Teleflex Marine MV3-E Series User manual

MV3-E Series

Installation and Operation Manual

for Hybrid Engine Controls

ISCHMV3E

Revision 1.0

Page 2 User Manual: MV3-E Hybrid Controls

Notice to Boat Manufacturer, Installer, and Consumer

Please read these instructions through carefully and entirely before beginning installation or operation. This

manual must be accessible to the owner/user of this Teleex Marine product.

Throughout this manual, warnings are used to alert the installer/operator to special instructions concerning a

particular service or operation that may be hazardous if performed incorrectly or carelessly. Observe these

alerts carefully!

These “safety alerts” alone cannot eliminate the hazards that they signal. Strict compliance to these special

instructions when performing installation, operation, and maintenance plus “common sense” operation are the

most effective accident prevention measures.

This device should not be used as a navigational aid to prevent collision, grounding, boat damage, or personal

injury. When the boat is moving, water depth may change too quickly to allow time for you to react. Always

operate the boat at very slow speeds if you suspect shallow water or submerged objects.

Disassembly and repair of this electronic unit should only be performed by authorized service personnel. Any

modication of the serial number or attempt to repair the original equipment or accessories by unauthorized

individuals will void the warranty. Handling and/or opening this unit may result in exposure to lead, in the form

of solder.

This product contains lead, a chemical known to the State of California to cause cancer, birth defects, and other

reproductive harm.

The information contained in this manual is believed to be accurate at the time of going to print but no responsibility, direct or

consequential, can be accepted for damage resulting from the use of this information. The manufacturers reserve the right to make

changes, without notice, to any of its products.

Warning

Warning

User Manual: MV3-E Hybrid Controls Page 3

Table of Contents

Introduction......................................................................................................................................................4

Important Safety Notes ................................................................................................................................4

Control Congurations.................................................................................................................................4

Operation..........................................................................................................................................................5

Neutral Locking Ring ..................................................................................................................................5

Neutral Throttle Warm-up Button................................................................................................................5

Installation........................................................................................................................................................6

Location of Control......................................................................................................................................6

Measuring the Shift Cable ...........................................................................................................................6

Inboards and Stern Drives............................................................................................................................6

Side Mount Cabling .....................................................................................................................................7

Shift Cable Connection - Engine End..........................................................................................................8

Shift Cable Connection - Control End.........................................................................................................8

Connect Shift to Engine Control............................................................................................................8

Throttle Wiring Harness...............................................................................................................................9

Installation of the Wiring Harness .........................................................................................................9

Preparation of the Control Head Wiring Harness ..................................................................................9

Connection of the Wiring Harness.........................................................................................................9

MV3-E Throttle Wiring Connections ..................................................................................................10

Mount the Control......................................................................................................................................11

Shift Cable Connection and Adjustment....................................................................................................11

Maintenance ...................................................................................................................................................12

Maintenance and Corrosion Protection......................................................................................................12

General Control Dimensions.........................................................................................................................13

Mounting Dimensions....................................................................................................................................14

Warranty.........................................................................................................................................................15

Page 4 User Manual: MV3-E Hybrid Controls

Introduction

The Teleex Marine MV3-E Control is designed to provide convenient, one hand, single lever operation

of shift and throttle for most popular inboards equipped with hydraulic reverse gears and stern drives with

MEFI V engine control module.

A safety feature of the MV3-E is a Neutral Locking Hand Lever. It can only be disengaged from Neutral by

raising the lifter under the ball knob. The MV3-E accepts Teleex Marine 33 style cables.

Important Safety Notices

Teleex Marine Controls highly recommends the installation and usage of an engine emergency shut-off switch

as an important safety feature for Class “A” and Class “1” boats. This switch should be connected by a cord to

the boat driver. This shut-off switch is not a standard part of the control you are using.

