Telebyte 458-CC-16 User manual

Model 458-CC-16/458-CM

(16-Slot Chassis & Control Module)

Rev.I

Date of Publication: 02/25/2019

Line Modules Not Included

“Results You Can Count On”

Customer Support

Thank you for your purchase of the Telebyte Model 458-CC-16/458-CM (16-Slot

Chassis & Control Module). This versatile product provides a wide variety of

configurations through the use of up to 16 plug-in Line Modules. The Model 458-

CC-16/458-CM is ideally suited for testing DSL modems and other bandwidth-

compliant telecom devices in a high-volume production line environment. When

used in conjunction with up to 16, 8-channel 458 Line Modules, it becomes a

128-channel local loop simulator. The 458-CM Control Module interfaces with a

PC or terminal via IEEE-488 or RS-232/Ethernet to control loop-length settings or

the 458-CC-16/458-CM can be used as a stand-alone unit. User-command

language may be used for control. In addition, line length is displayed on the front

of the unit and can be set via a keypad on the front panel.

Contact Information:

Telephone E-mail/Internet

Fax: 631-385-8184 www.telebytebroadband.com

Mail

Telebyte, Inc.

355 Marcus Blvd

Hauppauge, NY 11788

Customer Care

Warranty

One-year Warranty

•Telebyte will furnish parts and labor for the repair or replacement of products found by Telebyte to be defective

in material or workmanship during the warranty period.1

Extended Customer Care

Refer to the Customer Care section of the Telebyte web site for the most current information on extended

warranty and calibration contracts 2,3,4:

http://www.telebytebroadband.com/customercare.html

Disclaimer of Warranties and Other Terms and Conditions

1TELEBYTE, INC. warrants its broadband simulation equipment to be free from defects in material and workmanship, under normal and proper use

and in its unmodified condition, for 12-months, starting on the date it is delivered for use. TELEBYTE’S sole obligation under this warranty shall be to

furnish parts and labor for the repair or replacement of products found by TELEBYTE to be defective in material or workmanship during the warranty

period. Warranty repairs will be performed at the point of manufacture. Equipment approved for return for warranty service shall be returned F.O.B.

TELEBYTE factory and will be redelivered by TELEBYTE freight prepaid, except for non-continental U.S.A. locations. These deliveries will be sent

COD freight and import/export charges.

2 The customer is responsible for freight and customs charges when shipping products to and from Telebyte for calibration services.

3 You must purchase the extended warranty at the time of purchase or during the initial warranty period.

4 You must purchase the calibration contract at the time of purchase or during the initial warranty period. The above warranty is in lieu of all other

warranties, expressed or implied, statutory or otherwise, including any implied warranty of merchantability or fitness for a particular purpose.

TELEBYTE shall not be liable for any damages sustained by reseller or any other party arising from or relating to any equipment failure, including but

not limited to consequential damages, nor shall TELEBYTE have any liability for delays in replacement or repair of equipment.

Equipment Returns

Out of warranty equipment may be returned, prepaid, to the Hauppauge, N.Y.

customer service facility. Return shipping charges will be billed to the customer.

The repaired unit will have a 90-day warranty. In those cases where "no trouble"

is found, a reduced charge will be billed to cover handling, testing, and

packaging. Whether in or out of warranty, a Return Material Authorization

number (RMA) is required and may be obtained by:

Calling customer service at 631-423-3232 or 800-835-3298

Sending a request via Fax at 631-385-8184

Visiting us at http://www.telebytebroadband.com/main/support_index.asp

Please be sure to reference the RMA number on the outside container.

