Telefire TSA-1000 User manual

Control Panels

TSA-1000

Conventional

Multi-Zone

Fire Alarm and Extinguishing

Control Panel

Technical Manual

T

ELEFIRE

F

IRE

&

G

AS

D

ETECTORS

L

TD

PO Box 7036

Petach Tikva 49250

Israel

Tel: 972 3 970 0400

Fax: 972 3 921 1816

eMail: marketing@telefire.co.il

Web: www.telefire.co.il

TSA

TSATSA

TSA-

--

-1000

10001000

1000En

EnEn

En112

112112

112.pdf

.pdf.pdf

.pdf

Revision 1.12

April 2012

The information contained in this document is proprietary and is subject to all relevant copyright, patent and

other laws protecting intellectual property, as well as any specific agreement protecting TELEFIRE FIRE AND

GAS DETECTORS rights in the aforesaid information. Neither this document nor the information contained

herein may be published, reproduced or disclosed to third parties, in whole or in part, without the express,

prior, written permission of TELEFIRE FIRE AND GAS DETECTORS. In addition, any use of this document

or the information contained herein for any purposes other than those for which it was disclosed is strictly

forbidden.

TELEFIRE FIRE AND GAS DETECTORS reserves the right, without prior notice or liability, to make changes

in equipment design or specifications.

Information supplied by TELEFIRE FIRE AND GAS DETECTORS is believed to be accurate and reliable.

However, no responsibility is assumed by TELEFIRE FIRE AND GAS DETECTORS for the use thereof nor for

the rights of third parties, which may be effected in any way by the use thereof.

Any representation(s) in this document concerning performance of TELEFIRE FIRE AND GAS DETECTORS

TSA-1000(s) are for informational purposes only and are not warranties of future performance either express

or implied. TELEFIRE FIRE AND GAS DETECTORS standard limited warranty, stated in its sales contract or

order confirmation form, is the only warranty offered by TELEFIRE FIRE AND GAS DETECTORS in relation

thereto.

This document may contain flaws, omissions or typesetting errors; no warranty is granted nor liability assumed

in relation thereto unless specifically undertaken in TELEFIRE FIRE AND GAS DETECTORS sales contract

or order confirmation. Information contained herein is periodically updated and changes will be incorporated

into subsequent editions. If you have encountered an error, please notify TELEFIRE FIRE AND GAS

DETECTORS. All specifications are subject to change without prior notice.

LEGAL NOTICE

i

Note

Fire alarm systems are composed and assembled of different devices and

subsystems, such as control panels, annunciators, smoke detectors, heat

detectors, manual call points, extinguishing activation devices, and

annunciating devices intended to alert to fire / smoke.

Using this system does not ensure protection from or prevention of fire and/or

smoke damages, but proper use of the system may reduce fire and smoke

damages.

Proper system configuration design, including all of its components

and infrastructure, as well as proper installation according to the

manufacturers' instructions and the applicable standards – are a

conditioned precedent for the proper and efficient function of the

system.

The designer and installer should have the appropriate skills and

qualifications for performing said installation and all damages or losses

resulting from improper design and/or installation lie with the designer and/or

installer alone.

All loss or damage caused by improper action shall lie with the

originator of said improper action.

The manufacturer shall not be liable for any fire and/or fire damages caused

by fire in location where fire systems are installed and or results of direct or

indirect fire damage that may be caused to any persons and/or property

and/or third parties as a result of using the TSA-1000 and/or resulting from its

inaction.

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

— I —

Record of Changes

No. Date Revision Details Author

1 25.01.2012 1.12 Update Introduction, Para 2.2 (UL),

UPDATE SYMBOLIC DIAGRAM, Update note about

reading and UNDERSTANDING this document Move

Number of adapters and extinguishant quantities to appear

after "Extinguishing Adapters"

Replace Fig. 1 with original dwg. from Ylan UPDATE

INSTRUCTIONS FOR IMMEDIATE ACTION

I. Reshef

i

Note

The terms Control Panel" as used in NFPA 72 guideline and UL 864 standard

and Control and Indicating Equipment (CIE) as used in EN 54 standards are

used interchangeably throughout this manual.

i

Note

The terms “Trouble” as used in NFPA 72 guideline and UL 864 standard and

“Fault” as used in EN 54 standards are used interchangeably throughout this

manual

i

Note

All maintenance and repair work performed on the TSA-200 shall be

performed by qualified and authorized personnel ONLY

i

Note

Do not install, operate, or maintain this product before fully reading and

thoroughly understanding this manual.

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

— II —

Table of Contents

1INTRODUCTION ............................................................................................1

2FUNCTIONS AND OPTIONS.........................................................................3

2.1

EN 54-2

O

PTIONS WITH

R

EQUIREMENTS

......................................................... 3

2.2

UL 864 ......................................................................................................... 3

3IMPORTANT NOTES .....................................................................................4

3.1

M

ANUAL

T

RIGGERING

..................................................................................... 4

3.2

M

ANUAL

T

RIGGERING

D

EVICES

....................................................................... 4

3.3

D

EPENDENCY ON

M

ORE

T

HAN

O

NE

A

LARM

S

IGNAL

.......................................... 4

3.4

T

WO

Z

ONES

C

OINCIDENCE

............................................................................. 5

3.5

N

OTE

R

EGARDING

D

EFAULT

C

ONFIGURATION

.................................................. 6

3.6

M

AXIMUM

N

UMBER OF

D

ETECTORS

................................................................. 6

3.7

S

UITABILITY OF USE IN VARIOUS ENVIRONMENTS

.............................................. 6

3.8

L

IMITING THE

C

ONSEQUENCES OF

F

AULTS

....................................................... 6

4TERMS, DEFINITIONS AND ABBREVIATIONS ...........................................8

4.1

A

BBREVIATIONS

: ............................................................................................ 8

4.2

T

ERMS AND

D

EFINITIONS

................................................................................ 8

