TELEVAC MC 300 2A User manual

INSTRUCTION MANUAL

MC 300 2A & 4A

DUAL CHANNEL THERMOCOUPLE / CONVECTION

VACUUM MEASUREMENT INSTRUMENT

TELEVAC

A DIVISION OF THE FREDERICKS COMPANY

2400 PHILMONT AVENUE,

HUNTINGDONVALLEY, PA 19006

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

1

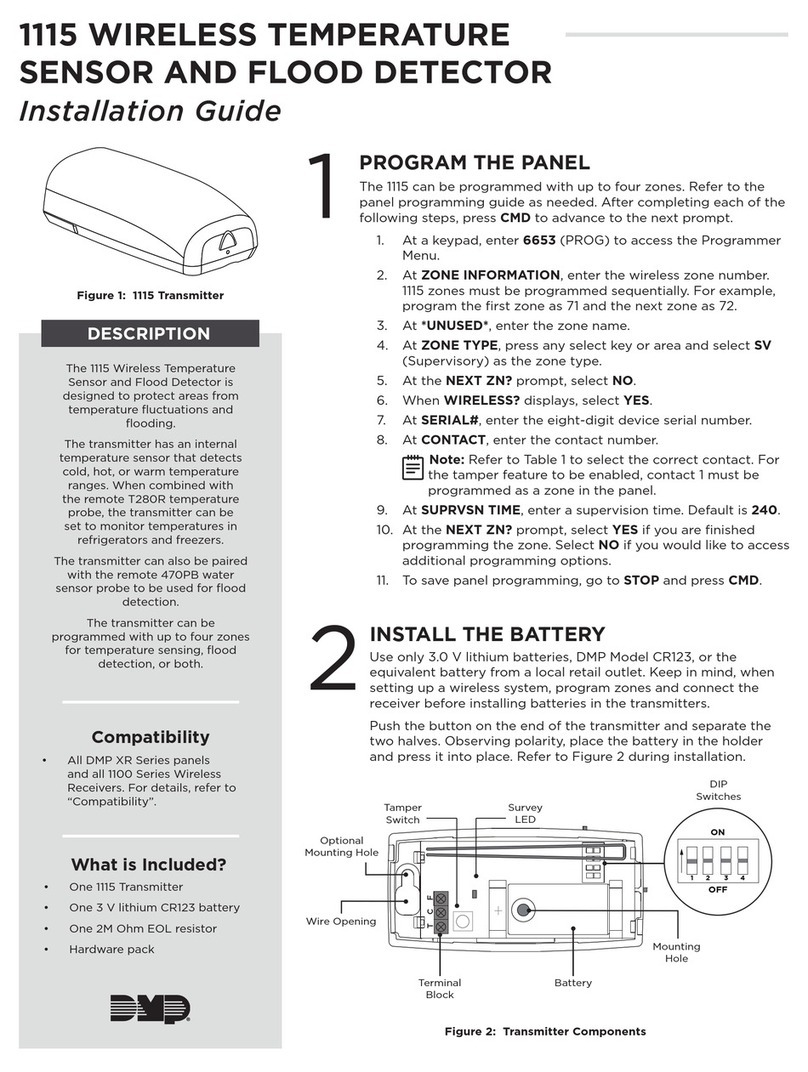

PARTS LIST

1

32

6

MOUNTING

KIT

5

4

# QTY ITEM DESCRIPTION

1 1 MC300 Thermocouple, Convection, Measurement Instrument

2 1 Instruction Manual

3 3 Sensor Cables (sold separately)

4 4 Sensors (sold separately)

5 1 Mounting kit

6 1 AC Power Cable

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

2

TABLE OF CONTENTS

SECTION & TITLE

01. DESCRIPTION

02. SAFETY INSTRUCTIONS

03. PRINCIPLES OF OPERATION

04. INSTALLATION & OPERATION

05. ANALOG RECORDER OUTPUTS

06. MAINTENANCE

07. CALIBRATION

08. CALIBRATION VERIFICATION

09. TROUBLESHOOTING

10. DIMENSION

11. SPECIFICATIONS

12. UNPACKING & INSPECTION

13. WARRANTY INFORMATION

14. ORDERING INFORMATION

PLEASE READ THIS MANUAL THOROUGHLY BEFORE USING THIS

INSTRUMENT. REPORT ANY PROBLEMS IMMEDIATELY.