Table of Contents

1.0 Introduction....................................................................................................................................................... 1

2.0 Specifications.................................................................................................................................................... 4

3.0 RS-232 Connections & Commands.................................................................................................................. 5

RS-232 Connections ........................................................................................................................................... 5

User Command Interface.................................................................................................................................... 6

RS-232 Mode Command List............................................................................................................................. 6

4.0 IEEE Connections & Commands...................................................................................................................... 9

Connections......................................................................................................................................................... 9

User Command Interface.................................................................................................................................... 9

IEEE Mode Command List............................................................................................................................... 10

5.0 Ethernet Connections & Commands............................................................................................................... 14

Enabling Ethernet Connectivity........................................................................................................................ 14

Before You Begin ............................................................................................................................................. 15

Installing IP Address Assignment Software..................................................................................................... 15

Configure Virtual Com Port on Remote PC..................................................................................................... 22

Install Software................................................................................................................................................. 22

Create Virtual COM Port.................................................................................................................................. 25

Connecting to the Model 458-3SLB via Ethernet Connector........................................................................... 30

Communicating with a 458 Chassis using Remote terminal software ............................................................. 30

Using the Web Interface to Change Settings.................................................................................................... 33

Local Port Setting ............................................................................................................................................. 35

Selecting/Setting Baud Rate ............................................................................................................................. 36

RS-232 Mode Command List........................................................................................................................... 41

6.0 Keypad Controls ............................................................................................................................................. 45

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 1

1.0 Introduction

The Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) accepts 1 - 16 line modules and

controls from 1 - 128 channels. It is ideal for testing DSL modems and other bandwidth-compliant

telecom devices in a high-volume production environment. While the 458-CC-16/458-CM can be used

as a stand-alone unit, the 458-CM interfaces with a PC via RS-232, IEEE-488, or Ethernet. Line

lengths and configuration settings appear on an LCD display on the front of the unit and can be set

via a keypad. For added convenience, the 458-CM firmware is field-upgradeable through the RS-232

port.

The Model 458-CC-16/458-CM is used with our advanced 458 Line Modules that simulate several

cable types and offer the bandwidth requirements for today’s xDSL technologies such as varieties of

ADSL, ADSL2+ and VDSL2. User-friendly GUIs (included with line modules) provide another means

of controlling loop lengths and communication parameters. For more information about Telebyte’s

plug-in line modules, refer to the individual datasheets or manuals.

While the 458-CC-16 (16-Slot Chassis) and 458-CM (Control Module) are purchased

separately, they are both addressed in this manual, together or separately, as required.