5SAFETY .........................................................................................................9

5.1

G

ROUNDING AND

M

AINS

S

UPPLY

C

ONNECTION

................................................ 9

5.2

B

ATTERIES

H

ANDLING AND

S

AFETY

............................................................... 10

6ACCESS LEVELS........................................................................................11

7TECHNICAL SPECIFICATIONS..................................................................12

7.1

M

AIN

E

LEMENTS

,

B

ASIC

U

NIT

....................................................................... 12

7.2

E

XPANSION

M

ODULES

.................................................................................. 12

7.3

I/O

F

UNCTIONS OF THE

D

IFFERENT

E

XPANSION

B

OARDS

/M

ODULES

................ 12

7.4

R

ELAYS

....................................................................................................... 12

7.5

TSA-1000C

C

OMMUNICATION

E

XPANSION MODULE

....................................... 13

7.6

T

ABLE OF

T

ECHNICAL

S

PECIFICATIONS

,

TSA-1000 ........................................ 14

7.7

D

EFAULT

P

ORTS

A

LLOCATION AND

C

ONFIGURATION

...................................... 21

8TSA-1000 CONTROL PANEL ASSEMBLY.................................................22

8.1

P

OWER

S

UPPLY

,

C

HARGER AND

B

ATTERIES

.................................................. 22

8.2

M

AIN

B

OARD

................................................................................................ 23

8.3

E

XPANSION

M

ODULES

.................................................................................. 23

8.4

F

RONT

D

OOR

............................................................................................... 24

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

— III —

9USER INTERFACE-DISPLAY AND KEYBOARD .......................................26

9.1

G

ENERAL

D

ISPLAY

A

REA

.............................................................................. 26

9.2

D

IGITAL

D

ISPLAY AND

D

IGITAL

D

ISPLAY

I

NDICATORS

...................................... 30

9.3

Z

ONE

I

NDICATORS

........................................................................................ 31

9.4

K

EYBOARD

.................................................................................................. 31

10 WORK STATES ...........................................................................................33

10.1

N

ORMAL

S

TATE

........................................................................................... 33

10.2

A

LARM

S

TATE

.............................................................................................. 33

10.3

F

AULT

S

TATE

............................................................................................... 34

10.4

S

UPERVISORY

S

TATE

................................................................................... 34

10.5

D

ISABLEMENT

S

TATE

................................................................................... 35

10.6

T

EST

S

TATE

................................................................................................. 35

11 INSTALLATION ...........................................................................................36

11.1

P

RE

-I

NSTALLATION

P

LANNING

....................................................................... 36

11.2

M

OUNTING

................................................................................................... 37

11.3

W

IRING

....................................................................................................... 38

11.4

I

NSTALLING

D

ETECTORS

,

I

NPUT AND

O

UTPUT

D

EVICES

,

AND

O

THER

D

EVICES

. 42

11.5

C

ONNECTING THE MAINS

,

BATTERIES AND THE GROUND WIRE

. ........................ 44

11.6

P

OST

-I

NSTALLATION

..................................................................................... 45

11.7

C

ONNECTING A

TDM-500

I

D

IALER

................................................................ 46

12 EXTINGUISHING .........................................................................................48

12.1

A

UTOMATIC

E

XTINGUISHING

......................................................................... 48

12.2

M

ANUAL

E

XTINGUISHING

.............................................................................. 48

12.3

E

XTINGUISHING

O

UTPUT

.............................................................................. 48

12.4

E

MERGENCY

H

OLD AND

E

MERGENCY

A

BORT

................................................. 48

12.5

P

OST

-A

CTIVATION

I

NDICATION

...................................................................... 48

12.6

A

CTIONS TO

P

ERFORM

A

FTER

E

XTINGUISHING

A

CTIVATION

............................ 49

12.7

R

EESTABLISHING THE

Q

UIESCENT

C

ONDITION AFTER

E

XTINGUISHING

............. 49

13 CONNECTING EXTINGUISHING EQUIPMENT ..........................................50

13.1

E

XTINGUISHING

A

DAPTERS

........................................................................... 50

13.2

N

UMBER OF

E

XTINGUISHING

A

DAPTERS

........................................................ 50

13.3

E

XTINGUISHANT

Q

UANTITIES

........................................................................ 51

13.4

F

IKE

FIRERASER ....................................................................................... 51

13.5

F

IKE

GCA.................................................................................................... 52

13.6

G

REEN

EX

A

EROSOL

C

ONTAINERS

................................................................ 52

13.7

F

IRE

P

RO

A

EROSOL

C

ONTAINERS

.................................................................. 53

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

— IV —

13.8

A

T

YPICAL

A

PPLICATION

–

E

XTINGUISHING AND

E

LECTRICITY

D

ISCONNECT

..... 53

14 CONTROL PANEL PROGRAMMING..........................................................55

14.1

M

ENU

S

TRUCTURE

....................................................................................... 55

14.2

E

NTERING

P

ROGRAMMING

M

ODE

.................................................................. 55

14.3

K

EY

F

UNCTIONS DURING

P

ROGRAMMING

....................................................... 55

14.4

D

ISPLAY

D

URING

P

ROGRAMMING

.................................................................. 56

14.5

P

ROGRAMMING

S

EQUENCE

........................................................................... 57

14.6

D

IALER

P

ROGRAMMING

................................................................................ 58

14.7

H

ORN

O

UTPUT

P

ROGRAMMING

..................................................................... 58

14.8

E

XPANSION

C

ARD

P

ROGRAMMING

................................................................ 58

14.9

R

EMOTE

A

NNUNCIATOR

P

ROGRAMMING

........................................................ 59

14.10

N

ETWORK

P

ROGRAMMING

............................................................................ 59

14.11

R

ELAY

P

ROGRAMMING

................................................................................. 59

14.12

Z

ONE

P

ROGRAMMING

................................................................................... 61

14.13

O

UTPUT

P

ROGRAMMING

............................................................................... 62

14.14

S

AVING

D

ATA AND

E

XITING

P

ROGRAMMING

M

ODE

......................................... 64

15 OPERATION AND MAINTENANCE ............................................................65

15.1

E

VACUATION

(EVC) ..................................................................................... 65

15.2

O

N

/

O

FF

Z

ONE OR

O

UTPUT

(OFF) ............................................................... 65

15.3

F

IELD

T

EST

(

FT

) ........................................................................................... 65