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

3

CHAPTER 1 TELEVAC

Description

The TELEVAC Series MC300 vacuum-measuring instrument is a combination sensor,

which incorporates various range options, as shown in the table below:

Range of Options

Model Range Sensors

MC300 2A 0 - 20,000 millitorr 2AThermocouple

MC4A 0 – Atmosphere 4A Convection

The 2A thermocouple gauge tube will monitor pressures between 1 millitorr

(1 micron) and 20,000 microns ).

The 4A convection sensor tube will monitor pressures between 1 millitorr (1

micron) and 999 Torr. (1 atmosphere = 760 Torr @ sea level ).

The vacuum measuring system consists of various gauge tubes, which sense the vacuum,

an electronics unit and interconnecting signal/power cables. The customer must supply

power at 115VAC 50-60 Hz. (220 Volt operation is a factory selectable option). The

measured vacuum is displayed on the front panel LED displays. (See figure 1)

The power cable, gauge tubes, relay outputs and output voltages of 0 to 10 VDC

connections are on the back panel. (See figure 2)

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

4

CHAPTER 1(cont) TELEVAC

Figure 1

Figure 2

The MC300 FEATURES

Large bright LEDs

Built-in self-diagnostics

Selectable Units (Torr, microns, mBar or Pascal)

Gas compensation (Argon/Air-Nitrogen)

Four process relays with individual assignable set points

Analog outputs for each sensor

Operator lockout switch

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

5

CHAPTER 1 (cont) TELEVAC

Theory of Operation:

The MC300 is a microprocessor-controlled instrument utilizing modern data acquisition

techniques to achieve a high degree of accuracy at a reasonable cost.

The microprocessor in the instrument performs two basic tasks:

1. Controls the acquisition and conversion of all sensor data

2. Processes all operator interface inputs and requests

After power is applied to the instrument, the software initializes all of the circuitry

associated with acquiring and displaying sensor information then performs a self-

diagnostic. If there are no errors detected, the MC300’s data acquisition process is

started. Both input channels are read periodically and a reading for each sensor is stored.

After several readings the data is averaged, then converted using the appropriate sensor,

units and gas compensation settings. Set point relays and the microprocessor controlled

Analog outputs are also updated at the same time. This method of averaging samples

results in a smooth and accurate transition from reading to reading.

Each sensor has its own conversion algorithm. The data conversion process always

occurs regardless of the instrument mode (operation set-up). However, during the set-up

mode the converted data is not sent to the display but the set-point relay control and

analog output operations continue to operate.

Whenever the instrument software is not processing sensor data for the displays or

recorder outputs, the Set-Up, Test/Operate and Up & Down (if enabled) buttons are

checked for operator interaction. The Set-Up button is used to sequence through all of the

operator settable parameters. Each depression of the Set-Up button may change the

function of the displays as well as the Up & Down buttons. Each time the Set-Up button

is pressed, the data from the previous level is stored in non-volatile memory to ensure

that the instrument’s gas compensation, units and set point parameters are preserved. This

information is used to restore the instrument’s configuration each time power is applied.

For simplicity, the Up & Down buttons are enabled and disabled at the proper time to

prevent the operator from entering an invalid value. In addition, each time an On Point is

adjusted, the corresponding Off point is verified to ensure that it is higher then the new

On Point. If lower, the Off Point is adjusted to be one increment higher than the new On

Point. In this instance both the On and the Off Point values are updated in the non-

volatile memory.

When “GAS” is selected in SETUP, a correction is applied to the instrument readings to

compensate for the use of Argon as a gas instead of nitrogen/air. Both the displayed

readings and the set point calibrations are compensated as well as the linear thermocouple

and the linear by decade convection gauge recorder outputs at the back panel. Note,

however, that the “traditional” thermocouple, “linear” convection gauge outputs and ion

gauge outputs are NOT compensated.

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

6

CHAPTER 2 TELEVAC

Safety Instructions

START BY READING THESE IMPORTANT SAFETY INSTRUCTIONS AND

NOTES collected here for your convenience and repeated with additional information at

appropriate points in these instructions.

These safety alert symbols in this manual or on the Product rear panel mean

cautions - personal safety, property damage or danger from electrical shock.