Control Congurations

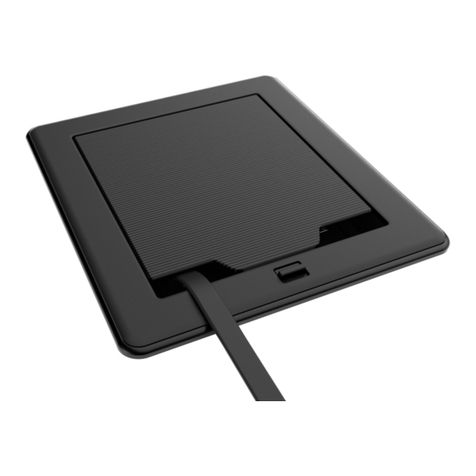

The MV3-E Control can only be mounted in a horizontal position.

WARNING:

Do not remove the hand lever to change position.

User Manual: MV3-E Hybrid Controls Page 5

Operation

MV3-E Side Mount Control

Neutral Interlock Ring

To prevent bumping the MV3-E side mount control out of neutral,

a Neutral Interlock Ring has been installed as a preventative

safety feature.

Operation:

• When the Control Hand Lever is in Neutral, lift the Neutral

Interlock Ring and move the lever forward or reverse to

engage the gears.

Neutral Throttle Warm-up Button

This feature provides a “Throttle Only” option to operate the

engine throttle without going into gear.

Operation:

•When the Control Hand Lever is in Neutral, lift the Neutral

Interlock Ring and pull out the Neutral Throttle Warm-up button

at the same time.

•While holding the ring and button (releases), move the lever

forward to throttle up the engine.

•When the handle is returned to the Neutral position, the releases

will reset automatically.

•Once the releases reset, the Control Hand Lever will work both

shift and throttle functions.

Page 6 User Manual: MV3-E Hybrid Controls

Installation

Location of Control

Choose a mounting location for the control head which will provide comfortable operation of the hand lever,

unobstructed movement of mechanism arms and a clear path for cables to engine.

1. Allow adequate clearance for hand and lever swing (forward and reverse positions). See page 13 for the

control dimensions and the recommended clearance around and behind the mounting surface.

2. Allow adequate clearance under the console or in the gunwale for the cables AND allow a minimum of 36”

from the cable nest connection with no restraint. When supporting the cables beyond 36”, do not tie or clamp

tightly.

3. After a suitable location for the control is determined, use the separate mounting template to make the cut-out.

The templates are supplied with the control (also see mounting dimensions on page 14).

4. Closely follow the instructions provided on the template. Cut and drill the mounting holes required.

Measuring the Shift Cable

Measure the cable routing path from the control head connection to the engine connection.

Inboards & Stern Drives

Measure from the control connection -- along an unobstructed cable routing -- to the SHIFT connection.

Round this dimension UP to the next whole foot and order the required cable part number.

(Last two digits of the Teleex cable number equal the length of the cable in feet.)

NOTE: To determine the correct control assembly for inboards with hydraulic transmissions, you must

determine if the Shift Cable “pulls” or “pushes” to go into forward.

To outboard or stern

drive shift connection

User Manual: MV3-E Hybrid Controls Page 7

Installation

Side Mount Cabling

Page 8 User Manual: MV3-E Hybrid Controls

Shift Cable Connection - Engine End

See engine or stern drive instructions for shift cable connection.

Installation

Shift Cable Connection - Control End

Connect Shift Cable To Control

1. Insert shift cable through opening in hanger assembly in line with shift arm pivot attachment hole and lock

cable in hanger slot.

2. Screw pivot onto cable rod, allowing threads to protrude through pivot 1/8” for standard travel or 1/4” for

long travel.

3. Lubricate pivot with grease, then insert into required hole in shift arm. Fasten with cotter pin. Tighten cable

nut against pivot.

CAUTION:

The pivot must be in the hole nearest to the cable entry end of the control. Using the hole in the shift

arm (furthermost away from the cable mounting) support will produce unequal shift travel between the

“neutral to forward’ and the “neutral to reverse” positions; resulting in improper shift action.

To obtain standard (2 3/4 inch) cable shift travel at the engine use the shift arm on the control at the short pivot

hole location.

For Mercury, long (3 inch) cable shift travel at the engine is necessary. Assemble the shift arm to the control

using longest pivot hole location.