15.4

E

VENT

L

OG

(LOG)....................................................................................... 66

15.5

A

LARM

C

OUNTER

(ALC) ............................................................................... 66

15.6

C

HANGING

P

ASSWORD

(PAS)....................................................................... 66

15.7

S

ETTING

T

IME AND

D

ATE

(

T

+

D

)..................................................................... 66

15.8

L

AMP

T

EST

(

LT

)............................................................................................ 67

15.9

A

DDITIONAL

I

NFORMATION

(

IN

F).................................................................... 67

15.10

R

ESTORING

D

EFAULT

C

ONFIGURATION

(

D

EF)................................................ 67

16 TROUBLESHOOTING .................................................................................68

16.1

M

AINTENANCE

A

LERT

................................................................................... 68

16.2

S

YSTEM

S

TATES

.......................................................................................... 68

16.3

S

YSTEM

F

AULTS

.......................................................................................... 68

16.4

P

ROGRAMMING

F

AULTS

................................................................................ 70

17 COMMISSIONING........................................................................................72

18 MAINTENANCE ...........................................................................................74

19 ROUTINE TESTING.....................................................................................75

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

— V —

19.1

W

EEKLY

I

NSPECTION

–

T

O

B

E

P

ERFORMED BY

S

ITE

P

ERSONNEL

.................... 75

20 CERTIFICATION..........................................................................................76

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

— VI —

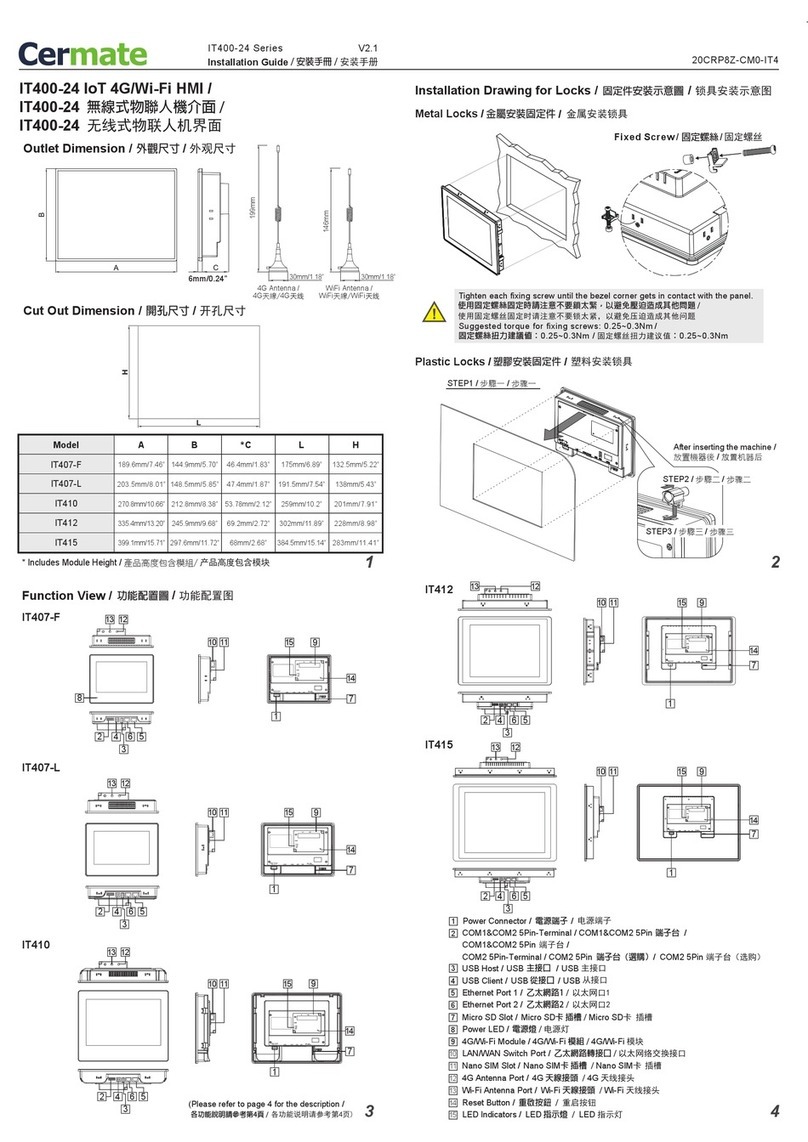

Tables of Figures

Figure 1

TSA-1000 typical system 7

Figure 2

Module location 22

Figure 3

Display and Keyboard 25

Figure 4

General Display Area 26

Figure 5

Digital Display and Digital Display Indicators 31

Figure 6

Zone Indicators 31

Figure 7

Keyboard 31

Figure 8

Chassis Mounting Holes 38

Figure 9

Routing High- and Low Voltage cables in the TSA-1000 Chassis 40

Figure 10 RM-1000 connection 41

Figure 11 Connecting a network 41

Figure 12 Main Board Connectors 42

Figure 13 Expansion Module Connectors 43

Figure 14 Connecting Two Detectors and a TPB-10R Break-Glass 43

Figure 15 Connecting Programmable and General Sounders 43

Figure 16 Connecting the grounding wire to the Chassis 44

Figure 17 Connecting a TDM-500i Dialer (W/W rev C5, S/W rev 2.05.01) 46

Figure 18 Connecting a FIRERASER Cylinder for Automatic Extinguishing 51

Figure 19 Connecting a GCA-Activated Extinguishing Cylinder 52

Figure 20 Connecting a GreenEX Aerosol Extinguishing Container 52

Figure 21 Connecting FirePro Aerosol Generators 53

Figure 22

A typical application – cross-zone activation of electricity disconnect,

evacuation volume extinguishing 54

Figure 23 Programming Menu Structure 55

Figure 24

The seven-segment display and representation of digits and letters 57

Figure 25 Device selection 58

Figure 26 Display during relay programming 60

Figure 27

Programmable Relay Contacts During Normal Operations and Upon

Activation 61

Figure 28 Display during input programming 62

Figure 29 Display during output programming 63

List of Tables

Table 1

Technical Specifications 20

Table 2

TSA-1000 – number of inputs and outputs of the various configurations 24

Table 3

IDC cable selection 36

Table 4

Wiring Characteristics’ influence on System Performance 39

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

– Page 1 of 1 –

1 Introduction

Telefire's TSA-1000 Conventional (i.e. Non Addressable) Multi-Zone Fire Alarm Control

Panel complies with numerous standards. It is certified to EN 54-2 and EN 54-4. It is

also CE marked and is certified to GOST 53325-2009 and to IS 1220. It also complies

with UL 864 edition 9.