Read these instructions carefully.

In these instructions the word “product” refers to the MC300 and all of its approved parts

and accessories.

NOTE: These instructions do not and cannot provide for every contingency that may

arise in connection with the installation, operation, or maintenance of this product.

Should you require further assistance, please contact Televac at the address on the title

page of this manual.

This product has been designed and tested to offer reasonably safe service provided

in it’s installed, operated and serviced in strict accordance with these safety

instructions.

Failure to comply with these instructions may result in serious personal injury, including

death, or property damage.

These safety precautions must be observed during all phases of operation,

installation, and service of this product.

Failure to comply with these precautions or with specific warnings elsewhere in

this manual violates safety standards of design, manufacture, and intended use of

the instrument. Televac disclaims all liability for the customer’s failure to comply

with these requirements.

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

7

CHAPTER 2(cont.) TELEVAC

The service and repair information in this manual is for the use of Qualified Service

Personnel. To avoid shock, do not perform any procedures in this manual or perform any

Servicing on this product unless you are qualified to do so.

READ Instructions:

Read all safety and operating instructions before operating the product.

RETAIN instructions:

Retain the Safety and Operating Instructions for future reference.

HEED warnings:

Adhere to all warnings on the product and in the operating instructions.

FOLLOW instructions:

Follow all operating and maintenance instructions.

ACCESSORIES:

Do not use accessories not recommended in this manual as they may require a technician

to restore the product to its normal operation.

To reduce risk of fire or electric shock, do not expose this product to rain or moisture.

`

Objects and Liquid Entry – Never push objects of any kind into this product through

openings as they may touch dangerous voltage points or short out parts that could result in

a fire or electric shock. Be careful not to spill liquid of any kind onto the products.

Do not substitute parts or modify instrument.

Because of the danger on introducing additional hazards, do not install substitute parts or

perform any unauthorized modifications to the product. Return the product to Televac fo

r

service and repair to ensure that safety features are maintained. Do not use this product

if it has unauthorized modifications.

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

8

CHAPTER 3 TELEVAC

Principles of Operation

2A Thermocouple Sensor

The 2A thermocouple sensor tube consists of a

metal shell containing fine wire filaments of

dissimilar metals, which form a thermocouple.

The thermocouple sensor measures absolute

pressures by determining the temperature of a

thermocouple junction as the surrounding

pressure changes. The response of the sensor

depends on the gas pressure and type.

The range of these sensors is from 1 millitorr to

20,000 millitorr (10-3 Torr to 20 Torr). The

sensor housing is constructed of stainless steel or

alternately nickel plated brass. Both are capable

of withstanding 150 psi overpressure.

Figure 3

2A Thermocouple Sensor Tube

Figure 4

4A Convection Sensor Tube

Convection Sensor

The convection sensor measures absolute pressures

by determining the heat loss from a thermocouple

heated to a constant temperature by a current source.

A second thermocouple compensates for ambient

temperature changes and extends the vacuum

measurement range above 2 Torr by measuring the

convection effects. The range of these sensors is 1

millitorr to 1000 Torr

The convection sensor must be mounted vertically

for accurate measurements. Sensors are available in

Stainless Steel or Nickel plated Brass and can

withstand 150-psi overpressure.

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

9

CHAPTER 4 TELEVAC

Installation and Operation

Instrument Installation

The MC300 is pre configured for immediate installation and use. The unit should be first

mounted in the desired location and properly secured. In choosing a location, the display

should be clearly visible by an operator and positioned in such a way that the operator

can easily make adjustments to the instrument. All wiring should be neatly dressed and

bundled with special care not to have any wiring adjacent to AC power distribution. After

proper installation of sensors and wiring, the unit can be connected to an AC power

source and put into operation.

IT IS RECOMMENDED THAT POWER IS NOT APPLIED TO THE INSTRUMENT

DURING THE INSTALLATION OF ANY WIRING AND SENSORS.

Sensor Installation

It is desirable that the thermocouple and cold cathode sensor tubes be mounted on the

vacuum system in a VERTICAL POSITION open end extending downward. The 4A

convection sensor MUST be installed in the VERTICAL POSITION.

The electronic unit is factory calibrated at time of order. To ensure proper operating

conditions it is necessary to use factory-manufactured cables.

