Page 4

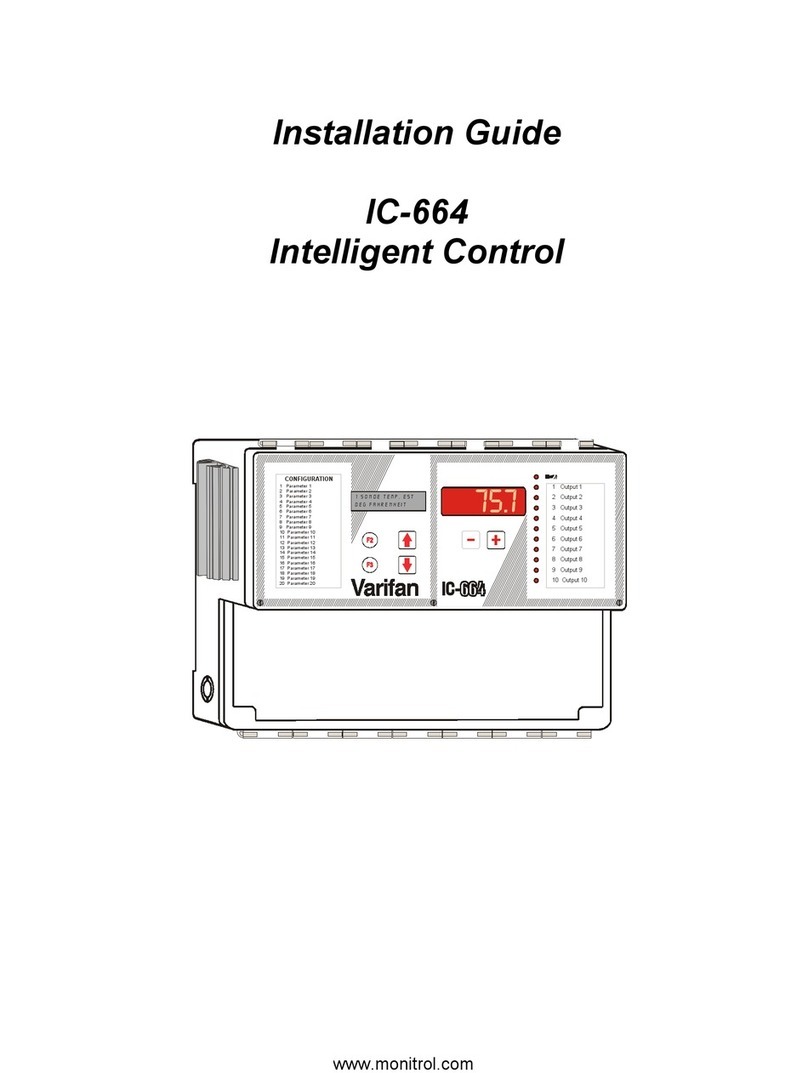

IC-610 - Intelligent Control

CHAPTER 3 - USER’S GUIDE

3.1 Faceplate........................................................................ 27

3.1.1 Settings List.................................................................... 27

3.1.2 LCD Display ................................................................... 27

3.1.3 Function Buttons ............................................................ 27

3.1.4 LED Status Window ....................................................... 27

3.1.5 Setting Buttons (arrows)................................................. 27

3.1.6 Value Buttons (+ and -) .................................................. 29

3.1.7 Output Segments ........................................................... 29

3.2 Settings .......................................................................... 29

3.2.1 Time of Day .................................................................... 29

3.2.2 Growth Day .................................................................... 30

3.2.3 Ramping ......................................................................... 30

3.2.4 Probes ............................................................................ 33

3.2.5 Supervisor Mode ............................................................ 34

3.2.6 Feed and water consumption ......................................... 35

3.3 Configuration .................................................................. 36

3.3.1 Downloading a New Configuration ................................. 36

3.4 Abbreviations.................................................................. 37

FIGURES

1 Figure 1 IC-610SL Faceplate ......................................... 6

2 Mounting Position and Devices ...................................... 14

3 IC-610 Main Board (for 1059 board A, B ou C) ............. 16

4 IC-610 Main Board (for 1059 board D) .......................... 17

5 Safety Control Backup Wiring 1 ..................................... 19

6 Safety Control Backup Wiring 2 ..................................... 20

7 Typical Sensor Wiring .................................................... 21

8 Connections for an Alarm .............................................. 24

9 Connections for the Installation of a Siren...................... 24

10 Typical Ramping Curve .................................................. 31

11 Three Point Ramping Curve........................................... 33

APPENDIX

Troubleshooting.............................................................. 39

Specifications ................................................................. 41

WARRANTY .................................................................. 43