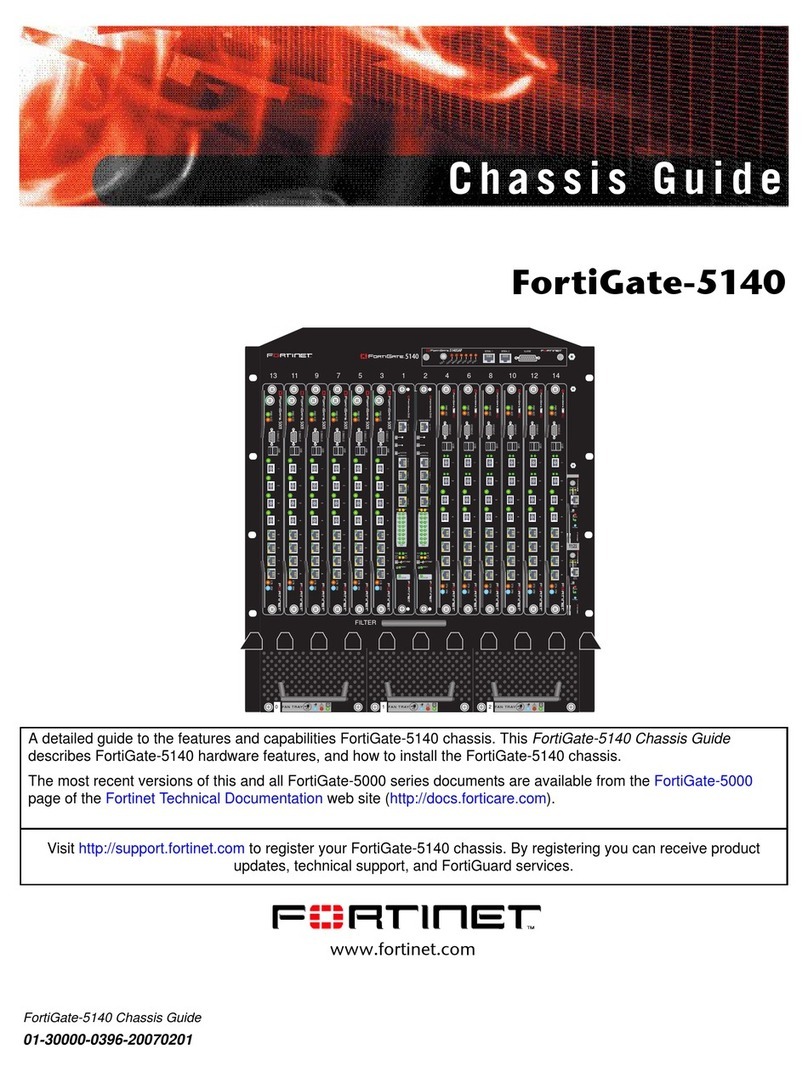

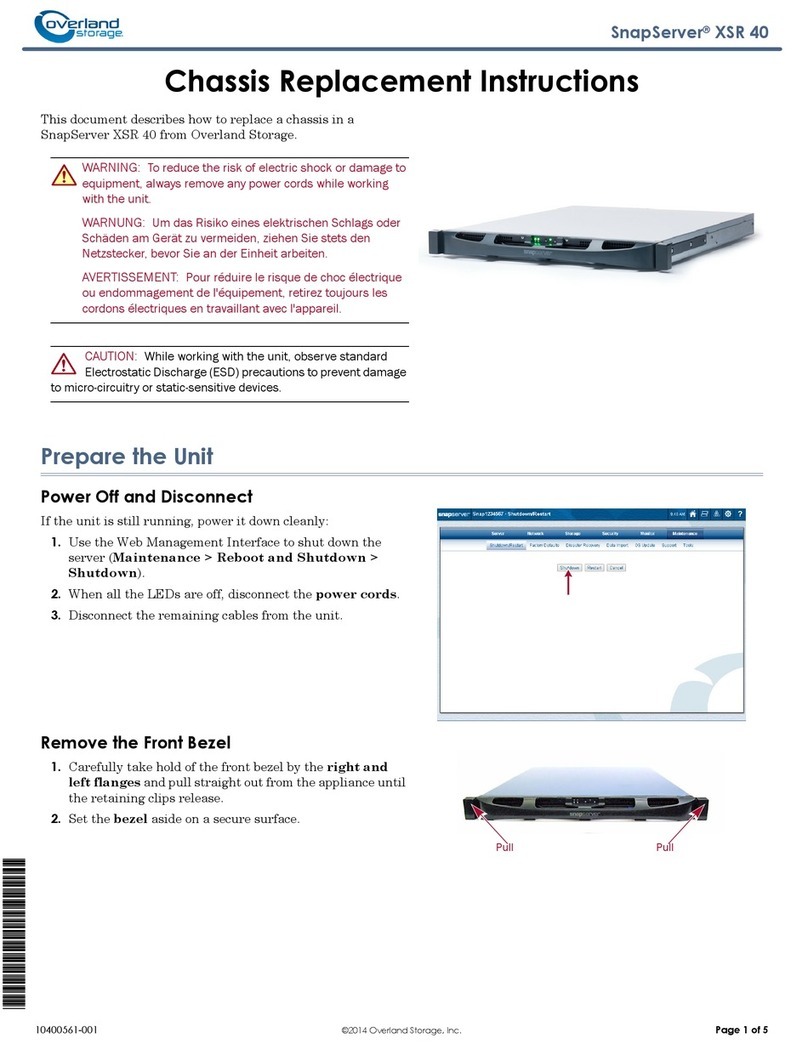

Chassis

The 458-CC-16 may be mounted in a standard 19-in rack and accepts a maximum of 16 Line

Modules.

The front of the Model 458-CC-16 is shown with the 458-CM and 16 line modules installed.