Contamination of thermocouples sensor can be caused by the process occurring in the

vacuum vessel, or by pump fluid back streaming and is a critical factor affecting the

measurement of high vacuum.

Depending upon the degree of contamination and the accuracy required, it is

recommended that sensor be periodically replaced and that filters (with line of sight

baffles (P/N 2-2100-50) be used to protect thermocouple sensors.

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

10

CHAPTER 4(cont.) TELEVAC

The thermocouple and convection sensor tubes incorporate a 1/8” National Pipe Thread

(1/8” NPT) fitting for connection to the vacuum system and other mounting

configurations are available.

The instrument may be turned on at any time, since atmospheric pressure will not harm

the thermocouple sensor tube elements or cause overdrive on the metering circuit. A brief

15-minute warm up is required before vacuum measurements can be made within stated

tolerances.

Wiring the instrument

Sensor wiring

The MC300 requires sensors & cables (sold separately) for each channel. Certain levels

of calibration require a specific cable and sensor be used with channel 1 or 2. In this case

the cable and sensor are marked for use as a set and must be used as such. Otherwise the

cables can be used with either rough vacuum channel. To ensure measurement integrity

and protection from ambient electrical noise, ground lugs are provided on each sensor

cable shield. These lugs should be connected to the ground screws provided on the rear

panel.

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

11

CHAPTER 4(cont.) TELEVAC

Analog Output Wiring

Provisions are made to connect the instrument to a chart recorder or programmable logic

controller. Two different format signals are provided and are described in Section 5

Analog Outputs. In all cases follow the external device manufacturer’s instructions for

wiring and using these signals. Linear (LIN) output is computer generated so that the

voltage signal is plotted as a straight line as a function of pressure.

Traditional (TRDL) signal is one that represents the non-linear signal that is

representative of the actual raw sensor data. The 4A Convection version has

Linear/Decade and Linear outputs. By means of a factory settable internal jumper a full

range Traditional signal is available in lieu of the Linear/Decade recorder output. Please

refer to Section 5 Analog Output (4A) for a summary of the signals available

Relay Contact Wiring (Set point Relays)

There are four set point relays available for use to control ON/OFF or Open/close (binary

state) devices. The relays are assignable to any one of the vacuum signal input channels

through front panel software control.

There are three connections for each relay. They are NORMALLY CLOSED (NC),

COMMON (C) and NORMALLY OPEN (O). The operation mode of each is described

as follows.

NORMALLY CLOSED:

In this state there is an electrical continuity path between terminals Cand NC. This

continuity path is broken when the software set point values dictates an ON state for the

specific measurement channel. Continuity is returned when the OFF state is dictated by

software control. In the power off mode of the MC300 (due to failure of the main power

source or turning off the instrument), the relay will revert to this state.

NORMALLY OPEN:

In this state there is no electrical continuity path between terminals Cand NO. This Path

is established ONLY when the Instrument control software satisfies conditions for the

ON state. It will break continuity under the instrument control parameters for the OFF

condition or the power off mode of the MC300 (due to failure of the main power source

or turning off the instrument).

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

12

CHAPTER 4(cont.) TELEVAC

CAUTION:

In utilizing the process relays it is important not to exceed the relay’s power handling

capacity described in Section 10 Specifications and to fully understand the behavior of

the control relay state conditions. Failure to do so will result in premature relay or

equipment failure.

Operating the Instrument

This section describes the operation of a properly installed MC300 Instrument

Prior to using the instrument on a vacuum chamber, the unit can be set up in a test mode

using simulators to represent the vacuum gauges. This is done to gain familiarity with the

unit and to preset relay set points. The following describes operation of the instrument

with simulators or vacuum applied to the sensors.

POWER ON:

The instrument is turned on and off by means of a rear mounted power switch. The unit

will first display the Software version number and instrument type in a four-digit code.

The first two digits refer to the software version and the second two digits refer to the

Instrument Sensor type summarized below.

The instrument will then perform a self-diagnosis after which it will begin displaying

vacuum measurements. If the unit doesn’t pass the self-test, an error code will appear.

Pressing the “TEST OP ” button can clear the code, but proper operation of the

instrument may be curtailed. It is recommended not to use the instrument if the self

diagnosis fails. Contact the factory for instructions. Allow a minimum of 15 minutes

from an instrument “cold start” for the sensor readings to stabilize.