NOTE: The Control Shift Lever and the Transmission Shift Lever must coincide at the "Forward," "Neutral,"

and "Reverse" positions. Different makes of transmissions my require different amounts of shift travel. For

this reason, the Control Shift Lever is provided with two positions for attaching the shift cable: one for the

standard travel and one for the longest travel.

User Manual: MV3-E Hybrid Controls Page 9

Throttle Wiring Harness

Installation of the Wiring Harness

A wire harness must be prepared for connection of the MV3-E control head to the engine TAC module. Every

boat is different and there may be several ways to route the harness. Inside the boat there is often a channel or

conduit used for wiring. This can also be used to route the wire harness for the MV3-E control.

When routing the wiring harness, care must be taken not to damage the cable insulation. If a harness is short,

replace it with a correct length harness. Don’t add a short harness to make up the required length. Run the

harness over the shortest and straightest possible path. Secure the harness every 2 feet (0.6 m) with stainless

steel screws and mounting head ties or clamps. Excess harness length should be neatly coiled and secured with

nylon ties. The mounted harness should be as far as practical from high current wires or wiring runs and should

not be subjected to water, fuel, lubricants, or excess heat.

Preparation of the Control Head Wiring Harness

Measure from the control head mounting location along unobstructed wire runs to the engine module.

Round measurement to the next whole foot and add additional length if uncertain.

Prepare harness as shown in the diagram on the next page. It is recommended that conductors be stranded tinned

copper (UL 1426 or equivalent), 18 AWG min. Colors shown are optional.

Connection of the Wiring Harness

NOTE: Always connect the wiring harness to the Control Head before connecting to the engine. The engine

connection should not be made until the control has been completely installed.

Ensure that the watertight seal is in place and connect the 6-pin connector from the completed harness assembly

into the rear of the potentiometer mounted on the control head mechanism. The connector should be fully seated

and latched for proper operation.

Installation

Page 10 User Manual: MV3-E Hybrid Controls

Installation

MV3-E Throttle Wiring Connections

121622611.85 – 1.47

121622602.15 – 1.65

121622102.66 – 2.00

DELPHI PACKARD P/NCABLE O.D. (mm)

BOAT CONTROL CONNECTOR BODY

(Cable seal included)

121240760.50 – 0.35

121240751.0 – 0.80

DELPHI PACKARD P/NCABLE RANGE (mm2)

BOAT CONTROL FEMALE TERMINALS

12124264TERMINAL POSITION

ASSURANCE (TPA)

1206542510 POSITION HOUSING

DELPHI PACKARD P/NDESCRIPTION

TAC MODULE CONNECTOR BODY

DELPHI PACKARD

CONNECTOR ASSEMBLY

(METRI-PACK SERIES 150.2)

DELPHI-PACKARD

CONNECTOR ASSEMBLY

(METRI-PACK SERIES 150)

Yellow

Black

Red

Green

Orange

Blue

TO MV3-E

BOAT CONTROL TO ENGINE

TAC MODULE

D

C

B

G

J

F

F

E

D

C

B

A

120842000.50 – 0.35

120480741.0 – 0.80

DELPHI PACKARD P/NCABLE RANGE (mm2)

TAC MODULE FEMALE TERMINALS

120841931.009 – 0.995

120480871.70 – 1.29

120896782.15 1.60

120480862.85 – 2.03

DELPHI PACKARD P/NCABLE O.D. (mm)

TAC MODULE CABLE SEAL

(Seal all unused

cavities to maintain

watertight

connection)

xx LENGTH

PPS 2 RTN

PPS 1 REF

PPS 1

PPS 1 RTN

PPS 2 REF

PPS 2

H

SHIELD

12059168CAVITY PLUG

DELPHI PACKARD P/NDESCRIPTION

TAC MODULE CAVITY PLUG

User Manual: MV3-E Hybrid Controls Page 11

Installation

Mount the Control

1. Run the cable, which is connected to the control, back to the shift location of the engine and drive.

2. The cables should run as straight as possible, avoiding any sharp bends. Make no bends in the cable of less

than 8 inch (203.2 mm) radius.

3. Shift the control into “Forward” to move shift arm out of the way. This allows the control to be inserted into

the cut out.