The control panel is modular and can be extended up to 16 input zones, with options for

other expansions.

The base control panel contains four programmable zones, four programmable outputs,

a horn output, a Fire Alarm dialer output, and three programmable relays.

The control panel is modular and is expandable via various modules that include inputs,

outputs, and relays to implement complex logic functions.

Up to four remote panels can be connected via an RS-485 interface (part of the

TSA-1000C, a communication expansion card). Computer communication and remote

panels are also supported through the TSA-1000C

The TSA-1000 supervises two-wire IDC lines ("zones") and outputs that can be used to

activate sounders, automatic extinguishing devices, evacuation sounders, or other

notification equipment. Additionally, the control panel has separate outputs for activating

a main sounder, automatic dialer, and "dry" contacts (of relays) to indicate alarm, fault,

and supervisory events of the system.

All input and output lines are fully supervised. The output lines are constantly monitored

and are automatically disconnected when current draw exceeds the allowed values.

Input and output line protection is done without the use of fuses, using Telefire's unique

ACM (Advanced Current Management) that provides high resilience even during fault

events and automatic return to normal operation with problem resolution.

Any event in the system is clearly displayed in detail and allows quick and easy

troubleshooting for the user, operator, and service technician.

All programming and configuration can be done easily through the panel's keyboard or

via dedicated software.

As the system is computerized, it allows working in various modes that can be easily

reconfigured in the field without special tools, yet allowing access only to authorized

personnel.

The TSA-1000 can be programmed as a fire alarm panel, fire alarm and extinguishing

panel that includes cross-zoning, extinguishing activation delay, or a combination of the

two. Additionally, it is possible to delay alarm from specific zones and cross zones to

neutralize false alarms from difficult locations such as areas with forklift activities, etc.

The system's inputs, outputs, and relays are fully configurable including complex logic

operations involving multiple outputs and multiple inputs.

The TSA-1000 allows output activation in four ways: general, specific zone, cross-zones

of several zones, and one of several zones, through unique matrix logic (AAM –

Advance Activation Matrix).

The system includes a maintenance alert for detectors (dependant on using Telefire

detectors), a function that required, until now, analog addressable panels.

Battery charging is fully supervised – including charging voltage, charging current, and

monitoring of the battery's ability to supply the required current.

A special work mode (Field Test) allows detector testing using only one technician,

whilst differentiating between activations that are done for testing purposes and real

alarms.

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

– Page 2 of 2 –

The system supports an automatic alarm verification feature, to decrease the occurrence

of false alarms, and a time and date clock for logging system events. System log can be

viewed via a PC or printed for system investigation purposes.

The TSA-1000 can be connected to form a network of control panels.

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

– Page 3 of 3 –

2 Functions and Options

2.1 EN 54-2 Options with Requirements

The TSA-1000 conforms fully to European standards BS EN 54-2:1998 and

BS EN 54-4:1998 and the following optional features:

•Output to fire alarm devices – EN 54-2 Section 7.8 option with requirements

•Output to fire alarm routing equipment – EN 54-2 Section 7.9 option with

requirements

•Output to fire protection equipment – EN 54-2 Section 7.10 option with requirements

•Coincidence detection– EN 54-2 Section 7.12 option with requirements

(Provided as a two zones coincidence and as a single/Dual zone AVF- Alarm

Verification Function)

•Alarm Counter – EN 54-2 Section 7.13 option with requirements

•Total loss of power supply – EN 54-2 Section 8.4 option with requirements

•Output to fault warning routing equipment – EN 54-2 Section 8.9 option with

requirements

•Test condition – EN 54-2 Section 10 option with requirements

2.2 UL 864

The TSA-1000 complies with UL 864 edition 9

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

– Page 4 of 4 –

3 Important Notes

3.1 Manual Triggering

Any of the inputs can be configured as a manual (extinguishing) release input, or as a

Manual Call Point (i.e. Manual Alarm Input). Asserting the Manual release (i.e. pressing

the PB) causes immediate extinguishing.

i

Note

If a remote (non panel mounted) extinguishing manual triggering device is

used, then USE ONLY an approved and certified Extinguishing Triggering

Device of the correct color as per EN 12094-3.

i

Note

If a remote (non panel mounted) Manual Call Point is used, then USE ONLY

an approved and certified Device of the correct color as per EN 12094-3 and

EN 54-2.

If two zones coincidence is not required by your national regulations, you may change

the configuration so the ECD activates on any single zone which is configured as a

member of the Extinguishing Decision Group.

i

Note

Trigger on coincidence of more than two independent sources does not

comply with the 12094-1 standard.

3.2 Manual Triggering Devices

i

Note

When an extinguishing manual triggering device is used, then USE ONLY an

approved and certified Extinguishing Triggering Device of the correct color as

per EN 12094-3.

3.3 Dependency on More Than One Alarm Signal

The TSA-1000 supports Coincidence detection– per EN 54-2 Section 7.12 option with

requirements

(Provided as a two zones coincidence and as a single/Dual zone AVF- Alarm Verification

Function)

The "Dependency on more than one alarm signal" function, also termed (By UL) "Alarm

Verification Function" (AVF), as detailed in EN-54-2, paragraph 7.12.