GAS CORRECTION FACTOR:

The instrument is calibrated for use in Nitrogen (dry air) but the MC300 has the ability to

adjust its pressure readings to compensate the thermal conductivity gauges for the use of

ARGON as a background gas. When Argon gas is selected, the GAS light will flash

during operation of the gauge.

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

13

CHAPTER 4(cont.) TELEVAC

To change the gas correction factor:

1) Assure the rear mounted operator lock out switch is in the “OFF” position

(the switch is in the down position)

2) Press the SETUP button once

3) The Nitrogen (N2) or Argon (Ar) display will flash

4) Press the UP or DOWN arrow buttons to select a gas correction, The flashing

display is the gas selected)

5) Press the TEST OP button to complete the selection

(Note: if the TEST OP switch is not pressed in 60 seconds the instrument will return to

normal operation and the change in gas correction is not accepted)

CHANGE MEASUREMENT UNITS:

The MC300 has the ability to display vacuum values in Pascals, MBAR or MICRONS

and TORR.

1) Assure the rear mounted operator lock out switch is in “OFF” position, (the

switch is in the down position)

2) Press the SETUP button once

3) Nitrogen (N2) and Argon (Ar) display will flash

4) Press the SETUP a second time

5) The Pascal, MBAR or TORR lamp will flash

6) Press the UP or DOWN arrow buttons to select the desired unit of measurement

7) Press the TEST OP button to complete the selection

(Note: if the TEST OP switch is not pressed in 60 seconds the instrument will return to

normal operation and the change in gas correction is not accepted)

ASSIGN SET POINT RELAYS AND VALUES:

The instrument has four relays that are assignable to any of the vacuum measurement

channels. Thermocouple (or Convection) Channel 1 is Channel 1 (CH1), thermocouple

(or Convection) Channel 2 is Channel 2 (CH2) and the Ion gauge is Channel 3 (CH3).

Setpoint SP 1 is relay #1, setpoint SP 2 is relay #2 etc.

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

14

CHAPTER 4(cont.) TELEVAC

1) Assure the rear mounted operator lock out switch is in the “OFF” position, (the

switch is in the down position)

2) Press the SETUP button once

3) The Nitrogen (N2) or Argon (Ar) display will flash

4) Press the SETUP a second time

The measurement units (PASCAL, MBAR or TORR)lamp will flash

5) Press the SETUP a third time

6) The set point SP 1 will appear in the left display, the channel number CH1, 2 or 3

will appear in the right display

7) Use the UP or DOWN arrows to select the channel number 1,2 or 3

8) Press the SETUP button again. “ON” will appear in the right display, the “ON”

value will appear in the lower left display

9) Press the UP/DOWN button to adjust the “ON” value. Press and hold the

UP/DOWN button to rapidly advance the “ON” value.

10)Press the SET UP button again. “OFF” will appear in the right display the relay

“OFF” value will appear in the lower left display

11)Press the UP/DOWN buttons to adjust the “OFF” value. Press and hold the

UP/DOWN button to rapidly advance the “OFF” value.

12)Press the SET UP button again and the next relay, SP 2 will appear. The sequence

listed in steps 6 and 11 are repeated until all four relays have been assigned.

The MC300 will return to its normal operating mode after the fourth relay has been set up

or 60 seconds have elapsed since the last button press. Changes are stored after the

complete set up of an individual relay channel. These set up parameters are stored in Non

volatile memory and are not lost during Power outages.

NOTE: Set point changes are also accepted by the MC300 by pressing the “TEST OP”

button at any point in the set up. The Instrument will not accept “OFF” values that are

lower than the “ON” value. “ON” values entered that are greater than the ”OFF”

values will automatically change the “OFF” value one unit higher than “ON”.

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

15

CHAPTER 5 TELEVAC

Analog Recorder Outputs

0-10VDC analog recorder output voltage/pressure conversions are provided for

each type of Sensor in the figures 5 & 6.

These voltage signals are available at the rear panel of the MC300. See figure 2

for locations of the connections.

Outputs #1 and #2 are for thermocouple or convection sensors. These outputs

are 0-10 volts and are available in a traditional or linear format. See figures 5 or 6.