4. When satised with the position of the control, fasten the housing to the mounting surface with three (3) #10

thread cutting screws. One screw is 1.50 inches (38.1mm).

Shift Cable Connection and Adjustment

The shift cable must be connected so that the “Forward,” “Neutral,” and “Reverse” positions of the control shift

lever will coincide with the forward, neutral and reverse positions of the transmission lever.

Readjust the cable terminals until the correct function of the shift lever is achieved. Proper adjustment of the

shift cable will result in a much better operating control.

Overjamming the transmission stop on either end of the shift travel may:

1. Cause excessive wear of the drive and the shift gear.

2. Result in a “heavy” feel of the hand lever; and / or

3. Over-stress and damage the cable.

Page 12 User Manual: MV3-E Hybrid Controls

Maintenance and Corrosion Protection

For maximum protection, especially in a saltwater environment, the control head and hand lever should be

washed lightly with fresh water on a regular basis.

• Periodically check the control head mechanism for loose fasteners and signs of wear on moving parts.

• Keep moving parts well lubricated with a moisture-displacing lubricant.

• Periodically check the cables and engine connections for signs of wear and corrosion. Replace as necessary.

Maintenance

User Manual: MV3-E Hybrid Controls Page 13

General Control Dimensions

Front View

Side View

Page 14 User Manual: MV3-E Hybrid Controls

Mounting Dimensions

MV3-E Side Mount Control

Note: These dimensions are NOT to scale.

When mounting, use the template - 311370E - which is included with this control.

User Manual: MV3-E Hybrid Controls Page 15

Teleex Marine 2-Year Limited Warranty

We warrant to the original retail purchaser that Teleex Marine products have been manufactured free from

defects in materials and workmanship. This warranty is effective for two years from the product manufacture

date, except where Teleex Marine products are used commercially or in any rental or other income producing

activity; then this warranty is limited to one year from the date of original purchase for mechanical and electrical

products.

Teleex Marine, Inc. products found to be defective and covered by this warranty will be replaced or repaired

at Teleex Marine’s option, and returned to the customer. Items must be returned (freight prepaid) within the

warranty period to the dealer from whom such products were purchased, or directly to Teleex Marine.

Teleex Marine’s sole responsibility under this warranty is limited to the repair or replacement of product that

is, in Teleex Marine’s opinion, defective. Teleex Marine is not responsible for charges connected with the

removal of such product or reinstallation of replacement or repaired parts.

We will have no obligations under this warranty for any product which:

• was improperly installed;

• was used in an installation other than as recommended in our installation or operation instructions or

specications;

• failed or was damaged due to an accident or abnormal operation including racing, misuse or alterations

outside our factory;

• was repaired or modied by entities other than Teleex Marine;

• was used on an engine/boat combination where the engine horsepower exceeds the rating established by the

boat manufacturer;

• was used with other product(s) which, in Teleex Marine’s opinion, are incompatible with the Teleex Marine

product.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES, OBLIGATIONS OR

LIABILITIES ON THE PART OF TELEFLEX MARINE AND WILL BE THE CUSTOMER’S EXCLUSIVE

REMEDY EXCEPT FOR ANY APPLICABLE IMPLIED WARRANTIES UNDER STATE LAW WHICH

ARE HEREBY LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL PURCHASE.

IN NO EVENT WILL TELEFLEX MARINE BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES FOR BREACH OF ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE

PRODUCTS. Some states do not allow limitations on an implied warranty, or the exclusion of incidental or

consequential damages, so the above exclusions may not apply to you. You may also have other rights which

vary from state to state.

Teleex Marine products returned under this warranty must be tagged with the customer’s name, street address,

and phone number to ensure proper handling, and returned freight prepaid to the selling dealer or to the

appropriate Teleex Marine manufacturing facility. User manual contains the facility return addresses.

Warranty

Page 16 User Manual: MV3-E Hybrid Controls

Teleex Marine

6980 Professional Parkway East

Sarasota, FL 34240

941-907-1000

FAX 941-907-1020

www.teleexmarine.com

Teleex Marine is a division of Teleex Incorporated ©2006, Teleex Inc.

Table of contents