The alarm Delay and Confirmation (verification) feature allows the control panel to ignore

false, short and transient alarm events, which may cause a nuisance and unnecessary

extinguishing.

This feature is based on an Alarm Delay Period, and an Alarm Confirmation Period.

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

– Page 5 of 5 –

The alarm delay can be programmed, PER ZONE, to OFF (No Delay, No Alarm

Verification) or to ON. Each detection zone can be programmed independently.

If the zone Alarm Delay is programmed ON, there is a 30 seconds alarm Delay. During

the delay period alarms are ignored. This is followed by a 180 seconds confirmation

period.

When a zone programmed for alarm verification is first triggered, the control panel resets

the zone in alarm, waits for 30 seconds (if Delay is ON) and enters a 180 seconds (3

minutes) confirmation period. During the 30 seconds delay period, alarms are ignored.

During the 180 seconds confirmation period, the control panel enters the alarm state

immediately if a trigger from the same zone or from another zone is received, even if the

other zone is programmed for alarm delay and confirmation).

If, during the alarm confirmation period, no alarm is received, the ECD reestablishes the

quiescent condition.

Each detectors zone can be independently programmed for Alarm Delay and

Confirmation, (Alarm Verification).

The dependencies supported, as per EN 54-2, paragraph 7.12 are type A or type B,

depending on the configuration of the TSA-1000.

3.4 Two Zones Coincidence

The detailed explanation of the operation of the ECD is provided in Work States, page

33, and in Operation and Maintenance, page 65.

Coincidence detection– EN 54-2 Section 7.12 option with requirements

is implemented in the TSA-1000 as a two zones coincidence and as a single/Dual zone

AVF- Alarm Verification Function).

AVF was explained above. "Two Zones Coincidence" is explained below

When the ECD is configured for two zones coincidence, then a trigger from one of the

zones which are members of the extinguishing decision group will change the state of

the ECD to "Fire Alarm", and to the "Preactivated State". Trigger from a second zone,

which is a member of the extinguishing decision group, will cause the CIE to enter the

"Activated" state. If a Non-Zero Delay is programmed, the CIE will enter the "Pre

Discharge Warning Time", (extinguishing delay). If Delay is zero, or the warning time

(delay) expires, the extinguisher is triggered.

i

Note

If zones, which are not members of the extinguishing decision group, are

triggered, the ECD changes state to "Fire Alarm", BUT DOES NOT start the

extinguishing process, and the extinguisher is NOT ACTIVATED even if two

such zones are triggered.

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

– Page 6 of 6 –

3.5 Note Regarding Default Configuration

i

Note

By default, the TSA-1000 is programmed for all input zones are detectors

zones and all outputs are general outputs.

To modify these and additional settings, the TSA-1000 must be programmed

accordingly.

3.6 Maximum Number of Detectors

EN 54-2 specifies a limit of 32 detectors per zone, which is the limit of each zone of the

TSA-1000; hence the TSA-1000 max number of detectors is dependant on the

configuration, and the number of zones.

3.7 Suitability of use in various environments

See Mounting, page 37

3.7.1 Environmental Limits and Protection Level

The TSA-1000 environmental limits are specified in EN-54-02:1998 para. 12.

The TSA-1000 is specified for -5°C to +40°C, RH max 95% temperature range, and

IP30 protection level.

i

Note

See Routing cables into the ECD and maintaining the protection level,

page 38, for information about maintaining the protection level.

i

Note

Do not operate the ECD outside the specified limits.

3.7.2 Suitable Environment

The TSA-1000 environmental limits are stated above. It is to be installed in an indoors

location, well ventilated location, protected from the elements.

Avoid locating the CP in direct sunlight or near sources of heat.

It is recommended to install the CP in an electrically quiet location (i.e. away from high

power cables, motors, etc).

3.8 Limiting the Consequences of Faults

See POWER SUPPLY, CHARGER AND BATTERIES, page 22, for explanation of

PS/Charger limiting/protection devices.

The Main Board, which contains the charging circuitry and the battery protective

resettable PTC, also has a common electronic limiter for most output ports (It does not

protect the contacts of relays!), which are monitored by the CPU

If there is an overload on an output (or outputs), the common limiter shuts off, the buzzer

sounds and the visual fault indication and the Fault relay are switches ON. The CPU

switches OFF all the controlled outputs. It then switches ON the separate outputs in

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

– Page 7 of 7 –

sequence, until the faulty output is isolated. All appropriate "good" outputs are then

switched back ON, except for the faulty outputs.

The controlled outputs (i.e. not relays' contacts or OC outputs) are continuously

monitored.

Recovery from faults is detected by the CPU and all relevant recovered outputs are

reactivated, if necessary.

Open Collector outputs are current limited by design, by series connected high value

resistors.

i

Note

Relays' contacts are not monitored, supervised or protected.

Connect external protective circuitry to the relays' contacts circuitry.