MICRONS

ARGON

READS

TRAD’L

REC

OUT

VOLTS

LIN REC

OUT

OUT

(-5) 10.59 -0.05

(-1) 10.16 -0.01

0 10.00 0.00

1 9.84 0,01

5 9.41 0.05

10 8.92 0.10

20 8.03 0.20

30 7.23 0.30

40 6.63 0.40

50 6.13 0.50

60 5.69 0.60

70 5.31 0.70

80 4.95 0.80

90 4.63 0.90

100 4.37 1.00

150 3.37 1.50

200 2.89 2.00

300 2.23 3.00

400 1.88 4.00

500 1.67 5.00

600 1.58 6.00

700 1.50 7.00

800 1.42 8.00

900 1.34 9.00

1000 1.26 10.00

2000 1.02 10.20

5000 0.92 10.20

10000 0.90 10.20

20000 0.88 10.20

CABLE 0.00 10.20

Analog Output (2A) Linear

0

1

2

3

4

5

6

7

8

9

10

0 100 200 300 400 500 600 700 800 900 1000

PRESSURE (microns)

VOLTS

Analog Output (2A) Linear

0

1

2

3

4

5

6

7

8

9

10

0 100 200 300 400 500 600 700 800 900 1000

PRESSURE (microns)

VOLTS

Figure 5

Analog Output (2A)

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

16

Figure 6

Analog Output (4A)

CHAPTER 5(cont.) TELEVAC

TORR/

MICR

ARG

READS

TRDL

OUT

L/D REC

OUT

1 VOLT/

DEC

LIN OUT

VOLTS

(-5)-OL’D -0.065 3.500 <-.050

(-1) -0.013 3.900 -.010

0- 0.000 4.000 0.000

1 u 0.013 4.100 0.010

5 u 0.065 4.500 0.050

10 u 0.124 5.100 0.100

20 u 0.238 5.200 0.200

30 u 0.344 5.300 0.300

40 u 0.450 5.400 0.400

50 u 0.546 5.500 0.500

60 u 0.638 5.600 0.600

70 u 0.730 5.700 0.700

80 u 0.816 5.800 0.800

90 u 0.898 5.900 0.900

100 u 0.980 6.100 1.000

150 u 1.350 6.150 1.500

200 u 1.670 6.200 2.000

300 u 2.285 6.300 3.000

400 u 2.630 6.400 4.000

500 u 2.992 6.500 5.000

800 u 3.824 6.800 8.000

1 T 4.226 7.100 10.000

2 T 5.440 7.200 13.500

3 T 6.080 7.300 “

4 T 6.440 7.400 “

5 T 6.772 7.500 “

10 T 7.412 8.100 “

20 T 7.782 8.200 “

30 T 7.910 8.300 “

40 T 7.936 8.400 “

50 T 7.976 8.500 “

60 T 8.006 8.600 “

80 T 8.042 8.800 “

100 T 8.072 9.100 “

120 T 8.124 9.120 “

150 T 8.180 9.150 “

160 T 8.224 9.160 “

170 T 8.256 9.170 “

180 T 8.280 9.180 “

200 T 8.328 9.200 “

300 T 8.756 9.300 “

400 T 9.208 9.400 “

500 T 9.544 9.500 “

600 T 9.772 9.600 “

760 T 10.000 9.760 “

900 T 10.142 9.90 “

1000 T 10.232 10.000 “

CABLE >10.5 10.11 “

If L/DOUT = INT .DDD Volts

TORR = 0.DDD x 10 EXP (INT –6)

If .DDD < 0.1, use 0.1

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

17

CHAPTER 6 TELEVAC

Maintenance

The vacuum measuring sensors, if installed properly, require very little maintenance

under normal operating conditions.

If the unit should cease to operate properly, certain checks can be made:

1. If a sensor tube simulator is available, it can be used. The sensor tube simulators

are designed to be used as a check to see if the cable and the electronics are

working properly.

The simulators are marked for use with the various sensors. Although no

maintenance is required to keep the tube simulator in working condition, a

periodic check should be done against a calibrated standard unit.

To use the simulator, turn off and disconnect the cable from the sensor tube and

plug the sensor tube simulator in its place. Turn power on and check the output

voltage, it should correspond to the pressure that is written on the sensor tube

simulator’s label.

