This is used to set the MIN output

volume when pushbutton III is set to Min/Run/Max

operation.

6. MAX OUTPUT -- This is used to set the MAX output

volume when pushbutton III is set to Min/Run/Max

operation.

7. LOW LIMIT -- This is used to set the fume cupboard

minimum volume when the sash is closed (limits the

damper closed position).

8. HIGH LIMIT -- This is used to set the fume cupboard

maximum volume (limits how far the damper opens).

9. OUTPUT RANGE -- This is used to set the output range to

0-10v (Inverter) or 2-10v (actuator).

10. PROP BAND -- This is the main control parameter

for the VAV control output. If the value is too low the

damper will be unstable and hunt, if the value is too low

the damper will react too slowly. The ideal setting for

this value is to select a value that is as small as possible

but that gives stable control of the damper or Inverter

without ‘hunting’.

11. INTEGRAL TIME -- The Integral Time is the corrective

action of the control output. The PROP BAND control

will result in an oset from the set point, the Integral

will correct the error in small steps over time. The ideal

setting is to select the highest possible value that gives

stable control.

12. INTERAL CUT OFF -- This is a unique parameter that is

used to give a rapid response in control output when

the sash is raised to boost the speed of the output.

The parameter monitors the rate of change of the face

velocity. This parameter should not require changing

from the factory default setting.

13. BOOST DURATION -- The BOOST DURATION is used in

conjunction with a sash position sensor for VAV control.

The controller will drive the output to a pre-determined

position for a brief periof of time before switching back

to face velocity control.

Installation &

Calibration Guide

Connection

Details

Temperature Electronics Ltd. Unit 2, Wren Nest Road, Glossop SK13 8HB UK

Installation &

Calibration Guide

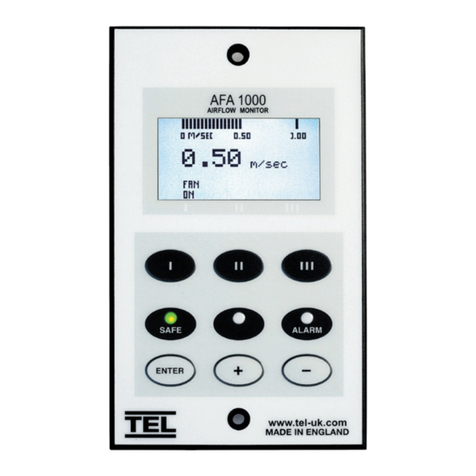

Control Panel Dimensions

Temperature Electronics Ltd. Unit 2, Wren Nest Road, Glossop SK13 8HB UK

Control Panel Cutout Dimensions

(NOT shown to scale)

5.83”

(148mm)

3.46”

(88mm)

1.57”

(40mm)

1.57”

(40mm)

4.65”

(118mm)

3.15”

(80mm)

4.96”

(126mm)

2 xing holes

2.5 mm diameter

for 2 #4 self-

tapping screws,

provided.

0.47”

(12mm)

0.47”

(12mm)

1.45”

(37mm)

1.45”

(37mm)

0.67”

(17mm)

1.45”

(37mm)

2.91”

(74mm)

1.45”

(37mm)

2.91”

(74mm)

SM6 Sensor Dimensions (rear view) SM6 Sensor Dimensions (front view)

0.79”

(20mm)

1.18” (30mm) Dia. Sensor

Hole for Vent Tube

0.157” (4mm)

Tapped

Fixing Hole

0.157” (4mm)

Tapped

Fixing Hole

1”

(25mm)

1”

(25mm)

1.06”

(27mm)

1.06”

(27mm)

0.47” (12mm) Dia.

Hole for SM6 cable

0.39”

(10mm)

Installation &

Calibration Guide

Temperature Electronics Ltd. Unit 2, Wren Nest Road, Glossop SK13 8HB UK

Airow Sensor Installation Diagram

For complete manual and product information, log on to www.tel-uk.com

Table of contents

Other TEL Controllers manuals

Popular Controllers manuals by other brands

WindowMaster

WindowMaster MotorController WCC 310 UL Installation instructions manual

Emerson

Emerson E2 Enhanced RX Technical bulletin

KBR

KBR multimax D6-5 Series user manual

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-R Series Reference manual

STI

STI Select-Alert STI-SA5000 Series quick start guide

Jula

Jula Anslut 414-110 User instructions