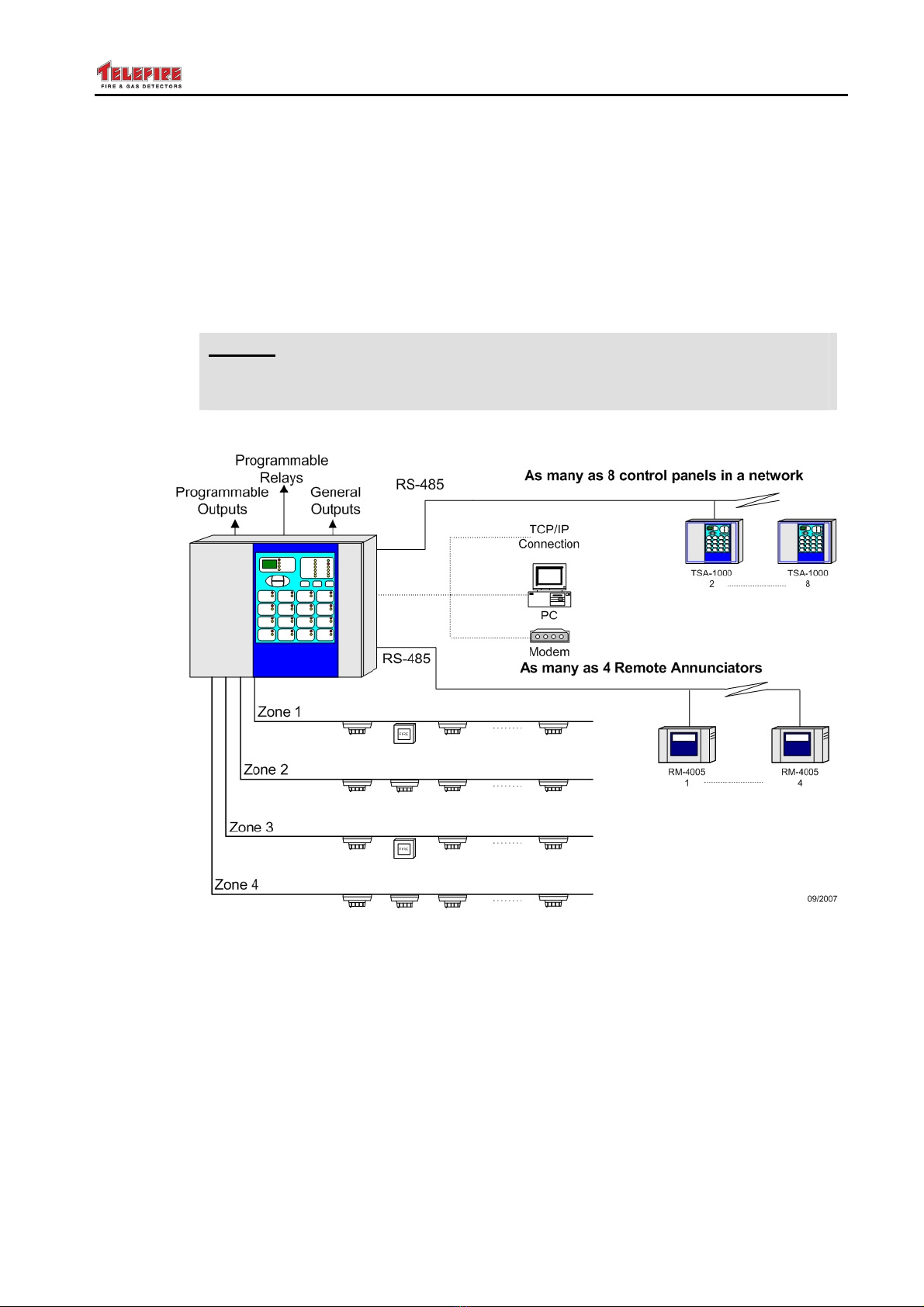

Figure 1 TSA-1000 typical system

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

– Page 8 of 8 –

4 Terms, Definitions and Abbreviations

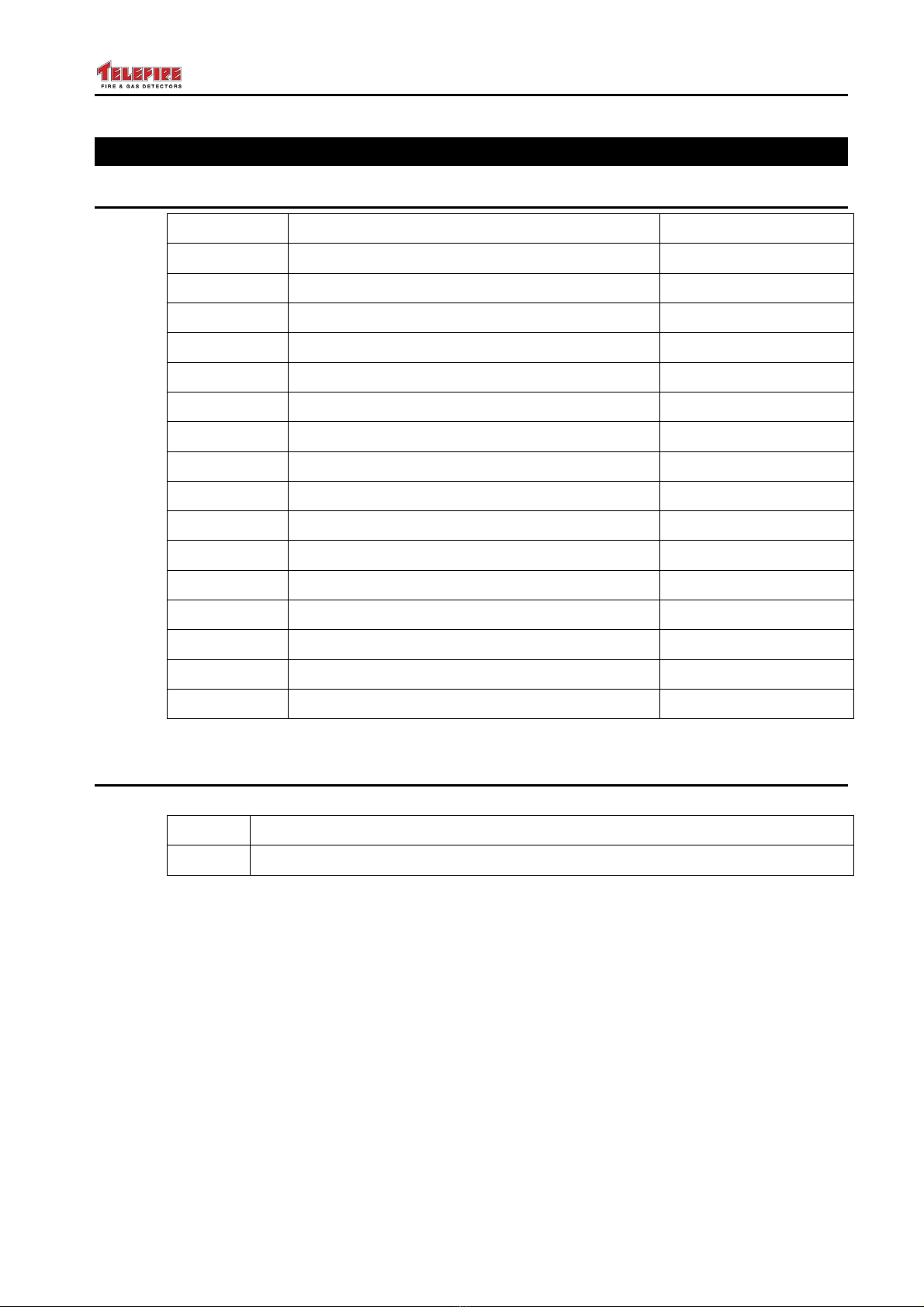

4.1 Abbreviations:

Abbreviation

Meaning Remarks

CP Control Panel

ECD Electrical Automatic Control and Delay Device

TB Terminal Block

MCP Manual Call Point

PB Push Button

PC Personal Computer

PS Power Supply

PW Password

M Minute

# (Number)

FWRE Fault Warning Routing Equipment Fault Dialer

FARE Fire alarm Routing Equipment Alarm Dialer

AC Alternating Current

AH Ampere Hours

RH Relative Humidity

PTC Positive Temperature Coefficient (FUSE)

4.2 Terms and Definitions

TERM MEANING

Event A change which is detectable by the ECD and causes a response

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

– Page 9 of 9 –

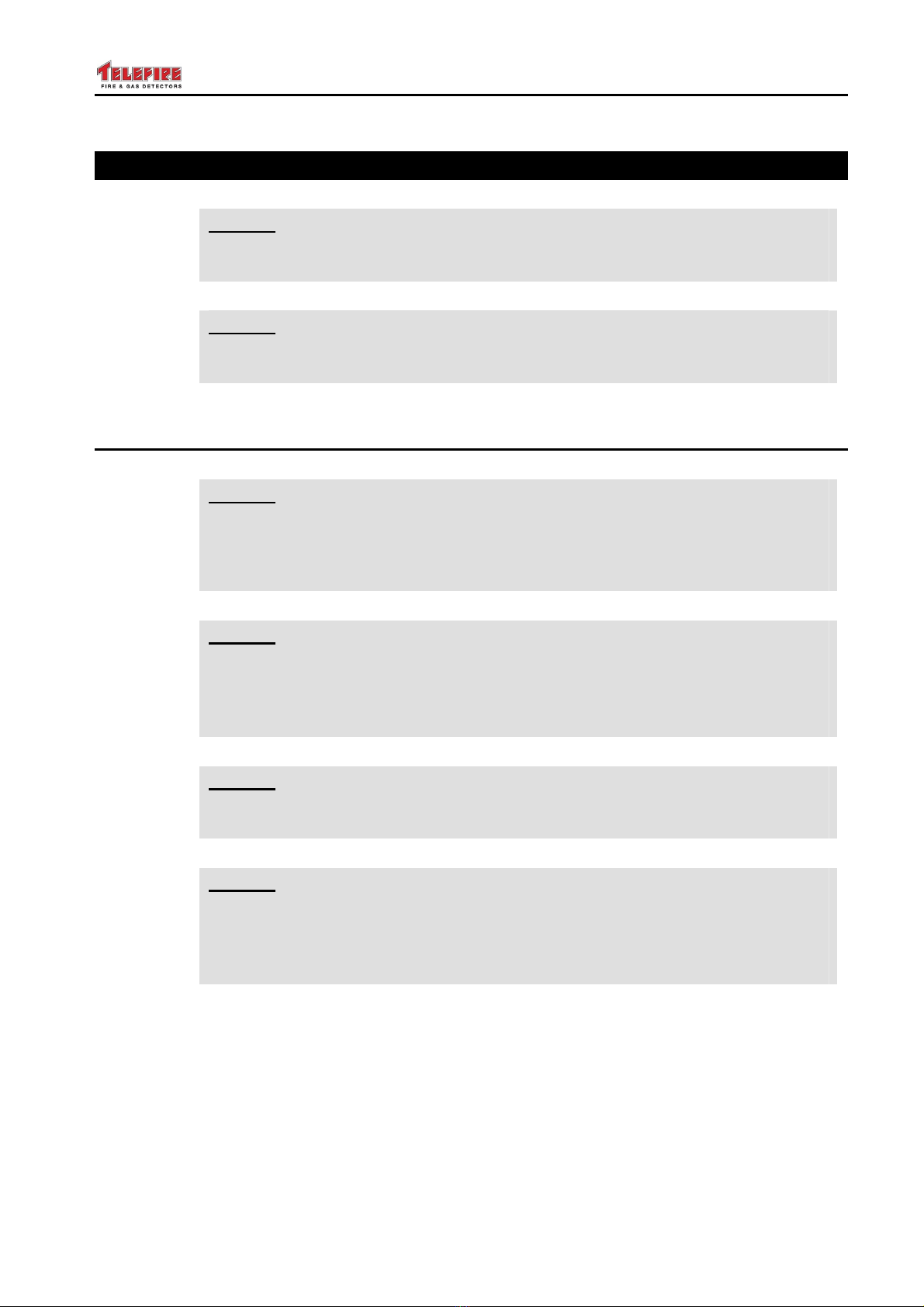

5 Safety

i

Note

Do not install commission, operate, or maintain this product before fully

reading and thoroughly understanding this manual.

i

Note

Whenever possible, disconnect all power sources (Line AND Battery) from

the product before performing any work on the ECD.

5.1 Grounding and Mains Supply Connection

i

Note

All installation, maintenance work and connecting/Disconnecting of the ECD

to power sources shall be performed according to applicable international,

national, regional and local codes and regulations, and the specific

instructions by the manufacturer.

i

Note

All maintenance work should only be performed by trained, qualified and

certified personnel only.

Personnel that work on this equipment must fully read and comprehend this

manual.

i

Note

Connection/Disconnection of the control panel to the mains should be

performed by QUALIFIED AND AUTHORIZED personnel ONLY

i

Note

Disconnect all mains power wires (Line AND Neutral) to the circuit to which

you intent to connect the control panel, before actually connecting the mains

input power cable to the ECD.