2. If you do not have a tube simulator, it is still possible to check the operation of the

instrument if you are able to reduce the system pressure to 10-5 Torr. At this

pressure, the thermocouple and the convection sensors should display zero and

give Analog output of zero volts. The “ZERO” adjust trimmers at the rear panel

can be used to set up the zero readings. If output still appears to respond

incorrectly, a new sensor tube should be replaced to restore the assembly to proper

operation.

3. The following table summarizes the messages on the MC300 display under several

different operating conditions as well as the expected Analog outputs.

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

18

CHAPTER 6(cont) TELEVAC

2A

Display

Conditions

Traditional Analog

Output (Volts)

Linear

Analog Output (Volts)

-OLd <-1 micron +10.59 -0.05

-1 Incorrect ZERO adjust +10.16 -0.01

0 microns Lowest Reading +10.00 0.00

20 Torr Highest Reading +0.88 +10.20

CabL > 20 Torr +0.00 +10.20

4A

Display

Conditions

Traditional

Recorder Output

Fact Option

(Volts)

Linear

Decade

Analog Output

(Volts)

Linear Analog

Output (Volts)

-OLd <-5 microns -0.07 +3.50 <-.05

-1 Incorrect ZERO

adjust

-0.01 +3.90 -0.01

0 microns Lowest Reading 0.00 +4.00 0.00

990 Torr Highest Reading +10.23 +9.99 +13.50

CAbL >990 Torr >+10.50 +10.11 +13.50

CHAPTER 7 TELEVAC

Calibration

All TELEVAC instrumentation is calibrated at the factory. No further calibration at the

customer’s facility should be required.

For a reliable re-calibration at a later date, it is necessary to have a reference standard

vacuum system whose pressure is known very accurately. For such a calibration, the

instrument, sensor tube and cable should be returned to TELEVAC for re-certification.

However, if the vacuum calibration certification is to be done at the customer’s facility,

equipment of certifiable accuracy should be used by a knowledgeable electronics

technician trained in vacuum calibration.

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

19

CHAPTER 8 TELEVAC

Calibration Verification

1. Connect sensor to the known vacuum source.

2. Plug unit into 115VAC. Allow a minimum of 15 minutes warm-up.

3. Pump the system down to high vacuum. At 10-5 TORR verify that the

thermocouple or convection gauge reads at “0” VDC. If not, adjust the “zero”

potentiometer.

4. Make a comparison table of indicated pressure on the instrument to that of the

reference vacuum standard. The comparisons should be made typically at “0”

(red line), 10, 100 and 1,000 millitorr and at 1, 10, 100, 500 and 760 Torr,

(depending on the 2A or 7A gauge type).

CHAPTER 9 TELEVAC

Troubleshooting

Troubleshooting of the circuit or components is similar to any industrial electrical

equipment, i.e., checking for circuit continuity, shorts, grounds, resistors, values, etc.

Generally, those familiar with electrical equipment should have no difficulty location

faults in either gauge or electronics unit by systematically proceeding through the circuit.

The enclosed diagram should facilitate maintaining the instrument. In order to

troubleshoot the unit, your gauge tube and cable must be in working condition and

plugged into the unit.

NOTE: If, after doing some or all of the above, the unit is still inoperative, return to

factory for repair.

Phone:(215) 947-2500 fax:(215) 947-7464 e-mail: [email protected] web site:www.televac.com

6-8000-002 REV A

20

This manual suits for next models

1

Table of contents

Other TELEVAC Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Emerson

Emerson Klauke UAP432CFM manual

Datalogic

Datalogic VLASE IR 1109-1 42 Series user manual

Sierra Monitor Corporation

Sierra Monitor Corporation 4400 Specification sheet

Siemens

Siemens SITRANS F Function manual

VWR

VWR OX 4100 H operating manual

Endress+Hauser

Endress+Hauser PROline promag 53 Documentation

Leuze electronic

Leuze electronic CML 720i Original operating instructions

DAKOTA ULTRASONICS

DAKOTA ULTRASONICS PVX Operation manual

DMP Electronics

DMP Electronics 1115 installation guide

LOVATO ELECTRIC

LOVATO ELECTRIC DMG300 installation manual

Tornatech

Tornatech GT-FluxFP operating instructions

HT Italia

HT Italia HTA102 user manual