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 2

Control Module

The image above shows the connectors on the back of the 458-CM, labeled

RS232, IEEE-488 and Ethernet.

The 458-CM is used to configure a Line Module to a particular length via a pushbutton keypad on the

front of the unit. The user may also use the IEEE-488, RS-232 or Ethernet port for remote control.

When configured for IEEE-488, the 458-CM can be operated from an IEEE Controller such as a PC

equipped with an IEEE interface board. In RS-232 mode, the unit can be connected to any RS-232

device (e.g., a terminal or PC) that has a terminal emulation program such as Hyper Terminal

installed. In Ethernet mode, RS-232 commands are sent over an Ethernet connection. This allows a

remote PC connected to a LAN to communicate with the 458-CM.

In order to send RS-232 commands over an Ethernet connection, this feature must be

enabled. Refer to section Enabling Ethernet Connectivity for detailed instructions.

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 3

Line Module Series

A maximum of 16 Model 458 Line Modules (sold separately) can be placed into the chassis. Each

458 Line Module can be individually set by the 458-CM. Communications between the 458-CM and

the 458 Line Module are via a backplane. The backplane will pass power and the signals to control

the length of each card. The RJ-45 connectors used to connect to the unit to be tested are mounted

directly on the 458 Line Module. Telebyte provides GUI software for a user-friendly interface when

configuring 458 Line Modules (available for download from our Web site at

www.telebytebroadband.com). Refer to the individual documentation for more information on our Line

Module series.

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 4

2.0 Specifications

Product Specifications 458-CC-16 (16-Slot Chassis) & 458-CM (sold separately)

Controls

Keypad for setting loop lengths and IEEE-488 address, RS-232, or

Ethernet communication parameters.

Indicators

Backlit LCD display of line length and set up parameters.

Power

88 to 264 VAC, 50 or 60 Hz

Size

[7U] 19 in W x 22 in D x 12.22 in H

(482.6 mm W x 558.8 mm D x 310.4 mm H)

Environmental

Operating: +32 F to +122 F (0 to +50 degrees C)

Storage: 0 to 95% relative humidity (non-condensing)

Remote Control

Connectors

RS-232: DB9 female (DCE); GPIB:IEEE488 24-pin connector. Ethernet:

RJ-45

Plug-In Compatibility

Accepts 1-16 458 Line Modules

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 5

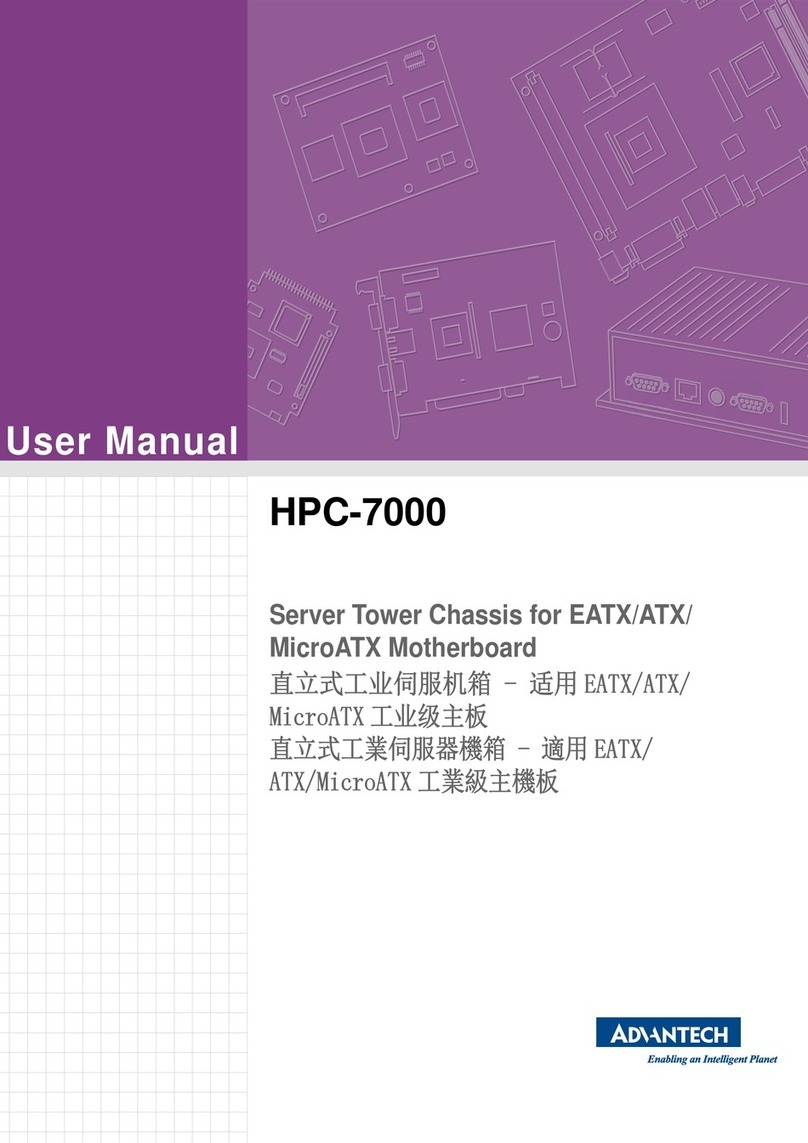

3.0 RS-232 Connections & Commands

RS-232 Connections

The Model 458-CM is completely controllable from an RS-232 source. The following section

explains the connections and the controls necessary for RS-232 operation. See Figure 2 for an

illustration of the pin connectors.

CONNECTOR DB9

5

9

4

8

3

7

2

6

1

RXD

TXD

CTS/DSR

Figure 2 DB-9 for RS-232 Control

Pin 2 on the Model 458-CM connects to the RECEIVED DATA pin in the Communications Port

Connector on the PC or controller.

Pin 3 on the Model 458-CM connects to the TRANSMIT DATA pin in the Communications Port

Connector on the PC or controller.

Pin 5 on the Model 458-CM connects to the GROUND pin in the Communications Port

Connector on the PC or controller.

Pins 6 and 8 are connected together and held at a positive voltage.

Common Communications Port Connectors, such as those found on PCs, are DB-9 and DB-

25. The standard pin assignments for these connectors are as follows:

DB-9

DB-25

Direction

Received Data

2

3

Serial Data from Model 458-CM

Transmitted Data

3

2

Serial Data to Model 458-CM

Ground

5

7

Common Ground

CTS

8

5

+ Voltage Out

DSR

6

6

+ Voltage Out

The remaining pins are not connected to the Model 458-CM.

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 6

User Command Interface

ASCII command set compliant with IEEE 488.2 and in Hex ASCII two-character bytes per 488

bus data byte.

RS-232 - LF, Baud rate 300 to 19200, commands use terminating character (Carriage Return),

eight Data Bits, one Stop Bit.

RS-232 Mode Command List

All Set card lengths, English/Metric mode and Echo enable/disable are maintained

during power off in both RS-232 and IEEE modes. Manual control is enabled at power

on.

id

Identify model no. and rev.

Read model no. and software revision code

re

Read last error

Read description of last error

ee

Echo enable

Echo all inputs and format output for terminal display

ed

Echo disable

Inputs not echoed and format output for user control program

h

Help RS232 command list

Read RS232 command list

cs:BR

Configure serial

Where BR = 300, 600, 1200, 2400, 4800, 9600 or 19200

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 7

cp:ADD

Configure 488

Where ADD = 1, 2, ... 29, 30 (No leading zeroes used)

Set Length command

sl:LM:H:LE,C

Where:

LM = Module slot number →01 –16

H = Channel number →1 - 8

LE = Length (in feet)

C = Connect mode:

N = connect both CO and CPE ends.

P = connect CPE only CO is open.

O = connect CO only CPE is open.