Verify that the ECD enclosure is properly grounded before applying power

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

– Page 10 of 10 –

5.2 Batteries Handling and Safety

i

Note

Batteries require special care and safety precautions.

Refer to the batteries’ manufacturer literature for full information.

The following information supplements and highlights manufacturer’s information.

WHEN HANDLING BATTERIES, OBSERVE THE MANUFACTURER’S

RECOMMENDATIONS REGARDING CLOTHING AND PROTECTIVE GEAR

Use two 12V 5 AH sealed Lead Acid batteries, such as Yuasa NP5-12 or equivalent,

connected in series.

Use the supplied wires to connect to the batteries, and to connect two batteries in series.

Since the batteries used are maintenance free, and the ECD automatically controls the

battery charging, discharge and test, no SPECIAL maintenance is required.

OBSERVE THE FOLLOWING:

Connect the battery to the ECD main board battery terminal block using the supplied

wires. Observe polarity.

Keep the batteries clean and dry

Keep the area well ventilated

Smoking, fire or sparks ARE NOT ALLOWED near batteries.

When working on batteries, DISCONNECT THE BATTERIES AND ALL OTHER

POWER SOURCES

i

Note

If batteries show any signs of swelling, rupture, fluid leakage, emission of

gases or fluids, heating or discoloration, or accumulation of corrosion

products near the terminals, OR YOU HEAR A HISSING SOUND, disconnect

the batteries and replace with a new pair of the appropriate type.

Follow the manufacturer’s instructions for cleaning the batteries and the enclosure, if

necessary

Dispose of batteries properly

Do not short-circuit, puncture, crush, or dispose of batteries in fire.

Do not connect batteries to makeshift chargers or power supply.

Do not expose the batteries or its terminals to mechanical stress

Handling of materials that leak from the batteries should be done by qualified personnel

using the appropriate protective gear, materials, and procedures.

If the ECD indicates a battery fault, check the wiring.

If necessary, replace the batteries

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

– Page 11 of 11 –

6 Access Levels

The control panel provides protection from unauthorized access of certain functions by

various access levels.

The TSA-1000 includes electronic and mechanical mechanisms that enact 4 access

levels, as per EN 54-02 Annex A:

•Access level 1 – not limited, immediate access by operator

•Access level 2 (operator) – protected by an operator password. Provides all of

access level 1 functions and allows access to additional functions that are

performed on a regular basis by the system’s operator.

i

Note

To avoid multiple PW key punching, there is a 3 minutes period after the

operator's PW has been entered, when the PW remains valid and effective,

which enables the operator to perform several tasks continuously without

entering the PW separately for each action.

(Since. In the password delay, the reentering of level 2 PW is not required,

level 2 access appears to be level 1 access, and level 3 appears to be level 2

access)

Access level 3 (programmer & installer) – protected by a programmer

password (different from the operator's password!)or a mechanical key.

Provides all of access to level 1 and 2 functions and allows access to

additional functions such as programming, and access for functions

performed during installation.

i

Note

Access levels 2 and 3 have different passwords. This is not correlated to the

number of times the password has to be keyed in to access a certain menu.

Some sub-menus which are accessible at level 3, require that the level 3

(programmer) password be entered in a single menu, while others (for

additional safety) require the level 3 password to be entered in to different

menus

•Access level 4 (manufacturer) – Only accessible using a dedicated PC SW tool or a

mechanical key.

The mechanically controlled access elements are detailed below.

The ECD enclosure has a door/front-panel with a mechanical lock. A detachable key is

required to open the lock, which requires a positive and deliberate action and prevents

accidental and non authorized access. Hence the access level to the batteries and AC

power lines and the field wiring connections is 3/4.

Two switches are located on the front panel. A Manual &Automatic/Manual Only key-

switch and a Manual Activation Push Button switch.

TSA-1000

© 2008 –2012 Telefire Fire & Gas Detectors Ltd Revision 1.12 האיגש!אצמנ אל הינפהה רוקמ .

– Page 12 of 12 –

7 Technical Specifications

7.1 Main Elements, Basic Unit

The TSA-1000 comprises the following major elements:

•A metal enclosure with a hinged and mechanically lockable door. The door also

serves as the front panel

•PS40W Power Supply / Charger

•TSA-1000 Main Board (1 change polarity output, 5 level activation outputs, 4 inputs,

3 relays)

•TSA-1000D Display board

•Flat Cable for connecting the Main Board to the Display board

•Two 12V 5AH batteries (Connected in series).

•Link wire for connecting the two batteries in series

•Two (single) wires for connecting the batteries to the PS "BATTERY" TBs.

•Flat Cable for connecting the PS to the main Board

•Two 4 wire cables, for connecting the MB to the TSA-1000E8 card.

•Clamp On ferrite on AC input cable

•Clamp On ferrite on flat cable from MB to the display board.

7.2 Expansion Modules

The TSA-1000 basic unit functionality can be extended using the following expansion

boards/modules;

•TSA-1000E4 expansion board (4 inputs)

•TSA-1000E8 expansion board (8 inputs)

•TSA-1000EM083 expansion board (8 Open Collector outputs, 3 relays)

Prerequisite: TSA-1000E4 or TSA-1000E8

•TSA-1000EM422 expansion board (4 inputs, 2 programmable outputs, 3

programmable relays)

Prerequisite: TSA-1000E4 or TSA-1000E8

•TSA-1000C Communication module

7.3 I/O Functions of the Different Expansion Boards/Modules

The MB inputs and the expansion modules inputs are of the same design and have

identical electrical characteristics. So are the Relays, Level Activation outputs, Open

Collector outputs, etc.

The alarm dialer output is a level activation output with educed current capability (0.6A

instead of 0.8A).

7.4 Relays

Relays' contacts are not monitored, supervised or protected.

Connect external protective circuitry to the relays' contacts.

Relays are intended for same room connection only.

Table of contents

Other Telefire Control Panel manuals