Z = open both CO and CPE ends

Example: SL:01:1:2000,N sets channel 1 to 2000 ft for a line module in slot 1.

The connect mode may be used to create an “open loop” condition at either the CO or CPE

ends, or both.

Set all channels on all boards in the system command

sl:all:LE,C

Example: sl:all:2000,n sets all channels in the system to 2000 ft

Set all channels on a range of boards command

sl:LM-LM:LE,C

Example: sl:01-03:2000,n sets all channels on boards 1, 2, and 3 to 2000 ft.

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 8

Set all channels on one board command

sl:LM:a:LE,C

Example: sl:01:a:2000,n sets all channels on the board in slot 1 to 2000 ft.

Read Length command

rl:LM:H

Example: rl:01:1 reports the length of channel 1 on the board in slot 1.

Read the Lengths of all channels on one board command

rl:LM:a

Example: rl:01:a reports the lengths of all channels on the board in slot 1.

Read the lengths of all channels on all boards command

rl:all

Example: rl:all reports the lengths of all channels on all boards

Read the serial number of one line module command

rs:LM

Read the serial numbers of all cards command

rs:all

Responses to SL (Set Length) Command

*

Command valid and completed execution. Ready for

next command.

?[XXX] Card Not Found

Card not found in slot specified.

?[XXX] Invalid Card Number

Card number outside the range for the type of control

module.

?[XXX] Invalid Channel Number

Channel number out of range (e.g., not 1 –8)

?[XXX] Invalid Length

Length not valid for the specific line module and/or

channel

?[XXX] Invalid Command

Any error not covered in the above list, including the

specification of incorrect line numbers for a given

channel.

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 9

4.0 IEEE Connections & Commands

Connections

The Model 458-CM is completely controllable from an IEEE 488.1 (488.2) source. The

following section explains the connections and controls necessary for IEEE operation.

Figure 3 IEEE 24-pin Connector

Connect a standard IEEE cable from the Model 458-CM to the IEEE General Purpose

Interface Bus controller.

User Command Interface

The Model 458-CM is intended to be operated from an IEEE Controller such as a PC equipped

with an IEEE interface board. The set up of your computer and IEEE controller board may be

different depending on the manufacturer of your equipment. Follow the set up instructions

supplied with your equipment.

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 10

IEEE Mode Command List

All Set card lengths, English/Metric mode and Echo enable/disable are maintained

during power off in both RS-232 and IEEE modes. Manual control is enabled at power

on.

:manual:disable

Disable manual control

Disable manual setting of lengths or configuration

:manual:enable

Enable manual control

Enable manual setting of lengths or configuration

:lasterror

Read last error

Read description of last error

*idn?

Identify model no. and rev.

Read model no. and software revision code

*esr?

Event Status Register read

Read IEEE esr

*sre?

Status Request Enable read

Read IEEE sre

*stb?

Status Byte register read

Read IEEE stb

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 11

*ese?

Enable Status Event read

Read IEEE ese

*sre xx

Status Request Enable write

Write IEEE sre xx

*ese xx

Enable Status Event write

Write IEEE ese

:cs:BR

Configure serial

Where BR = 300, 600, 1200, 2400, 4800, 9600 or 19200

:cp:ADD

Configure 488

Where ADD = 1, 2, ... 29, 30 (No leading zeroes used)

*SRExx

Enables Status Bits as defined by the numerical value of the bits following the

command.

*SRE?

Used to read the Enabling Bits in the Status Register.

*STB?

Reads the Status Register

*ESExx

Enables Event Status Bits as defined by the numerical value of the bits

following the command.

*ESE?

Used to read the Enabling Bits in the Event Status Enable Register.

*ESR?

Reads the Event Status Enable Register.

Status Byte Register

Bit

Value

Set

Operation

0

1

0

Not Supported

1

2

0

Not Supported

2

4

0

Not Supported

3

8

0

Not Supported

4

16

1

Enable Message Available bit (MAV)

5

32

1

Enable Event Status Bit (ESB)

6

64

1

MSS this bit is always enabled

7

128

0

Not Supported

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 12

Event Status Enable Register

Bit

Value

Set

Operation

0

1

1

Operation Complete

1

2

0

Not Supported

2

4

1

Query Error

3

8

0

Not Supported

4

16

1

Execution Error

5

32

1

Command Error

6

64

0

Not Supported

7

128

1

Power On

Set Length command

:setcard:length:LM:H:LE,C

Where:

LM = Module slot number →01 –16

H = Channel number →1 - 8

LE = Length (in feet)

C = Connect mode:

N = connect both CO and CPE ends.

P = connect CPE only CO is open.

O = connect CO only CPE is open.

Z = open both CO and CPE ends

Example: :setcard:length:01:1:2000,n sets channel 1 of the line module in slot 1 to 2000 ft.

Responses to SC (SetCard) Command

*

Command valid and completed execution. Ready for

next command.

?[XXX] Card Not Found

Card not found in slot specified.

?[XXX] Invalid Card Number

Card number outside the range for the type of control

module.

?[XXX] Invalid Channel Number

Channel number out of range (e.g., not 1 –8)

?[XXX] Invalid Length

Length not valid for the specific line module and/or

channel

?[XXX] Invalid Command

Any error not covered in the above list, including the

specification of incorrect line numbers for a given

channel.

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 13

Set all channels on all boards in the system command

:setcard:length:all:LE,C

Example: :setcard:length:all:2000,n sets all channels on all boards to 2000 ft.

Set all channels on a range of boards command

:setcard:length:LM-LM:LE,C

Example: :setcard:length:01-03:2000,n sets boards 1, 2 and 3 to 2000 ft.

Set all channels on one board command

:setcard:length:LM:a:LE,C

Example: :setcard:length:1:a:2000,n sets all channels on the board in slot 1 to 2000 ft.

Read Length command

:readcard:length:LM:H

Example: :readcard:length:01:1

Read the lengths of all channels on one board command

:readcard:length:LM:a

Example: :readcard:length:01:a

Read the lengths of all channels on all boards command

:readcard:length:all

Read serial number of one line module command

:readcard:sn:LM

Read all serial numbers command

:readcard:sn:all

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 14

5.0 Ethernet Connections & Commands

Enabling Ethernet Connectivity

RS-232 commands may be sent over an Ethernet connection to control the Model 458-CM. This is

made possible by a Lantronix XPort transceiver installed in the unit. A one-time set up must be

performed to assign an IP address to the transceiver and configure a virtual COM port. This is all

done using a remote PC. It requires one software installation to assign an IP address to the

transceiver and a second one to configure the virtual COM port.

Model 458-CC-16/458-CM (16-Slot Chassis & Control Module) Rev I Page 15

Before You Begin

Connect the 458-CM and a remote PC to the LAN using Ethernet cables. Please note, when

connecting the Model 458-CM directly to a PC a crossover Ethernet cable is used for communication;

when connecting to a network (through a switch or router) a straight-through Ethernet cable is used.

Administrator access to the remote PC is required.

Installing IP Address Assignment Software

The IP address assignment software (Lantronix Device Installer) is obtained from the CD supplied

with your unit or downloaded from www.telebytebroadband.com (select Support/Software option). It

is then copied to the remote PC and expanded. After installation, it is used to assign an IP address to

the XPort.

Obtain the IP address and subnet mask for the XPort from your network administrator as it is needed

during the assignment process. In addition, note the MAC address of the XPort which is located on

the back of the 458-3SLB. This address allows the assignment software to locate the XPort.

In some cases, firewall protection on the PC may interfere with the installation or

assignment process. If this occurs, contact your network administrator.

Install Software

1. Save the 4583SL-Ethernet-Install.zip file to the desktop.

2. Extract the files and then navigate to the folder on the desktop.

3. Double-click on the setup_di_x86x64cd_4.3.0.1.exe program file.

4. Select the language.

This manual suits for next models

1

Table of contents

Other Telebyte Chassis manuals